2018 – Edition 8 – September 7

Table of Contents

Note: The order of material varies in hotline emails, but is always presented the same on this landing page. Readers scrolling through content on or printing this page will find it organized consistent with the table of contents.

Hotline Feature

ARSA Works

Legal Brief

ARSA on the Hill

Regulatory Update

Getting Facetime

Training

Membership

Resources

Industry Calendar

Hotline Feature

Budgeting for Success

By Sarah MacLeod, Executive Director and Brett Levanto, Vice President of Communications

Doubling down on your commitments to short and long-term efforts during yearly budget development is a must in the business of international aviation.

The measure of ARSA and its members is judged by ensuring compliance to minimum standards while reaching maximum efficiencies, effectiveness and profitability. To achieve the maximum profit, a commitment to quality and safety is not without constant vigilance and cost.

Investing in an association that is devoted to ensuring that government oversight is based upon the regulations and not “thoughts” or “guidance” means more than paying dues.

Where can you place additional resources? Think of your support for ARSA across six pillars – each is needed to ensure success both short and long term:

- Membership – This is your baseline amount, but a vital foot in the door. When will yours lapse? Get the dues amount in the budget and keep access to ARSA’s wide range of member benefits. You can mange your membership directly through the new online member portal and explore the many ways to begin expanding on the initial investment…

- Publications for compliance – Whether you’ve been in business for years or are new to aviation, ARSA provides an invaluable resource through its model manuals, supplements, forms and other materials to help ensure regulatory compliance. See what’s available for free in the members’ section of ARSA’s secure online portal and shop for the expanded resources in its new online store.

- Events – The Annual Conference, which includes the Executive to Executive Briefings, Legislative Day and the Annual Repair Symposium, is the civil aviation maintenance community’s premier event for regulatory compliance and networking. Book the time and dedicate funds for registration, sponsorship and travel to ensure participation.

- Training – Did you know ARSA’s constantly-expanding training library has more than 60 on-demand sessions for immediate viewing? Budget for your whole team to “attend” throughout the year. The money you spend will be returned triple the next time a compliance issue raises its head.

- Sponsorship – Event content, publicity programs and member resources are a result of the generosity of industry partners who invest in ARSA through sponsorship. Set aside funds to help highlight the good work of your company and further the efforts of the association. (Send a message for guidance.)

- Members getting members – Who or what other business can help you get something for free? Ten percent of every paid members’ dues you refer will be credited to your membership fee; at the same time, you can benefit from contact with potential partners, suppliers or customers.

Find a way to work for ARSA; the association will be able to continue working for you. It’s an unprecedented return on investment.

ARSA Works

ARSA Urges SBA Review of Maintenance Manual Availability

ARSA has filed a comment with the U.S. Small Business Administration National Ombudsman’s office urging it to review the Federal Aviation Administration’s (FAA) inconsistent enforcement of rules relating to availability of maintenance manuals.

The ombudsman’s mission is to assist small businesses that experience excessive or unfair federal regulatory enforcement actions, such as repetitive audits or investigations, excessive fines, penalties, threats, retaliation or other unfair actions by a federal agency.

ARSA’s comment (effectively a complaint designed to initiate the ombudsman’s review of an issue) requests that SBA investigate the FAA’s aggressive enforcement of the requirement that repair stations possess “current” versions of maintenance manuals (14 CFR. § 145.109(d)) while the agency fails to enforce the regulation requiring design approval holders (i.e., manufacturers) to create and make that same maintenance data available (14 CFR. § 21.50(b)). Due to this inequity, many repair station small businesses face unnecessary administrative and financial burdens and significant loss of business opportunities.

While the ombudsman’s office does not have the authority to change FAA policy, it can investigate small business issues and work with regulatory agencies to resolve matters. Additionally, the ombudsman’s annual report to Congress highlights unfair regulatory activities and can lay the foundation for legislative queries and action.

“ARSA has attempted to work with the FAA for more than three decades to bring consistency to the agency’s application of its rules. Unfortunately, our concerns have failed to illicit serious consideration or any discernible action,” ARSA Executive Director Sarah MacLeod said.

“We’re left with no choice but to use every available avenue to spotlight the agency’s failure to act and to make other agencies in the executive branch and the Congress aware of how FAA’s inequities are hurting small businesses,” MacLeod said.

ARSA has developed a toolkit to assist individual companies in filing similar comments with the SBA national ombudsman. To access it, click here.

To review ARSA’s complete comment, click here.

FAA, Industry Connect on Remote Connectivity

On Aug. 7, the FAA confirmed it would finalize and publish the industry-produced draft advisory circular providing “guidance for using remote connectivity technology and tools.”

“The Aircraft Certification Service (AIR) and Flight Standards (AFS) are working together to finalize the draft of the AC and begin the publication process,” the letter from AIR and AFS executive directors Dorenda Baker and Rick Domingo said. “We anticipate final publication in October 2019.”

To bridge the expected 13-month gap before the expected publication date, the letter explained that AIR would publish a policy statement aligned with the AC’s guidance. Since “AFS policy and guidance does not prohibit the use of remote connectivity,” Flight Standards will continue to “support industry requests until the AC is released.”

On May 7, the association and 15 of its aviation industry allies had jointly submitted the draft AC. The new guidance would provide a baseline for the FAA, its applicants and certificate holders to comply with 14 CFR while taking advantage of advances in connectivity technology and related video, live-stream and other visual and audio tools. The process began after the FAA opened a “Remote Witnessing Using Video” draft policy for comment in early 2018.

To read the complete industry submission and draft AC, click here.

To read the agency’s response, click here.

ARSA Remembers – Stewart Mercer (1938-2018)

Stewart Mercer, passionate aviation professional, community leader and world traveler, passed away on Aug. 12. He was 80.

“The industry lost another of its ardent supporters, ARSA Executive Director Sarah MacLeod said. “For those that did not know Stewart, his is an example of a life well-lived for the many of us who loved, admired and respected him. We who were lucky enough to have met him will remember him and his family with affection. Our love and prayers remain with his family and many friends who will miss him dearly.”

Stewarts family shared an announcement of his death on Aug. 17. The following edited version of that announcement is provided to help old friends remember and the rest of the maintenance community learn about his great life (service and remembrance information included):

Born July 20, 1938 in Flushing, New York to Quintin Ulysses Mercer & Dorothy Westervelt Mercer. Raised by his mother and sister, Kathleen; they lived in a great many places while growing up. He attended different schools in NY: Elementary school, Sunday school, High school, Reform school, and the “School of Hard Knocks.” (and he would be the first to say the knocks were often self-inflicted!) He left home at the early age of 14, and eventually enlisted in the USAF at 17, with his mother’s reluctant consent.

On July 10, 1982, he married Noelle Carlson whom he met in Denver, CO; They married in the Catholic Chapel at San Geronimo, on the Taos Indian Reservation, in New Mexico.

He lived in many places including New York City, where he was born, and New Orleans after he left home at 14. Later he lived in Tripoli, Libya and spent a short-term residence in Valetta (St. Paul’s Bay) Malta. Stewart also resided in Portuguese Bend, Rolling Hills, and Palos Verdes, California. His time in Denver, Colorado marked his fortuitous meeting of Noelle in December 1981. Together, they also lived in Miami Springs, Florida and Dallas, Texas. His travels took him to more than 100 different countries around the world and numerous cities within those countries. He encountered various war zones in Beirut, Lebanon, Managua, Nicaragua, Larnaca and Nicosia, Cyprus, and Amman, Jordan.

He chose to be in the commercial aviation industry during his long career. He founded AV-EX, Aviation Excellence and headed the global aircraft parts distribution firm, debt free, for his entire tenure as CEO & President, until its sale in 2009. He was proud of the business until the end, particularly of its continuing to thrive and support many of the same employees who worked under his ownership.

Stewart provided good counsel for his aviation colleagues until the end of his life, focusing his consultation on operational excellence, airline parts distribution and sales growth. His personal and business life were always based on the principle that “The harder he worked, the luckier he got.”

Persistence was his mantra, and they served each other well.

Notes about Stewart’s life, family and interests:

General Aviation Flying – He flew more than 36 different aircraft types into more than 100 different airports.

Airports – Those 100+ airports witnessed his non-spectacular, non-eventful landings hundreds of times, including 9 of the top 10 busiest airports in the nation; dozens of times.

Skydiving – His first official log book entry was in 1966 at Lake Elsinore, California

Paragliding, Parasailing, and Hang Gliding

Stewart supported several philanthropic organizations including the SPCA, The Dallas Symphony, and The Dallas Summer Musicals (where he was a member of the Board of Directors), The Frontiers of Flight Museum, where he also served as a Member of their Board. He also mentored entrepreneurs personally and through his participation in “The Board Room.”

He and Noelle created a Scholarship Fund at The Texas A&M College of Veterinary Medicine & Biomedical Sciences for students of veterinary medicine. The Scholarship Fund was named in honor of their long-time veterinarian, Dr. Terry Ford, and the staff at North Dallas Veterinary Hospital.

Survivors include his wife Noelle, her children Dori & Derrik and their children Richie, Kenny, and Krystall, his sister Kathleen Smyth and her husband Dennis Smyth, sisters Judith Gingras; Linda Thorsen, Diane Mercer Toomey, and nieces & nephews; Kathleen, Kerry, Doreen, Denise, Laure, & Tim; Jeffrey & Matt.

Stewart was preceded in death by his mother & father, Dorothy & Quintin.

Among the thousands of people that Stewart met over the years, he was most proud of having met and been in the company of several Four-Star Generals, including John R. Dailey, Stanley Allen McChrystal, Raymond T. Odierno, H. Norman Schwarzkopf, David Petraeus, Tommy Franks; and Admiral John Walsh.

Dallas was where Stewart chose to spend most of his life, but in his heart and mind, New York was always “home”.He particularly enjoyed his times there with Noelle and introducing daughter, Dori, son Derrick and the 3 grandchildren to the wonderments of New York City!

Remembrances:

Memorial contributions are welcome at the Dallas Symphony Orchestra and/or Texas A&M College of Veterinary Medicine. (Mercer Scholarship Fund)

Legal Brief

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

A Repair Station Security Refresher

By Christian A. Klein, Executive Vice President

Aviation security was back in the news in August after a Horizon Air employee at Seattle-Tacoma International (Sea-Tac) Airport stole a Q400 turboprop and eventually crashed it into a Puget Sound island.

Sea-Tac’s security apparently complies with all federal requirements and includes a higher level of screening for employees in secure areas than many other airports. Additionally, the employee gave no advance clues about his intentions. There’s therefore little that could have been done to prevent the unauthorized flight. Policymakers generally recognize that fact and, as a result, we thankfully haven’t seen the rush to impose a slew of new, unnecessary and poorly-thought-out regulations as often follows other outlier incidents.

(To see what ARSA did to help share information after the incident, read about how the association works in such situations in this month’s ARSA on the Hill.)

That said, the recent event is a reminder that aviation security is important. Repair stations must understand and comply with the rules that are in place, but also adopt commonsense measures that go above and beyond the basic legal requirements to protect employees, customer property and the public. With that in mind, this month’s “Legal Brief” provides a quick refresher about the federal security standards applicable to repair stations.

A Bit of Backstory

The Transportation Security Administration (TSA) issued security rules for repair stations in 2014. The rules were mandated by Congress in the 2003 FAA reauthorization bill. ARSA believed the congressional directive was unnecessary – a “solution in search of a problem” and driven mainly by contract maintenance opponents seeking to drive up compliance costs for repair stations. We made the case that there was no evidence of systematic security lapses in the industry and that repair stations routinely take security precautions in the ordinary course of running their businesses.

TSA initially ignored the congressional mandate, focusing its limited resources on other, more significant threats. However, TSA was ultimately forced to comply when Congress temporarily banned new FAA foreign repair station certifications until the rules were issued.

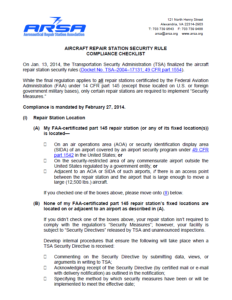

The Basic Requirements

TSA took a relatively measured and reasonable approach in crafting the rules. The agency focused oversight on the point of greatest perceived risk – where maintenance personnel have access to flyable aircraft on or near an airport. However, if you have a part 145 certificate, no matter what your company does or where you do it (unless you’re located on a U.S. or foreign government military base), Title 49 of the Code of Federal Regulations (CFR) part 1554 applies to you.

For repair stations not located at airports, compliance is fairly straightforward. The regulations require all repair stations to comply with TSA Security directives and allow unannounced TSA inspections.

However, if a repair station is located on or adjacent to an airport, under 49 CFR § 1554.101, the facility must also:

- Designate a point of contact (POC) for TSA who is responsible for security compliance and must be available 24-hours a day, seven days a week;

- Restrict access to, and prevent the unauthorized operation of, large aircraft (more than 12,500 lbs.) that are capable of flight.

- Verify background information for TSA POCs and those having access to the means used to prevent the operation of large, unattended aircraft.

- Maintain records to demonstrate compliance.

Under 49 CFR § 1542.113, a repair station that is the tenant of an airport must also comply with the airport’s security program. All individuals allowed unescorted access to a Security Identification Display Area (including an employee of a repair station at an airport) are fingerprinted and must pass a background investigation that includes a criminal record check, employment history verification and TSA Security Threat Assessment check against terrorist, immigration and law enforcement databases.

Companies that fail to comply face dire consequences. Under 49 CFR part 1554, subpart C, the TSA may direct the FAA to suspend or revoke the certificate of a repair station that fails to correct security deficiencies or is deemed an immediate security risk. (For individuals holding mechanic or repairman certificates, the TSA can also direct FAA suspension or revocation under 14 CFR § 65.14.)

The TSA rules establish a security baseline, but it’s imperative that repair stations regularly reassess risks and adopt commonsense measures to keep employees, customer property and the public safe. Alarm systems, video surveillance, employee security training, perimeter locks and fences, liaison with local law enforcement, employee badging and utilizing security guards are common industry risk mitigation practices.

As ARSA tells policymakers all the time, good security is good business. Security is inherent in how repair stations operate. But industry must make good on that promise by holding itself to a higher standard than the regulations require. If not, the maintenance industry may find itself burdened by additional onerous regulatory requirements in the future.

Keep in mind that this article is just a cursory overview and shouldn’t be the only source you rely on to comply or develop a security program. ARSA has developed other resources to help members understand all their obligations under the security rules, including a compliance checklist and an online training program. But, of course, there’s no substitute for reading the rules yourself!

Finally, ARSA members should be aware that I was recently appointed to represent repair stations on the TSA’s Aviation Security Advisory Committee (ASAC). Established in 1989 after the terrorist attack on Pan Am flight 103, ASAC provides advice to the TSA administrator on aviation security matters, including the development, refinement, and implementation of policies, programs, rulemaking and security directives pertaining to aviation security. If you have concerns about current regulations or enforcement or suggestions about ways they can be improved (either to enhance compliance efficiency or mitigate risks), please let me know.

Supporting Documents: Repair Station Security Resources

On Aug. 15, ARSA released a Repair Station Security Fact Sheet as a resource for the media, policymakers and the general public understand the rules applicable to FAA-certificated maintenance facilities.

The fact sheet should be utilized by the maintenance community and other interested stakeholders alongside the association other security related resources:

Repair Station Security Resources |

|

| Fact Sheet | Compliance Checklist |

|

|

| Online Training | |

|

|

To review past coverage of ARSA’s engagement with the TSA on security issues, review the content at arsa.org/security.

ARSA on the Hill

ARSA’s Work After Incidents and on Capitol Hill

By Christian A. Klein, Executive Vice President

“ARSA Works” is part of the association’s brand. It encompasses everything we do to advance and protect the aviation maintenance industry’s interests with regulators, on Capitol Hill and in the media. This month’s ARSA on the Hill takes a look behind the curtain to see just how “ARSA Works” to avoid potentially negative policy consequences when a national incident shines a spotlight on our industry. With FAA’s budget authorization set to lapse at the end of September, I’ll also provide an update on where things stand in the reauthorization fight.

By now, everyone is familiar with the incident in early August when 29-year old Horizon Air ground services employee Richard Russell stole one of the airline’s Q400 turboprops from the Sea-Tac airport, flew it on a 90-minute joyride and eventually crashed on a Puget Sound island.

Given that Sea-Tac’s employee screening is tighter than at many other airports and the perpetrator had no known history of crime or mental illness, policymakers have generally recognized there’s little that could have been done to prevent the unauthorized flight. But that doesn’t mean an interest group or politician wouldn’t use it to pursue their own policy objective – for example, new and unnecessary repair station security rules.

As a general rule, ARSA doesn’t comment on specific aviation incidents. Rather, when an outlier aviation event like the Sea-Tac plane theft occurs, the way “ARSA Works” is to educate policymakers and the media about the regulatory landscape and rules already in place.

In response to Sea-Tac, ARSA quickly developed a one-page fact sheet about repair station security rules and distributed it to media outlets and congressional staff involved in aviation policy. The association also provided links to other ARSA security-related materials, including its compliance checklist and online training. In a similar vein, after the Southwest Airlines engine failure earlier this year, the association reached out to media outlets and offered reporters access to airworthiness directive (AD) training resources to help them better understand the AD process (leading to informed coverage from a number of outlets including the Dallas Morning News).

Aside from educating about a specific and timely topic in the short-term and ensuring ARSA’s voice is included in media coverage, these efforts also position the association in the long-term as an unbiased and objective source. We want policy and media coverage based on facts, not emotions. Which is how and why “ARSA Works.”

|

Want to Learn More About ARSA PAC? ARSA’s Political Action Committee helps elect congressional candidates who share ARSA’s commitment to better regulation and a strong aviation maintenance sector. In this critical election year, ARSA PAC has never been more important. But ARSA is prohibited from sending PAC information to members who haven’t opted in to receive it. Please take a second to give us prior approval to talk to you about ARSA PAC. Doing so in no way obligates you to support PAC. It just opens the lines of communication. Click here to give ARSA your consent today. |

FAA Bill: Still on Track, But Behind Schedule

Over the past two years, ARSA has been working the FAA reauthorization process. Congress is in trying to establish a new, multi-year budget blueprint for the agency, which is also an opportunity for policymakers to guide aviation policy and establish priorities.

Aside from preventing new and unnecessary mandates for repair stations, ARSA’s focus has been on workforce and urging Congress to address the technician shortage plaguing repair stations. The association developed a proposal to create a new FAA-administered grant program to incentivize businesses, schools and government entities to work together to find solutions. The ARSA bill has been introduced in the both the House (H.R. 5701) and Senate (S. 2506), where more than 25 senators from both parties and all parts of the country have signed on. ARSA has also built a coalition of more than 30 organizations to lobby in support of the proposal.

Our goal is to get the workforce provision added to the Senate’s FAA reauthorization bill. The good news is that our proposal is included in the Senate Commerce Committee’s FAA bill managers amendment package and is set to be added to the bill when the Senate takes up FAA. The bad news is that we don’t know when that will be.

The bill has been delayed partially because the Senate’s attention is focused elsewhere. Appropriations bills and judicial nominations are top priorities for leadership. The Senate hasn’t debated an FAA bill in many years and senators are likely to offer a large number of amendments meaning the bill could be on the Senate floor for a week or more. Finding a block of time to consider the bill has proven difficult. Senate leaders are working through the list amendments to determine which have broad support or fervent opposition with the hopes of coming up with an expeditious way to bring the bill to the floor and pass it.

Also, because the FAA bill is still regarded as one of the pieces of legislation still likely to get done this year, members of Congress are trying to use it as a vehicle for other priorities. For example, both the House and Senate bill include a non-aviation provision to standardize break rules for truck drivers that’s opposed by unions and many Democratic senators.

House and Senate staff are known to be meeting on the FAA bill to speed up the conference process once the Senate passes it. Those conversations could also lead to a Senate bill acceptable to the House that the House could simply take up and pass, avoiding the need for a conference.

I’m still confident that an FAA bill can and will get done this year, but it’s going to take more time for the process play out. At this point, the smart money is on Congress passing a clean (i.e., no policy riders) three-month extension of FAA’s authorization, which would give lawmakers the rest of the year to finish the bill. In past years, the lame duck session that takes place after an election has been surprisingly productive period.

However, the mid-term elections are looming over everything Congress does. Democrats are bullish about their chances of taking control of the House. If they do, it’s less likely that the FAA bill will get done in 2018 because Democrats might want to restart the process and rewrite the legislation next year. In the interim, Congress would pass a longer-term extension (perhaps six months) to keep the FAA’s doors open.

The least likely scenario is that Congress would allow FAA’s budget authority to lapse at the end of September. In that case air traffic control would keep operating, but most agency employees would be temporarily furloughed.

In the final analysis, we can’t control what Congress does, but we can control what we do to nudge the process in the right direction. Take a moment to contact your congressional representatives in support of ARSA’s workforce provision and tell them to get the FAA bill done. All the resources you need are available in the Workforce Grant Program Action Center:

http://arsa.org/legislative/grant-program-action-center/

Urging Senate FAA Reauthorization Action

On Aug. 15, ARSA joined 32 other industry organizations in delivering a letter to Senate leadership urging quick FAA reauthorization action.

The Senate FAA bill (S. 1405) is on the move after the process had been stalled in the upper chamber for more than a year. The legislation would set the agency’s budget for at least the next three years and includes important aviation policy directives sought by ARSA.

“It is essential that the FAA is provided long-term authorization for its activities and programs to maintain and advance the safest, most efficient aerospace system in the world,” the letter said. “The U.S. aviation sector supports nearly 11 million jobs and contributes $1.6 trillion in economic activity. The aerospace industry needs dependable authority from the FAA and policymakers to continue to provide the highest level of service for aviation customers and meet the needs of the aviation industry and workforce.”

The focus of ARSA’s reauthorization campaign has been urging Congress to address the maintenance technician shortage by creating a new aviation workforce development program. On July 20, ARSA coordinated its own letter signed by 28 allied organizations asking leaders of the Senate Commerce, Science and Transportation Committee to include AMT grant program legislation in the Senate’s FAA reauthorization package.

The House FAA bill (H.R. 4), was approved on April 27 by a vote of 393 to 13, includes similar maintenance priorities to its Senate counterpart, but does not include the grant program. Notably, neither the House nor Senate bills currently contain language imposing unnecessary new regulatory mandates on repair stations, a testament to the effort that ARSA and its members have expended during the current reauthorization cycle improve awareness about how repair stations are contributing to the safest period in civil aviation.

“There is bipartisan support for moving the FAA bill forward now to ensure safety, economic benefits, regulatory reform, and international competitiveness through a long-term reauthorization bill for the FAA,” the letter concluded.

If you have questions or want to get more involved in ARSA’s legislative program, contact ARSA Executive Vice President Christian Klein at christian.klein@arsa.org.

To read the full letter, click here.

Sonico Hosts State Representative

Washington State Rep Tom Dent (left) poses with SONICO’s Jim Perdue and Amber Rel-Daves during his August to the company’s Moses Lake facility.

On Aug. 7, ARSA Regular Member Sonico, Inc. hosted Washington State Rep. Tom Dent (R-13th District) at its facility in Moses Lake.

(To learn more about the company and its long support for ARSA, read this month’s Member Spotlight.)

Rep. Dent had previously attended an invitation-only open house at the facility, but Sonico Vice President Jim Perdue hadn’t been able to visit with him. Perdue, a member of the ARSA board of directors who is well schooled on engagement with elected officials, followed up with a personal invitation to Rep. Dent for a return visit.

Upon that return, Rep. Dent joined Sonico personnel for lunch and a facility tour. He spent time talking with personnel throughout the facility – taking advantage of constituent facetime in the final months of his election campaign.

During the visit, Perdue learned about Rep. Dent’s aviation experience owning a crop-dusting business. Based on that shared knowledge, the visit to Sonico was an opportunity to connect the dots between agricultural operation and the broad range of maintenance work performed at certificated repair stations.

ARSA Executive Vice President Christian Klein regularly reminders members about the value of hosting elected officials at your facility. At every level of government, there is benefit to getting your work and people in front of your legislators. For information and assistance in hosting a facility visit, contact Christian directly at christian.klein@arsa.org.

There’s still time to share your experience engaging elected officials. Take a moment to respond to the “quick question”:

Constituents Matter – Town Hall Meetings

Last month’s hotline reviewed the role of the district office in communications with your congressional representative. This month, we look at another opportunity to get involved on the local level: town hall meetings.

Many representatives or their supporters host town hall or other community meetings. These fora provide an opportunity to gain insight into your representative’s priorities as well as his or her position on national, international and community issues. Most importantly, these events are a chance to initiate meaningful dialogue.

To get information on events scheduled or occurring in your area, contact the staff at the district office. You may also learn of an event through your local paper, newscast or congressional office’s newsletter or website.

When attending a town hall meeting, be prepared to make the most of the event. Here are a few suggestions:

- Speak Up and Be Prepared. Be ready to ask thoughtful, concise questions. Have data to support your concerns and positions. This will ensure you are remembered by the representative and staff.

- Make it Personal. It is important to establish yourself not just as a constituent but as a representative of other voters. Tell your representative about your company – the type of work it does and number of employees. Know how a policy will affect you or your family, business or community and provide firsthand accounts of that impact.

- Talk to Staff. Members usually bring several members of their staff to meetings. Be sure to interact with them, particularly if you are unable to interact with the representative. In all cases, obtain their business cards or at write down names, titles and contact information.

- Leave Paper. Create a company profile from ARSA’s Legislative Page (download the template: http://arsa.org/wp-content/uploads/2013/07/ARSA-CompanyProfile-20130722.docx). Provide it along with any documents that support your position or concerns, including ARSA’s legislative priorities brochure, to the representative or staff member.

- Follow Up. Be persistent (but also polite) in following up with your representative after an in-person event. Remember that creating a dialogue is only the first step, maintaining that dialogue is key.

- Attend Multiple Events. Also have other people from your company attend meetings, so that the representative can hear about the issue from multiple voices with the same concerns.

Use in-person events to form a relationship with your representative and staff. The more often you are seen and heard, the more likely the member will heed your concerns. Town hall meetings are a good way to stay in touch with your elected officials and keep yourself updated on what action being taken by your government, be it local, state or federal.

To find your representative and senators, visit www.govtrack.us/congress/members/map. You can find your legislators by entering your address and zip code.

The search will bring up your representatives and senators. Clicking on respective links allows you to view a background and contact information page for each of your elected officials, including websites, Twitter and Facebook pages and Washington, D.C. phone info.

Regulatory Update

Another Parts Documentation Extension

Effective Aug. 7, the FAA again explained a repair station’s authority to inspect and issue FAA Form 8130-3 with a right-side signature for new articles received without documentation required by change 6 to the U.S.-EU Maintenance Annex Guidance (MAG).

The cancellate date for Notice 8900.479 is Aug. 7, 2019. It is otherwise identical to the policy document issued by the agency in 2016 (N 8900.380) and renewed in 2017 (N 8900.429). Just like those previous documents, the new notice references “recent” concerns stemming from “recent” revisions to the MAG. ARSA has led an industry-wide coalition of efforts to address parts documentation issues caused by those revisions since September 2015 (review the history of the effort below).

In response to a July member question – which was reported in the hotline’s “A Member Asked” – ARSA inquired with the FAA about the then-approaching cancellation of the policy. The quick response from Office of Safety Standards Deputy Director Tim Shaver indicated this new notice would extend the short-term patch, as it now has, until a permanent correction can be made with the issuance of MAG change 7.

The ultimate solution of incorporating parts documentation issuance into the MAG has been indicated in the disposition section of each instance of this policy. ARSA will continue to press regulators on both sides of the Atlantic in order to realize that long-sought goal.

To read N 8900.479, click here.

Final Documents/Your Two Cents

This list includes Federal Register publications, such as final rules, Advisory Circulars and policy statements, as well as proposed rules and policies of interest to ARSA members.

Quality Time

Researching the Maintenance Workforce

The challenge of finding and retaining skilled technical workers has gained national attention.

In September, the FAA will host its inaugural one-day Aviation Workforce Symposium at Reagan National Airport outside of Washington, D.C.

Individuals from ARSA member companies regularly contact the association in search of resources to help describe the challenges facing the industry. All can speak eloquently of their personal experience, often highlighting the current state of workforce development with stories of their own career development – explaining how traditionally-reliable pipelines for talent are no longer sufficient.

What they need, though, is help creating a larger context. Some resources can help. The following list is a useful start – take advantage of it and share your own information with ARSA:

(1) This year’s state-by-state data sheet compiled for ARSA by CAVOK, along with the executive summary of this year’s complete report: arsa.org/market-assessment

(2) Two infographics ARSA produced based on “quick questions” regarding technician onboarding and certification breakdown in the workforce:

(a) Time to Onboard a New Technician

(b) Technician Workforce by Certification

(3) Salary data from the Bureau of Labor Statistics: www.bls.gov/ooh/installation-maintenance-and-repair/aircraft-and-avionics-equipment-mechanics-and-technicians.htm.

(4) “My Next Move,” a resource sponsored by the Labor Department that provides analysis related to the employment outlook for aircraft mechanics and service technicians: www.mynextmove.org/profile/summary/49-3011.00.

(4) ARSA’s Workforce Legislative Action Center: arsa.org/legislative/grant-program-action-center

(5) The “Pipeline Report” produced by the Aviation Technician Education Council, which has great data on industry turnover and demographics, including certification: www.atec-amt.org/2017-survey.

(6) A presentation presented on by ATEC Executive Director Crystal Maguire at the National Training Aircraft Symposium on Aug. 14 in Daytona Beach. Maguire compiled resources from multiple sources – including ARSA – to produce a quick review of most relevant data related to the maintenance workforce:

On Oct. 9, ATEC will present a webinar providing “A Closer Look at Boeing’s 2018-2037 Technician Outlook.” For more information and to register, click here.

There is no perfect data source for capturing the aviation maintenance workforce and describing each issue. Each has drawbacks and blind spots, but taken as a whole and combined with personal observation, they help to tell a powerful story.

Training

Repair Station Security Rule

This session covers the requirements set forth in the Transportation Security Administration’s repair station security rule. Learn from ARSA, which represents the maintenance community on TSA’s Aviation Security Advisory Committee, how to stay compliant with mandatory security responsibilities.

TSA’s Repair Station Security Rule – Effectively Complying with the Regulation

On-Demand – Available Anytime

Click here to register and get access for 90 days.

(To see all of ARSA’s security-related resources for repair stations, review the content across the edition or visit arsa.org/security.)

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording made available after the live session is complete.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit PotomacLaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Congressional Testimony

With Congress debating President Trump’s nomination of Brett Kavanaugh to serve as the next justice of the Supreme Court, congressional hearings are dominating news coverage. Let that attention serve as the perfect reason to learn about the hearing process and consider how it can work for you.

As the voice of the aviation maintenance industry, ARSA wears a path across Capitol Hill every day. While the association’s legislative team has a deep bench of contacts and long experience sharing the good work of repair stations, lawmakers often need to hear the message directly from their constituents. As business leaders, community members and technical experts, ARSA members are perfect participants for congressional hearings – maintenance executives, managers and technicians can provide the hands on experience and real world insight that legislators need to make good laws.

Instructors: Christian A. Klein & Daniel B. Fisher

Click here to register and get access for 90 days.

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording made available after the live session is complete.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, PLC, the firm that manages ARSA. To go directly to OFMK’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Guest Lecture – “Check Yourself”

The aviation industry has long depended on checklists for proper completion of tasks. From the cockpit to the component shop, these tools help distill complex and repetitive procedures down to a series of basic steps and enable those performing work to track progress and ensure proper completion.

Thanks to its remarkable safety record, aviation has become an example to others – notably doctors, nurses and other health professionals – of how to mitigate risk. Join the discussion of NPR’s “Hidden Brain” podcast and consider how your personal and professional performance could be enhanced by modeling good checklist use:

Hidden Brain’s You. 2.0: Check Yourself (Click here to access)

Regulatory Compliance Training

Test your knowledge of 14 CFR § 65.83 – Recent experience requirements.

Click here to download the training sheet.

Membership

AMS Update – Corporate Members & Continuous Improvement

ARSA is continuing the phased rollout its new association management system (AMS): Contacts from the 17 corporate members have been uploaded – all individuals from paid member organizations now have records and online portal accounts.

For a refresher on ARSA’s membership categories and which organizations fall into each, visit arsa.org/membership.

ARSA’s membership team is learning a lot and gathering considerable information about how the new system works (and doesn’t). Addressing technical issues, managing organizational structures, communicating with primary contacts and coordinating with the company that produced the AMS is a full time job for the whole team.

You can help:

(1) Be patient. As with any major software transition, working out the kinks takes time. ARSA’s team is investing resources in getting the AMS right and continuing to provide the services and benefits its members value.

(2) Test the system. If you haven’t already, log into the new secure online member portal. Find your copy of the launch email with the subject “The ARSA Portal is Open!” and follow its instructions. Report back immediately to arsa@arsa.org if you didn’t receive the message or have technical issues accessing the portal. Once inside, test the functions of your dashboard and provide feedback using the inquiry system.

(3) Clean up your organization’s profile. Primary contacts should log into the system and review the employees connected to their membership. Fill out your team by inviting new members and removing those whose information isn’t needed anymore. Primary contacts from corporate members should look out for messages from ARSA’s membership team regarding review of all company and subsidiary information.

(4) Accept system messages. The new AMS sends a variety of automated emails to help you manage your membership and renew on time. Get “sendgrid.net” on your email safe list to ensure it can speak to you.

(5) Answer your phone (or email). Working through these issues can be made easier with some direct feedback from a user. If an ARSA team member contacts you regarding your experience with the new portal, to test a function related to your membership or with any other issue, spare a few minutes and provide some firsthand information.

Stay tuned as ARSA continues to progress through the launch process…

Don’t Let Technology Keep You from ARSA

The association’s new secure online portal (and the associated messages and alerts it delivers to members) adds a new email domain that should be on every member’s “safe list.” Thanks to spam filters, firewalls and quarantines, it can sometimes be difficult to get into your inbox – help us get through. Get access to every newsletter, update and reminder by ensure that the following domains don’t get flagged as spam:

@arsa.org

@potomac-law.com

@multibriefs.com

@sendgrid.net (new)

Know what to look for:

Weekly: The Dispatch newsletter is distributed every Wednesday.

Monthly: The hotline newsletter is distributed the first week of each month.

Various: Member alerts are distributed as necessary – usually the association sends two or three each month.

Membership Term Dependent: Renewal reminders begin flowing out of the system 90 days before the expiration of membership term.

To learn more about ARSA’s communications efforts — including how to advertise — visit arsa.org/news-media. For assistance with technical issues, consult your organization’s IT department/assistant as necessary.

Welcome & Welcome Back – New & Renewing Members

ARSA’s members give the association life – its work on behalf of the maintenance community depends on the commitment of these organizations. Here’s to the companies that joined or renewed in August:

New Members (Member Category)

Action Aero, Inc., R03

Ajeton, Inc., R01

B.V. Aviation, Inc. dba Universal Turbine Parts (UTP), R03

Central Washington University, Educate

Ford Instruments & Accessories, LLC, R01

Perkins Aircraft Windows, Inc., R02

R.T. Turbines, Inc., R01

Rotorcraft Services Group, R03

Renewing Members (Member Category, Member Since)

AAR Corp, Corp, 1985

Accessories, Inc., R01, 1995

Aero-Mark MRO, LLC-dba Certified Aviation Services, R02, 2015

Aerospace Testing Engineering & Certification Inc.-dba AeroTEC, Assoc, 2017

Aircraft Systems Division of Com-Jet Corp, R03, 2011

Ametek Ameron, LLC dba Ameron Global Product Support, R01, 1989

Ametek MRO Florida, Inc., R03, 2007

Aviation Repair Resources, Inc. (ARR), R02, 2009

Bemidji Aviation Services, Inc., R04, 2017

Berkley International, Inc., R01, 2007

C J Aviation, Inc., R01, 2017

Critical Care Mediflight Inc., Assoc, 2017

E.U.A. Air Support, Inc., R01, 2003

Federal Express Corporation, Assoc, 2000

Fleet Support Services, Inc., R01, 2013

John Hanson, Sr./ Aerocerts Quality Assurance, Affil, 2006

Lynden Air Cargo, LLC, Assoc, 2000

MT Texas, LLC, R03, 1990

MTI Aviation, Inc., R01, 2011

New Image Aero Interiors-dba NIA Interiors, R01, 2017

R.W. Raddatz, Inc., R02, 2004

REB Technologies Inc., dba REBTECH, R02, 2003

Texas Air Services, Inc. dba Texas Air Repair, R02, 2003

The Boeing Company, Corp, 1996

Quick Question – Using ARSA’s Online Portal

ARSA’s effort to transition to its new association management system (AMS) has included plenty of lessons learned. As members explore the new system through the secure online portal (visit arsa.member365.com to log in, using the “Forgot Password?” function if necessary), the association seeks specific feedback regarding the user experience.

This month’s “quick question” allows for general input. Help ARSA refine its use of the “customer-facing” functions of the new system by sharing your experience:

Note: The question is displayed in its own, embedded window. If the “Submit” button is not visible on the screen, you must scroll within the survey window in order to submit your response.

For more information about this or any other question, contact Brett Levanto (brett.levanto@arsa.org).

Click here to see what questions have been asked and answered…and keep a lookout for more.

A Member Asked…Maintenance or Fabrication?

Note: In the following exchange. The questioner’s points are provided in italics and ARSA’s responses are in normal text.

I read through the information on ARSA’s Drug & Alcohol Testing Issue page and found it very informative. I have a few questions regarding 14 CFR part 120 drug testing requirements as applied to the fabrication of parts destined to go into an aircraft or aircraft subassembly operating under 14 CFR part 135.

We are a part 135 air carrier and understand all maintenance performed must be done by drug tested personnel in accordance with 14 CFR §§ 120.105 and 1.1.

We also understand that fabrication is not maintenance or preventive maintenance, so we need to know where to draw the line on when fabrication stops and where maintenance begins.

In a fabrication scenario described below, how does each step in the process described fit into the D&A testing requirements of part 120?

(1) Subcontractor A fabricates an instrument panel blank from raw aluminum via hydro-form and then heat-treats it.

Not maintenance, all steps relate to fabricating the “new” part.

(2) Subcontractor B water-jet cuts the same panel blank to our specifications.

Not maintenance, all steps relate to fabricating the “new” part.

(3) We install a few new angles to the back of the same panel to attach Avionics mounting trays, this is done in our shop by our own employees that are drug tested.

Not maintenance, all steps related to fabricating the “new” part.

(4) Subcontractor C powder coats the panel

Not maintenance, all steps related to fabricating the “new” part.

This is where we draw the line between fabrication and maintenance…

It is more likely between 6 and 7 below, when are you no longer working on “new” assembly? When do you start “replacing” parts? Imagine that you could buy each of the items you are making from a manufacturer, all the steps to make that “new” thing would NOT be maintenance. When you “install” it in or on something else (that is “used”), you cross the line into maintenance.

(5) Subcontractor D silk-screens the panel. This is done by the repair station’s D&A-tested personnel.

Not maintenance, the step relates to fabricating the “new” part.

(6) We finish the panel by installing all the switches, lights, instruments and avionics, etc. done by our own drug tested employees.

Are these “new” switches, lights, etc.? If so, the steps are related to the fabrication of a new instrument panel; if “used” or “serviceable” parts are being “replaced”, then it is maintenance.

(7) Finished part goes into aircraft as part of an avionics upgrade package. Done by our own drug tested employees.

The installation (replacement) of the panel on the aircraft is maintenance.

The need for D&A testing is based upon safety-sensitive positions, of which maintenance (as defined in section 1.1) and preventive maintenance (also, defined in that section of the regulations) is included.

In other words, persons that perform maintenance and preventive maintenance are in safety-sensitive positions and must be drug/alcohol tested under a DOT/FAA program. So, at the point where maintenance steps are being performed, the individuals performing that work must be included in the testing program. The definitions of maintenance and preventive maintenance establish the basis for testing.

For a thorough review of D&A testing requirements in both 14 and 49 CFR and ways maintenance providers can avoid “traps for the unwary,” review ARSA’s online training series. All five sessions are available for immediate access:

Editor’s note: Member questions may now be submitted through the inquiry system run through ARSA’s new online member portal. Members can use their portal access to submit inquiries by logging in through https://arsa.member365.com/sharingnetwork.

Make ARSA’s Voice Your Own: Advertise

ARSA has a menu of advertising opportunities for arsa.org, the hotline and the ARSA Dispatch.

Take advantage of these great opportunities today to showcase your company, a new product or event. For more information go to arsa.org/advertise.

Stand Up for ARSA by Sponsoring in 2018

In order to provide world-class resources for its members, the association depends on the commitment of the aviation community. By sponsoring events and activities, supporters can help ARSA’s work on behalf of repair stations to endure.

Need a place to start? For information about opportunities, contact Vice President of Communications Brett Levanto (brett.levanto@arsa.org).

Member Spotlight – Sonico, Inc.

Sonico began business in 1980 and became an FAA-certificated repair station in 1985 at Grant County International Airport in Moses Lake, Washington. It became an ARSA member in 1995 and has remained an engaged part of the association for more than 20 years.

Sonico began business in 1980 and became an FAA-certificated repair station in 1985 at Grant County International Airport in Moses Lake, Washington. It became an ARSA member in 1995 and has remained an engaged part of the association for more than 20 years.

Sonico’s services include flight line maintenance and aircraft storage, which are supported by back-shops for component repair, non-destructive testing, machining and parts fabrication. Sonico carries a major inventory of aircraft spare parts and operates its own trucks to and from Boeing Seattle Spares Distribution Center each day.

The company’s customer base includes some of the world’s largest airlines: United, Delta, American and many international carriers including China Air, Malaysia Airlines and Qantas. The firm also provides services to major manufacturers and parts producers.

Sonico Vice President Jim Perdue has served on ARSA’s Board of Directors since 2006 and last served as president in 2015. You can read in this edition of the hotline about Perdue’s good example of advocacy outreach in hosting Washington State Representative Jim Dent at Sonico’s Moses Lake facility.

To learn more about the company, visit: http://www.sonicoinc.com

Resources

ARSA strives to provide resources to educate the general public about the work of the association’s member organizations; should you need to provide a quick reference or introductory overview to the global MRO industry, please utilize AVMRO.ARSA.org.

ICA Issue Page (Updated)

Since its inception, ARSA has worked to ensure that basic safety information (i.e., Instructions for Continued Airworthiness [ICA], including component maintenance manuals [CMM]) is made available at a fair and reasonable price to operators, maintenance providers, and any other person required by 14 CFR to comply with those instructions. ICA Issue Page (Updated)

Brexit Resource Page (Updated)

On June 23, 2016, citizens of the United Kingdom voted to withdraw from the European Union in a national referendum. This page is provided as a resource for the aviation maintenance community regarding transition negotiations between the British government and the European Commission. Brexit Resource Page (Updated)

AVMRO Industry Roundup

ARSA monitors media coverage on aviation maintenance to spread the word about the valuable role repair stations play globally by providing jobs and economic opportunities and in civic engagement. These are some of this month’s top stories highlighting the industry’s contributions.

You can explore these stories through ARSA’s Dispatch news portal.

Industry Calendar

Speednews Aviation Industry Suppliers Conference – Toulouse, France – September 10-12

FlightGlobal Aerospace Big Data Americas – Miami – September 11-12

Aero-Engines Europe – Hamburg, Germany – September 12-13

FAA Aviation Workforce Symposium – Washington, D.C. – September 13

ATEC Annual Fly-In – Washington, D.C. – September 12-14

Speednews Business & General Aviation Conference – Paradise Valley, Arizona – October 2

MRO Europe – Amsterdam – October 16-17

MRO Asia-Pacific – Singapore – November 6-8

MRO Latin America – Cancun, Mexico – January 16-17, 2019

the hotline is the monthly publication of the Aeronautical Repair Station Association (ARSA), the not-for-profit international trade association for certificated repair stations. It is for the exclusive use of ARSA members and federal employees on the ARSA mailing list. For a membership application, please call 703.739.9543 or visit arsa.org/membership/join. For information about previous editions, submit a request through arsa.org/contact. This material is provided for educational and informational purposes only. It does not constitute legal, consulting, tax or any other type of professional advice. Law, regulations, guidance and government policies change frequently. While ARSA updates this material, we do not guarantee its accuracy. In addition, the application of this material to a particular situation is always dependent on the facts and circumstances involved. The use of this material is therefore at your own risk. All content in the hotline, except where indicated otherwise, is the property of ARSA. This content may not be reproduced, distributed or displayed, nor may derivatives or presentations be created from it in whole or in part, in any manner without the prior written consent of ARSA. ARSA grants its members a non-exclusive license to reproduce the content of the hotline. Employees of member organizations are the only parties authorized to receive a duplicate of the hotline. ARSA reserves all remaining rights and will use any means necessary to protect its intellectual property.

© 2018 Aeronautical Repair Station Association