2019 – Edition 11 – December 6

Table of Contents

Note: The order of material varies in hotline emails, but is always presented the same on this landing page. Readers scrolling through content on or printing this page will find it organized consistent with the table of contents.

The Lead

2020 Annual Conference

ARSA Works

Legal Brief

ARSA on the Hill

Regulatory Update

Training

Membership

Resources

Industry Calendar

The Lead

Honesty, Truth and “Alternative Truth”

By Christian A. Klein, Executive Vice President

As a “side hustle”, I teach public relations courses at the University of Virginia. An overarching theme in the ethics class is that policy advocates must be both honest and truthful in communications. That means telling the truth, but also ensuring that the facts conveyed are in the proper context and provide an accurate picture. It is frustrating when colleagues in the policymaking process – whether members of Congress or my fellow lobbyists – do not hold themselves to that standard.

The ongoing fight over the anti-repair station bill (H.R. 5119) introduced in November by House Transportation & Infrastructure (T&I) Committee Chairman Peter DeFazio (D-Ore.) is a case in point (see full coverage in this month’s “ARSA on the Hill”). During a committee hearing, DeFazio conflated two unrelated topics to paint repair stations in a negative light, saying the sabotage of an American Airlines jet by an airline-employed union mechanic in Miami underscored why he was so concerned about security at foreign repair stations. (Yes, you read that right. If you don’t believe me, watch the hearing here; DeFazio’s comments are at 26:10).

Another example is a recent article about DeFazio’s bill from Forbes entitled, “Boeing 737 MAX Fiasco Brings New Scrutiny To ‘Insane’ Gap In Oversight Of Foreign Repair Stations”. The article is like a greatest hits record of the negative themes on contract maintenance. The classics are there, including claims that the certification standards for foreign are “far less stringent” than those for domestic repair stations, that foreign and domestic repair stations aren’t subject to surprise FAA inspections and that personnel at foreign repair stations aren’t qualified.

The article also quotes Transport Workers Union President John Samuelson as saying, “We don’t want to have a situation where America wakes up one morning to a catastrophic disaster involving foreign maintenance of passenger aircraft, which is what happened with the MAX.”

It’s true that in October the FAA revoked the certificate of a U.S. repair station that repaired and approved for return to service a sensor installed on the aircraft that served as Lion Air 610 in October 2018. The Indonesian National Transportation Safety Committee (KNKT) report on the event also cited the failure by Batam Aero Technic (Lion Air’s maintenance contractor, which is wholly owned by the airline) to identify the apparently miscalibrated sensor during installation as a potential contributing factor in the accident. It’s also true that a former Ethiopian Airlines chief engineer has alleged that the airline may have tampered with maintenance records in the wake the Ethiopian Airlines Flight 302 crash. But when he insinuates that “foreign maintenance” was to blame for the MAX crashes, Samuelson is way off base.

Those examples underscore ARSA’s challenge. We’re confronting opponents who are willing to bend and twist the truth to support an anti-contract maintenance narrative and policy goals. The unions promoting H.R. 5119 speak in vague terms about the supposed safety risks posed by repair stations. They cite a few hackneyed anecdotes about repair station maintenance mistakes uncovered by union members but can’t point to systematic problems and completely ignore the fact that the increased use of contract maintenance has coincided with the safest period in the history of U.S. civil aviation.

They claim contract maintenance is a job killer, but ignore the fact that repair stations employ 188,000 technicians around the United States (about six times more than the number of mechanics working at airlines) and neglect the role repair stations play in making U.S. air carriers more efficient and economically stable (thereby helping save airline jobs; learn more at ARSA’s “Data and Advocacy” page).

They claim that the FAA doesn’t have the authority to perform surprise inspections of foreign repair stations while ignoring the fact that U.S. rules already require any FAA-certificated repair station to open its doors to regulators at any time. They misrepresent the qualifications required of foreign repair station employees and insist they be tested for drugs and alcohol (D&A) while ignoring the fact that under current rules U.S. airline mechanics who work outside the country are removed from their employer’s D&A testing pool.

If our opponents want to have an honest and open discussion about repair stations, we’re all for it; we know the facts and law are on our side. The folks on the other side must know that, too, which explains why they rammed H.R. 5119 through committee just five days after being introduced without hearings or any opportunity for industry input.

We may be right, but that doesn’t mean we’ll win. The unions supporting H.R. 5119 are well organized and well-resourced. They have a powerful ally in DeFazio (and “consumer advocate” Ralph Nader). And their anti-trade messages, cloaked in a thin veneer of aviation safety, resonate on both sides of the aisle in the current political environment.

Victory depends on you speaking truth to power and making sure the facts (and not “alternative facts”) about YOUR industry are understood on Capitol Hill and in the media. To find out what you can do to help support ARSA’s fight against H.R. 5119, go to www.arsa.org/hr5119.

2020 Annual Conference

Register & Sponsor Now, Pay a Little Later

Registration is now open for ARSA’s 2020 Annual Conference, which will be held in and around Washington, D.C. from March 10-13, 2020. Have 2019 money to spend? Need to wait until your 2020 budget starts? Either way, now is the time to reserve your spot and the events team will help with invoice timing.

Registration is now open for ARSA’s 2020 Annual Conference, which will be held in and around Washington, D.C. from March 10-13, 2020. Have 2019 money to spend? Need to wait until your 2020 budget starts? Either way, now is the time to reserve your spot and the events team will help with invoice timing.

ARSA Works

Act Now

Association members, allies and industry colleagues must support ARSA’s current initiatives to improve aviation policy. Here’s your to-do list for November 2019 (click each page link for more information and instructions):

Plan now to land at ARSA’s Annual Conference in March…

Register Now

Registration is now open for ARSA’s 2020 Annual Conference, which will be held in and around Washington, D.C. from March 10-13, 2020. Have 2019 money to spend? Need to wait until your 2020 budget starts? Either way, now is the time to reserve your spot and the events team will help with invoice timing.

Protect the industry from crippling congressional overreach…

ARSA Highlights Threats from Anti-Repair Station Bill

On Dec. 5, ARSA hosted a webinar to encourage industry action in opposition to an anti-contract maintenance bill rushed through the U.S. House of Representatives Transportation & Infrastructure (T&I) Committee on Nov. 20.

Help push through funding for industry workforce grant programs (and get ready to apply for them)…

FAA Takes Small Step Towards Workforce Grants

On Nov. 26, the Federal Register published notices regarding new aviation workforce development grant programs created by Sec. 625 of last year’s FAA reauthorization law.

Utilize DoD resources for recruiting transitioning military personnel…

Military Skills to Industry Careers

On Nov. 13, ARSA Vice President of Operations Brett Levanto attended an industry and government working session focused on easing transitions for military technicians into civilian aviation careers. Of immediate interest to industry was a DoD briefing on its SkillBridge Program.

ARSA Reviewing Its EASA Supplement

On Nov. 18, EASA published change 7 to the Maintenance Annex Guidance (MAG) associated with the bilateral aviation safety agreement (BASA) between the United States and the European Union (U.S.-EU). Repair stations have 90 days to implement changes, which means no later than Feb. 17, 2020.

Since the release of MAG Change 7, ARSA’s regulatory team has been working on a new revision to the association’s Repair Station and Quality Manual (RSQM) EASA Supplement. In advance of releasing the new revision, ARSA has produced a summary document describing the areas of the supplement impacted by changes to the MAG. Persons already using the supplement can utilize the summary document to determine what updates are required. Those seeking to make a first-time purchase of the supplement should contact ARSA.

The summary is organized by the impacted supplement sections and can be accessed by clicking here.

For more information on all of ARSA’s publications, including the RSQM itself as well as a number of resources available for free to members, visit arsa.org/publications.

ARSA Presses for Rule-based Guidance

On Nov. 14, ARSA sent a letter to FAA Chief Counsel Arjun Garg expressing concern with the disconnect between agency guidance and the aviation safety rules.

The letter noted that compliance “begins and ends with the plain language of the rules,” quoting the association’s welcome message to Administrator Steve Dickson (read a public version via the August 2019 Aviation Week/MRO Network Editorial “Dear Mr. Administrator”). Recognizing this principle and citing President Trump’s Oct. 9 Executive Order “Promoting the Rule of Law Through Improved Agency Guidance Documents,” the message to Garg sought immediate attention for two FAA orders:

(1) FAA Order 8000.373A, “Federal Aviation Administration Compliance Program” (Oct. 31, 2018). The document purports to provide methods for the agency and the industry to work through compliance issues that do not pose a risk to the aviation safety system. As the language now stands, agency personnel can base, and are basing, decisions upon “guidance”, which unfortunately does not always comport with the rules.

(2) FAA Order 8900.1, Volume 1, Chapter 1, Section 1 (May 3, 2019). This document contains guidance to aviation safety inspectors (ASI) on certification and surveillance activities. It must be clear that regulations trump any guidance.

“ARSA urges the Chief Counsel’s Office to take immediate action to conform the above-referenced documents to basic principles of administrative law,” the letter to Garg said, providing specific recommendations for revising each order.

In addition to citing the October executive order, the letter referenced instructions from the Departments of Justice and Transportation as well as the Office of Management and Budget. To see ARSA’s analysis of these documents and their implications for aviation oversight, refer to the April 2018 and March 2019 editions of the hotline or “Are We There Yet?” in the June 2019 edition of DOM Magazine.

To read the complete letter, click here.

Military Skills to Industry Careers

![]() On Nov. 13, ARSA Vice President of Operations Brett Levanto attended an industry and government working session focused on easing transitions for military technicians into civilian aviation careers.

On Nov. 13, ARSA Vice President of Operations Brett Levanto attended an industry and government working session focused on easing transitions for military technicians into civilian aviation careers.

The core participants at the meeting were representatives to the Joint Services Aircraft Maintenance Technician Certification Council (JSAMTCC), a Department of Defense-FAA body on which Levanto has served since 2018. The council issues certificates of eligibility to military service members confirming attainment of necessary knowledge gained through training and experience to meet the requirements of 14 CFR § 65.77 (see Order 8900.1 Vol. 5. Ch. 5. Sec. 2 Para. 5-1134-B). As part of the current intense focus on workforce and career development, the JSAMTCC has become a venue for ARSA and others to explore new ways of streamlining military transitions and tapping into the broad range of skills held by uniformed personnel.

Over the course of the day, the group discussed credentialing programs, explored examples – like commercial drivers’ licenses – from other industries, planned updates to the military aviation curriculum structure and began the long process of overhauling FAA airman testing requirements for military personnel. Of immediate interest to industry was a DoD briefing on its SkillBridge Program.

“The DoD SkillBridge program is an opportunity for service members to gain valuable civilian work experience through specific industry training, apprenticeships, or internships during the last 180 days of service,” the program’s website explains. “Separating Service members can be granted … permissive duty to focus solely on training full-time with approved industry partners … [who] offer real-world training and work experience in in-demand fields of work while having the opportunity to evaluate the service member’s suitability for the work.”

SkillBridge provides a mechanism for aviation employers to connect directly with service members, provide training and grow them into career positions for immediate placement upon their separation from service. There is cost sharing by the government, as the service member’s salary will initially be paid by their military unit, and applications can come from any specialty or job; since the interest of the applicant is the primary factor in program selection, repair stations and related employers can pull from technical skill sets beyond aviation.

As ARSA works to improve policy and provide resources (visit arsa.org/grant-program for updates on its efforts to fund new workforce training grants) related to aviation career development, the association encourages members to connect today to programs like SkillBridge that can provide access to military talent and professionalism.

To get started, visit: dodskillbridge.usalearning.gov.

For more information about military transition assistance efforts, contact Brett Levanto.

SOCAC Kicks Off

On Nov. 13, the Department of Transportation hosted the first meeting of the Safey Oversight and Certification Advisory Committee (SOCAC). The SOCAC’s creation was mandated by the FAA Reauthorization Act of 2018 to provide advice to the Secretary of Transportation regarding issues facing the aviation community related to FAA safety oversight and certification programs.

The content of the meeting focused on introducing committee members to the Federal Advisory Committee Act (FACA) procedures and the Aviation Safety organization’s certification and oversight activities. The members, which include ARSA Executive Director Sarah MacLeod, then exchanged views on prioritizing the congressionally-mandated list of issue areas within the body’s scope:

(1) Aircraft and flight Standards certification processes, including efforts to streamline those processes.

(2) Implementation and oversight of safety management systems.

(3) Risk-based oversight efforts.

(4) Utilization of delegation and designation authorities, including organization designation authorization.

(5) Regulatory interpretation standardization efforts.

(6) Training programs.

(7) Expediting the rulemaking process and giving priority ot rules related to safety.

(8) Enhancing global competitiveness of United States manufactured and United States certificated aerospace and aviation products and services throughout the world.

A general consensus was reached to study the list vis-à-vis the current efforts being made in each of the areas, including recommendations from other committees that have covered the issues. After the efforts have been consolidated, the SOCAC would be able to focus on those areas that need further attention.

Stay tuned for more updates from ARSA as MacLeod represents the maintenance community’s interests on the SOCAC. To review the Aug. 22 DOT press release announcing committee’s membership, click here.

Legal Brief

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

MAG 7 Mostly Clarifies but Angst May Exist

By Joseph Corrao, Vice President of Regulatory Affairs

The FAA and EASA published change 7 of their bilateral Maintenance Annex Guidance (MAG 7) document on Nov. 18.

A simple comparison of the new MAG 7 to its predecessor MAG 6 suggests the entire document has been revised; the reality is less traumatic. Most of the changes are commas added or removed, paragraphs reformatted to block style, and text moves that clutter up tracked Changes but don’t really change a thing.

Nevertheless, MAG 7 introduces several changes that will impact affected repair stations. ARSA has produced an annotated table that identifies pertinent changes. Among these are:

(1) Liberalization and clarification of requirements for work on components and parts. For example:

- Documentation requirements are relaxed for new parts installed by EU-based repair stations working on U.S.-registered aircraft. FAA Form 8130-3 remains recognized but is no longer required.

- Maintenance on components that are included in designs approved by either FAA or EASA but not both may be signed off using a single release under the authority that granted design approval, enabling repair stations operating pursuant to MAG 7 to install such components on eligible aircraft without reference to the authority that did not approve the design.

- Clarification that direct shipment of new components under the U.S. Part Approval Holder’s (PAH) quality system, with the necessary documentation, is acceptable to EASA.

(2) Training requirements. MAG 7 requires EASA-approved repair stations to:

- Develop recurrent training curricula on human factors that references “errors/lessons learned” rather than periodically repeating initial human factors training. This may require updating the auditing forms to ensure human factor elements are captured and the development of lessons on what went wrong or right.

- When utilizing line stations exercising the privileges of the EASA Part-145 certificate, affected repair stations must specify in the contract the training requirements for staff who will approve the work for return to service.

(3) The demise of the “triple release” and refocusing to multiple bilateral agreements among aviation authorities. As ARSA Managing Director & General Counsel Marshall Filler explained in the October edition of the hotline: “[the] Maintenance Management Team (MMT), comprised of the civil aviation regulatory authorities of Brazil, Canada, the European Union and United States…and its sister quadrilateral group, the Certification Management Team (CMT), focus on issues of common interest to the four authorities while recognizing that any formal changes to existing aviation safety agreements occur bilaterally.”

Some of MAG 7’s extensive revisions eliminate references to Transport Canada, conforming the MAG to the bilateral format and clarifying the authorities’ intent to address the U.S.-EU, Canada-EU, and U.S.-Canada relationships in separate documents.

ARSA remains committed to the goal of mutual recognition, pursued through and documented in bilateral and, when appropriate, multi-lateral arrangements. Currently, this change does not impact repair stations in the United States or AMOs in Canada or Europe since all three jurisdictions have bilateral agreements with each other. Thus, work performed in the U.S. or Canada is acceptable to either country and if the repair station is approved by EASA under either bilateral, a dual release can be issued.

(4) Reciprocal “grandfathering” of parts in inventory. EASA and FAA earlier agreed to permit installation of airworthy components received into inventory prior to Oct. 1, 2016. Both now expand this provision to include parts issued through an approved design in addition to those from a PAH or supplier with direct ship authority.

(5) Updating Mutual Acceptance of Repair Data. MAG 6 includes language from the Technical Implementation Procedures (TIP) Revision 5, which did not include reciprocal acceptance of repair data on critical components developed by persons other than the TC/STC holder. However, TIP Revision 6 eliminated the restriction on non-design approval holder (DAH) repair data on such components. Therefore, MAG 7 is now properly aligned with TIP 6.

(6) Clarification of line maintenance authority and hangar requirements. MAG 7 clarifies that EASA hangar requirements apply to base maintenance operations; by implication, the hangar requirement does not apply to line maintenance.

(7) Clarification that EASA will only permit a U.S.-certificated repair stations holding EASA approval to perform “urgent defect rectification” (i.e., Aircraft on Ground (AOG)) work away from its “fixed location.”

- One time only and with prior authorization by EASA if the repair station does not hold FAA OpSpec D100;

- On a recurring basis and with prior notice to EASA, but not prior authorization from EASA, if the repair station holds FAA OpSpec D100.

The new MAG enters into force on Feb. 17, 2020. A last-minute change to the text of Section D caused momentary confusion about the date. This was resolved when ARSA Managing Director & General Counsel Marshall Filler brought it to the attention of FAA and EASA representatives.

ARSA members holding FAA authority and EASA approval have until the effective date of MAG 7 to conform their repair station documentation to the new language. As in years past, ARSA is updating its EASA Supplement to the Model Repair Station and Quality Manual (RSQM) and related forms to facilitate compliance.

Stay tuned to arsa.org/mag and future editions of the hotline for further updates.

ARSA on the Hill

ARSA Highlights Threats from Anti-Repair Station Bill

By Christian A. Klein, Executive Vice President

ARSA is leading a coalition in opposition to the Safe Aircraft Maintenance Standards Act (H.R. 5119), an anti-contract maintenance bill rushed through the House Transportation & Infrastructure (T&I) Committee in mid-November. On Dec. 5, ARSA hosted a webinar to brief members about the status of the legislation and to encourage industry action in opposition to the bill.

To stream a recording of the webinar, click here.

To download a PDF copy of the presentation, click here.

ARSA is on high alert given concerns that the bill, which would cause massive disruptions for repair stations, air carriers and manufacturers, could be considered by the full House before the end of the year. Among other things, H.R. 5119 would:

- Impose burdensome new maintenance-related reporting requirements on air carriers.

- Ban the FAA from issuing or renewing repair station certificates in countries designated as Category 2 under the International Aviation Safety Assessment Program (and ban U.S. air carriers from using maintenance contractors in those countries). Countries currently designated as CAT 2 are Thailand, Malaysia, Cost Rica, Ghana, Bangladesh and Curacao, but the list can and does change.

- Require the FAA to directly certificate workers at foreign repair stations.

- Impose a moratorium on the issuance of new FAA repair station certificates outside the United States if the agency does not complete all the tasks directed by the bill and pending foreign repair station-related rulemakings within one year of the bill’s enactment (a laundry list so long the FAA will never meet the deadline).

House T&I Chairman Peter DeFazio (D-Ore.) introduced the bill on Nov. 15 and brought it up for a committee vote just five days later. No hearings were held to discuss the bill or committee concerns about repair station oversight. Given the “no huddle offense” strategy that Chairman DeFazio and his airline mechanic union allies employed to get the bill through committee, there’s a strong possibility they will try to get it to the House floor for a vote before the end of the year. Given that all T&I Committee Democrats and seven Republicans voted in favor, if it were taken up by the House today, there’s a good chance it would pass.

If the bill becomes law, U.S. repair stations with foreign approvals and their employees would almost certainly be targets of the retaliation by foreign authorities. U.S. commercial and general aviation operations outside the country would be disrupted because of a shortage – or complete lack of – FAA certificated maintenance facilities in destination countries. And U.S. manufacturers seeking to provide product support in growing foreign markets would be prevented from obtaining FAA certification at those overseas facilities.

If you weren’t able to listen in on the Dec. 5 webinar, a recording is available for streaming. The association is also coordinating meetings with congressional offices and correspondence between the coalition and Congress. ARSA has developed additional materials (available at www.arsa.org/hr5119) to support members’ and allies’ advocacy. With the specter of a House vote looming, time is of the essence. Your personal outreach to House and Senate offices is critical to stop H.R. 5119 from becoming law.

|

Want to Learn More About ARSA PAC? ARSA’s Political Action Committee helps elect congressional candidates who share ARSA’s commitment to better regulation and a strong aviation maintenance sector. In this critical election year, ARSA PAC has never been more important. But ARSA is prohibited from sending PAC information to members who haven’t opted in to receive it. Please take a second to give us prior approval to talk to you about ARSA PAC. Doing so in no way obligates you to support PAC. It just opens the lines of communication. Click here to give ARSA your consent today. |

Appropriations Drama Delays Aviation Workforce Funding

ARSA’s signature legislative achievement in 2018 was convincing Congress to create a new aviation technician workforce development grant program as part of the 2018 FAA reauthorization. The program, authorized at $5 million per year, would provide resources to businesses, schools and governmental entities that collaborate to recruit and train the next generation of maintenance workers.

Thanks to the ongoing work of a coalition led by ARSA, both the House and Senate FY 2020 appropriations bills for the Department of Transportation include funding for the new program (the House bill would fully-fund the program at $5 million; the Senate bill includes partial funding). Unfortunately, more than two months after FY 2020 began on Oct. 1, government funding for the coming year is still up in the air and monies for the grant program is a captive to that process.

Congress passed a short-term continuing resolution in November to keep the government running through Dec. 20. Negotiations between the House, Senate and the Trump administration over a longer-term government funding deal are ongoing. A key sticking point is funding requested by President Trump for a wall on the U.S.-Mexico border.

There were signs of progress before Thanksgiving, when Rep. Nita Lowey (D-N.Y.) and Senator Richard Shelby (R-Ala.), the chairs of the House and Senate Appropriations Committees, reportedly agreed on FY2020 302(b) allocations, the top-line funding number for each of the 12 government funding bills. Leaders of the appropriations subcommittees must now meet to decide how much money programs under their jurisdiction will get next year.

While the process seems to be moving in the right direction, getting agreement among and between Congress, the White House, Republicans and Democrats and passing all the bills before the Dec. 20 deadline will be a tall order. One big elephant in the room is the House impeachment process, which could consume valuable floor time if Democrats bring an impeachment resolution up for a vote before the holidays. Given everything on lawmakers’ plates, it’s likely that Congress will need to pass at least one more short-term extension to keep the government running through the new year.

In related news, the FAA is finally showing signs of getting the technician grant program and a related one for pilot education up and running. The Nov. 26 edition of the Federal Register contains notices and requests for comment regarding the collection of information from eligible entities by the FAA to select and oversee grant recipients. The notices are related to the Paperwork Reduction Act of 1995 and provide an estimate of the reporting burden for grant applicants and recipients.

The fact that the FAA is focusing on the grant program is good news and suggests the agency understands the urgency of workforce shortage plaguing the U.S. aerospace industry.

Members need to keep the pressure on and help us get the ball across the goal line. Send a note to your congressional representatives asking them to make aviation workforce a priority. Everything you need (including contact information for congressional offices, a draft email and instructions for how to send it is at arsa.org/legislative/grant-program-action-center).

In addition to that grassroots advocacy in search of appropriated funds, repair stations can begin preparing to take advantage of the programs whenever money becomes available by reviewing the information collection notices. These requests lay out the basic structure of the grant programs as the agency expects to construct them and can be instructive for those preparing to submit applications.

The notice for the technician program can be found by clicking here.

The notice for the pilot education program can be found by clicking here.

|

Tell Congress to Make Aviation Workforce a Priority ARSA’s signature legislative victory in 2018 was convincing Congress to create a new grant program help repair stations recruit and train aviation maintenance technicians. Our priority now is getting the program funded … and we need your help. ARSA has completely revamped our grant program action center to help you learn more about the issue and urge your members of Congress to appropriate the money we need. It’s quick and easy. Take a second now the tell your elected represents to make aviation workforce a priority! |

Regulatory Update

U.S.-EU MAG Change 7 Released

On Nov. 18, EASA published change 7 to the Maintenance Annex Guidance associated with the bilateral aviation safety agreement between the United States and the European Union. As reported in the October edition of ARSA’s hotline newsletter, the FAA and EASA announced during the fall meeting of Maintenance Management Team that the long-awaited change had been signed. Repair stations have 90 days to implement applicable changes and must do so no later than Feb. 17, 2020.

A non-exhaustive list of the “significant changes” as identified by the MAG’s revision history includes:

- Training requirements clarified, Section A, Section I , paragraph 3.3.1, 3.3.2.

- Revised PAH by removing reference to TCCA, Section A, Section IV, paragraph 19.

- Revised evidence of need, Section B, Section I, paragraph 2.2.1.

- Added requirement of immediate notification to EASA of Level 1 findings, Section B, Section II, paragraph 2.2.4.

- Revised work away from fixed location and added Note, Section B, Section V, paragraph, 1 and 1.1.2.

- Revised FAA Actions when repair station surrenders EASA approval, Section B, Section VI, paragraph 3.3.2.

- Added paragraph addressing components acceptable to other BA’s, Section B, Appendix 1, paragraph k(1)vii, and k(2)iv.

- Added provisions for release of components non-US type certificated, Section B, Appendix 1, paragraph n(1)(2)(3)(4)(5)(6)(7).

- Clarified EU registered aircraft release to service i/a/w EASA part 145.A.50, Section B, Appendix 1, paragraph 12(d).

- Clarified contract maintenance, Section B, Appendix 1, paragraph 16 and 16(a)(b), 3(i), 4.

- Revised EASA supplement line station requirements, Section B, Appendix 1, paragraph 18(e)(2).

- Revised work away from fixed location EASA supplement, Section B, Appendix 1, paragraph 19(a)and (b) and added Note.

- Added 60 day notice to applicant responsibility, Section C, Section I, paragraph 7.

- Added approved maintenance function information, Section C, Section I, paragraph 9.5.1.

- Revised acceptability of component information, Section C, Appendix 1, paragraphs 7 C, C(1)(a)(i)(ii)(iii)(iv)(v) and Notes, paragraph 7 C, C(1)(x), C2(a)(i)(ii)(iii)(iv)(vi).

- Added provisions for possible cases of components after maintenance, Section C, Appendix 1, paragraph 2(d)(e) and US and EASA return to service entries.

- Added release for components used in a FAA TC/STC, Section C, Appendix 1, paragraph 2(f)(1)(2)(3)(4)(5)(6)(7).

- Revised contract maintenance information, Section C, Appendix 1, paragraphs 10 and 10(3)(i).

- Removed critical component information from major repairs and alterations, Section C, Appendix 1, paragraph 11.

Stay tuned to the association for more analysis of the MAG and utilize the relevant contact tools to submit questions or comments related to the most-recent change.

To view change 7 as released by EASA, click here.

To review a comparison document identifying differences between the published versions of change 6 and change 7, click here.

Review the ARSA Works, Legal Brief and Membership content in this edition of the hotline to learn more.

FAA Takes Small Step Towards Workforce Grants

On Nov. 26, the Federal Register published notices regarding new aviation workforce development grant programs created by Sec. 625 of last year’s FAA reauthorization law. The FAA requested comment regarding the collection of information from eligible entities by the agency to select and oversee grant recipients. The notices are related to the Paperwork Reduction Act of 1995 and provide an estimate of the reporting burden for grant applicants and recipients.

The notice for the technician program can be found at www.federalregister.gov/documents/2019/11/26/2019-25681/agency-information-collection-activities-requests-for-comments-clearance-of-a-new-approval-of.

The notice for the pilot education program can be found at www.federalregister.gov/documents/2019/11/26/2019-25680/agency-information-collection-activities-requests-for-comments-clearance-of-a-new-approval-of.

The deadline for comment on each is Jan. 27, 2020.

While these notices do not represent the initiation of the programs, they suggest the FAA is moving in the right direction. However, Congress has yet to appropriate the necessary FY 2020 money. As previously reported (see below), the FY 2020 House Transportation, Housing and Urban Development and Related Agencies (T-HUD) bill contains full funding for both ($10 million total – $5 million each). The Senate’s T-HUD package contains partial funding ($5 total). The most recent appropriations continuing resolution expires on Dec. 20, so the next few weeks will be crucial in determining final FY 2020 spending levels.

Keep the pressure on Congress and FAA to fully fund and initiate these important programs. Advocacy resources (including the most recent industry coalition letter to Congress) can be found at arsa.org/legislative/grant-program-action-center/.

http://arsa.org/legislative/grant-program-action-center/

Administrator Reflects on First 90 Days

Approaching the end of his third month on the job, FAA Administrator Stephen Dickson spoke to the aviation community on Nov. 12 at the Aero Club of Washington’s monthly luncheon. Being Dickson’s first time at the Aero Club; he joked, “somebody told me you have to give up your ‘outside the Beltway’ membership card if you come to one of these, so that’s why I stayed away.”

The administrator proved adept at making prepared remarks sound fresh without straying off-script, no small gift in Washington. Although there was little new in his statement, a few things may be of interest to aviation maintenance professionals:

On Boeing’s 737 MAX: Dickson repeated his previous public statement that “I am not going to sign off on this aircraft until I fly it myself and am satisfied that I would put my own family on it without a second thought.” (Dickson, a former airline captain, is rated on Boeing 727, 737, 757, 767 and Airbus A320 series aircraft.)

On MAX investigation fallout: “Some key themes are emerging regarding aircraft certification processes not only in the [United States], but around the world,” Dickson said. “I am committed to addressing each of these issues. They include: Moving toward a more holistic versus transactional, item-by-item approach to aircraft certification; Integrating human factors considerations more effectively throughout the design process, as aircraft become more automated and systems more complex; and Ensuring coordinated and flexible information flow during the oversight process.”

On the composition of the future fleet: The administrator noted the FAA has “registered about 1.5 million small drones, about 400,000 of which are for commercial purposes, and we’ve approved two Part 135 drone operators…[T]he FAA and its predecessors have been registering manned aircraft for 92 years, and after only four years…we’ve got four times as many on the books.” In addition to the expansion of registered UAS, Dickson noted the agency is currently engaged with the manufacturers of more than 15 electric vertical takeoff and landing aircraft.

In facing its challenges, Dickson believes the FAA “must continue leaning into our role as a data-driven, risk-based decision-making oversight organization that prioritizes safety above all else.”

For its part, the association has urged the administrator to focus in several key areas (see Aug. 13 update on arsa.org/dickson):

(1) Support and enhance efforts to grow the aviation workforce, stand up the grant program established by the 2018 FAA reauthorization law, support industry efforts to reconsider every “pathway” through which maintenance professionals progress and modernizing the requirements for overseeing maintenance training and measuring competency.

(2) Maintain the collaboration among and between regulators and the regulated community to identify, assess, and mitigate risk.

(3) Commit to regulatory consistency.

(4) Stand up to political and media pressure and focus on initiatives that achieve the highest possible level of safety, based on risk, while minimizing additional burdens on industry.

ARSA’s engagement with the Administrator and FAA continues with these goals in focus.

Final Documents/Your Two Cents

This list includes Federal Register publications, such as final rules, Advisory Circulars and policy statements, as well as proposed rules and policies of interest to ARSA members.

Training

Part 65 – Overview

This session overviews 14 CFR part 65, Certification: Airmen Other than Flight Crewmembers. It introduces the statutory authority through which the FAA administers certificates and outlines the rules for application, issuance, testing, disqualification and duration of agency-issued certificates. It then introduces the five different certifications issued under part 65 by reviewing the relevant eligibility requirements for each.

Instructor: Sarah MacLeod

Click here to register and get access for 90 days.

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording made available after the live session is complete.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Part 65 – Getting a Mechanic’s Certificate

This session reviews the requirements of 14 CFR part 65 subpart D, which concerns aviation mechanics. It walks through the requirements for an individual to apply for a mechanic’s certificate, then defines the privileges and limitations bestowed on that individual by his or her certificate. Finally, it covers the enhancements to a mechanic’s privileges produced by obtaining Inspection Authorization.

Instructor: Sarah MacLeod

Click here to register and get access for 90 days.

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording made available after the live session is complete.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Part 65 – Getting a Repairman’s Certificate

This session reviews the requirements of 14 CFR part 65 subpart E, which concerns aviation repairmen. It presents the language of part 65 in the context of parts 121, 135 and 145 as well as agency guidance regarding the management of repairman applications. Throughout, the session connects and compares the repairman’s requirements to those of the mechanic’s certificate issued under part 65.

Instructors: Sarah MacLeod & Brett Levanto

Click here to register and get access for 90 days.

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording made available after the live session is complete.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Going Global – International Regulatory Law

International markets mean expanded business opportunities that require an expansive regulatory understanding. Working on your global knowledge with two on-demand training sessions from ARSA Managing Director & General Counsel Marshall S. Filler.

A Primer on International Regulatory Law

This session summarizes the framework for international safety regulation, introduces ICAO’s mechanisms for allocating regulatory responsibilities among member states and addresses the important role bilateral agreements play in enhancing efficiency and facilitating international commerce.

Click here to register and get access for 90 days.

Bilateral Agreements

This session focuses on the purpose and scope of bilateral agreements and describes how they are developed and structured. The presentation explains specific activities covered in a typical BASA including design approvals and post-design approvals, production and surveillance, export airworthiness approvals, technical assistance between authorities and special arrangements. It also covers bilateral maintenance agreements, their associated special conditions and the latest maintenance developments out of ICAO.

Click here to register and get access for 90 days.

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording made available after the live session is complete.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Regulatory Compliance Training

Test your knowledge of 14 CFR Part 65 – Airmen Other Than Flight Crewmembers. The combined packet contains training sheets for each section found within Part 65; the sheets were presented in each hotline from August 2017 to October 2019.

Click here to download the training booklet.

Membership

ARSA Recognizes Retirements of Lynden’s Pull & Willing

On Nov. 22, ARSA helped to recognize the retirement of two colleagues from member company Lynden Air Cargo. Jeff Pull and Paul Willing have long been steadfast supporters of aviation safety and committed backers of ARSA’s work on behalf of the entire aviation maintenance community.

“When ARSA found out that two of our internal regulatory experts were retiring they dashed around to provide two awards, both of which are being presented for the first time tonight and I have the honor in assisting that presentation,” said LAC President Rick Zerkel during the ceremony held at the company’s facility in Anchorage, Alaska.

LAC President Rick Zerkel assists in presenting the association’s honors to Jeff Pull (left) and Paul Willing (Center, in brown jacket).

Since the association’s team had such fun procuring the necessary materials for each “award” and developing the script for their presentation – which Zerkel utilized – it is providing the entirety of that script for all of its members’ reading pleasure (Should you know someone getting ready to retire whom you believe is deserving of such recognition, let ARSA know):

Script for November 22, 2019 Presentation of “Golden Shovel” Award and Doctoral Degree in Regulatory B.S.

For those of you who may not know, LAC has for years been a member of a trade group in Washington, D.C. called the Aeronautical Repair Station Association. Although LAC is not a repair station, we belong because of two lawyers – Sarah MacLeod and Marshall Filler – that help the company navigate the slalom course of aviation safety regulations.

Sarah and Marshall’s firm provides discounts to association members, which makes membership financially valuable for LAC. Beyond that, Sarah uses ARSA as a platform to practice what she calls “prophylactic lawyering,” which helps keep the entire aviation industry out of trouble and has made our 19-year connection to the association a business imperative.

When ARSA found out that two of our internal regulatory experts were retiring they dashed around to provide two awards, both of which are being presented for the first time tonight and I have the honor in assisting that presentation.

The Golden Shovel Award – Jeff Pull

On ARSA’s behalf, I present Jeff Pull with the association’s first-ever “Golden Shovel” award for service to the maintenance industry.

This award has long existed only in the mind of ARSA’s Executive Director Sarah MacLeod and in discussions among and between the association’s team members. It represents the years of “shoveling” that must be done by any determined aviation professional in order to stay in business and ensure aviation safety while surviving the whims of regulators, inconsistency between the plain language of the rules and their implementation and the constant struggle to make sense of it all.

At best it feels like shoveling against an incoming tide and hoping to keep the water beneath your chin.

At worst it feels like shoveling someone else’s manure – plenty of which flows out of Independence Avenue in Washington, through regions and districts across the country and onto the desks, workbenches and repair shop floors of maintenance professionals – and finding yourself consumed by the mess.

While many have undertaken this effort, only the very best see it through for a career in continued commitment to good aviation safety and good business sense. The “Golden Shovel” could not be made real until today, with the retirement of a member of the industry whose career demonstrated the dedication worthy of its gleaming handle. It is in recognition of Jeff’s tireless shoveling on that we can bestow this award.

Jeff, wear this pin, whose true meaning will be unknown to most who see it, with pride.

The Doctoral Degree in Regulatory B.S. – Paul Willing

Paul willing receives the certificate recognizing his earning of ARSA’s “Doctorate in Regulatory B.S.”

Paul willing receives the certificate recognizing his earning of ARSA’s “Doctorate in Regulatory B.S.”

On behalf of ARSA, I confer upon Paul Willing the association’s highest degree: A doctorate in regulatory B.S.

While no academic accrediting body or government regulator has yet had the insight or courage to bestow on ARSA the authority to confer degrees, the association has taken upon itself the right to recognize and rightly honor those who have—

(1) Successfully completed the required course of study – presented every day by the university of professional life, and

(2) Accumulated the compulsory practical experience to survive the often maddening and frequently comical FAA regulatory slalom course.Though ARSA’s regulatory experts are currently all legal professionals holding their own Juris Doctor degrees, the team recognizes the need to honor Paul’s attainment of these standards with the true Ph.D.: “Piled Higher and Deeper.” As we’ve already recognized the considerable shoveling necessary to survive in this industry, a professional with the experience and mastery of Paul surely has accumulated his own considerable pile.

Given the importance of credentialing in both academic and professional interests, not to mention personal pride, we trust you will display your newest degree for all to see.

Congratulations to Jeff and Paul

The joy of recognizing Jeff and Paul’s retirement is dimmed only by the knowledge of the deep loss represented by their departure. Their life beyond work has been well earned, but ARSA’s team recognizes their precious value to the aviation industry, the maintenance community and the general public throughout their long careers. Jeff’s “Golden Shovel” and Paul’s “Ph.D.” will hopefully bring smiles to their faces for years to come, a small “thank you” on behalf of the association, it’s team and the many people who depended on their good work.

Congratulations.

Spread YOUR Word!

Regular readers of ARSA’s Dispatch newsletter will recognize the association’s weekly periodical as a concise roundup of news and updates impacting the maintenance community. The communication’s team reviews key sources every day and in order to ensure the Dispatch covers key policy updates, highlights ARSA’s work on behalf of the industry, calls association members and allies to action and appropriately celebrates the good work of maintenance providers worldwide.

You can help continue to improve the newsletter by:

(1) Ensuring that you, your colleagues and industry contacts are subscribed. Contact Kimberly Dimmick for assistance.

(2) Sending interesting news pieces and/or relevant media outlets to Brett Levanto for possible inclusion in the Dispatch (or providing commentary on pieces already included..

(3) MOST IMPORTANT: Getting ARSA’s communication’s team looped in on any press releases, events or other communications from your company that deserve wider circulation (again, start with Brett Levanto).

The aviation maintenance industry consists mostly of small-to-medium-sized businesses who depend on ARSA to ensure a consistent flow of useful information. Help in that work by getting involved in the association’s communications efforts: It is already spreading the word…help it to spread YOUR word.

Reminder 1: An Occasional Word from Our Sponsors

From time to time, ARSA provides a mechanism for sponsors of its Dispatch and hotline newsletters to reach readers directly through sponsored “blast” emails. Allowing this advertising option gives companies a chance to directly show their support of the association and provide useful information and resources to readers.

While receiving this message, ARSA subscribers and members should be assured that:

(1) The frequency of special “blast” messages is kept to a minimum. This maintains the special focus provided to advertisers sending the messages and prevents “overload” in readers’ inboxes.

(2) Advertisers are not provided direct access to newsletter subscription lists. Messages are constructed and distributed through ARSA’s partner Multiview, which oversees its periodicals.

(3) ARSA team members review and approve all messages prior to distribution.

For questions about ARSA’s advertising options, including ways to stand up for the association through your company’s support, contact Vice President of Communications Brett Levanto (brett.levanto@arsa.org).

Reminder 2: Don’t Let Technology Keep You From ARSA

hanks to spam filters, firewalls and quarantines, it can sometimes be difficult to get into your inbox – help us get through. Get access to every newsletter, update and reminder by ensure that the following domains don’t get flagged as spam:

@arsa.org (direct emails/alerts)

@potomac-law.com (messages from members of ARSA’s management team)

@multibriefs.com (periodicals/newsletters)

@sendgrid.net (automated membership reminders from ARSA’s database)

Know What to Look For

Weekly: The Dispatch newsletter is distributed every Wednesday.

Monthly: The hotline newsletter is distributed the first week of each month.

Various: Member alerts are distributed as necessary – usually the association sends two or three each month.

Membership Term Dependent: Renewal reminders begin flowing out of the system 90 days before the expiration of membership term.

Avoid Duplication

From time to time and for various reasons, members report duplicate delivery of ARSA emails. If this happens to you, contact Brett Levanto to explore the problem and try to correct it.

To learn more about ARSA’s communications efforts – including how to advertise – visit arsa.org/news-media. For assistance with technical issues, consult your organization’s IT department/assistant as necessary.

Quick Question Answered – SMS Implementation

ARSA has submitted comments to EASA’s Notice of Proposed Amendment regarding Safety Management System requirements. To continue its work on the issue, the association has collected feedback (and will take more, see below) from the industry regarding progress towards implementing SMS.

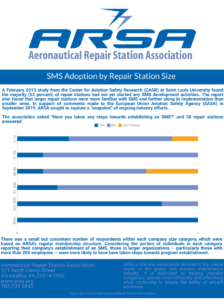

A February 2013 study from the Center for Aviation Safety Research (CASR) at Saint Louis University found the majority (52 percent) of repair stations had not yet started any SMS development activities. The report also found that larger repair stations were more familiar with SMS and further along in implementation than are smaller ones. In support of its comments to EASA, ARSA sought to capture a “snapshot” of ongoing industry efforts.

The association asked “Have you taken any steps towards establishing an SMS?” and 38 repair stations answered. :

There was a small but consistent number of respondents within each company size category, which were based on ARSA’s regular membership structure. Considering the portion of individuals in each category reporting their company’s establishment of an SMS, those in larger organizations — particularly those with more than 200 employees — were more likely to have have taken steps towards program establishment.

Add to the Data…

The original survey is still open to collect addition information regarding SMS adoption. If you did not participate in the original “quick question,” you should take a moment to provide your company’s experience:

Note: The question is displayed in its own, embedded window. If the “Submit” button is not visible on the screen, you must scroll within the survey window in order to submit your response.

If the embedded survey does not appear/load, open the survey independently by visiting: https://www.surveymonkey.com/r/sms-2019.

Click here to see what questions have been asked and answered…and keep a lookout for more.

Quick Question – Small Business Connections

ARSA is leading a coalition of industry organizations and companies to oppose the the Safe Aircraft Maintenance Standards Act (H.R. 5119). If the bill becomes law, U.S. repair stations with foreign approvals and their employees would almost certainly be targets of the retaliation by foreign authorities. U.S. commercial and general aviation operations outside the country would be disrupted because of a shortage – or complete lack of – FAA certificated maintenance facilities in destination countries. And U.S. manufacturers seeking to provide product support in growing foreign markets would be prevented from obtaining FAA certification at those overseas facilities. (See more about ARSA’s efforts at arsa.org/hr5119)

Opponents of repair stations – like those responsible for this bill – claim they “steal jobs,” when in reality contract maintenance providers employ 188,000 Americans and generate $25 billion in annual economic activity in the United States. To be able to expand that statement of impact to business partners and service providers would be very effective.

Help ARSA’s legislative team consider this impact by answering this month’s “quick question”:

Due to the layout of one question, this month’s questionnaire is best viewed in its own window. To complete it, visit: https://www.surveymonkey.com/r/qq-smallbiz.

Click here to see what questions have been asked and answered…and keep a lookout for more.

Welcome & Welcome Back – New & Renewing Members

ARSA’s members give the association life – its work on behalf of the maintenance community depends on the commitment of these organizations. Here’s to the companies that joined or renewed in November:

New Members (Member Category)

Airborne Maintenance & Engineering Services dba PEMCO World Air Services, R05

Bridger Aviation Repair, LLC, R01

FlyBoyz Aviation, LLC, R01

Mel Marengo, Edu

SDMAvionics, R01

Renewing Members (Member Category, Member Since)

Aerospace Turbine Rotables, Inc., R04, 2011

Airforce Turbine Service, Ltd., R03, 2010

Aviation Blade Services Inc., R02, 2018

Columbia Helicopters, Inc., R05, 1998

First Aviation Services, Inc., Assoc, 2014

Fieldtech Avionics & Instruments, Inc., R03, 2016

Gyros Unlimited dba North Bay Aviation, R03, 2011

HAECO Americas, Corp, 2000

Ikhana Aircraft Services, R04, 2003

Intrepid Aerospace, Inc., R02, 2016

Kellstrom Repair Services, Inc., R03, 2016

MT Texas, LLC, R03, 1990

New Image Aero Interiors-dba NIA Interiors, R01, 2017

Palm Beach Aircraft Propeller, Inc., R02, 2001

Rapco Fleet Support, Inc., R01, 2008

REB Technologies Inc., dba REBTECH, R02, 2003

Repairtech International, Inc., R03, 1992

Rotron, Inc., dba Ametek Rotron, R02, 2016

Safran Nacelles Services Americas, R02, 2017

Tennessee Aircraft Company, Inc., R01, 2012

Turbines, Inc., R02, 2017

Yuba-Sutter Aviation, R01, 2018

A Member Asked…

Q: In reading ARSA’s comments on the latest changes to the MAG and their impacts on the current revision of the association’s Model RSQM EASA Supplement, Human Factors (HF) recurrent training is described as an annual requirement, with a reference to MAG Section B, Appendix 1, Paragraph 17j.

I did not find an annual requirement mentioned in that paragraph; I also looked in other areas of the MAG and could not find a requirement for annual HF training. Please direct me to the EASA reference where the annual requirement is called out. I appreciate your continued vigilance on our behalf.

A: Thank you for the very careful reading. You are correct the MAG does not specify any time period for recurrent human factors training. For comparison, references to recurrent training in Section A of the MAG (for FAA ASIs) and also the guidance material for EASA Part 145 describe two-year cycles for recurrent training.

The language in ARSA’s supplement does describe annual training for human factors and the association encourages companies to keep that schedule since it ensures continued compliance. The addition in MAG Change 7 of the “lessons learned” requirement for recurrent HF training further underscores the usefulness of annual training so that the “lesson gathering” can be encapsulated within the calendar year and then acted on via the training program. Further, it allows for more frequent but shorter “sessions” – for example, you could hold fifteen-minute course every week or two, which can be much less disruptive to a production schedule than longer sessions – which helps to keep humans aware of their humanity.

The use of “annual” in the summary document without proper context made it read as if it was a MAG requirement. The language in the summary document has been updated.

We’ve also gotten a number of questions regarding the release of Revision 4 of ARSA’s Model RSQM EASA Supplement. The team is working on the updates and it will be available as soon as possible, but users of the current revision should take advantage of the summary document to see what, if any, changes to their supplement may be required.

For updates on the MAG, review the other content in this edition of the hotline and stay tuned to arsa.org/mag.

Member questions should be submitted through the inquiry system run through ARSA’s new online member portal. Members can use their portal access to submit inquiries by logging in through arsa.member365.com/sharingnetwork.

Make ARSA’s Voice Your Own: Advertise

ARSA has a menu of advertising opportunities for arsa.org, the hotline and the ARSA Dispatch. Take advantage of these great opportunities today to showcase your company, a new product or event. For more information go to arsa.org/advertise.

Stand Up for ARSA by Sponsoring

In order to provide world-class resources for its members, the association depends on the commitment of the aviation community. By sponsoring events and activities, supporters can help ARSA’s work on behalf of repair stations to endure.

Need a place to start? For information about opportunities, contact Vice President of Operations Brett Levanto (brett.levanto@arsa.org).

Resources

ARSA strives to provide resources to educate the general public about the work of the association’s member organizations; should you need to provide a quick reference or introductory overview to the global MRO industry, please utilize AVMRO.ARSA.org.

The U.S.-EU MAG

Keep up to date on ARSA’s analysis and resources related to the Maintenance Annex Guidance issued under the bilateral agreement between the United States and the European Union.

H.R. 5119 – Contract Maintenance Under Attack

Help combat a bill introduced in the U.S. Congress that would disrupt the global aviation industry.

Careers In Aviation Maintenance

Every year, more people are flying. The expansion of the global middle class and improvements in technology have opened aviation markets – for passengers and cargo – to a broader public than ever before. As the flying world gets larger, more men and women are desperately needed to keep it safely in flight.

Quick Question Portal

See what ARSA has asked and what’s been answered and participate in the conversation about what’s going on in the aviation maintenance world.

Industry News Roundup

ARSA monitors media coverage on aviation maintenance to spread the word about the valuable role repair stations play globally by providing jobs and economic opportunities and in civic engagement. These are some of this month’s top stories highlighting the industry’s contributions. You can explore these stories through ARSA’s Dispatch news portal.

Industry Calendar

| Conference | Dates | Location |

| MRO Latin America | 1/22-23/2020 | Cartagena, Columbia |

| Heli-Expo | 1/27-30/2020 | Anaheim, CA |

| MRO Middle East Summit & Expo | 2/24-26/2020 | Dubai, UAE |

| ARSA Annual Conference | 3/10-13/2020 | Washington, DC |

| MRO Australasia | 3/10-12/2020 | Brisbane, Australia |

| AEA International Convention and Trade Show | 3/24-27/2020 | Nashville, TN |

| ATEC Annual Conference | 3/29-4/1/2020 | Fort Worth, TX |

| MRO Americas | 4/28-30/2020 | Dallas, TX |

| Farnborough Air Show | 7/20-24/2020 | Farnborough, UK |

| Business Aviation Convention & Exhibition (NBAA-BACE) | 10/6-8/2020 | Orlando, FL |

the hotline is the monthly publication of the Aeronautical Repair Station Association (ARSA), the not-for-profit international trade association for certificated repair stations. It is for the exclusive use of ARSA members and federal employees on the ARSA mailing list. For a membership application, please call 703.739.9543 or visit arsa.org/membership/join. For information about previous editions, submit a request through arsa.org/contact. This material is provided for educational and informational purposes only. It does not constitute legal, consulting, tax or any other type of professional advice. Law, regulations, guidance and government policies change frequently. While ARSA updates this material, we do not guarantee its accuracy. In addition, the application of this material to a particular situation is always dependent on the facts and circumstances involved. The use of this material is therefore at your own risk. All content in the hotline, except where indicated otherwise, is the property of ARSA. This content may not be reproduced, distributed or displayed, nor may derivatives or presentations be created from it in whole or in part, in any manner without the prior written consent of ARSA. ARSA grants its members a non-exclusive license to reproduce the content of the hotline. Employees of member organizations are the only parties authorized to receive a duplicate of the hotline. ARSA reserves all remaining rights and will use any means necessary to protect its intellectual property.

© 2019 Aeronautical Repair Station Association