2019 – Edition 8 – September 6

Table of Contents

Note: The order of material varies in hotline emails, but is always presented the same on this landing page. Readers scrolling through content on or printing this page will find it organized consistent with the table of contents.

Sarah Says

ARSA Works

Legal Brief

ARSA on the Hill

Regulatory Update

Getting Facetime

Training

Membership

Resources

Industry Calendar

Sarah Says

Keeping it Real

By Sarah MacLeod, Executive Director

Unmanned Aircraft Systems (UAS) are hot and getting hotter. Tech savvy businesses are using so-called “drones” to support common and novel aviation services, including airborne inspection, cargo/package delivery, surveillance and even archeological site surveys. In January 2018, the Department of Transportation announced it had registered more than 1 million UAS, with about 12 percent belonging to commercial or public interests. New technology is the backbone of aviation and taking advantage of it for business purposes is exciting.

Amid all that entrepreneurship, ARSA has a simple reminder for UAS operators: Keep it real…as in, your unmanned vehicle is a “real” aircraft and its airworthiness is the key to flight.

ARSA found an example of a company that knows how to keep it real—UPS Flight Forward. The newly incorporated subsidiary of the well-established shipping company is seeking exemption from parts 91 and 135 in support of its application for a part 135 air carrier certification to transport blood and medical samples among and between facilities. The company’s aircraft would replace “…the inefficient and time-consuming ground courier services used currently with a much more efficient and timely unmanned aircraft service.” From the association’s perspective, Flight Forward’s petition for exemption is noteworthy not because of the new technology’s efficiency or life-saving impact, but because the petitioner is fully committed to aviation safety and the aviation system. It did not request exemptions from the proper maintenance of its aircraft.

After reading the petition, I sent a note to UPS Flight Forward’s president, expressing gratitude that an “aviation” oriented company can set the stage for others interested in similar operations. It was pleasing to see a full evaluation for the continued airworthiness of the “aircraft.”

In late 2017, ARSA used its monthly “quick question” to poll industry interest in drone maintenance. Of the handful of responses, a majority were working on UAS or were seeking opportunities to do so. As these vehicles enter our airspace – and begin to cross into others – they fall under the same kind of risk analysis performed on everything that takes off. The reality is that you cannot fly without maintenance performed by certificated professionals.

To read the full UPS Freight Forward petition, click here.

ARSA Works

Act Now

Association members, allies and industry colleagues must support ARSA’s current initiatives to improve aviation policy. Here’s your to-do list for September 2019 (click each page link for more information and instructions):

Help the small-business dominated maintenance industry cope with regulatory unfairness…

SBA to Host Regulatory Fairness Hearing

On Aug. 19, the U.S. Small Business Administration’s National Ombudsman, Stefanie Wehagen, will host small business owners, economic development specialists, trade group representatives and community leaders for a hearing on fairness in regulatory enforcement.

Help build the aviation workforce of the future by getting face-to-face with the people who are the future…

Homework Assignment – Teach at a Local School

ARSA members should be accustomed to the association’s general encouragement to get involved in the community. For the sake of good corporate citizenship and long-term workforce development, there are plenty of reasons for aviation businesses to become familiar with the people and organizations around them. For the willing, here’s a specific challenge…with some FAA resources to help.

Take part in the FAA’s review of engine-related accidents and incidents…

Take Part in the FAA’s Engine Safety Review

On Oct. 24, the FAA will host a one-day Engine & Airframe-Engine Integration Safety Summit. Industry participation is encouraged.

MacLeod to Represent Maintenance Community on SOCAC

On Aug. 22, the Department of Transportation announced the appointment of 22 members to the DOT’s new Safety Oversight and Certification Advisory Committee (SOCAC). ARSA Executive Director Sarah MacLeod was selected to represent the interests of maintenance providers.

The SOCAC was created by the Sec. 202 of the FAA Reauthorization Act of 2018 to provide advice to regarding aviation safety oversight and certification programs. As described in both the law and also the committee’s charter, the activities within its scope include:

(1) Aircraft and flight standards certification processes, including efforts to streamline those processes.

(2) Implementation and oversight of safety management systems.

(3) Risk-based oversight efforts.

(4) Utilization of delegation and designation authorities, including organization designation authorization.

(5) Regulatory interpretation standardization efforts.

(6) Training programs.

(7) Expediting the rulemaking process and giving priority to rules related to safety.

(8) Enhancing global competitiveness of United States manufactured and United States certificated aerospace and aviation products and services throughout the world.

In MacLeod’s nomination letter, which is dated before but was received after the public announcement by DOT, Transportation Secretary Elaine Chao explained MacLeod’s selection: “Your work representing the views of the Aviation Maintenance, Repair and Overhaul service providers will greatly benefit SOCAC and the Department’s efforts to improve FAA’s certification processes and oversight activities. Your experience and leadership will add valuable insights and perspectives that will help further SOCAC’s mission.”

To read the committee’s charter, click here.

“100-percent Replacement” Makes 1-percent Progress

On Aug. 9, the FAA ended ARSA’s two-year wait for a response to its request to the Regulatory Consistency Communications Board (RCCB) for clarity regarding the right of repair stations to replace 100 percent of an article while performing maintenance. For the most part, this “interim response” merely restated and “acknowledged” the association’s description of the issue.

“FAA regulations do not specify the amount of parts that may be replaced on an article during a single maintenance visit,” the RCCB said in its response, echoing the argument made in ARSA’s initial submission. “Accordingly, the FAA will actively explore developing guidance and whether a legal interpretation is appropriate.”

The status update, which did not claim to be the final word on the issue from the RCCB, did little to enhance consistency in regulatory communications but at least confirmed the FAA’s alignment with industry on the base issue.

To read the complete interim response, click here.

To read the association’s 2017 submission, click here.

For more insight into the “interim response” and what it means within ARSA’s ongoing effort to sensibly manage regulatory compliance, read this month’s Legal Brief.

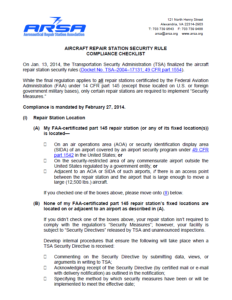

Repair Station Security Resources

ARSA’s Repair Station Security Fact Sheet is a resource for the media, policymakers and the general public to understand the rules applicable to FAA-certificated maintenance facilities.

The fact sheet should be utilized by the maintenance community and other interested stakeholders alongside the association’s other security related resources:

Repair Station Security Resources |

|

| Fact Sheet | Compliance Checklist |

|

|

| Online Training | |

|

|

To review past coverage of ARSA’s engagement with the TSA on security issues, visit arsa.org/security.

Legal Brief

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

Non Possumus Tecum Dissention

By Sarah MacLeod, Executive Director & Brett Levanto, Vice President of Operations

In legal analysis, it’s nice to have some Latin to throw around. It makes any argument seem grounded in classical thought. “Nulla poena sine lege” (here’s how you pronounce it) is a common law principle that means “no penalty without a law.” Its application in the United States is varied and focused on statutory enforcement rather than regulatory compliance, but as a practical matter it means that you can be found in violation of something unless the act you’ve performed is expressly prohibited.

For those seeking to comply with the aviation safety rules, the general concept is important. The language of 14 CFR (in addition to other relevant titles) prescribes the minimum standards for compliance and proscribes improper conduct. While agencies like the FAA produce guidance and instructive material meant to support industry adherence to the regulations, the plain language of the rules controls.

So, if the rules don’t expressly forbid, limit or otherwise impact a practice or action, then it can be performed. It’s a fundamental concept and one very important to ARSA’s advocacy for the industry when dealing with the government. It’s apparently not a simple one, though, as illustrated by an Aug. 9 “interim response” from the FAA’s Regulatory Consistency Communications Board that has been two years in the making.

In June 2017, ARSA submitted a request to the RCCB seeking clarity regarding the right of repair stations to replace 100 percent of an article while performing maintenance. Previous agency attempts to determine when a particular action is manufacturing, thus requiring a production approval, were not supported by a plain reading of the rules. “The regulations do not directly or indirectly prohibit the replacement of all parts in an article during a single maintenance visit,” the association’s submission said. “There are no limits on the number of parts that can or should be replaced during a maintenance action.”

The RCCB, which “purports to provide an avenue for internal and external stakeholders to raise issues of policy or regulatory inconsistency,” seemed the perfect forum to obtain the kind of clarity needed by ARSA and its industry members. Within two weeks, the board responded it had “carefully evaluated [the] issue” and accepted it for resolution; it was government engagement at work for the betterment of all.

Unfortunately, this initial “evaluation” was the last word on the matter for 759 days. The FAA has finally broken its silence, but unfortunately hasn’t progressed in its thinking. “FAA regulations do not specify the amount of parts that may be replaced on an article during a single maintenance visit,” the RCCB said in its response, echoing the argument made in ARSA’s initial submission. It seems like there’s violent agreement between ARSA’s positions and the agency’s as described by the RCCB. That agreement centers around the silence of the regulations with regards to the amount – whether in number or portion of the whole – of parts that may be replaced on an article.

So…that which is not expressly prohibited is allowed. The rules stipulate no limit for part replacement during maintenance so a repair station could, working under its certificate and according to the standards of part 43, replace 100 percent of an article while performing maintenance and not have manufactured the repaired item. Right?

Unfortunately, not. The RCCB failed to assert this point and instead continued: “Accordingly, the FAA will actively explore developing guidance and whether a legal interpretation is appropriate. [Flight Standards] intends to propose guidance recommending a process that repair facilities and maintenance personnel should follow when performing tasks that may result in 100 percent replacement of parts of an article in a single maintenance visit.”

Looking beyond the question of how to assess when a task “may result in 100 percent replacement of parts” (couldn’t that be any/all work, since replacement needs would be determined by inspection?), the RCCB has taken a wrong turn. While the agency could reasonably update its guidance to provide clarity and offer a “means, but not the only means” of compliance, such changes won’t alter the meaning of the plain language of the rules. The RCCB’s response also notes that such guidance “would likely address and be in accord with the requirements of § 43.13.” Though the performance rule is essential to maintenance activities, the real issue is with the § 43.9 recordkeeping requirements applied to an action the agency can’t seem to acknowledge as maintenance.

Overall, the continued saga of ARSA’s engagement with the RCCB regarding 100 percent replacement has begun to fit a familiar pattern. The association’s arguments, based on the rules, have been acknowledged and not refuted but the FAA fails to reach the reasonable result of that acknowledgement. Whether because of personality or tradition, the government can only go so far as admitting it “can’t disagree” but falls short of “agreement” and action.

So, perhaps the agency can add some Latin to its rhetoric: “Non possumus tecum dissention.” This might add some interest to the exchange for the aviation lawyer who happens to be ARSA’s executive director. It certainly is more intellectually stimulating than the English equivalent: “We can’t disagree with you.”

ARSA on the Hill

Earp Aviation’s Arnett Sets the Pace for Industry Engagement

By Christian A. Klein, Executive Vice President

There’s an old saying: Give a man a fish and you feed him for a day; teach a man to fish and you feed him for a lifetime. That philosophy is at the core of ARSA’s advocacy work.

Yes, we’re zealous champions for repair stations with regulators, the media and elected officials, but we also spend a lot of time teaching members how to be better advocates for themselves. Recent examples include toolkits to help seek exemptions from FAA’s “current” data requirements under 145.109(d), file a complaint with the Small Business Administration about the FAA’s inconsistent enforcement of maintenance manual rules and contact Congress to get funding for the new aviation workforce grant program.

Encouraging engagement by ARSA members serves dual purposes. It makes you more effective advocates for your own needs while also expanding ARSA’s reach and impact. While it may sometimes be hard to remember given all the things ARSA does, we’re a small organization with a tiny (but extremely talented!) staff. Your engagement helps us punch above our weight class and demonstrate broad industry support for the association’s priorities.

While we’re sometimes disappointed when members fail to pick up the ball, it’s extremely heartening when they do. A case in point is Bob Arnett.

|

Tell Congress to Make Aviation Workforce a Priority ARSA’s signature legislative victory in 2018 was convincing Congress to create a new grant program help repair stations recruit and train aviation maintenance technicians. Our priority now is getting the program funded … and we need your help. ARSA has completely revamped our grant program action center to help you learn more about the issue and urge your members of Congress to appropriate the money we need. It’s quick and easy. Take a second now the tell your elected represents to make aviation workforce a priority! |

Bob’s been a fixture at ARSA events like our Annual Conference and executive summits for decades. He’s also always ahead of the game when it comes to organizing meetings on Capitol Hill during ARSA’s annual Legislative Day. In his capacity as vice president of quality at Barfield, Inc. in Miami and as a member of our government affairs committee, he helped coordinate numerous ARSA meetings with local industry leaders and congressional offices.

Bob recently moved from Miami to the Phoenix area to start a new repair station called Earp Aviation Repairs LLC. Lest there be any doubt about Bob’s commitment to engagement, one of the first things he did in his new role was invite his local congressman, senators, their staffs and other local officials to Earp’s grand opening.

Bob recently moved from Miami to the Phoenix area to start a new repair station called Earp Aviation Repairs LLC. Lest there be any doubt about Bob’s commitment to engagement, one of the first things he did in his new role was invite his local congressman, senators, their staffs and other local officials to Earp’s grand opening.

That outreach and engagement doesn’t just help elected officials better understand how Bob’s company contributes to the local economy, it also helps raise the visibility of our entire industry with lawmakers by putting a local face on it. That, in turn, will make them more receptive and responsive when ARSA reaches out to talk about workforce, regulatory and other issues that impact its members. And it’s a good bet that when Bob calls those offices with a problem, he’ll get a quick response.

The maintenance industry is in a period of considerable political risk. The MAX 8 investigations are still underway and may lead to legislation that affects the whole industry. Hostility to free trade threatens the progress we’ve made to reduce regulatory burdens for approved maintenance organizations operating internationally. The new chairman of the House Transportation & Infrastructure Committee is a long-time contract maintenance skeptic. Repair station opponents on the Hill and their union allies have made noise about introducing hostile legislation. At the same time, there are opportunities, including securing full funding for the aviation technician grant program ARSA helped create as part of last year’s FAA bill.

With elections looming on the horizon, members of Congress and candidates are anxious to get to know businesses and their employees “back home”. Whether you’re an experienced political angler or want to learn how to fish, ARSA is the bridge over America’s troubled political waters that can help you connect.

Shoot me an email at christian.klein@arsa.org and let’s set up a congressional visit to your facility this fall.

|

Want to Learn More About ARSA PAC? ARSA’s Political Action Committee helps elect congressional candidates who share ARSA’s commitment to better regulation and a strong aviation maintenance sector. In this critical election year, ARSA PAC has never been more important. But ARSA is prohibited from sending PAC information to members who haven’t opted in to receive it. Please take a second to give us prior approval to talk to you about ARSA PAC. Doing so in no way obligates you to support PAC. It just opens the lines of communication. Click here to give ARSA your consent today. |

House Bill Would Address Contract Maintenance Transparency

On Aug. 8, Rep. Mark DeSaulnier (D-Calif.) introduced legislation that will potentially impact ARSA members and their airline customers. Generally, the Safe Landings Act (H.R. 4166) addresses the Air Canada near miss at SFO in 2017 (DeSaulnier’s district is in the San Francisco area), but it also includes other aviation safety-related measures.

Of particular interest, Sec. 5 would create a task force to examine human factors in aviation safety and Sec. 6 directs a new program to investigate and develop new approaches to aviation safety-related data analysis. Sec. 11 requires the DOT IG to review the FAA’s 2017 Flight Standards reorganization and its aviation safety inspection program and to specifically evaluate, among other things, the reorganization of Flight Standards, the implementation of FAA’s compliance philosophy (now a “program”) and the Safety Assurance System (SAS).

Sec. 10 is maintenance-related and is billed as an effort to improve transparency in maintenance contracting. It would require the FAA to update the Continuing Analysis and Surveillance System (CASS) implementation guidelines for part 121 certificate holders to include reporting at least every six months “of any failure to follow procedures in aircraft maintenance as well as any major alteration, complete overhaul, or repair of mechanical irregularities of each airframe, engine, propeller, and appliance.”

For each report, certificate holders would also be required to identify the name of the facility and physical location where the work was carried out “for each maintenance provider that performs work.” The FAA would be required to share the reports with the NTSB and would also be required to notify NTSB of any unscheduled landing at a U.S. airport by a part 121 certificate holder “in which a mechanical issue was a factor.” NTSB and FAA would be required to analyze the data “for the purpose of identifying any trends or emerging concerns with any individual air carriers” and share that information with Congress at least annually.

DeSaulnier, the bill’s sponsor, is a third term Democrat who sits on the House Transportation & Infrastructure Committee (but not the aviation subcommittee). He has a strong background in transportation, having served as the chair of the transportation committees in both the California General Assembly and Senate. He has union ties as a former Teamsters member.

The outlook for his bill is uncertain. Given the press of other business, the fact that DeSaulnier is not a member of the aviation subcommittee nor a member of the Science Committee (to which the bill was also referred), it is unlikely to move through the legislative process on its own anytime soon. Also, at this point it doesn’t appear to have support from any other member of Congress (no cosponsors are noted in the press release). However, transportation policy leaders on Capitol Hill are likely to consider legislative solutions to any problems uncovered by the various Boeing MAX accident investigations. DeSaulnier’s proposal could be rolled into a bigger aviation bill if the Congress decides to take legislative action later this year or next. His bill also has some high-profile support: Sully Sullenberger endorsed it and is quoted in the press release announcing its introduction. The bill is also supported by the Coalition of Airline Pilots Associations.

As a general proposition, the association opposes legislation that imposes additional burdens on industry or diverts government resources without any corresponding safety benefit; however, at least some parts of DeSaulnier’s bill do seem to address actual safety concerns, so ARSA is withholding judgment pending further analysis and coordination with allied organizations.

Feel free to share your thoughts on the bill (or experience with Rep. DeSaulnier) by sending a message to ARSA Executive Vice President Christian A. Klein at christian.klein@arsa.org.

To review the bill, click here.

Regulatory Update

Dickson Sworn in as New FAA Administrator

Former Delta Senior Vice President of Flight Operations Stephen Dickson was sworn in as administrator of the FAA by U.S. Transportation Secretary Elaine Chao on Aug. 12.

Steve Dickson, former senior vice president of flight operations for Delta Air Lines, was sworn in as the FAA administrator by Transportation Secretary Elaine L. Chao on Aug. 12.

Dickson is a former U.S. Air Force officer and F-15 fighter pilot, a 1979 Airforce Academy Graduate and a graduate of the Georgia State University College of Law.

In his role at Delta, Dickson was responsible for the safety and operational performance of Delta’s global flight operations, as well as pilot training, crew resources, crew scheduling and regulatory compliance. He also flew in line operations as an A320 captain and previously flew the Boeing 727, 737, 757 and 767 during his career.

In his remarks at the swearing in ceremony at DOT headquarters, Dickson thanked President Trump for the nomination, Secretary Chao for her support during the nomination process and Dan Elwell (who was briefly a classmate of Dickson’s at the Air Force Academy and has served as acting administrator since last January; he will continue to serve as deputy administrator) for his “strong, principled leadership during a very challenging time in the agency’s history.”

“The U.S. aviation system is the safest, most dynamic and innovative in the world, largely due to the collaborative approach to safety championed by the FAA and shared by various segments of the industry,” Dickson said during ceremony. “While we have earned [the public’s] trust through our robust approach to safety, the job is not done. In fact, it is never done. We all have to work together to retain – and in places, restore – that trust.”

“The public, and all those who work in American aviation, should know that FAA will continue to lead as a values-driven organization,” Dickson said. “Our highest and most important value is safety – this cannot be compromised. A lesson I learned in my service to our country in the Air Force, and will bring to my leadership of the FAA, is that safety is a journey and not a destination. It’s a journey that we must embark upon with renewed vigor each and every day.”

In reference to the biggest issue on Dickson’s plate as he assumes the reins at FAA – the grounding of the Boeing MAX aircraft – he said that, “this plane will not fly in commercial service until I am completely assured that it is safe to do so. FAA is following no timeline in returning the aircraft to service. Rather, we are going where the facts lead us and diligently ensuring that all technology and training is present and correct before the plane returns to passenger service.”

Dickson said that the foundation of any safety program is a just culture that “places an extremely high value on front-line employee reporting.” With that in mind, he stated his commitment to collaboration between operators, regulators and labor and said he would do everything is his power to “walk the walk” on employee safety reporting programs and “ensure this same philosophy permeates all sectors of the aviation system.”

He also committed the agency to “continuous improvement” and maintaining the highest levels of safety while adapting to technological advancements will be a key part of the FAA’s success. “What we did yesterday will simply not be good enough tomorrow,” Dickson said.

For its part, ARSA is urging the new administrator to focus in several key areas:

(1) Support and enhance efforts to grow the aviation workforce, stand up the grant program established by the 2018 FAA reauthorization law, support industry efforts to reconsider every “pathway” through which maintenance professionals progress and modernize the standards by which the agency oversees maintenance training and measures competency.

(2) Maintain the collaboration among between regulators and the regulated community to identify, assess and mitigate risk.

(3) Commit to regulatory consistency.

(4) Stand up to political and media pressure and focus on initiatives that achieve the highest possible level of safety, based on risk, while minimizing additional burdens on industry.

ARSA looks forward to working with Administrator Dickson to move the maintenance industry’s agenda forward.

Final Documents/Your Two Cents

This list includes Federal Register publications, such as final rules, Advisory Circulars and policy statements, as well as proposed rules and policies of interest to ARSA members.

Getting Facetime

Going Back for More “Big Data”

The coffees are as small as the data is big…That’s going to be my ice breaking joke at @FlightGlobal‘s Aerospace Big Data Miami… https://t.co/XAPiSQ8w46

— Brett Levanto (@LevantoAir) August 21, 2019

On Sept. 11-12, ARSA Vice President of Operations Brett Levanto will return to Miami for FlightGlobal’s Aerospace Big Data Conference.

Levanto will join an industry panel on “bridging data science and maintenance.” The moderated discussion will cover advanced skills development, workforce demands and personnel training related to developing technologies.

To learn more about the event and plan your own participation, visit www.flightglobalconferences.com/ehome/bigdataseries/miami19. In addition to ARSA, the following organizations are currently represented on the planned agenda:

Austrian Airlines

Cirium

Embry-Riddle Aeronautical University

Ford Motor Company

Frost & Sullivan

Gol Linhas Aéreas Inteligentes

IATA

JetBlue Technology Ventures

Ohio University

Oliver Wyman

Qatar Airways

Ryanair

Southwest Airlines

TAP Air Portugal

WestJet Encore

Training

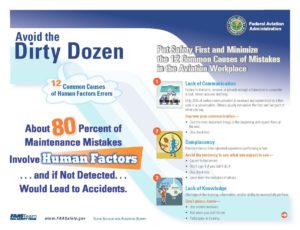

Ongoing Human Factors Series – The Dirty Dozen in Depth

ARSA is growing its library of human factors-related training sessions. In addition to the those already available on demand, the association is working through a new series of live sessions: Each 60-minute course will walk through a key factor contributing to human error in aviation as participants explore “the Dirty Dozen in Depth.”

The series is presented by ARSA Executive Director Sarah MacLeod, Executive Vice President Christian A. Klein and Vice President of Operations Brett Levanto and will run through Oct. 29. After each live session is complete, a recorded version will be available for on-demand viewing. For more information about ARSA’s online training program, click here.

For each element of “the Dirty Dozen,” the series provides:

(1) Basic definitions and context.

(2) Aviation safety regulatory references.

(3) Examples.

(4) Mitigations.

(5) Exercises.

All of ARSA’s human factors training sessions have been accepted by the FAA for Inspection Authorization renewal credit under § 65.93(a)(4).

Already On Demand – Human Factors Training Series

Each on-demand session is available for immediate viewing; registration provides all session materials as well as access to the recording for 90 days.

Session Title |

Registration/Information |

|

| Human Factors in Context | Click here. | |

| The Dirty Dozen – Human Factors Overview | Click here. | |

| The Dirty Dozen in Depth – Communication | Click here. | |

| The Dirty Dozen in Depth – Complacency | Click here. | |

| The Dirty Dozen in Depth – Lack of Knowledge | On-demand coming soon. | |

| The Dirty Dozen in Depth – Distraction | On-demand coming soon. |

Remaining Live Sessions – The Dirty Dozen in Depth

Session Topic |

Date |

Time |

Registration/Information |

|||

| Lack of Teamwork | Tuesday, Sept. 17 | 11:00 a.m.-12:00 p.m. EDT | Click here. | |||

| Fatigue | Tuesday, Sept. 24 | 11:00 a.m.-12:00 p.m. EDT | Click here. | |||

| Lack of Resources | Thursday, Sept. 26 | 11:00 a.m.-12:00 p.m. EDT | Click here. | |||

| Pressure | Tuesday, Oct. 1 | 11:00 a.m.-12:00 p.m. EDT | Click here. | |||

| Lack of Assertiveness | Tuesday, Oct. 8 | 11:00 a.m.-12:00 p.m. EDT | Click here. | |||

| Stress | Thursday, Oct. 10 | 11:00 a.m.-12:00 p.m. EDT | Click here. | |||

| Lack of Awareness | Tuesday, Oct. 22 | 11:00 a.m.-12:00 p.m. EDT | Click here. | |||

| Norms | Tuesday, Oct. 29 | 11:00 a.m.-12:00 p.m. EDT | Click here. |

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording made available after the live session is complete.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Security Rule Training

This session covers the requirements set forth in the Transportation Security Administration’s repair station security rule. Learn from ARSA, which represents the maintenance community on TSA’s Aviation Security Advisory Committee, how to stay compliant with mandatory security responsibilities.

TSA’s Repair Station Security Rule – Effectively Complying with the Regulation

On-Demand – Available Anytime

Click here to register and get access for 90 days.

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording made available after the live session is complete.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

From the FAA – The Dirty Dozen

Participants in ARSA’s ongoing human factors training series “The Dirty Dozen in Depth” have gotten to know it well: The FAA’s Dirty Dozen Poster. Access your copy today via the FAA Safety Team’s “Maintenance Hangar,” share it with colleagues, print out some copies and post them around your facility (and your home…because human errors occur everywhere):

Regulatory Compliance Training

Test your knowledge of 14 CFR § 65.107(c)-(d) – Repairman certificate (Light-sport aircraft): Eligibility, privileges, and limits.

Click here to download the training sheet.

Membership

Just the Right Number of ARSA Emails

Thanks to spam filters, firewalls and quarantines, it can sometimes be difficult to get into your inbox – help us get through. Get access to every newsletter, update and reminder by ensure that the following domains don’t get flagged as spam:

@arsa.org (direct emails/alerts)

@potomac-law.com (messages from members of ARSA’s management team)

@multibriefs.com (periodicals/newsletters)

@sendgrid.net (automated membership reminders from ARSA’s database)

Know What to Look For

Weekly: The Dispatch newsletter is distributed every Wednesday.

Monthly: The hotline newsletter is distributed the first week of each month.

Various: Member alerts are distributed as necessary – usually the association sends two or three each month.

Membership Term Dependent: Renewal reminders begin flowing out of the system 90 days before the expiration of membership term.

Avoid Duplication

From time to time and for various reasons, members report duplicate delivery of ARSA emails. If this happens to you, contact Brett Levanto to explore the problem and try to correct it.

To learn more about ARSA’s communications efforts – including how to advertise – visit arsa.org/news-media. For assistance with technical issues, consult your organization’s IT department/assistant as necessary.

Welcome & Welcome Back – New & Renewing Members

ARSA’s members give the association life – its work on behalf of the maintenance community depends on the commitment of these organizations. Here’s to the companies that joined or renewed in August:

New Members (Member Category)

Axis Aerotech, Inc., R01

CVG Aerospace, LLC, R01

DART Aerospace, R02

Rotorcraft Inc., R01

Renewing Members (Member Category, Member Since)

Aero Instruments & Avionics, Inc., R04, 1991

Aero-Marine Technologies, Inc., R01, 2001

Aerotron AirPower, Inc. dba Fokker Aerotron, R04, 1990

Air Cargo Equipment, Inc., R01, 2010

Aircraft Systems Division of Com-Jet Corp, R03, 2011

Airframe Components by Williams, Inc., R02, 2003

Ameron Global Product Support, R02, 2004

Aviation Repair Solutions, Inc., R02, 2006

Berkley International, In, R01, 2007

Camtronics, LLC, R03, 2012

Flight Deck Specialists, Inc., R01, 2002

General MRO Aerospace, R03, 2015

The Boeing Company, Corp, 1996

C J Aviation, Inc., R01, 2017

Dan Brauhn-Indian Hills Community College, Edu, 2015

HEICO Aerospace Corporation, Corp, 1992

Marvel-Schebler Aircraft Carburetors, LLC, R02, 2011

National Flight Services, Inc., R03, 2018

Regional Avionics Repair, LLC, R02, 2006

Signature Engines, Inc., R01, 2003

Sunshine Aero Industries, Inc., R01, 2003

United Technologies Corporation, Corp, 1997

Quick Question – SMS Implementation

As ARSA finalizes its comments to EASA’s Notice of Proposed Amendment (NPA) 2019-05, “Embodiment of Safety Management System (SMS) Requirements into Part 145 and 21,” the association would like feedback from the industry regarding progress towards implementing SMS.

A February 2013 study from the Center for Aviation Safety Research (CASR) at Saint Louis University found the majority (52 percent) of repair stations had not yet started any SMS development activities. The report also found that larger repair stations were more familiar with SMS and further along in implementation than are smaller ones. ARSA has been collecting anecdotal information over the past several years related to member SMS implementation, but would like to capture a broader “snapshot” of industry efforts and perspectives.

So, whether you’ve taken any steps towards establishing SMS or not, invest a minute in this month’s “quick question.”

Note: The question is displayed in its own, embedded window. If the “Submit” button is not visible on the screen, you must scroll within the survey window in order to submit your response.

If the embedded survey does not appear/load, open the survey independently by visiting: https://www.surveymonkey.com/r/sms-2019.

Click here to see what questions have been asked and answered…and keep a lookout for more.

A Member Asked…

This month’s column is dedicated to two queries the association received regarding recent design and production approval holder activities regarding (1) protection of “intellectual property” and (2) charging money for access to customer-specific information. Since both involve maintenance manuals or instructions for continued airworthiness, the answers are not easy or straight-forward.

The first involved a letter from a manufacturer questioning the repair station’s ability to perform work on certain articles, since the maintenance manuals were proprietary and the manufacturer had never provided the repair station permission or access to that information. The letter demanded the repair station cease and desist use or further bad things would happen.

The second involved a type and production certificate holder that is demanding more money for access to customer-specific information regarding maintenance of aircraft.

If a repair station is using data that (1) the FAA considers instructions for continued airworthiness (ICA) and (2) was obtained from or specifically for its airline or owner/operator customer to maintain that customer’s articles, the FAA is clear that design and production approval holders cannot restrict access.

The association has not delved into the specifics of the member scenarios as contracts and business arrangements are legal matters; ARSA is devoted to informing its members about regulatory compliance. Therefore, the particulars of each company’s situation must be reviewed by competent legal counsel to determine the contractual obligations between the air carrier or owner/operator and its chosen repair station. However, during that legal review, the policy issued by the FAA regarding unacceptable restrictions to maintenance data must be fully understood and appreciated. The association has discussed potential scenarios with several contract and business lawyers who believe that any restrictions between the air carrier or owner/operator and its chosen maintenance providers in contracts with design and production approval holders would be extremely problematic in light of the FAA’s policy. While the specific facts must be analyzed, contract clauses can be deemed void as against public policy if litigated. That fact can certainly be used in discussions with customers and manufacturers.

On the other hand, anyone has the right to protect their proprietary property against “unauthorized” use through appropriate contractual language. In other words, the manufacturers can restrict allowable uses to only the specified owner/operator (and their repair providers), and also can prohibit any use of that data for the purpose of developing independent repairs or manufacturing parts.

Many air carriers and owner/operators are unaware that the policy makes clear any restriction to sharing maintenance information that the FAA considers ICA is unacceptable. The policy contains two important statements:

- It is not appropriate for a DAH to place limitations on the use of its ICA between the owner/operator and the maintenance provider, whether the maintenance provider is rated or not, to perform that maintenance.

- While not exhaustive, the FAA finds the following practices of using restrictive language in the ICA or through restrictive access or use agreements unacceptable under the provisions of 14 CFR § 50(b) and related ICA airworthiness requirements:

(1) Requiring the owner/operator to only install DAH-produced or authorized replacement parts, articles, appliances, or materials.

(2) Requiring that alterations or repairs must be provided or otherwise authorized by the DAH.

(3) Requiring the use of only maintenance providers or other persons authorized by the DAH to implement the ICA. ‘

(4) Establishing, or attempting to establish, any restriction on the owner/operator to disclose or provide the ICA to persons authorized by the FAA to implement the ICA.

Repair stations that are receiving or have received ICA from the owner/operator or air carrier customer can develop letters explaining the FAA policy and asking for clear instructions to the manufacturer from the customer to that effect. While the association cannot construct an informational letter for all members, it stands ready to help with referrals to appropriate commercial resources after understanding each unique situation.

To see all of the association’s work related to ensuring reasonable availability of ICA, visit the issue page on ARSA.org.

Member questions should be submitted through the inquiry system run through ARSA’s new online member portal. Members can use their portal access to submit inquiries by logging in through arsa.member365.com/sharingnetwork.

Make ARSA’s Voice Your Own: Advertise

ARSA has a menu of advertising opportunities for arsa.org, the hotline and the ARSA Dispatch. Take advantage of these great opportunities today to showcase your company, a new product or event. For more information go to arsa.org/advertise.

Stand Up for ARSA by Sponsoring

In order to provide world-class resources for its members, the association depends on the commitment of the aviation community. By sponsoring events and activities, supporters can help ARSA’s work on behalf of repair stations to endure.

Need a place to start? For information about opportunities, contact Vice President of Operations Brett Levanto (brett.levanto@arsa.org).

Resources

ARSA strives to provide resources to educate the general public about the work of the association’s member organizations; should you need to provide a quick reference or introductory overview to the global MRO industry, please utilize AVMRO.ARSA.org.

ICA Issue Page

Since its inception, ARSA has worked to ensure that basic safety information (i.e., Instructions for Continued Airworthiness [ICA], including component maintenance manuals [CMM]) is made available at a fair and reasonable price to operators, maintenance providers, and any other person required by 14 CFR to comply with those instructions. ICA Issue Page

Brexit Resource Page (Updated)

On June 23, 2016, citizens of the United Kingdom voted to withdraw from the European Union in a national referendum. As the process of making that withdrawal happen drags on. This page is provided as a resource for the aviation maintenance community regarding the transition. Brexit Resource Page

Careers In Aviation Maintenance

Every year, more people are flying. The expansion of the global middle class and improvements in technology have opened aviation markets – for passengers and cargo – to a broader public than ever before. As the the flying public gets larger, more men and women are desperately needed to keep the world safely in flight.

Quick Question Portal

See what ARSA has asked and what’s been answered and participate in the conversation about what’s going on in the aviation maintenance world.

AVMRO Industry Roundup

ARSA monitors media coverage on aviation maintenance to spread the word about the valuable role repair stations play globally by providing jobs and economic opportunities and in civic engagement. These are some of this month’s top stories highlighting the industry’s contributions. You can explore these stories through ARSA’s Dispatch news portal.

Industry Calendar

the hotline is the monthly publication of the Aeronautical Repair Station Association (ARSA), the not-for-profit international trade association for certificated repair stations. It is for the exclusive use of ARSA members and federal employees on the ARSA mailing list. For a membership application, please call 703.739.9543 or visit arsa.org/membership/join. For information about previous editions, submit a request through arsa.org/contact. This material is provided for educational and informational purposes only. It does not constitute legal, consulting, tax or any other type of professional advice. Law, regulations, guidance and government policies change frequently. While ARSA updates this material, we do not guarantee its accuracy. In addition, the application of this material to a particular situation is always dependent on the facts and circumstances involved. The use of this material is therefore at your own risk. All content in the hotline, except where indicated otherwise, is the property of ARSA. This content may not be reproduced, distributed or displayed, nor may derivatives or presentations be created from it in whole or in part, in any manner without the prior written consent of ARSA. ARSA grants its members a non-exclusive license to reproduce the content of the hotline. Employees of member organizations are the only parties authorized to receive a duplicate of the hotline. ARSA reserves all remaining rights and will use any means necessary to protect its intellectual property.

© 2019 Aeronautical Repair Station Association