2017 – Edition 9 – October 6

Table of Contents

Note: The order of material varies in hotline emails, but is always presented the same on this landing page. Readers scrolling through content on or printing this page will find it organized consistent with the table of contents.

Sarah Says

SLC 2017

ARSA Works

Legal Briefs

ARSA on the Hill

Quality Time

Training

Membership

Resources

Industry Calendar

Sarah Says

Laissez-Faire? We Wish

By Sarah MacLeod, Executive Director

A recent article accused the FAA of taking a laissez-faire approach to aviation safety. The news item seems to have been triggered by the negative audit this year by the Department of Transportation’s Office of Inspector General of the FAA’s suspected unapproved parts program.

The Sept. 20 exposé from the Crime Report begins with the “news” that “[a] tide of defective and possibly counterfeit airplane parts has been making its way into U.S. aircraft unreported and unchecked…”. The story quotes a former inspector general, Mary Schiavo, in addition to a whistleblower and some former FAA employees.

The reason for this “tide,” it appears, is that the FAA takes a “laissez-faire” approach to aviation safety oversight. If that is true, I would hate to see what the general media would think is the proper amount of scrutiny. While it is true the FAA may not efficiently and effectively notify federal law enforcement authorities about “suspected” parts problems, it is equally true that the FAA will be looked upon by those same agencies to determine if there is enough evidence to establish a criminal case. The fact that the government will rely upon the design or production approval holder to determine whether an article is airworthy should not be taken as a “hands-off” approach to aviation safety oversight.

Unfortunately, the general media combines unsubstantiated and often unrelated information into a “story” for consumption by the general public. When the story involves highly technical issues in a closely regulated industry, both the oversight authority and individual companies become the target of misinformation and misconceptions.

As ironic as it sounds, counterfeit does not automatically mean unairworthy. Similarly, falsification of records does not mean that the article being examined failed to meet specifications. Each element of a non-compliance or non-conformity has to be evaluated thoroughly and carefully to determine impact on the aircraft and ultimately the safety of the flying public. It’s equally true that law enforcement agencies must present “evidence” – not merely suspicion – to a prosecutor and ultimately courts of law. The court system in America is based upon the premise that one is innocent until proven guilty—no such standard applies to the “free” press.

Unfortunately, negative stories “sell” and the industry has a laissez-faire approach to media relations. While ARSA responded to The Crime Report’s queries and was even quoted, the article managed to make it sound like repair stations thought the agency was justified in taking a “hands-off” approach to oversight. In aviation, we will continue “to hear the truth [we’ve] spoken twisted by knaves to make traps for fools,” but it will not deter us from responding to negative publicity.

SLC 2017

MOOG Aircraft Group & Easy Reference

Special thanks to MOOG Aircraft Group for its Gold Level Sponsorship of ARSA’s 2017 Strategic Leadership Conference in Washington, D.C. on Oct. 18 and 19. Participants will carry the company around during the event: Its logo will adorn the cover of the SLC handout materials.

By supporting the provision of agenda information, meeting descriptions and reference material, MOOG will help maintenance industry senior executives get around as they “engage for impact” in the U.S. capital.

Don't need more information? Register or sponsor right here...

Click here to submit your late registration now...

2017 SLC Registration Form

Oops! We could not locate your form.

Lufthansa Technik & Intellectual Sustenance

Special thanks to Lufthansa Technik for its Gold Level Sponsorship of ARSA’s 2017 Strategic Leadership Conference in Washington, D.C. on Oct. 18 and 19. As a result of the company’s support, participants will be well fed at the conference luncheon with both good food and policy insight from a special guest speaker (Just Announced: Check the agenda on the event page to see who it is.).

Participants will enjoy Lufthansa Technik’s menu and join maintenance senior executives to “engage for impact” in the U.S. capital.

Click here to visit the SLC event page for more information.

Don't need more information? Register or sponsor right here...

Click here to submit your late registration now...

2017 SLC Registration Form

Oops! We could not locate your form.

MRO Holdings & Starting Strong

Special thanks to MRO Holdings, which includes both Flightstar Aircraft Services and Aeroman, for its Gold Level Sponsorship of ARSA’s 2017 Strategic Leadership Conference in Washington, D.C. on Oct. 18 and 19.

MRO Holdings’ commitment will provide for a strong start to the event at the Wednesday evening reception. Register now to take advantage of this hospitality and join maintenance community leaders as they “engage for impact” in the American capital.

Click here to visit the SLC event page for more information.

Don't need more information? Register or sponsor right here...

Click here to submit your late registration now...

2017 SLC Registration Form

Oops! We could not locate your form.

ARSA Works

ARSA Form for New Article Inspections Remains Valid After FAA Extends Notice 8900.380

To see all of ARSA’s work on the MAG, visit arsa.org/mag.

In September 2016, ARSA released Form E100 as an FAA-accepted method of compliance with U.S. and EASA requirements for inspecting certain new parts. The association developed the form for its members to record an inspection of a new article received with the documentation required by the FAA-EASA Maintenance Annex Guidance (MAG).

At the time of its release, the form’s instructions referenced FAA Notice 8900.380, which became effective in August 2016 and confirmed that a repair station may inspect and approve for return to service any new part within its ratings that does not meet the documentation provisions of MAG Change 6. The Notice was scheduled for cancellation this year, before ARSA and a coalition of industry groups requested and received an extension: FAA Notice 8900.480 became effective on Aug. 9. The new notice extends a repair station’s authority to inspect and issue Form 8130-3 with a right-side signature for new articles received without required documentation.

Users of Form E100 may continue doing so without alteration, but should note the change in the referenced Notice. ARSA members not currently using the form should click here to learn more and then visit the publications page to request access to their free copy.

CMT Meeting and the Signing of FAA-EASA TIP Rev. 6

The four civil aviation authorities that comprise the Certification Management Team (CMT) – the FAA, EASA, ANAC and Transport Canada – held their semi-annual meeting in Ottawa, Canada the week of Sept. 18, 2017. The CMT discussed the next steps in the quadrilateral group’s efforts to reduce the amount of technical and administrative redundancy between and among their agencies as it relates to certification projects. As is customary since the CMT was established eight years ago, Sept. 22 was dedicated to an “Industry Day” for government and business representatives.

International oversight redundancy is built into the ICAO legal structure established at the end World War II by the Convention on International Civil Aviation, better known as the Chicago Convention of 1944. The convention and its annexes (which contain Standards and Recommended Practices) vest in the State of Registry the responsibility for airworthiness and continued airworthiness, among other things. As a result, applicants for and holders of type certificates seeking to sell their products to customers in foreign countries must have those type certificates validated by the State of Registry. Such validation can take the form of acceptance without any further action, streamlined validation (administrative issuance of a certificate or approval without technical involvement) or technical involvement by the validating authority.

For example, in Rev. 5 to the FAA-EASA Technical Implementation Procedures (TIP), the two agencies agreed that except for a small number of TSOA articles, each would mutually accept each other’s (E)TSOAs without any involvement by the validating authority, subject to the conditions in the agreement. On Sept. 22, TIP Rev. 6 was signed expanding mutual reciprocity to include the TSOA’d articles previously excepted. Therefore, on or about March 22, 2018 (the day TIP Rev. 6 will enter into force), all TSOA articles will be mutually accepted (i.e., without either administrative or technical involvement by the validating authority), subject to the provisions of the TIP. Similar (but somewhat different) TSOA reciprocity provisions exist in other bilateral agreements among CMT members, ( see TIP Rev. 3 signed by EASA and Transport Canada on Sept. 18, 2017 and Rev. 2 to the FAA-Transport Canada IPA, signed Nov. 10, 2016).

In addition, and of particular interest to ARSA members, TIP Rev. 6 also provides for the mutual acceptance of all repair data. Some ARSA members may remember when EASA was established in 2003 it decided to approve all repair data on its State of Registry articles, even if the data had been approved by the FAA. ARSA was instrumental in persuading EASA that this was impractical and unnecessary. EASA and the FAA agreed shortly thereafter to mutually accept all repair data except that used on critical parts developed by an entity other than the EASA type or supplemental type certificate holder. TIP Rev. 6 eliminates the need for the State of Registry to approve repair data on critical parts developed independent of the TC/STC holder provided the data has been approved by the exporting authority.

To review all of TIP Rev. 6, click here.

Final Documents/Your Two Cents

This list includes Federal Register publications, such as final rules, Advisory Circulars and policy statements, as well as proposed rules and policies of interest to ARSA members.

Legal Briefs

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

Advisory Committees Merely Advise

By Sarah MacLeod, Executive Director

You may have noticed that the FAA’s Aviation Rulemaking Advisory Committee (ARAC) recommendations on removing or changing duplicative, unnecessary or burdensome aviation safety regulations got some attention from the general media in October. Despite being dubbed “influential,” ARAC, as with all “advisory” committees, may only recommend actions to agencies—the committee has absolutely no power to force or compel action.

The ARAC is an unusual committee organized under the Federal Advisory Committee Act (FACA) as it is “standing” in nature. Most FACA committees are developed to address a single issue. ARAC was first suggested and later created by the FAA when Anthony Broderick headed the Aviation Safety organization (then known as Regulation and Certification) in the 1990s. ARSA has been on the committee since its inception and has been an active member for its entire existence.

The ARAC is meant to help the FAA by recommending actions, up to and including rulemaking, on a wide-range of technical issues. It has been most instrumental in developing “harmonized” rules that contain similar language or concepts as those developed by bilateral partners, such as the European Aviation Safety Agency (EASA). Similarly, it has been asked to develop recommendations on tough issues such as major/minor determinations, recordkeeping and many other matters. If you care to review those recommendations, you will quickly note that FAA has not taken all or even most of the advice provided.

Under FACA, the meetings of an advisory committee must be open to the public, whereas the internal wrangling of a committee’s working groups may be closed sessions. The reasoning behind the distinction is deliberations of the body (ARAC) responsible for making recommendations should be open, while the ideas that may be floated during the industry’s exchange of views should provide for open, honest, private communications over the pros and cons of a potential direction.

In the matter of recommending rules that should be repealed or modified, the ARAC’s ad hoc working group took under advisement literally hundreds of rules submitted by various members and only forwarded those that could be justified in some manner. The hoopla you’ll see below over the reduction of required hours for a pilot to qualify for transport category certificates was a result of ARAC members’ misunderstanding of the impact a recommendation can or would have. The more contentious an issue, the more likely dissenting opinions will be filed and the less likely a unanimous recommendation will be sent to the agency.

In the end, the general media added its own spin on the ARAC’s recommendations for repealing or modifying rules. A sample of the misinformation can be found in a few headlines from September:

Industry Panel Recommends Roll Back Of Aviation Safety Rules

An influential industry committee recommended Thursday that the Federal Aviation Administration eliminate or scale back dozens of safety rules, including one on airline pilot qualifications.

Aviation panel recommends Trump roll back safety rules

An industry-led aviation panel is recommending that the Trump administration roll back or ease dozens of safety rules, according to The Associated Press.

Fight erupts over training hours for pilots

A controversial push to change the training requirements for pilots is gaining speed under the Trump administration.

FAA deregulation panel’s recommendations prompt worries from safety advocates

A federal advisory committee’s sweeping deregulation proposals are roiling the world of airplane safety.

A key part of ARSA’s work is not only to understand the nuances of regulatory creation and compliance, but also provide a sensible voice for the industry and government as they work together – through bodies like ARAC – to improve the system.

ARSA on the Hill

Congress Avoids FAA Shutdown, Kicks Reauthorization Down the Road … Again

By Christian A. Klein, Executive Vice President

There was some drama as things came down to the wire, but Congress ultimately did what everyone expected and voted Sept. 28 to keep the FAA running for another six months.

Early in the week of Sept. 25, the House sent the Senate a short-term FAA authorization bill that included unrelated language to encourage the creation of private flood insurance markets. The flood provision drew bipartisan opposition from senators wanting to address the issue as part of a broader flood insurance debate. The Senate ultimately stripped the controversial language, passed the bill and sent it back to the House for quick approval and ultimately a signature from President Trump.

The extension keeps FAA’s lights on through March 30, 2018 and buys more time for lawmakers to hash out the details of a longer-term FAA reauthorization bill. Congress’ efforts at long-term policy have been hampered in the House by disagreement over whether to spin off air traffic control responsibilities from the FAA and in the Senate over language to reform pilot training requirements.

Aggressive lobbying by ARSA this year helped prevent the inclusion of language in the House and Senate bills hostile to contract maintenance. The association is now playing offense and building support for its five separate amendments to reduce regulatory burdens on repair stations, address the technician shortage and enhance the maintenance industry’s impact on FAA policymaking. For more information about the status of the maintenance industry’s amendments, see the box score, which has been posted and updated throughout the legislative process. To get involved in ARSA’s FAA reauthorization campaign or learn more about our positions, contact ARSA Executive Vice President Christian A. Klein at christian.klein@arsa.org.

FAA Bill Maintenance Amendments Box Score

| ARSA Proposal | In House Bill | In Senate Bill |

| Adding “aviation maintenance” to stakeholders on new Certification & Oversight Advisory Committee | Yes – Amendment by Rep. Hank Johnson (D-Ga.) and Rob Woodall (R-Ga.) adopted in committee by voice vote | Yes – Amendment by Sen. Jim Inhofe (R-Okla.) adopted in committee by voice vote |

| Asking FAA to explore ways to enhance value of repairman certificates | No – Rep. Eddie Bernie Johnson (D-Texas) has filed amendment | Yes – Amendment by Sen. Jim Inhofe (R-Okla.) adopted in committee by voice vote |

| Directing FAA to undertake rulemaking to reinstate voluntary surrender of repair station certificates | No – Rep. Dan Webster (R-Fla.) has filed amendment | Yes – Amendment by Sen. Jim Inhofe (R-Okla.) adopted in committee by voice vote |

| Directing GAO to study causes, effects and solutions to aviation technician shortage | Yes – Amendment by Rep. Cheri Bustos (D-Ill.), Brenda Lawrence (D-Mich.) and Bruce Westerman (R-Ark.) adopted in committee by voice vote | No – ARSA is working to identify sponsor |

| Creating grant program to support aviation maintenance workforce development initiatives | No – ARSA is working to identify sponsor | No – Sens. Jim Inhofe (R-Okla.) and Richard Blumenthal (D-Conn.) planning to sponsor amendment on Senate floor |

Say Thanks To Our Champions!ARSA is fortunate have several members of Congress are going to bat for repair stations and supporting maintenance-related FAA bill amendments. If someone from your state is on the list below, please shoot a quick note of thanks. It doesn’t have to be anything fancy and could be as simple as: “Thank you for your leadership on aviation maintenance issues in the FAA bill. As a member of the YOURSTATE repair station industry, I sincerely appreciate your efforts on our behalf.” (Clicking on the names below will open up a blank email address to their aviation staffers.) |

Tax Reform Process Kicks Off … Again

The last week in September saw the political spotlight once again turn to taxes as congressional Republicans and White House negotiators unveiled a new, slightly more detailed (than prior efforts) reform plan, entitled, “A Unified Framework for Fixing Our Broken Tax Code”.

The “framework” builds on objectives articulated by President Trump: making the tax code simple, fair and easy to understand; reducing taxes on working-class Americans; improving the tax environment for American companies; and encouraging the repatriation of money held overseas by U.S. corporations. The framework is designed to be a guide for the House and Senate tax-writing committees as they draft legislation.

For individuals, the framework would:

- Simplify and double the standard deduction effectively creating a larger “zero tax bracket” by eliminating taxes on the first $24,000 of income earned by a married couple and $12,000 earned by a single individual.

- Consolidate the seven current tax brackets would be consolidated into three brackets: 12, 25, and 35 percent.

- Repeal the personal exemption for dependents, significantly increase the Child Tax Credit, and increase the income levels at which the Child Tax Credit begins to phase out.

- Repeal the alternative minimum tax (AMT) for individuals

- Eliminate most itemized deductions, but retain tax incentives for home mortgage interest and charitable contributions.

- Retain tax benefits that encourage work, higher education and retirement savings.

- Eliminate the estate and generation skipping transfer taxes.

For businesses, the framework would:

- Limit the maximum tax rate applied to the business income of small and family- owned businesses conducted as sole proprietorships, partnerships and S corporations to 25 percent.

- Reduce the corporate tax rate to 20 percent (which is below the 22.5 percent average of the industrialized world) and eliminate the corporate AMT.

- Allow businesses to immediately write off (or “expense”) the cost of new investments in depreciable assets (other than structures) made after September 27, 2017, for at least five years.

- Partially limit the deduction for net interest expense incurred by C corporations and direct the tax committees to consider the appropriate treatment of interest paid by non-corporate taxpayers.

- Eliminate the domestic production (“section 199”) deduction and eliminate or restrict “numerous other special exclusions and deductions” (however, the framework specifically preserves the research and development (R&D) and low-income housing tax credits).

- “Modernize” the “special tax regimes exist to govern the tax treatment of certain industries and sectors.”

With the broad outlines of a tax reform established, the House Ways & Means and Senate Finance Committees can now get to work hashing out the details, but there are many details still work out (the framework document provides little detail beyond the bullet points above). As those details are developed, the conversation is likely to be more fractious.

While tax writers draft the bills, congressional leadership will be smoothing the path towards ultimate passage. The Republican strategy is to have the House and Senate first pass a budget resolution, which would allow a tax reform package move through a process called reconciliation and avoid a Democratic filibuster in the Senate. However, completing a budget resolution won’t be without its challenges: The budget resolution unveiled in the Senate on Sept. 29 would allow for deficit increases of up to $1.5 trillion over ten years and Republican budget hawks are likely to object. How aggressively they do so and in what numbers will determine the budget resolution’s fate.

The Senate Budget Committee is expected to markup the resolution during the first week in October. Assuming it passes the Senate, conferees will work to resolve differences between the Senate and House versions.

Quality Time

Editor’s note: The views and opinions expressed by contributing authors do not necessarily state or reflect those of ARSA and shall not be used for endorsement purposes. A version of this article was published in the August-September 2017 edition of AMT Magazine and is reprinted with permission.

What a Hip Replacement Can Teach Us About Aircraft Maintenance

By Marc Szepan, Lecturer, University of Oxford Saïd School of Business and Dr. Bill Johnson, Chief Scientific and Technical Advisor for Human Factors in Aircraft Maintenance Systems, FAA

Introduction

This article started when Bill Johnson (aka. Dr. Bill) was discussing his upcoming hip replacement (i.e., “major repair and alteration”) with Marc Szepan, a former Lufthansa senior executive and now a Lecturer at the University of Oxford Saïd Business School. The two realized that there might be similarities between performing “surgery” on Dr. Bill and an aging aircraft. Even more importantly, from Bill’s point of view, there surely could be similarities in terms of what one would expect from a hospital and a repair station. So, they discussed the characteristics of an aviation maintenance service provider and a hospital that would be most desirable to complete the service in an efficient, effective and safe manner. Even though the prospect of undergoing hip surgery was not all that pleasant, the discussion itself was fun. With Dr. Bill’s successful surgery over, here is a short summary of that original discussion about patient safety during major repairs …

Is A Repair Necessary?

First, what is the non-routine finding and the necessity to undergo repair? Too many landing cycles or hard landings on an aging airframe can result in the main landing gear attach fitting not reaching its intended OEM service life. A maintenance, repair, and overhaul facility detects such damage, writes up a nonroutine finding and replaces the damaged or worn attach fitting.

In the case of human beings, this sort of strain on the main landing gear system and its attach fittings – i.e. the legs and hips – can occur as well. Dr. Bill was fortunate that his doctor properly diagnosed failure of his right hip prior to reaching its, for lack of a better term and without any blasphemous intent, “OEM design life.” Just like an aircraft, Dr. Bill had to schedule around the anticipated out-of-service time during repair, recovery and new component break-in period.

Right Service Provider

In general, many maintenance facilities offer landing gear services. It is very important to ask around to find the very best maintenance provider – to find a facility large enough to have top-notch hangars, shops, and modern equipment. On the other hand, very busy large maintenance providers may be more focused on major airframe maintenance checks and structural repairs or full landing gear overhauls; a mere main gear attach fitting replacement job may be squeezed in between the higher-revenue “big item” jobs.

Bill wanted a well-known provider that specialized in landing gear main attach fitting replacement and takes pride in performing this very procedure. Johnson’s choice of service provider was influenced by prior family experience with the repair facility (aka, hospital), just as maintenance providers strive for return customers.

Of course, Bill wanted to be able to perform an informal on-site audit himself, which is not always possible in an aviation environment. However, in our experience, nothing really beats walking around the flight line, the hangar floor and engineering offices to get a feel for the facility and observe cleanliness, attitude and overall demeanor of people. The fact that the hospital and medical team welcomed patient safety questions, before the procedure, was a good sign that they were on the right track. He found the right place.

Right People and Right Team

Maintenance work requires highly-qualified and experienced personnel working together as a team and accomplishing the job with the highest care and resulting quality. Individual specialists must be properly trained and current in their respective areas of work. For a single, one-time customer, it might not be feasible to check the credentials of all maintenance staff and to verify the level of recurrent training across the entire maintenance team, which is why aviation customers rely on the certification agency. There is variance across different part 145 maintenance facilities but the certification agency(ies) must ensure an acceptable level of compliance to established standards. In the same spirit Bill selected medical professionals with the right type of initial training (i.e. medical school), evidence of adequate levels of recurrent training and appropriate certifications.

Successful maintenance work is not just a function of the excellence of an individual contributor but a true team sport. Replacement of a landing gear main attach fitting can require technicians remove and reinstall the landing gear, avionics mechanics to work on disconnecting and reconnecting wiring, structural experts to perform the replacement of the attach fitting itself, engineers to develop or coordinate repair schemes in case of secondary findings that are out of limit, tools and logistics specialists to ensure availability of spare parts, consumables, and tooling, facility experts to keep the hangar and shops in good condition, and – depending on an aircraft operator’s standards – pilots to perform a post-maintenance test or verification flight. Similarly, Bill did not judge the hospital of his choice by the quality/reputation of the orthopedic surgeon alone, but made sure to have a good feel for all other members of his surgical team – anesthesiologists, nurses, facility managers, etc. – in their own right and, above all, in terms of their team spirit.

Right Organizational Culture

Even the best people and the best team are likely to fail in a maintenance organization that has the wrong culture. A dedication to safety and to an appropriately-configured safety culture must be a shared and non-negotiable goal. In a short visit, it’s difficult to sense this on-site, though it certainly is worth trying to verify by looking for visible indications of a service provider’s safety culture. For example:

(1) Walk past bulletin boards and pay attention to whether safety-related matters are displayed prominently, up to date and measure the right Key Performance Indicators (KPIs).

(2) Ask about voluntary reporting systems.

(3) Ask how the organization deals with honest errors.

(4) Ask if individual employees get sufficient rest and if teams are adequately staffed for the tasks at hand.

(5) Ask about human factors training.

Sometimes even the marketing material talks about safety. That’s worth looking for!

Bill checked on all of this and only settled for a hospital once he was reasonably sure the facility had the same type of safety culture that he would expect from any repair station to which he would entrust an aircraft repair.

Right Facilities, Equipment, Procedures, and Parts

The best team working in the best organizational culture will struggle to produce high-quality repairs if they are forced to work without being properly resourced. If possible, check the facilities, equipment and tooling available to employees. Good lighting, work stands for easy access and cleanliness are important. Consider tooling and equipment-related procedures as well. Check specifics. For example, consider tool control procedures. Do mechanics perform a toolbox check upon completion of maintenance work? You don’t want tools left behind inside the airframe after closing up. And you certainly don’t want your doctor to leave behind a scalpel or the like after closing the cowling. (An old- fashioned television in the pre-operating prep room did raise concern, but the nurse commented that it was the oldest device in the hospital except for a couple of the nurses and doctors. She said that all surgical equipment state-of-art and in calibration.)

Regarding procedures in general, are working procedures clearly documented, sound and consistently applied? Johnson observed that his provider was extremely diligent about explaining the specifics regarding what would be done and that those steps were clearly trained and repeatable. They also demanded that patients take a class, prior to the repair, to be sure that the post-op break-in was accomplished properly.

Do employees have easy access to and perform maintenance work in accordance with authorized and up-to-date controlled documentation such as Aircraft Maintenance Manuals (AMMs) or Structural Repair Manuals (SRMs)? Replacing the main attach fitting of a landing gear is a complicated procedure. First, the gear must be removed from the airframe. Then the main attach fitting must be replaced and any secondary corrosion must be addressed. The gear must be mechanically reinstalled and all electrical and hydraulic lines must be reconnected. Hip replacement is similarly complicated. You want your surgeon to work in accordance with proper procedures. You surely don’t want your surgeon to just “wing it.”

When undergoing parts replacement – like getting a new hip – you want to make sure that the replacement part itself is of acceptable quality. Both in the case of “surgery” on human beings and on aircraft you want to beware of Suspected Unapproved Parts (SUPs). Ask about the procedures your maintenance provider – i.e. hospital – has in place to control the risk of SUPs and utilizes the most modern, proven technology. Ask about procedures to ensure that consumables have not expired.

Dr. Bill looked into all of this before feeling at ease with his choice of hospital!

Aircraft Maintenance vs. Medicine

As aviation safety professionals, we all appreciate the direct comparison between aircraft repair and surgery. Our maintenance processes, particularly Safety Management Systems, ensure continuing safety worldwide. Our industry strives to identify and address hazards while seeking every opportunity to manage safety.

Before his surgery (especially), Bill did not want to ponder patient safety statistics: The U.S. rate of deaths due to patient safety is about 250,000 lives per year, which is 500 times the aviation accident fatality rate (granted, many patients undergoing surgery are dangerously sick to begin with). The good news is medical professionals and hospitals are seeking advice from aviation safety risk experts; some aviation consultancies have even reduced their aviation workload in favor of patient safety consulting. Medical schools are increasing their offerings related to patient safety. Insurance companies have stepped up to incentivize with lower rates for patient safety initiatives.

After doing his homework of checking on people and teams, the organizational culture, and facilities, equipment, procedures, and parts at the hospital of his choice, Bill was ready for his major repair and alteration. His total hospital time was less than 6 hours and he was hobbling around by the end of the day. He is looking forward to returning to walking and running his favorite trails. Better yet, to doing more “walk-arounds” at your maintenance facility.

Marc Szepan recently completed all requirements for the Ph.D. in Business from the University of Oxford Saïd Business School,Oxford, UK. He holds an MBA from Duke University and a Masters in Asian Studies from the Kennedy School of Diplomacy at Harvard University. Marc’s primary professional experience has been in leading technical and digital aviation businesses in Europe, Asia, and the U.S. Most recently, he served as Senior Vice President, Airline Operations Solutions, at Lufthansa Systems, the IT services business segment of Lufthansa Group.

Dr. Bill Johnson advises on the identification of practical ways to ensure continuing effective, efficient, and safe human performance in maintenance and engineering. Dr. Johnson has over 40 years applied research and development experience with a focus on human performance in maintenance and repair of complex systems. His research efforts concentrated on every day solutions that affect human behavior and performance.

Training

Live Session on Duty-Free Parts Importation

On Oct. 11, join Executive Vice President Christian A. Klein for an hour-long session on parts importation requirements. Klein will review the issues surrounding duty-free import of civil aviation parts and articles and introduce the association’s resources for managing the process.

Interested participants can prepare for the session by reviewing arsa.org/regulatory/customs.

Session Information: Importing Aircraft Parts for Maintenance – Establishing Duty Free Rates

October 11, 2017 at 11:00 a.m. EDT

The session reviews the World Trade Organization’s exemption of civil aviation products and parts from import duties and describes the U.S. implementation of rules and guidance to support duty-free importation. It then walks through the association’s resources for ensuring that eligible imports are made free of Customs tariffs.

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit PotomacLaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Eight ARSA Training Sessions Accepted for IA Renewal Credit

On Sept. 12, ARSA announced that eight of its on-demand training sessions have been accepted by the FAA for Inspection Authorization renewal credit under 14 CFR § 65.93. Each session is currently available for registration and immediate access:

ICA – The Basics

IA Course Acceptance: C-IND-IM-170830-K-010-002

This session provides an overview of the regulatory basis for ICA, including what documents are considered ICA and the obligations of design approval holders to prepare, furnish and otherwise make them available under 14 CFR § 21.50(b). It also covers the related regulations that apply to operators and maintenance providers regarding the use of ICA and their availability. Finally, it shows how the FAA has interpreted some of the more important ICA requirements in Order 8110.54.

ICA – Case Study: Testing Your Knowledge

IA Course Acceptance: C-IND-IM-170830-K-010-001

This session tests the participants’ knowledge of the ICA regulations in Title 14 CFR and FAA guidance by presenting several hypothetical case studies. Each one will focus on one or more of the significant ICA regulatory principles.

Major/Minor – Major Pain Over a Minor Issue

IA Course Acceptance: C-IND-IM-170830-K-010-003

This session reviews the regulations that govern the terms “major” and “minor” in the world of civil aviation repairs and alterations. Learn the regulatory facts and how to train your FAA inspector so this minor issue doesn’t become a major pain in the derrière.

Part 21 – Overview

IA Course Acceptance: C-IND-IM-170830-K-010-004

This session provides an overview of the aviation safety regulations governing design and production of civil aviation products and articles as well as airworthiness certification of civil aircraft.

Part 65 – Getting a Mechanic’s Certificate

IA Course Acceptance: C-IND-IM-170830-K-010-005

This session reviews the requirements of 14 CFR part 65 subpart D, which concerns aviation mechanics. It walks through the requirements for an individual to apply for a mechanic’s certificate, then defines the privileges and limitations bestowed on that individual by his or her certificate. Finally, it covers the enhancements to a mechanic’s privileges produced by obtaining Inspection Authorization.

Recordkeeping for Mechanics

IA Course Acceptance: C-IND-IM-170830-K-010-006

This session defines the regulatory responsibilities of the operator versus the maintenance provider in creating and maintaining maintenance records, including how obligations can be shifted by contract, but not under aviation safety regulations. It also covers maintenance recordkeeping regulations; the documents essential to making airworthiness determinations.

Regulations Impacting the Purchase of Aircraft Parts

IA Course Acceptance: C-IND-IM-170830-K-010-007

This session reviews the civil aviation regulations in Title 14 Code of Federal Regulations that impact the purchase of civil aviation parts, as well as other requirements that should be considered.

What is “Acceptable to the Administrator”? – The Performance Rules of § 43.13

IA Course Acceptance: C-IND-IM-170830-K-010-008

This session provides an overview of the regulations that use the language “acceptable to” the Federal Aviation Administration and how to determine what makes something acceptable to the agency.

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording made available after the live session is complete.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit PotomacLaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Part 39 – Airworthiness Directives

This session provides an overview of 14 CFR part 39 – Airworthiness Directives (ADs). It describes: What an AD is; Its force and effect; What work it may require; How an AD interrelates with maintenance instructions; The basic structure of an AD; and How to access and keep current on these rules.

Instructors: Sarah MacLeod & Christian A. Klein

Click here to register and get access for 90 days.

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit PotomacLaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Part 65 Repairman Certificates

This session reviews the requirements of 14 CFR part 65 subpart E, which concerns aviation repairmen. It presents the language of part 65 in the context of parts 121, 135 and 145 as well as agency guidance regarding the management of repairman applications. Throughout, the session connects and compares the repairman’s requirements to those of the mechanic’s certificate issued under part 65.

Instructors: Sarah MacLeod & Brett Levanto

Click here to register and get access for 90 days.

This is the third session on part 65 the association has made available (see the other two below). Want all three? Click here to purchase together and save.

Other Sessions on Part 65

Part 65 – Getting a Mechanic's Certificate

This session reviews the requirements of 14 CFR part 65 subpart D, which concerns aviation mechanics. It walks through the requirements for an individual to apply for a mechanic’s certificate, then defines the privileges and limitations bestowed on that individual by his or her certificate. Finally, it covers the enhancements to a mechanic’s privileges produced by obtaining Inspection Authorization.

Instructor: Sarah MacLeod

Part 65 – Overview

Part 65 – Overview

This session overviews 14 CFR part 65, Certification: Airmen Other than Flight Crewmembers. It introduces the statutory authority through which the FAA administers certificates and outlines the rules for application, issuance, testing, disqualification and duration of agency-issued certificates. It then introduces the five different certifications issued under part 65 by reviewing the relevant eligibility requirements for each.

Instructor: Sarah MacLeod

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit PotomacLaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

From the FAA – The Prime Directive

The FAA’s “Maintenance Hangar” on faasafety.gov contains information and resources the agency has produced or compiled to support safety in maintenance operations. The “toolbox” section includes alerts, guidance, tips, training information, posters and handout materials. Members of the maintenance community working on U.S.-registered aircraft should become familiar with these resources; at the very least they help highlight the areas considered most important by the agency.

To provide a taste of the content available in the “maintenance hangar,” this edition of the hotline is taking a look at the agency’s poster on Airworthiness Directives. It’s a simple complement to the association’s training released this month:

The “Maintenance Hanger” can be found at: www.faasafety.gov/content/TabLanding.aspx?tab=mechanics.

Regulatory Compliance Training

By ARSA Training and Regulatory Teams

Test your knowledge of 14 CFR § 65.12 – Offenses involving alcohol or drugs.

Click here to download the training sheet.

Membership

MRO Asia – VIP Invitations, ARSA Discounts

On behalf of its partners at Aviation Week, ARSA is helping extend a “VIP” invitation to association contacts employed by airlines or lessors and discounted registration to all other members. Join the maintenance community at MRO Asia-Pacific (Oct. 31-Nov. 2). This industry-wide event attracts airline decision makers and commercial transport leaders, providing the ability to network in a uniquely personal environment.

On behalf of its partners at Aviation Week, ARSA is helping extend a “VIP” invitation to association contacts employed by airlines or lessors and discounted registration to all other members. Join the maintenance community at MRO Asia-Pacific (Oct. 31-Nov. 2). This industry-wide event attracts airline decision makers and commercial transport leaders, providing the ability to network in a uniquely personal environment.

“VIP access” includes:

- All content sessions including keynotes, forecasts, technology updates, case-studies, and co-located conferences.

- Networking opportunities with your airline peers.

- All included meals.

- Access to Exhibition Hall during all posted times.

- Post event access to all presentations and conference materials.

Non-airline or lessor members (and colleagues) can use the promo code ARSA25 to save 25 percent of any conference pass.

MRO Asia Pacific

Singapore, Oct. 31-Nov. 2, 2017

Join the global community of airlines, MROs and OEMs at MRO Asia-Pacific for three days of unrivaled content and networking opportunities with 4,500+ attendees and 150+ exhibitors.

New in 2017:

- Meet The Buyers

- Interiors Zone

Co-Located Programs:

- Aerospace Manufacturing Asia-Pacific: Actionable strategies that accelerate your supply-chain, delivery schedules and development pipel, and take your business to the next level.

- Aero-Engines Asia-Pacific: Manufacturing to retirement and everything in between.

Confirm your participation today…

Contact:

Kristina Nicos

kristina.nicos@aviationweek.com

+1.646.257.4830.

To register online:

MRO Asia-Pacific

mroasia.aviationweek.com

Remember to use the promo code ARSA25 to save 25 percent of any conference pass.

Quick Question: Event Attendance

The world is growing more digital, but high-level aviation business still requires personal attendance.

Whether at major trade shows, local fly-ins, government meetings or industry symposia, members of the maintenance industry have to make careful decisions about how to invest their resources and time on event participation. For its part, ARSA provides two opportunities for face-to-face engagement at its Annual Repair Symposium and Strategic Leadership Conference each year.

Knowing where its members – and other professionals – choose to spend their time will help the association refine its own events, structure communications resources and best plan for its work throughout the year. Take a moment to describe where it is you go (and how often):

Note: Complete the survey directly on this page. You may have to scroll down in the embedded window in order to click the “Done” button.

If you have questions or want to provide additional information, contact Brett Levanto (brett.levanto@arsa.org).

Click here to see what questions have been asked and answered…and keep a lookout for more.

Help Hurricane-Affected Repair Stations

On Sept. 12, ARSA Executive Director Sarah MacLeod sent the following message to all of the association’s member contacts. MacLeod’s message, which followed closely on a similar note supporting the Texas repair station community, addressed the damage caused by Hurricane Irma. ARSA calls on its members to reach out in aid to fellow maintenance providers in Texas, Florida and Puerto Rico as they rebuild from the damage of catastrophic storms (Puerto Rican repair stations can be found on the FAA’s directory by clicking here and selecting “Puerto Rico” from the state menu):

Last week, ARSA called on its members to help Texas maintenance facilities affected by Hurricane Harvey. Now, another storm – Hurricane Irma – has landed in another state and threatened another center of aviation business: Florida.

When our team went to the FAA repair station directory to pull a list of most-likely impacted repair stations, we realized that in a state like Florida, facing a storm like Irma, nobody is completely out of harm’s way. So, in lieu of an enumerated list I’m asking members to click here to download a spreadsheet of FAA certificate holders in the state. If you do business with a facility or know people working with one of these companies, give them a call – ask how we can support each other in this trying time (if you need contact information, you can search the internet or the FAA’s repair station directory).

As you do this, keep ARSA in the loop and ask us first if you strike any regulatory issues or need help dealing with the government. Also, let us know if the association should support any specific policy from Washington as lawmakers consider relief options.

Irma is barely finished, but we’re already watching Jose’s meandering path across the Atlantic. No matter what the weather brings, this industry must endure: the world can’t fly without us.

If your email settings prevented you from clicking the link to download the spreadsheet, visit http://bit.ly/FLMRO-2017.

Your Servant,

SarahSarah MacLeod

Executive Director

Aeronautical Repair Station Association

sarah.macleod@arsa.org

Previous calls for help...

8/29/17 - (Harvey) Help the Texas Repair Station Community

August 29, 2017

On Aug. 29, ARSA Executive Director Sarah MacLeod sent the following message to all of the association’s member contacts:

The storm isn’t even over as I’m writing this, but the devastation of Hurricane Harvey seems beyond imagination. Emergency service agencies are overwhelmed by distress calls and private citizens have begun taking action to help their fellow Texans.

For the repair station community, the situation along the Gulf Coast is serious. Aviation businesses will face technical and economic obstacles as they try to recover and get back to work.

Most of us can’t float down the floodwaters to rescue stranded neighbors, but we can help. ARSA is calling on its members – no matter where they are located – to reach out to repair stations affected by the storm. Below is a list taken from the FAA Repair Station Directory of companies in Texas with coastal area codes. Review the names, in addition to any other Texas-based organizations you may know personally, and look for suppliers, competitors or partners. Find those performing similar work or supporting the same portion of the industry as you. Determine which might benefit from a simple check-in call and then pick up the phone. Remember that we’re all in this together and must support each other in a trying time.

As you do this, keep ARSA in the loop and ask us first if you find regulatory issues or need help dealing with the government. Also, let us know if the association should support any specific policy from Washington as lawmakers consider relief options.

Every day, ARSA reminds the world that it can’t fly without your work…today we remember that we can’t fly without each other.

Your Servant,

SarahSarah MacLeod

Executive Director

Aeronautical Repair Station Association

sarah.macleod@arsa.org

Coastal Texas Repair Stations

*The links below will take you to the company’s page on the FAA Repair Station Directory, which contains location and contact information.

A Member Asked…

Q: Last month in the hotline you ran a piece (Legal Brief: Importing Aircraft Parts into the United States Duty-Free) about importing civil aviation parts into the United States for repair duty free under the World Trade Organization’s civil aircraft agreement (CAA). How do I determine what parts qualify for the tariff exemption?

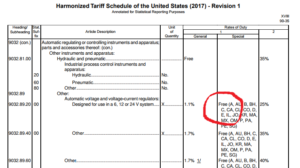

A: The starting point is the Harmonized Tariff Schedule of the United States (HSTUS) maintained by the U.S. International Trade Commission. Chapter 88 deals with aircraft and aircraft parts, which fall under heading 8803. The general code for rotors, propellers and related items is 8803.10.00; the general code for undercarriages and related articles is 8803.20.00; the general code for other civil aviation articles is 8803.30.00.

However, 88 is by no means the only HTSUS chapter in which exempt aviation items are listed. For example, Chapter 90 deals with “Optical, photographic, cinematographic, measuring, checking, precision, medical or surgical instructions and apparatus; parts and accessories thereof. If you look at item 9032.89.20 (“Automatic voltage and voltage-current regulators designed for use in a 6, 12 or 24 V system” (see picture), you’ll see a “C” in the “Rates of Duty – Special” column. That “C” is the official designator throughout the HTSUS that indicates the item is eligible for duty free treatment under the CAA. You can look through other HTSUS chapters to determine whether items you are importing are “Special C” and might qualify.

precision, medical or surgical instructions and apparatus; parts and accessories thereof. If you look at item 9032.89.20 (“Automatic voltage and voltage-current regulators designed for use in a 6, 12 or 24 V system” (see picture), you’ll see a “C” in the “Rates of Duty – Special” column. That “C” is the official designator throughout the HTSUS that indicates the item is eligible for duty free treatment under the CAA. You can look through other HTSUS chapters to determine whether items you are importing are “Special C” and might qualify.

Keep in mind that the fact the item is designate as “Special C” in the HTSUS isn’t the sole determiner of whether you can import it duty free. For more about what factors apply, see 19 CFR § 10.183 (“Duty-free entry of civil aircraft, aircraft engines, ground flight simulators, parts, components, and subassemblies”).

To see the association’s background on the importation of aviation parts, visit arsa.org/regulatory/customs.

To register for ARSA’s Oct. 11 online training session, click here:

http://arsa.org/parts-import-training/

Have a question for ARSA? Click here to let us hear it.

Make ARSA’s Voice Your Own: Advertise

ARSA has a menu of advertising opportunities for arsa.org, the hotline and the ARSA Dispatch.

Take advantage of these great opportunities today to showcase your company, a new product or event. For more information go to arsa.org/advertise.

Stand Up for ARSA by Sponsoring in 2017

In order to provide world-class resources for its members, the association depends on the commitment of the aviation community. By sponsoring events and activities, supporters can help ARSA’s work on behalf of repair stations to endure.

Need a place to start? For information about opportunities, including sponsorship of the Strategic Leadership Conference in October (click here for info), contact Vice President of Communications Brett Levanto (brett.levanto@arsa.org).

Resources

ARSA strives to provide resources to educate the general public about the work of the association’s member organizations; should you need to provide a quick reference or introductory overview to the global MRO industry, please utilize AVMRO.ARSA.org.

AVMRO Industry Roundup

ARSA monitors media coverage on aviation maintenance to spread the word about the valuable role repair stations play globally by providing jobs and economic opportunities and in civic engagement. These are some of this month’s top stories highlighting the industry’s contributions.

You can explore these stories through ARSA’s Dispatch news portal.

Industry Calendar

NBAA BACE – Las Vegas – Oct. 10-12

Airline Engineering & Maintenance: North America – Miami – Oct. 18-19

AVMRO Strategic Leadership Conference – Washington – Oct. 18-19

MARPA Annual Conference – Orlando – Oct. 25-26

MRO Asia-Pacific – Singapore – Oct. 31-Nov. 2

Aerospace Manufacturing Asia-Pacific – Singapore – Nov. 1-2

Aero-Engines Asia-Pacific – Singapore – Nov. 1-2

China Aviation & MRO Aftermarket Conference – Shanghai – Nov. 8-9

Commercial Aero Engine Forum – Shanghai – Dec. 5-6

Previous Editions

| 2017: | Jan | Feb | Mar | Apr | May | June | July | Aug | Sept | |||

| 2016: | Jan | Feb | Mar | Apr | May | June | July | Aug | Sept | Oct | Nov | Dec |

| 2015: | Jan | Feb | Mar | Apr | May | June | July | Aug | Sept | Oct | Nov | Dec |

| 2014: | Jan | Feb | Mar | Apr | May | June | July | Aug | Sept | Oct | Nov | Dec |

| 2013: | Jan | Feb | Mar | Apr | May | June | July | Aug | Sept | Oct | Nov | Dec |

| 2012: | June | July | Aug | Sept | Oct | Nov | Dec |

the hotline is the monthly publication of the Aeronautical Repair Station Association (ARSA), the not-for-profit international trade association for certificated repair stations. It is for the exclusive use of ARSA members and federal employees on the ARSA mailing list. For a membership application, please call 703.739.9543 or visit http://arsa.org/membership/join/. This material is provided for educational and informational purposes only. It does not constitute legal, consulting, tax or any other type of professional advice. Law, regulations, guidance and government policies change frequently. While ARSA updates this material, we do not guarantee its accuracy. In addition, the application of this material to a particular situation is always dependent on the facts and circumstances involved. The use of this material is therefore at your own risk. All content in the hotline, except where indicated otherwise, is the property of ARSA. This content may not be reproduced, distributed or displayed, nor may derivatives or presentations be created from it in whole or in part, in any manner without the prior written consent of ARSA. ARSA grants its members a non-exclusive license to reproduce the content of the hotline. Employees of member organizations are the only parties authorized to receive a duplicate of the hotline. ARSA reserves all remaining rights and will use any means necessary to protect its intellectual property.

© 2017 Aeronautical Repair Station Association