2020 – Edition 7 – August 7

Table of Contents

Note: The order of material varies in hotline emails, but is always presented the same on this landing page. Readers scrolling through content on or printing this page will find it organized consistent with the table of contents.

Taking Lead

Anti-Viral Measures

ARSA Works

Legal Brief

ARSA on the Hill

Training

Membership

Resources

Industry Calendar

Taking Lead

Confirming What You Knew…

By Christian A. Klein, Executive Vice President

It’s summer and it’s hot. Without a thermometer, you don’t really know how hot. The same applies to the health of the maintenance industry in the wake of the pandemic. We knew things are bad…terrible, actually; now we know exactly how terrible.

In June, ARSA took the unusual step of conducting a mid-year economic survey to update data gathered prior to the national emergency. The goal was to get a handle on the new industry business conditions to advocate for the industry as lawmakers consider additional economic relief.

The results are bleak, but not surprising given the massive disruptions we’ve experienced since March. The picture is of an industry reeling from sharp drops in revenue and widespread layoffs.

Cashflow is a big problem. U.S. respondents reported revenue declines cutting their 2019 income nearly in half. That economic jolt led to big job losses: the responding companies shed more than a quarter of their workforce. Projecting that loss across the entire maintenance industry indicates American repair stations lost more than 50,000 workers since the beginning of the year. Those figures mirror the Bureau of Labor Statistics, which recently reported a 25 percent reduction in year-over-year aviation industry employment.

Most respondents believe the maintenance industry will take a long time to recover and that business will not return to normal until at least 2021. While most agreed that recovery would not happen this year, maintenance professionals were divided on just how long it will take. Given how unpredictable the markets have become, the safest predictors are the one-fifth of respondents who admitted they had no idea when business would return to normal. Topping that bleak news, a third of respondents believe their business’s very survival is at stake.

The full survey results were released on July 28 and are available here. Review them to get the specific data behind each storyline and to put any insights to use. ARSA is getting the information to policymakers drafting the next stimulus bill (see this month’s “ARSA on the Hill”).

Thanks to more than 100 member companies that took the time to respond to survey—that type of input is critical.

Anti-Viral Measures

Grim Picture of Pandemic’s Impact on Aviation Maintenance

To keep tabs on all of ARSA’s work related to the current pandemic, visit arsa.org/anti-viral-measures.

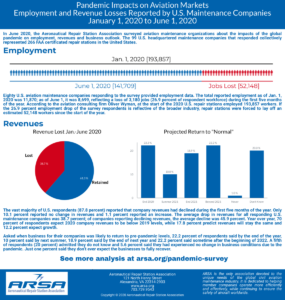

Click here to expand the InfoGraphic; you may save a copy of the expanded image. To see versions of the graphic with only employment or revenue data, visit http://arsa.org/news-media/economic-data.

The aviation maintenance industry has been decimated by coronavirus-related economic disruptions, a survey by ARSA found. ARSA members reported widespread revenue declines that have in turn led to significant job losses. In the face of continued economic uncertainty, the survey results suggest more layoffs are imminent.

The overwhelming majority (87.8 percent) of U.S. respondents to ARSA’s June survey of FAA-certificated repair stations reported revenue declines in the first five months of the year, with an average drop of 45.9 percent from 2019 levels. Not surprisingly, 70 percent of respondents expect this year’s revenues to fall below 2019’s.

Economic volatility has led to big job losses. Aggregate employment at responding companies fell 26.8 percent, from 11,879 workers on Jan. 1 to 8,699 on June 1. If the survey results are projected across the entire maintenance industry – which had 193,857 workers as of March 9, 2020 – American repair stations may have lost more than 50,000 workers since the beginning of the year. ARSA’s findings mirror those of the Bureau of Labor Statistics, which recently reported a 25 percent reduction in year-over-year aviation industry employment.

“Maintenance companies are desperate to hold on to the technical talent they’ve worked so hard to cultivate,” ARSA Executive Vice President Christian A. Klein said. “It’s extremely disheartening to watch all these layoffs happen in an industry that just a few months ago was facing severe worker shortages. This massive loss of technical talent is going to haunt aviation for years to come.”

CARES Act Helped, But Restrictions and Limitations Likely Cost Jobs

The survey found that workforce reductions are spread unevenly, with 46.9 percent of companies reporting declines in employment, 43.2 percent reporting no change and 9.8 percent adding employees. One apparent factor is federal relief. Employment at companies that received CARES Act Paycheck Protection Program (PPP) loans fell at just 5.8 percent. However, due to various eligibility requirements for the PPP, the payroll support program for airlines and their contractors and other CARES Act programs, many repair stations, both small and large, were unable to tap into federal relief.

The PPP was far and away the most popular federal assistance program identified by survey respondents, with 54.1 percent saying their companies had received its support. Only 9.6 percent received Small Business Administration disaster loans, 4.3 percent received Air Carrier Worker Support grants or loans (aka, payroll support) and 1.5 percent received loans from the special CARES Act fund for repair stations and airlines.

The various tax preferences created by Congress in the face of the pandemic are also likely to benefit some repair stations. More than half (52.2 percent) plan to use the employee retention tax credit, 37.3 percent expect their companies to take advantage of the tax credit for sick and family leave and 32.8 percent plan to use the payroll tax deferral.

“The CARES Act and other recent legislation have saved repair station jobs, but it was clearly a mistake to make relief unavailable to small companies with unique ownership structures and to larger companies that employ the most people – particularly those not located at airports,” Klein said. “To prevent more job losses, as Congress gears up for the next round of stimulus, lawmakers must ensure than any company that needs help can get it. That means continuing the PPP, loosening the strings and making changes to eligibility for ACWS payroll support.”

As Pandemic Continues to Impact Businesses, More Job Cuts Looming

Respondents cited several ways their companies have responded to the pandemic. Two-thirds (66.7 percent) of respondents said their companies had implemented additional sanitizing and clearing of facilities between shifts, 50 percent have encouraged or mandated remote work for eligible employees, and 28.9 percent have instituted shifts to allow employees to socially distance. More companies have apparently instituted wage and salary cuts for administrative and management personal (21.1 percent of respondents) than have cut pay for all employees (14.4 percent).

Most respondents believe the maintenance industry will take a long time to recover and that business will not return to normal until next year at the earliest. Just 22.2 percent of respondents said they expect business conditions to return to pre-pandemic levels by the end of 2020, while 10 percent expect recovery by next summer, 18.9 percent by the end of next year and 22.2 percent sometime after the beginning of 2022. A fifth of respondents (20 percent) admitted they do not know when the business will return to normal and 5.6 percent said they had experienced no change in business conditions in recent months.

Among business impacts cited by survey respondents, 59.5 percent reported a drop in cash on hand, 50 percent noted airline customers have been unwilling to pay for work performed prior to the pandemic, 46.4 percent report non-airline customers have been unwilling to pay their bills, and 42.9 percent report cost increases due to heightened workplace safety measures. A rare bit of good news is that only 9.5 percent report trouble accessing credit.

Business disruptions, cash flow problems and economic uncertainty are casting a shadow over industry employment and more job losses are in the offing. Almost one third of respondents (28.9 percent) plan temporary reductions through end of the year and a tenth plan permanent layoffs. On a more positive note, 37.8 percent of respondents said their companies do not plan to change the number of employees and 13.3 percent plan to add additional workers to the payroll.

A third of respondents believe their business’s very survival is at stake. The ARSA survey asked respondents to indicate on a scale of one to five how concerned they were about their company’s ability to withstand the economic disruptions (one = not at all concerned; five = very concerned). 42.5 percent answered one or two (a low level of concern), but 33.3 percent were pessimistic about their company’s future (answering four or five).

“Whether you’re an optimist or pessimist, no one knows when things will get back to normal,” Klein said. “That lack of certainty is a strong disincentive for companies to invest and hire, so we expect the effects of the pandemic to be felt for a long time and will remain committed to helping the maintenance community mitigate them.”

ARSA’s survey was conducted online in June 2020. Of the 114 companies that respond, 98 were U.S. headquartered maintenance companies representing more than 250 repair station certificates in the United States and approximately two dozen foreign facilities.

FAA Exemptions & Extensions for Operators

To keep tabs on all of ARSA’s work related to the current pandemic, visit arsa.org/anti-viral-measures.

Note: ARSA has been posting guidance, exemptions and other resources to arsa.org/faa-strategy as they become available. Review below to see new content.

In July, the FAA issued and extended a number of exemptions for part 121 and 135 operators

Updated July 30:“Grace Months” Under Part 121 Training Requirements (Corrected Copy) (Extension Issued through Oct. 30, 2020) (Additional extension issued through Dec. 31, 2020)

Updated July 30: “Grace Months” Under Part 135 Training Requirements (Extension issued through Oct. 30, 2020) (Additional extension issued through Dec. 31, 2020)

Updated July 30: Avoiding Touching Certain Cabin/Cockpit Equipment Under Part 121 Training Requirements (Extension issued through July 31, 2020) (Additional extension issued through Nov. 30, 2020)

Updated July 30: Avoiding Touching Certain Cabin/Cockpit Equipment Under Part 135 Training Requirements (Extension issued through July 31, 2020) (Additional extension issued through Nov. 30, 2020)

Added July 14: Partial Grant of Exemption for Carrying Cargo on Main Deck of Transport Category Airplanes Used in Part 121 Operations

ARSA Works

What ARSA Has Done Lately – Second Quarter 2020

Each quarter the board of directors receives reports on the association’s activities and finances. Step into a board member’s shoes by reviewing the financial health and operations, legislative and regulatory reports highlighting advocacy on behalf of aviation safety between April and June 2020:

Financial Health

While the association cash reserves are always low, it is sustaining its membership and income at acceptable levels; with plans for further advocacy and outreach, the board found the financial reports and position acceptable.

Regulatory Advocacy

- Submitted petition for rulemaking to FAA to amend part 43 in order to provide agency flexibility to accept foreign maintenance organization certificates – without issuing its own certification under part 145 – by authorizing such acceptance in the United States’ bilateral aviation safety agreements.

- Participated in virtual meeting of EASA’s Engineering and Maintenance Technical Committee (EM.TEC).

- Reported on Civil Aviation Administration of China (CAAC) guidance regarding its “Simplified Approval Process for OEM’s MROs.”

- Began draft protesting requirements for special consideration of “electronic” recordkeeping.

- Drafting initial report for ARAC part 145 Working Group; participating in weekly meetings to draft acceptable means of compliance document.

Pandemic Response

- Reported on policy updates from both the FAA Aircraft Certification and Flight Standards Services on the use of remote connectivity tools and technologies.

- Reported on Executive Order 13924, “Regulatory Relief to Support Economic Recovery.”

- UrgedS. Treasury Department to interpret CARES Act to ensure repair stations were included in airline contractor relief programs, then reported on agency’s initial clarification regarding those entities operating on airports.

Legislative and Lobbying

- Lobbied Congress and Treasury Department to influence implementation of CARES Act Air Carrier Worker Support Program (ACWSP), including ensuring repair stations have access to $3 billion airline contractor grant/loan program.

- Developed and promoted policy to provide additional economic relief to maintenance industry and enhance repair station access to CARES Act resources (esp., ACWSP and Paycheck Protection Program).

- Coordinated “virtual lobbying day” with ARSA government affairs committee members to brief congressional staffers on ARSA relief proposals.

- Supported efforts to include maintenance data availability language in 2021 National Defense Authorization Act.

- Worked in coalition with Aerospace Industries Association and General Aviation Manufacturers Association to promote Warner-Moran manufacturing and maintenance workforce retention “public private partnership” bill.

- Promoted legislation to expand aviation workforce grant program and update 14 CFR part 147.

- Opposed language in House economic relief bill (HEROES Act) to bar airline recipients of federal relief from expanding use of foreign repair stations.

- Analyzed and monitored Senate FAA certification reform bill (Aircraft Safety and Certification Reform Act of 2020).

Communications and Surveys

- Produced membership recruitment and retention video based on 2020 Conference interviews.

- Began planning to develop additional videos (esp. career pathways) based on interviews.

ARSA in the News – Selected Industry Coverage

MROs Embrace Remote Technology During COVID-19 Crisis

April 22, 2020

Aviation Week

Lindsey Bjerregaard reported on ARSA’s participation in an April 22 AvWeek webinar and the association’s year’s long efforts to move the agency – and industry – forward towards use of remote technologies.

Coalition Letter on Liability Relief Legislation In Response to the Pandemic

May 27, 2020

U.S. Chamber of Commerce

Publication by the U.S. Chamber of a letter supported by ARSA pursuing liability relief for businesses dealing with pandemic impacts. The effort, which was also supported by a larger coalition of stakeholders from many industries, was one of many supported by the association during the quarter.

ARSA Seeks Broader Input from Mx Providers in Survey

June 9, 2020

AIN Online

To expand the reach of “Part II” of its annual survey, ARSA publicized an open invitation via its newsletters as well as media outlets (the member survey administered each spring is sent only to primary member contacts).

ARSA-placed Industry Editorials

| AMT Magazine | What Relief Looks Like | April/May 2020 | Brett Levanto |

| Getting More for Phase IV | June/July 2020 | Christian Klein | |

| Aviation Week | MRO Retention: Add Cooking Classes? | April 2020 | Brett Levanto |

| COVID-19 Podcast: How MROs Can Access Financial Assistance | April 2020 | Christian Klein | |

| The Regulatory Piece Of Remote Connectivity Tools | May 2020 | Sarah MacLeod | |

| Virtual Gatherings Must Still Deal With Reality | June 2020 | Brett Levanto | |

| DOM Magazine | Hold It Up | April 2020 | Brett Levanto |

| One Program at a Time | May 2020 | Brett Levanto | |

| Ahead, Alongside and Behind | June 2020 | Sarah MacLeod |

Surveys

- Quick questions re: Pandemic Response (12 responses) (April), ARSA Activism (nine responses) (May), 2021 Conference Attendance Plans (23 responses) (June).

- Conducted special 2020 mid-year member survey in June to gauge impact of COVID-19 (see full analysis in this edition of the hotline).

Events, Meetings and Training

Events

Investigating how to provide multiple formats for the 2021 ARSA Conference – live (to accommodate the hotel contract), live-streaming with ability to interact and taped.

Meetings

- Christian conducted a brainstorming session with government affairs committee members to discuss the next round of COVID-19 relief (April 8).

- Sarah participated in a series of calls with FAA and allied organizations regarding the agency’s operational status (April 1 and 22).

- Christian and Sarah participated in a call with Department of Defense personnel on legislation to improve access to detailed manufacturing process information (April 22).

- Brett presented during Aviation Week webinar on pandemic impacts and regulatory compliance, focusing on remote connectivity (April 22).

- Sarah participated in the EASA EM.TEC meeting (May 5).

- Christian participated in the U.S. Chamber of Commerce’s “State of the Aviation and Travel Industry” call (May 12).

- Sarah and Brett presented during Helicopter Association International webinar on maintenance and training compliance during pandemic (May 14).

- Sarah and Brett participated in the FAA’s aviation safety virtual town hall meeting (May 14).

- Christian participated in the TSA Aviation Safety Advisory Committee meeting (May 19).

- Christian participated in Bloomberg’s 2020 Spring Hill Watch with Sen. John Thune (R-S.D.) (May 28).

- Christian and Brett participated in a meeting with FAA’s senior workforce team members on the status of the FAA workforce grant program (May 28).

- Christian participated in a call with Deputy Secretary of the Air Force for Logistics and Product Support Angie Tymofichuk regarding DOD’s acceptance of FAA approvals (June 3).

- Christian participated in an ASAC call regarding the Air Cargo Subcommittee’s Known Shipper Program (June 9).

- Christian and Brett participated in a series of webinars regarding association conference and meeting issues related to COVID-19 (June 17).

- Christian and Brett participated in the FAA’s general aviation virtual townhall meeting (June 18).

- Sarah and Brett participated in a call with Government Accountability Office personnel regarding FAA workforce development and training

- Christian and Brett participated in a call with Government Accountability Office personnel regarding CARES Act implementation (June 25).

- Christian and Brett participated in a call with FAA’s senior workforce team members and association allies regarding apprenticeship programs (June 25).

Online Training

Growing Maintenance via Youth Task Force

On July 17, U.S. Transportation Secretary Elaine Chao announced the appointment of 20 representatives to the Youth Access to American Jobs in Aviation Task Force. The task force’s creation was mandated by the 2018 FAA reauthorization law to encourage high school students to pursue careers in aviation. ARSA Vice President of Operations Brett Levanto will represent aircraft repair stations.

The task force will recommend strategies for the FAA to:

(1) Facilitate and encourage U.S. high school students to enroll in and complete career and technical education courses, including science, technology, engineering, and mathematics (STEM).

(2) Facilitate and encourage these students to enroll in a course of study related to an aviation career, including aviation manufacturing, engineering, and maintenance.

(3) Identify and develop pathways for students to secure registered apprenticeships, workforce development programs, or careers in the aviation industry of the United States.

Stay tuned for updates as Levanto and the other 19 representatives get to work. ARSA encourages industry members to support the effort by sharing workforce development thoughts, questions, needs or lessons learned to arsa.org/contact.

To review the list of task force appointees, click here.

To learn more about the task force via the FAA’s website, click here.

Final Documents/Your Two Cents

This list includes Federal Register publications, such as final rules, Advisory Circulars and policy statements, as well as proposed rules and policies of interest to ARSA members.

Legal Brief

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

Sticks, Stones and Electronic Records

By Sarah MacLeod, Executive Director

Before paper was created, man chiseled stone; reading the tablet didn’t require knowing where the stone was mined or the chisel made. Society refined and technology advanced to dragging the right kind of stick across flat paper, leaving legible marks. Surely, nobody demanded to know the production methods for pencils or ink pens to find compliance with laws written in the new medium. Typewriters and word processors allowed the press of a finger to mark the page…those marks turned ink into perfectly readable letters without confirming the makes or models of the storage and printing devices.

It seems that technology has advanced to the point where we get so nervous about the medium that we lose the message. Using electronic media to create, sign and store records are no different than their predecessors; they are no more vulnerable to falsification, loss or destruction than stone or paper. Modern methods, however, have been under intense scrutiny for over two decades by civil aviation authorities.

In America, you supposedly need a special approval added to your certificate to use “electronic manuals”. The “requirement” cannot be found in regulation or law, but if the manual is provided to personnel through a computer, it is considered “electronic” and “requires” the agency to issue its “permission.” The requirement to have today’s stone tablets “approved” needs to be vigorously challenged if the industry is ever going to adopt block-chain tools or any other stone replacement efficiencies.

For U.S. repair stations, a rule change two decades ago clearly enunciated the expectation that the “media” by which manuals and other required documents would be created, stored and made available was up to the certificate holder. The agency’s preamble said the government’s focus would be on the fact that the documents were available and current, rather than the method by which that requirement was met—the certificate holder could use hammer and chisel or a document management system controlled by IT administration.

As is often the case, the plain language of a regulation and its meaning and intent from preambles is lost in the development of guidance material that does not change with or follow the rule. Certificate holders are reluctant to challenge the agency demand since few are reading the regulations themselves or truly understand the extent and nature of the government’s legal authority. The local inspector can certainly make life difficult, but failure to follow the regulations can be worse. In the end, when failure to take advantage of the plain language of a rule is stymied by ignorance or reluctance to “buck” the system, the entire industry’s efforts to become efficient suffers.

It appears that sticks and stones can keep perfect records, but a digital file can really hurt us.

ARSA on the Hill

When It Rains It Pours

By Christian A. Klein, Executive Vice President

As the hotline went to press, House and Senate leaders continued to negotiate with ARSA actively working to shape follow-up legislation to the $3 trillion CARES Act. At the same time, the association finds its continuing to defend the maintenance industry from anti-repair station legislation while promoting industry-wide priorities.

The Democratically-controlled House of Representatives passed its follow-on bill, the HEROES Act, in mid-May. The Senate’s GOP leaders took a “go-slow” approach to assess the effectiveness of the CARES Act before moving additional legislation. However, with the CARES Act’s additional $600 per week unemployment benefit set to expire at the end of July and coronavirus cases surging, the Senate was finally forced into the debate.

The $1 trillion plan unveiled by Senate Majority Leader Mitch McConnell (R-Ky.) on July 27, with its $1,200 stimulus checks for some taxpayers and a reduction of the CARES Act unemployment benefit to $200, was assailed from both sides of the aisle. Crafting a bill that could win enough Republican and Democratic votes to pass the Senate is a challenge. As McConnel said: “I think it’s a statement of the obvious, that I have members who are all over the lot on this. There are some members who think we’ve already done enough, other members who think we need to do more. This is a complicated problem.”

Key points of disagreement between the parties are the appropriate level of assistance for state and local governments (Democrats have called for $1 trillion), whether to continue additional unemployment benefits (which Republicans say disincentives returning to work) and protecting businesses, health care providers and others from coronavirus-related lawsuits (a GOP priority – supported by ARSA – that McConnell considers essential).

As the debate on the Hill continues, ARSA is working with allies on a number of proposals to sustain repair stations and help the maintenance industry recover:

- Protecting aerospace jobs. Senators Jerry Moran (R-Ks.) and Mark Warner (D-Va.) ( 3705) proposed creating a new public-private partnership to protect jobs at aviation manufacturing and maintenance companies. ARSA is working in tandem with the Aerospace Industries Association (AIA) and the General Aviation Manufacturers Association (GAMA) to build support for the plan, which would allow manufacturers and repair stations to receive support to pay up to half the compensation for up to a quarter of their workers.

- Expanding eligibility for the CARES Acts Air Carrier Worker Support (ACWS or “payroll support”) program. As drafted, the CARES Act is unclear about whether repair stations not located at airports are eligible for payroll support. ARSA has proposed language clarifying that anyone providing maintenance services to pursuant to 14 CFR part 43 in the United States would eligible for payroll support, regardless of where the work is performed. Labor unions are lobbying to continue the ACWS program, but there is risk that Congress will not double down on the program but instead let it expire, which would render the issue of clarifying eligibility moot.

- Forcing the FAA to update 14 CFR part 147. While reforming the way technicians are educated at FAA certificated schools might not seem to fit neatly into the category of coronavirus relief, ARSA is thinking long term. Before the pandemic struck, the industry was facing a severe technician shortage. When aviation comes roaring back, it will need even more people to maintain the global fleet. ARSA and its allies at the Aviation Technician Education Council and Aircraft Mechanics Fraternal Association have been meeting virtually with congressional offices to make the case that updating part 147 would be like hitting the reset button for the aviation workforce and position the industry for future success. The PARTT 147 Act (R. 5427 and S. 3043), is supported by industry, labor and academia and has bipartisan support in both chambers. However, it’s unclear whether Congress will be willing to think as expansively as the industry does and include the PARTT 147 Act in the next relief bill.

- Extending the Paycheck Protection Program and streamlining loan forgiveness. More than half the respondents to ARSA’s recent member survey reported receiving CARES Act PPP loans. ARSA supports extending the program and making it easier for companies that have already borrowed to have their loans forgiven. We’ve joined a broad coalition supporting legislation to forgive all PPP loans of less than $150,000 upon the borrower’s completion of a simple, one-page document. It’s estimated this would save business owners $7 billion worth of time that would otherwise be spent just filling out paperwork. ARSA has also urged Congress to make it easier for small companies that have private equity backing or other unique ownership structures to participate in PPP.

As you can see throughout this edition of the hotline, ARSA is engaging on multiple fronts—get involved by sending an email to christian.klein@arsa.org.

|

Want to Learn More About ARSA PAC? ARSA’s Political Action Committee helps elect congressional candidates who share ARSA’s commitment to better regulation and a strong aviation maintenance sector. In this critical election year, ARSA PAC has never been more important. But ARSA is prohibited from sending PAC information to members who haven’t opted in to receive it. Please take a second to give us prior approval to talk to you about ARSA PAC. Doing so in no way obligates you to support PAC. It just opens the lines of communication. Click here to give ARSA your consent today. |

House T&I Committee Reports Anti-Repair Station Bill

On July 29, the House Transportation & Infrastructure Committee reported the Safe Aircraft Maintenance Standards Act (H.R. 5119). Dubbed “the anti-repair station bill,” the legislation would cause significant disruptions for the global aviation maintenance industry, U.S. air carriers, passengers and cargo shippers, general aviation operators and aerospace manufacturers. ARSA is leading a coalition of 10 organizations to defeat the legislation.

Given that H.R. 5119 was approved by the House T&I Committee last November, it’s unclear why the House T&I Committee leaders have chosen this moment to report it to the full House. The bill has been added to the Union Calendar, which means it is ripe for consideration on the House floor. Adding fuel to the fire, detrimental repair station language was included in the second major coronavirus relief passed by the House earlier this summer, so its clear that anti-repair station lawmakers and their union allies are determined to impose new restrictions on contract maintenance. ARSA opposes using regulatory policy and false safety arguments to achieve labor’s economic objectives. H.R. 5119 would make it even harder to recover the present economic crisis.

What you can do to help prevent H.R. 5119 from becoming law? Visit arsa.org/legislative/hr5119-actioncenter.

House Passes Transpo Approps Package with Workforce Grant Funding

On July 31, the House passed a package of FY 2021 appropriations bills, including one for the Department of Transportation. The good news is H.R. 7617 includes $5 million to fully fund the aviation technician workforce development grant program ARSA helped create. Given that the FAA has yet to initiate it (despite the program receiving full funding for FY 2020), the bill also requests the agency provide a status report.

The package would also provide $18.1 billion for the Federal Aviation Administration (FAA), an increase of $522 million above the FY 2020 enacted level. Of that, $1.5 billion would be available for aviation safety programs ($96 million more than was appropriated last year).

The outlook for the bill is unclear. The Senate Appropriations Committee has yet to pass its annual transportation funding bill. President Trump has also threatened to veto the House package (which also includes funding for the Departments of Defense, Commerce, Homeland Security, Education and others) over a range of issues, including renaming military bases named after Confederate officers, money for the president’s border wall, restricting federal contracts with companies in which the president, vice president or their families have more than a 20 percent ownership stake and a requirement that airline passengers and crew wear masks to reduce the spread of coronavirus.

Training

Three Perspectives on Recordkeeping

Proper maintenance demands proper documentation. Review the association’s recordkeeping sessions – led by Sarah MacLeod and Marshall S. Filler – and learn how to “finish the job with proper paperwork.”

Recordkeeping for Mechanics

Instructor: Sarah MacLeod

This session defines the regulatory responsibilities of the operator versus the maintenance provider in creating and maintaining maintenance records, including how obligations can be shifted by contract, but not under aviation safety regulations. It also covers maintenance recordkeeping regulations; the documents essential to making airworthiness determinations.

Click here to register and get access for 90 days.

Recordkeeping for Repair Stations

Instructor: Sarah MacLeod

This session delineates the differences between operator maintenance records and those required to be created, maintained and provided by repair stations.

Click here to register and get access for 90 days.

Recordkeeping for Airlines

Instructor: Marshall S. Filler

Air carriers have unique recordkeeping requirements under parts 121 and 135 that do not match the requirements for transferring an aircraft under part 91 or obtaining maintenance records from individual mechanics or repair stations under part 43. This session differentiates among and between the varying requirements so regulatory and contractual obligations can be clearly delineated.

Click here to register and get access for 90 days.

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

What training do you need? Contact ARSA to let the association know and help get it developed.

TED-Ed – Turbulent Times

“Turbulent” is one of the many descriptors for the unstable state of the pandemic-stricken world (as described by ARSA’s mid-year survey results). In aviation, “turbulence” has been and remains a mysterious but familiar phenomenon. Take a break from the turbulence of the times for a brief lesson from TED-Ed:

To jump to the TED website, click here.

Part 21 [Series]

Marshall S. Filler’s three-part series on 14 CFR part 21, “Certification Procedures for Products and Articles” is available for unlimited on-demand viewing.

Want all three sessions? Click here to purchase them together and save.

Part 21 – Overview

This session provides an overview of the aviation safety regulations governing design and production of civil aviation products and articles as well as airworthiness certification of civil aircraft.

Click here to register and get access for 90 days.

Part 21 – Design Approvals & Design Changes

This session reviews the elements necessary to obtain design approvals for civil aviation products, including type certificates, amended type certificates and supplemental type certificates. It will explain the requirements for obtaining approval of design changes to those certificates including the changed product rule. Finally, it will describe the design requirements for obtaining a parts manufacturer approval and technical standard order authorization, and for obtaining approval of design changes to those articles.

Click here to register and get access for 90 days.

Part 21 – Production Approvals

This session explains the requirements for obtaining a production approval for civil aviation products and articles as well as the elements of an FAA-approved quality system and the method for making revisions to that system. It also addresses the privileges and responsibilities of production approval holders including the issuance of airworthiness approvals and authorized release documents for aircraft engines, propellers and articles.

Click here to register and get access for 90 days.

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording (registrants may contact ARSA directly with questions or comments).

- A copy of the presentation and all reference material with links to relevant resources and citations.

- Upon completion of the class as well as any test material, a completion certificate.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit PotomacLaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Regulatory Compliance Training

Test your knowledge of 14 CFR § 21.1(b) – Definitions.

Click here to download the training sheet.

Membership

Save the Date for the 2021 Annual Conference

March 9-12, 2021

Washington, D.C. & Arlington, Virginia

ARSA’s team is planning both in-person and virtual attendance options for the 2021 Annual Conference. The event will be hosted in and around Washington, D.C. from March 9-12, 2021. While the association works to ensure a valuable, substantively-enriching experience for all of its attendees, members and colleagues should make sure their calendars are blocked for those four days in March. (Click here to download an Outlook Calendar appointment to block your time.)

What began decades ago as ARSA’s Annual Repair Symposium has evolved into a week-long event including executive branch briefings, grassroots legislative advocacy and world-class regulatory compliance and business content. The event provides a regular venue for members and invited guests from around the world to network and discuss issues that matter to the repair station community.

Update: Registration is open can be found at arsa.org/news-media/events/arsa-conference.

Quick Question – ASIAS

The Department of Transportation’s Office of Inspector General (OIG) is conducting an audit of the FAA’s Aviation Safety Information Analysis and Sharing System (ASIAS) as a congressionally-directed follow up to its 2013 activity on the same subject.

To help the OIG understand whether and how the system is used by repair stations, the association is asking the following questions:

If the embedded survey does not appear/load, open the survey independently by visiting: https://www.surveymonkey.com/r/arsa-qq-asias.

Note: The survey below is in an embedded window and you may need to scroll down within the window to see/click the “Submit” button.

Click here to see what questions have been asked and answered…and keep a lookout for more.

For more information about this or any other question, contact Brett Levanto (brett.levanto@arsa.org).

Welcome Back – Renewing Members

ARSA’s members give the association life – its work on behalf of the maintenance community depends on the commitment of these organizations. Here’s to the companies that renewed in July:

Renewing Members

AeroKool Aviation Corporation, R04, 2017

AllFlight Corp., R03, 2011

Ameron Global Product Support, R02, 2004

Bemidji Aviation Services, Inc., R04, 2017

Boeing Company, Corp., 1996

Calvin Taff Electronics, Inc., R01, 2003

EXTEX Engineered Products-A Kaman Company, Assoc, 2002

Gyro Specialist, Inc., R01, 2011

Honeywell International, Inc, Corp., 1996

Lynden Air Cargo, LLC, Assoc, 2000

MTU Maintenance Hannover GmbH, R06, 2007

R.W. Raddatz, Inc., R02, 2004

Reb Technologies Inc. DBA Rebtech, R02, 2003

Rotorcraft, Inc, R01, 2019

Skyteam International Company, R01, 2006

Sunshine Aero Industries, Inc., R01, 2003

Southwest Airmotive Corp, R01, 2012

Texas Air Services, Inc., R02, 2003

The Zee Company Inc., R02, 2019

Turbine Standard Ltd, R03, 2003

Warner Propeller and Governor Co., LLC, R01, 2010

Wencor, Corp., 2018

A Member Asked…

Q: Our training department developed some aircraft type training for our technicians following ATA 104 guidelines. However, sometimes the legality of this training is questioned by companies used to seeing approval documentation from a CAA, such as EASA 147 or from FAA. Is there a correct or a proper way to answer such inquiries that would convince our customers that our company is not doing anything wrong?

A. ARSA doesn’t always know how to battle ignorance of customers (or inspectors or anyone else), but here are some thoughts for addressing the issue.

14 CFR part 145 requires an approved training program: Courses, classes and other learning experiences are developed under the auspices of that program (see § 145.163). If the program develops and documents the courses and any “testing” or “competence” showing from those learning experiences, they should be as acceptable as sending someone to an “OEM” course or class and in some cases, the repair station’s courses or learning experiences are going to be better.

So, does your training program manual outline how courses are developed, provided, learning is verified (test or demonstration) and documented? Any of the above? If so, you should have no issues convincing customers that you are doing what is REQUIRED BY THE RULE – the training program is required to “ensure each employee assigned to perform maintenance, preventive maintenance, or alterations, and inspection functions is capable of performing the assigned task.” (Read, § 145.163(b).)

When training is required, such as what you are describing, the repair station’s program for developing and providing that training is an APPROVED method of showing compliance. If your program needs a bit of massaging to make it more professional in outcome, so be it, but it IS the method by which U.S. repair stations are to ensure their people know what the heck they are doing! How that can be “wrong” is a mystery to ARSA.

Member questions should be submitted directly to the association’s team via arsa.org/contact.

Make ARSA’s Voice Your Own: Advertise

ARSA has a menu of advertising opportunities for arsa.org, the hotline and the ARSA Dispatch. Take advantage of these great opportunities today to showcase your company, a new product or event. For more information go to arsa.org/advertise.

Stand Up for ARSA

In order to provide world-class resources for its members, the association depends on the commitment of the aviation community. By sponsoring events and activities, supporters can help ARSA’s work on behalf of repair stations to endure.

Need a place to start? For information about opportunities, contact Vice President of Operations Brett Levanto (brett.levanto@arsa.org).

Resources

ARSA strives to provide resources to educate the general public about the work of the association’s member organizations; should you need to provide a quick reference or introductory overview to the global MRO industry, please utilize AVMRO.ARSA.org.

Anti-Viral Measures

For the use of its members and the larger aviation community, ARSA is maintaining this page as a resource for pandemic-related updates on policy initiatives and business needs. It is the association’s central point of communication on the topic

H.R. 5119 – Contract Maintenance Under Attack

Help combat a bill introduced in the U.S. Congress that would disrupt the global aviation industry.

Industry News Roundup

ARSA monitors media coverage on aviation maintenance to spread the word about the valuable role repair stations play globally by providing jobs and economic opportunities and in civic engagement. These are some of this month’s top stories highlighting the industry’s contributions. You can explore these stories through ARSA’s Dispatch news portal.

Industry Calendar

| Conference | Dates | Location |

| ATEC Annual Conference | 9/13-16/2020 | Virtual Platform |

| MRO Asia-Pacific | 9/22-24/2020 | Virtual Platform |

| FlightGlobal Big Data Americas Cancelled | 9/29-30/2020 | Seattle, WA |

| Business Aviation Convention & Exhibition (NBAA-BACE) Cancelled | 10/06-08/2020 | Orlando, FL |

| MARPA Annual Conference | 10/21-22/2020 | Virtual Platform |

| MRO TransAtlantic | 10/27-29/2020 | Virtual Platform |

| MRO Middle East Summit & Expo | 3/1-3/2021 | Dubai, UAE |

| ARSA Annual Conference | 3/9-12/2021 | Washington, DC |

| HAI Heli-Expo | 3/22-25/2021 | New Orleans, LA |

| Aviation Safety Infoshare | 4/20-22/2021 | St. Louis, MO |

| MRO Americas | 4/27-29/2021 | Orlando, FL |

| EASA-FAA International Aviation Safety Conference | 6/2021 | TBD |

| MRO Beer | 6/2021 | Istanbul, Turkey |

| RAA 45th Annual Convention | 9/25-28/2021 | Phoenix, AZ |

| MRO Europe | 10/19-21/2021 | Amsterdam, The Netherlands |

the hotline is the monthly publication of the Aeronautical Repair Station Association (ARSA), the not-for-profit international trade association for certificated repair stations. It is for the exclusive use of ARSA members and federal employees on the ARSA mailing list. For a membership application, please call 703.739.9543 or visit arsa.org/membership/join. For information about previous editions, submit a request through arsa.org/contact. This material is provided for educational and informational purposes only. It does not constitute legal, consulting, tax or any other type of professional advice. Law, regulations, guidance and government policies change frequently. While ARSA updates this material, we do not guarantee its accuracy. In addition, the application of this material to a particular situation is always dependent on the facts and circumstances involved. The use of this material is therefore at your own risk. All content in the hotline, except where indicated otherwise, is the property of ARSA. This content may not be reproduced, distributed or displayed, nor may derivatives or presentations be created from it in whole or in part, in any manner without the prior written consent of ARSA. ARSA grants its members a non-exclusive license to reproduce the content of the hotline. Employees of member organizations are the only parties authorized to receive a duplicate of the hotline. ARSA reserves all remaining rights and will use any means necessary to protect its intellectual property.

© 2020 Aeronautical Repair Station Association