2024 – Edition 5 – June 7

Table of Contents

Note: The order of material varies in hotline emails, but is always presented the same on this landing page. Readers scrolling through content on or printing this page will find it organized consistent with the table of contents.

President’s Desk

Conference Corner

ARSA Works

Legal Briefs

ARSA on the Hill

Training

Membership

Resources

Industry Calendar

The President’s Desk

A Cast of Thousands

ARSA’s persistence helped push the FAA to face its inconsistent enforcement of instructions for continued airworthiness (ICA, or “maintenance manuals”) requirements. The effort’s rocky start is a lesson in long-term policy.

Title 14 CFR § 21.50(b) and its predecessors require design approval holders (DAH) to prepare and make ICA available to persons required to comply with those instructions. Owners ensure the information is followed and maintenance providers are often required to possess and/or perform maintenance in accordance with information provided by the manufacturer (see §§ 43.13, 145.51 and 145.109).

However, DAHs can refuse to make ICA available to repair stations, insist on onerous licensing schemes, or charge unreasonable prices for the information “essential to continued airworthiness.” For decades, ARSA and its members have pursued various regulatory and legal strategies to encourage equitable enforcement of the ICA rules, but the FAA has refused to act.

In another attempt to get the disparate treatment addressed, ARSA and 13 allies petitioned the agency to create a committee to recommend improvements to the ICA regulatory framework. When the FAA didn’t move on the petition, ARSA and its members took the issue to Capitol Hill. As a result, Sec. 349 of the new FAA authorization law directs the agency to create an ICA Aviation Rulemaking Committee (ARC).

Recognizing that congressional action was inevitable, the FAA announced the creation of an ICA ARC in January 2024. ARSA was asked to join, and its former president Josh Krotec (First Aviation) was named industry co-chair. So far so good. But when the ARC held its first meeting on May 14, more than 50 industry association and company representatives participated, along with 26 FAA personnel. Can a body that big accomplish anything?

There’s an old joke that a camel is a horse designed by a committee. Congress often creates agency committees and working groups to wade into divisive issues. In this case, ARSA itself asked for the committee because it didn’t want Congress to impose a solution on industry without a full vetting of the issues. The ARC was always intended to be inclusive and bring representatives of all relevant stakeholders to the table, but not to be a “cast of thousands” (or, in this case, close to 100).

Instead of populating the ARC with a diverse handful of experts with deep knowledge of the issues who can speak for their industry sector – the much-followed ODA expert panel had 20 members, the Youth Task Force created by the last authorization had 22 – the FAA has allowed the committee to grow out of control. Large bodies risk watering down results: Participants slow play agreeable solutions to defend their individual turf.

The FAA’s construction may make a positive ARC outcome more difficult – maybe that’s the point – but ARSA has vast experience working divisive issues through committees. Whether there are nine participants or 90, a smart committee member can steer final products in a way that leads to the next step in making positive change. While we all wish this ARC were the last step, the reality is that our association is ready for continued work…while celebrating the real but slow progress we’ve produced so far.

|

Gary Fortner 2024 ARSA president | Fortner Engineering & Manufacturing, Inc. vice president of engineering |

Conference Corner

From Legislative Day to Reauthorization

On March 13, Executive Vice President Christian Klein welcomed lobbyists from ally organizations to the Legislative Day stage to broadly discuss Congress’ ongoing effort to reauthorize the FAA. On that day, the briefing helped attendees show their elected officials how best to serve the industry; today, look back and see how that work translated into a new authorization for the agency.

To learn more about the association’s legislative program, visit arsa.org/legislative.

FAA Reauthorization: Industry Perspectives ![]()

Representatives of ARSA ally organizations discuss their priorities in the current FAA reauthorization and share insights about the likelihood of an FAA bill being enacted in 2024.

Karen Huggard, Vice President of Government Affairs, National Air Transportation Association

Jarrod Thompson, Vice President for Legislative and Regulatory Policy, Airlines for America

Sterling Wiggins, Senior Director, Transportation, Infrastructure, and Supply Chains, U.S. Chamber of Commerce

Save the date to take part next year: March 18-21, 2025

ARSA Works

Crawfish with Charlie

Charles Taylor

Charles Taylor, the Wright Brothers’ mechanic and father of aviation maintenance, was born on May 24, 1868. Now – 156 years later – we celebrate him through continued commitment to good work.

In 2008, a congressional resolution dedicated the date in honor of Taylor, establishing National Aviation Maintenance Technician Day. While the “holiday” doesn’t get anyone out of work (there are no days off from aviation safety), it’s important to celebrate the commitment, integrity and skill of every aircraft mechanic and all those who support them – this is Taylor’s legacy and our shared responsibility.

ARSA member Fairhope Aerospace in Fairhope, Alabama shared their southern-style celebration of Charlie. The company hosted a crawfish boil on May 24 for all of its staff; the crustacean delicacy was paired with a presentation about Taylor’s legacy and aviation safety. Also, technicians were given tool truck credits and a metallic model of the Wright Flyer (whether they put it together themselves or bring it home to their kids is up to each technician).

Hopefully all ARSA members recognized AMT Day this year. The association is grateful to Fairhope for sharing its activities and wants to hear about your company’s celebration of Taylor’s legacy and the vital importance of your people to the aviation community’s future (Contact ARSA to share your story.)

No matter how you celebrated AMT Day, it’s a small bit of well-deserved recognition. Thank you for your hard work, dedication and support.

The world can’t fly without you.

Click an image below to expand.

FAA Explains Position on EASA Form 1 Triple Release

In a May 23 letter to ARSA, the FAA clarified its position on the use of European Union Aviation Safety Agency (EASA) Form 1 as a triple release by EU maintenance organizations approved by the FAA under its bilateral agreement with EASA.

A Jan. 14, 2023, memo from the FAA’s International Field Management Branch created confusion. The sentence “Triple releases can only be issued by EASA Part 145 approved AMOs in the EU members [sic.] states.” was read by some to imply that such releases may only include the FAA, EASA, and Transport Canada Civil Aviation (TCCA). This, in turn, led to questions about FAA’s acceptance of EASA Form 1 as an EASA-FAA-Agência Nacional de Aviação Civil (ANAC Brazil) triple release when issued by an EU approved maintenance organization (AMO) under the applicable bilateral agreements (i.e., between the FAA and EASA and between EASA and ANAC).

“The AFS-54 memorandum was intended only to provide FAA guidance regarding EU AMOs issuing EASA-FAA-TCCA triple releases; it does not prohibit the issuance of EASA Form 1 as a multiple release involving other Civil Aviation Authorities (CAA) when consistent with EASA rules and international agreements,” the FAA’s May 23, 2024 letter to ARSA said. “The FAA has no objection to an EU AMO issuing EASA Form 1 as a multiple release for work performed under the U.S.-EU bilateral agreement and any other agreement between the EU and another CAA.”

Although ARSA welcomes the FAA’s clarification about when it will accept EASA Form 1 as a triple release, ARSA members are reminded that EASA is the final authority on Form 1’s use.

To read the full letter, click here.

Further Clarifying Part 145 using “Current Data” Proposal

On May 1, ARSA and three other trade associations commented on the FAA’s notice of proposed rulemaking addressing “miscellaneous maintenance-related updates.” The NPRM would remove the requirement from § 145.109 that repair stations maintain “current and accessible” versions of certain documents and data; it would also clarify language in §§ 145.201 and 145.217 regarding the privilege of contracting maintenance functions.

The group praised the FAA’s proposal, noting “[the] agency and industry have struggled with inconsistent language within part 145 for many years. [ARSA and its allies] strongly support making the language in part 145 consistent and clarifying the verbiage and intent.”

The comments showed that support by highlighting several points in part 145 the rulemaking can also amend to improve consistency and clarity. These edits would align the responsibilities of applicants and certificate holders regarding data availability and also match the standard in § 43.9(a)(4) that maintenance providers approve only the work performed on an article for return to service.

The comments provide suggested edits to the following sections: §§ 145.5, 145.51, 145.53, 145.101, 145.109, 145.201, 145.205, 145.211, 145.217, 145.219, and 145.223.

To review the complete comments, click here.

To see the 2010 legal interpretation referenced in the comments, click here.

In addition to ARSA, the submission was supported by the Aircraft Electronics Association, the Aviation Suppliers Association, and the Modification and Replacement Parts Association.

Final Documents/Your Two Cents

This list includes Federal Register publications, such as final rules, Advisory Circulars and policy statements, as well as proposed rules and policies of interest to ARSA members.

Legal Briefs

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

Criminality

By Christian Klein, Executive Vice President

A common question during the alleged parts fraud by U.K.-based AOG Technics was, “why isn’t there a law preventing this?” There are numerous U.S. laws and regulations prohibiting fraudulent activity but enforcing those laws in America and overseas is a challenge.

18 U.S.C. Sec. 1001 is the catch-all federal anti-fraud statute. It prohibits “in any matter within the jurisdiction of the executive, legislative, or judicial branch of the Government of the United States, knowingly and willfully”:

- Falsifying, concealing, or covering up any trick, scheme, or device, a material fact.

- Making any materially false, fictitious, or fraudulent statement or representation.

- Making or using any false writing or document knowing the same to contain any false, fictious, or fraudulent statement or entry.

Violations of that statute are punishable by fines and imprisonment for up to five years. Similarly, 18 U.S.C. Sec. 1341 and 1343 respectively prohibit mail and wire fraud. Violations are punishable by fines and up to 20 years in prison.

When considering international enforcement of U.S. criminal laws, first, there’s the question of whether the law applies overseas. If it is silent on that issue, it will generally be interpreted only to apply on U.S. territory. On the other hand, a law may explicitly state that it applies extraterritorially or list factors under which jurisdiction is extended beyond U.S. borders.

American laws may also be found to extend overseas when someone abroad commits an act that results in prohibited conduct in the United States (for example, selling someone in the United States an aircraft part based on false statements). Given that 18 U.S.C. 1001 applies to “matters within the jurisdiction of any department or agency of the United States,” it is hard to argue it would not apply to a falsified record. And 18 U.S.C. sec. 1343 applies to both interstate and foreign commerce.

But even if the law applies outside the United States, there are other legal and practical challenges, including the overseas application of Constitutional protections, conducting investigations in foreign countries (and the value of evidence from foreign sources), extraditing the accused, and where in America the trial should be held.

The foreign application of U.S. regulations is somewhat different in that the foreign citizen has voluntarily subjected themselves to the jurisdiction of U.S. regulatory agencies. For example, a foreign facility seeking an FAA repair station certificate agrees to comply with applicable laws and regulations in exchange for receiving the certificate. If it fails to comply (e.g., by making false statements in maintenance records), the company is subject to the agency’s enforcement action. Potential criminal activities will be referred to the U.S. Justice Department for prosecution. Of course, that’s not much help when a company doesn’t have a U.S. certificate or U.S. presence.

Criminal laws and regulations deter bad actors but don’t prevent them. Regardless of what the law says, there will always be people who try to commit fraud for a fast buck. Those best able to prevent fraud are well-trained industry professionals with sufficient experience to spot it and evaluate whether an article is eligible for installation on an aircraft, regardless of what the paperwork says. This point was demonstrated by the AOG Technics case, in which the allegedly fraudulent paperwork was first detected by a technician in Portugal doing his job. Ultimately, it’s the industry, not the government that’s responsible for safety.

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

Layman Lawyer – Anal Retentive

By Brett Levanto, Vice President of Operations

During review of an association editorial, a copy editor sought clarification of the following:

The ‘miscellaneous’ rulemaking provided an opportunity to reconcile Part 145 with the standard in Part 43 that the work performed is approved for return to service, not the article.

Specifically, this lay reader didn’t understand what “not the article” meant and sought assistance. While the concern was readability for a broad audience, critical attention to detail is vital for layman dealing with regulatory language.

The editorial in question reviewed ARSA’s comments on the FAA’s notice of proposed rulemaking (NPRM) that would remove from § 145.109 the requirement that repair stations maintain “current and accessible” versions of certain documents and data. It would also clarify language in §§ 145.201 and 145.217 regarding the privilege of contracting maintenance functions.

The association – and the three allied organizations – supported the proposal with 21 pages of additional edits to 11 other sections of part 145.

Why? Because survival in a heavily regulated industry demands an anal-retentive skillset. The capability to be extremely or excessively neat, careful, or precise (check Webster’s “non-technical” definition) may be natural for legal minds, but layman tend to read every other word. Fortunately, the legal minds leading ARSA’s regulatory compliance program focus on consistency and clarity in the plain language of a sentence, paragraph, and thankfully, related and multiple sections of regulations.

The rabbit hole led to pages of comments to point out and correct inconsistencies with the basic standards for maintenance performed by a repair station, which must be in accordance with part 43.

A simple but important comment relates to the incorrect reference to the approval of articles for return to service contrary to what the signature in § 43.9(a)(4) constitutes. The correct reference is to “the approval for return to service only for the work performed.” That approval cannot be issued until after that work is determined to have been performed satisfactorily.

Another practical application of anal retentiveness was found in the “miscellaneous” NPRM attempt to remove the requirement for repair stations to keep “current” versions of the documents and data listed in § 145.109(d). In 2019, ARSA petitioned for this exact change, since part 43 requires no other person performing maintenance to meet this standard. Further, at least one legal interpretation determined that using non-current versions of maintenance data could be an acceptable method, technique, or practice under § 43.13(a). However, the ARSA team is smarter now than it was five years ago. This year’s review of the language revealed multiple areas where repair stations are required to hold “current” data. Adhering to the plain language of regulations, like one requiring the quality control manual include information on establishing and maintaining current technical data, would put certificate holders in the middle of conflicting mandates in the same rule over the same data.

ARSA supported the NPRM’s suggested edits to part 145 but provided pages of commentary to help get all the connecting points aligned. The final rule will probably contain more that needs to be changed. To a copy editor and even many in the industry this might be hard to follow. For the industry, investing this level of attention and the willingness to do it repeatedly is necessary for survival. Getting deep into the details is familiar only to those with a certain anal sensibility.

To read ARSA’s comments on the “miscellaneous” NPRM, click here.

ARSA on the Hill

The Real Work Starts

By Christian Klein, Executive Vice President

The FAA bill signed by President Biden on May 16 included ARSA proposals aimed at improving agency oversight, forcing action on instructions for continued airworthiness (ICAs), and addressing the technician shortage. The signing ceremony marked the successful conclusion of the legislative process, but the implementation process is just starting.

For example, the Sec. 349 Aviation Rulemaking Committee (ARC) to examine issues surrounding ICAs was initiated this year in response both to the ARSA-led 2021 petition and the inevitable congressional mandate. Sarah MacLeod is ARSA’s representative on the ARC, which is co-chaired by immediate past president Josh Krotec (First Aviation). The ARC held its first meeting and has one year to complete its work, after which the FAA has 180 days to initiate a rulemaking or make policy changes based on the committee recommendations.

On the workforce front, ARSA teamed with the Aviation Technician Education Council, member AAR, and others for language easing transition of military technicians to civilian careers. Sec. 426 requires rulemaking to create a military mechanic written competency test and, if necessary, develop an Airman Certification Standard to qualify military technicians for part 65 mechanic certificates. Given the desperate need for technical talent in the maintenance sector, ARSA and its allies will pressure the agency to ensure the rulemaking is done on time (and sooner, if possible).

Another workforce provision, Sec. 405, directs the creation of an FAA working group to evaluate allowing high school students to take the general knowledge portion of the mechanic exam. This provision was requested by ARSA, ATEC, and AAR in response to more high schools offering maintenance curriculum thanks to the good work of Choose Aerospace. Early testing would make it more likely that a graduate stays in the industry. ARSA will apply to participate in this committee.

Sections 821 and 822 were included based on concerns expressed by ARSA and its members about inconsistency both in the application of FAA policy and between regulations and guidance. Sec. 821 directs the Department of Transportation’s Inspector General (DOT IG) to audit FAA’s Flight Standards and Aircraft Certification Services on the consistency of policy and regulatory interpretation and the application of policies, orders, and guidance as they relate to repair stations, supplemental type certificates, and technical standard orders. The provision requires the IG to engage with stakeholders in conducting the evaluation.

Similarly, Sec. 205 requires the agency to establish a review team comprised of FAA employees and outside experts to develop recommendations to improve the timeliness, performance, and accountability of the development and promulgation of regulatory materials. ARSA will apply to participate in this effort.

Including Sec. 302, which unnecessarily increases regulatory burdens on foreign repair stations and their U.S. air carrier customers, is disappointing. Among other things, Sec. 302 gives the FAA 18 months to ensure that supervisors and personnel authorized to approve an article for return to service are certificated as a repairman or mechanic under part 65 or under an equivalent certification or licensing regime. To minimize burdens and uncertainty, the FAA can quickly recognize equivalent foreign certification regimes that comply with the International Civil Aviation Organization’s (ICAO) aircraft maintenance license requirements in Annex 1, Chapter 4, paragraph 4.2 of the Chicago Convention. Sec. 302 also imposes new annual reporting requirements on part 121 air carriers that have heavy maintenance performed at foreign repair stations, restricts the certification and use of repair stations in countries classified as “Category 2” by the FAA’s International Aviation Safety Assessment program, and requires the FAA to perform “surprise” annual inspections of foreign facilities. Look for a deep dive into Sec. 302 in the next hotline.

Those are just a few of the things that will require hard work as the devil is always in the details.

|

Want to Learn More About ARSA PAC? ARSA’s Political Action Committee helps elect congressional candidates who share ARSA’s commitment to better regulation and a strong aviation maintenance sector. In this critical election year, ARSA PAC has never been more important. But ARSA is prohibited from sending PAC information to members who haven’t opted in to receive it. Please take a second to give us prior approval to talk to you about ARSA PAC. Doing so in no way obligates you to support PAC. It just opens the lines of communication. Click here to give ARSA your consent today. |

Finding Your Member of Congress

In the summer of an election year, senators and congressmen want to meet constituents. ARSA members should take advantage of this interest to schedule facility visits, town halls, meet and greets, or any other excuse to spend time with the person representing your business in Congress.

As ARSA Legislative Day participants hear every year, building an ongoing relationship with your elected officials is really a matter of simple effort. The most successful constituents are patient and persistent…and they know how to use a few simple tools for finding their members of Congress.

Who represents you?

Using ARSA’s Legislative Advocacy Tools – provided all year by Conference sponsor Aircraft Electric Motors – find your elected officials by entering your zip code in the “Election Center.” (Remember to enter your personal zip code and also the one for all facilities associated with your company; there may be multiple officials/offices with an interest in your needs.) Get started at arsa.org/congress.

When will they be home?

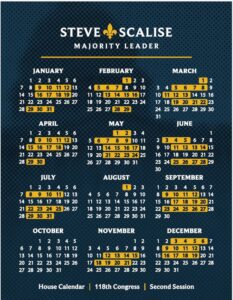

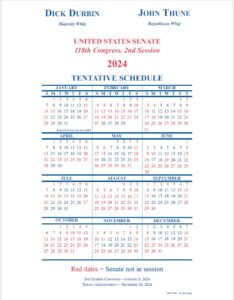

Members of the U.S. Congress try to spend as much time in their states/districts as possible. Both the House and Senate leadership have published session calendars for 2024. By reviewing these calendars, you can determine when your senators and congressman are likely to be “back home” by looking for dates not in session. Review the schedule documents below and find updated information at www.congress.gov/calendars-and-schedules.

| House | Senate | |

|

|

What do you do now?

Contact use the contact resources available at arsa.org/congress to get in touch with the offices that represent you and invite them to visit your facility on one of the dates for “district work.” For talking points and other guidance, visit arsa.org/legislative or contact ARSA.

Aviation Life Calendar

June Through September

Something exciting happens every day in an aviation career.

If you want to keep aviation in the forefront of career choices, celebrate success every day with these resources. Every one provides a positive view of the industry’s ability to make the impossible an everyday event by individuals from every walk of life, socio-economic level, race, creed, color, religion, orientation, and physical capability.

Check back regularly for updates.

| Month | Day | Event or Celebration |

| All | All | This Day in Aviation |

| June | All | This Day in Aviation History – June |

| June | 22 | National Aerobatics Day |

| June | 23 | International Women in Engineering Day |

| July | All | This Day in Aviation History – July |

| July | 20 | Neil Armstrong’s First Moon Walk |

| July | 24 | National Amelia Earhart Day |

| July | 25 | National Hire a Veteran Day |

| August | All | This Day in Aviation History – August |

| August | 16 | National Airborne Day |

| August | 19 | National Aviation Day |

| August | 19 | Orville Wright’s Birthday |

| August | 25 | Amelia Earhart Flies Coast to Coast – Nonstop |

| August | 30 | First African American in Space |

| September | All | This Day in Aviation History – September |

| September | 4 | Global Talent Acquisition Day |

| September | 15 | Hispanic Heritage Month |

Training & Career Development

A Young Farmer’s Wisdom – 2024 Scholarship Winner Brian Hill

ARSA 2024 Scholarship Winner Brian Hill. Photo courtesy Brian Hill.

Meet ARSA’s 2024 Scholarship winner Brian Hill of Pittsburgh Institute of Aeronautics. Hill is a third generation farmer whose hands-on learning began with his first chore assignments at age six and will undoubtedly continue through a long technical career.

Hill’s award was made as part of Choose Aerospace’s Aviation Maintenance Scholarship and Award Program. ARSA and its partner organizations combine to provide tens of thousands of dollars’ worth of scholarships, textbooks, training systems, and testing fee credits for educators and future aviators. The association assisted in reviewing applications for all awards, an exercise that is sure to boost confidence in the industry’s future as the program receives submissions from excellent candidates. Contributions like those made to the scholarship program help student’s like Hill, whose goal is to pay entirely for his own education without going into debt; he described these payments collectively as “an investment, rather than an expense.”

Hill answered a few questions for ARSA’s communications team, clearly investing time and careful thought in his responses. The association encourages its members to get to know this young technician – we can help you meet him if you like:

(1) Your family farming background was clearly a key to both your personal and skill development. How has the troubleshooting and mechanical competence you learned as a youth transferred into developing aviation knowledge?

Yes, growing up on the farm did develop my troubleshooting and mechanical competence. I was servicing and repairing a wide range of equipment: tractors, skid loaders, feed carts, lawn mowers, etc., plus my brother and I were often in the shop until late at night working on our own “toys” (trucks, cars, quads, side by sides, snowmobiles, and a homemade go-cart). We both are mechanically inclined, so we considered ourselves very fortunate to have the right facility and setup, most of the tools we needed, and access to heavier equipment (like a skid loader) to do the job right (and save money by doing it ourselves).

Gaining experience on the farm (10 years), at the Lebanon County Career & Technology Center’s Electromechanical Engineering Technology program (2 years), and with BHM Farm Equipment as a Service Technician (2 years) has presented a variety of things to work on. This has broadened my knowledge and given me more insight on how similar things really are.

So, in a very simplistic way, by understanding the basics of how anything mechanically works, all my abilities actually transfer across the board to anything else with a motor with similar principles. No matter what a person is troubleshooting, it is done systematically. So, whether it is a household item or an airplane – just having the knowledge to know how to assess and identify the solution is a similar process. When it gets way more complex is how many parts are inside the household product to make it run versus how many parts are inside a plane to make it operate… and operate safely. Another key factor in mechanical competency boils down to the man-hours put into learning the various parts, how they work, and what happens when they don’t work. That is why time in training is required for the FAA A&P Certification to ensure an aviation maintenance technician is qualified and well-versed in many areas – safety regulations, electrical systems, power plant, sheet metal, hydraulics, pneumatics, accessory systems, instrumentation and controls, and navigation systems – just to name a few.

So, whether I’m dealing with a loader boom on a tractor, mower deck and transmission on a lawn mower, or the flight controls on a plane – are all hydraulic, and the common denominator is fluid dynamics. Since I have the understanding of fluid dynamics and have had hands-on experience, it is easy to develop, build and elevate my knowledge in aviation. I also think I bring passion, dedication, and attention to detail to the table.

With any maintenance or repair, I enjoy the entire process from start to finish. I like checking into why something isn’t working properly (and making sure that nothing else went awry during the breakdown) and then having the answers to resolve the issue. So, the nose-to-tail expectations of an AMT are very attractive to me. While working with my dad on the farm, no two days were the same (which is what I would expect mirrors the aviation industry), so if every day in the hangar is different, that lights a fire inside me.

I’m excited about working with my hands, having my mind stimulated with troubleshooting challenges, and having the knowledge to resolve them — plus I will be proud that my expertise will positively impact the safety of others.

(2) What has the experience been like with your classmates, particularly in seeing the different backgrounds and pathways that brought others into aviation?

PIA classes are not too large which provides a great opportunity to interact with most classmates during instruction, in labs, the shop, and even on breaks. Even if the assignment in lab that day is one-on-one, we all end up giving input whenever the scenario allows for this exchange, so it feels like we are all on the same team and everyone rallies to help each other. Don’t get me wrong – there is still some (healthy) competitiveness going on among one another – but it is a good thing that actually pushes everyone to their fullest potential.

I was not expecting the variety of my peers’ ages, personal situations, and work backgrounds. Some have come right from high school, others came to PIA AMT school after years of service in the military, and some came from careers, both related and unrelated to the aviation industry. We have classmates with interests/experiences in automotive repair, and/or a work history as an electrician, military servicemen, teacher, and one is even an owner of a brewery who decided he wanted a change and a second career. But honestly, it usually enhances the discussion by someone having a different perspective or by those that have already been out in the workforce.

My first two semesters at PIA have been awesome! The AMT program definitely aligns well with my skills and interests, and I look forward to going to school every single day. I am forming solid friendships with several classmates, and I anticipate keeping in touch with some of my instructors that have already become mentors. It has been a great experience, and I would predict that some of my friendships could last a lifetime because of this shared experience and the interests we have in common.

(3) What have you found to be most surprising/unexpected about AMT school?

I anticipated AMT school would involve very technical, in-depth curriculum (like the ones I mentioned in the first question), as well as the obvious hands-on man-hours in the shop. But I was surprised with how broad the scope is of everything we need to learn because there are so many complicated and involved components to aviation, for example, piston and turbine engines, turbine engine designs, reciprocating engine instruments, engine fuel metering systems, engine fire detection and extinguishing systems, engine auxiliary systems, propulsion systems, fuel pumps, fabrication of fluid lines and fittings, starters and landing gear systems, propellers, powerplant lubrication systems, how to read blueprints and mechanical drawings, airframe inspection, warnings and environmental systems, non-destructive testing methods, composite materials, aircraft hardware and material identification, precision measuring techniques, aircraft corrosion control, FAA documentation, aircraft mechanic privileges and limitations, aircraft manufacturers’ specifications, ground operating rules, and airport operating procedures, etc.

It was unexpected to me that “the sky really is the limit” in the aviation industry. The A&P certification is very respected and sought after and will open the door to countless opportunities in many sectors (such as private, commercial, manufacturing, medical transport, space, maintenance, repair and overhaul, military, elevator repair, amusement parks, etc.) both nationally and worldwide.

(4) Other than working for an ARSA member company (kidding…but seriously), what are your goals for life after school?

PIA has a proven performance record, and I’m confident I will be job-ready to become an AMT. Having these credentials will give me a strong start in this in-demand industry and provide job security even when there are uncertainties in other businesses. There are constantly advances in technology, so I plan to keep my skills current to maintain the high standard that is expected, so there is only one option but to be exceptional at my job.

I am open to considering everything from working under a private repair station that is small enough to have that small town feel and know all of my co-workers well; working in a fast paced environment of line work where time is money and I can help save money; or working in a commercial airline. These collected options allow for chances at a lucrative salary, great benefits, and opportunities to advance into a supervisory or management position one day.

Some of my goals are to be considered an exemplary employee, have job satisfaction, a potential pathway for advancement (in both education and the corporate ladder), and have a good work-life balance. I believe the aviation industry could offer me a lifetime career and be fulfilling by utilizing my knowledge and abilities, giving me the opportunity to excel, and through making a difference for others with my contributions.

(5) It’s an admirable ambition to pay entirely for your own schooling and to do so without incurring Help ARSA’s members understand the value of the scholarship by sharing the expenses you have to cover while at school.

I had saved my paychecks from my last job before moving to attend PIA, sold my truck and one quad, bought a fuel-efficient car for $650 and repaired it myself so that I would have reliable transportation, and I currently work as many hours as possible at my part-time job at AutoZone to help towards my total costs, which I estimate will top $60,000 including tuition, fees, living expenses, transportation, and food, to reach my goal of paying for my own schooling and to start my aviation career debt-free. I have endured a setback with my housing (losing an initial rental because the owner sold the property, which required a less-favorable lease in another location) but I am still hopeful I will achieve what I have set out to accomplish. I see the AMT program at PIA as an investment, rather than an expense, as I know it will pay off going forward. I knew it would be challenging, and I am willing to make sacrifices along the way, so each and every scholarship is such a blessing toward these expenses. Thank you!

(6) If you learned that someone was considering school/career choices and they asked you about aviation maintenance, what would you say?

I would tell them – absolutely – go for it, you won’t regret it! But, I would also ask them why they are interested to be sure they have what it takes, which is mechanical interest/experience, strong math skills, great logical thinking, dedication and drive, willingness to put in the work, and ability to work under pressure. I would prepare them for what to expect (physically and mentally challenging work) so that they are focused and determined during the duration of the AMT program. I would also remind them that it is really hard because it is an AMT’s job to safeguard millions of travelers every day. There were 40 students at the beginning of the first semester and at the end of the second semester, my class has thinned out to about 25 students. So, it is fair to say that it is a demanding program and should be taken seriously.

(7) What do you think industry professionals should know in order to be most helpful in helping you and others to build aerospace careers?

I think it would be good for industry professionals to get the word out about the shortage of AMTs and plant the seed early to high school students about this career option. These representatives could have a presence at high school assemblies, shop classes or job fairs, plus go to Career & Technology Centers to meet with the juniors and seniors that are already interested in a trade (many of which could be relevant in aviation). Since my AMT program has a diverse age group and range of backgrounds, it might be good for aviation professionals to reach out to the military to bridge their civilian career and find ways to reach more adults that want a career change (via tv commercials, online ads, community events, fairs, etc.).

As far as AMT students already enrolled, it would be helpful for industry professionals to participate in PIA’s job fairs each semester to give us a chance to explore a day at XYZ aviation company. Because the aviation industry is so vast and has endless opportunities, it is a bit overwhelming to know where to start and how to narrow down our options. It could be worth investing the time for the company to have casual discussions outside of school with those students that have employee potential (such as over the phone, video conference, or inviting them for a tour on the weekend) before they graduate.

And I think the industry professionals sharing their stories would go a long way. It would be helpful to hear about their journey, their high points and personal milestones, but also share their pitfalls and lessons learned. It would be interesting to hear where they see the industry going and the employers’ plan for keeping AMTs current with their skills because the industry and its technology is ever-changing. This would also be a good time to discuss the possibilities of continuing education and learning about advancement opportunities within the company to supervisory and senior level positions to help me consider which path to pursue in building my career.

I believe it is important for new hires fresh out of AMT school to get adequate, hands-on training so they are clear on the company’s expectations, learn the ropes, and get questions answered so the new AMT can get up to speed quickly and begin to thrive.

Get to know Brian even better by reviewing his application package for the ARSA Scholarship, which he agreed to share with the public. Click here to see his answers to the review committee’s questions, which cover some of the same background details he shared with ARSA.

To learn more about the Choose Aerospace Scholarships and Awards Program, click here.

For more information on ARSA’s broader efforts to support industry career development, visit arsa.org/workforce.

Want to congratulate Brian? Help with his interest in gaining hands on experience? Learn more about how to find great candidates like him? Contact ARSA for a referral.

Part Marking

This session outlines the basic rules for aviation part marking and identification and reviews applicable guidance as it pertains specifically to the re-identification of parts while performing maintenance. It introduces the key requirements of 14 CFR part 45, Identification and Registration Marking.

Click here to register and get access for 90 days.

Registration for an ARSA training session includes:

- Access to the on-demand recording of each session for 90 days.

- Digital copies of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of each class.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Airworthiness Directives

Part 39 – Overview

This session provides an overview of 14 CFR part 39 – Airworthiness Directives (ADs). It describes: What an AD is; Its force and effect; What work it may require; How an AD interrelates with maintenance instructions; The basic structure of an AD; and how to access and keep current on these rules.

Click here to register and get access for 90 days.

Registration for an ARSA training session includes:

- Access to the on-demand recording of each session for 90 days.

- Digital copies of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of each class.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Quick Question – Human Factors Findings for Training Development

Approved maintenance organizations with EASA, TCCA, or ANAC approval must include human factors topics in their training programs. In November 2019, change 7 of the FAA-EASA Maintenance Annex Guidance (MAG) clarified that recurrent training must be based on lessons learned from discrepancies and corrective actions:

NOTE: The recurrent human factors training must not be a simple repetition of the initial training. Instead, it must be built upon errors/lessons learned and the experiences within the organization (or group of organizations). This should help ensure that the results of internal quality audits and occurrence reports are brought to the attention of all staff. (See Section B, Appendix 1)

While some members have already integrated ARSA’s existing human factors training sessions into their compliance, the association intends to expand its offerings as part of its new rollout of live training (which remain in the training catalogue as on-demand recordings). To help select topics for those classes, respond to this month’s “quick question.”

Note: The question is displayed in its own, embedded window. If the “Submit” button is not visible on the screen, you must scroll within the survey window to submit your response.

If the embedded survey does not appear/load, open the survey independently by visiting: https://www.surveymonkey.com/r/qq-HF-findings.

Click here to see what questions have been asked and answered…and keep a lookout for more.

Regulatory Compliance Training

Test your knowledge of 14 CFR §§ 21.7 & 21.8, transport category aircraft continued airworthiness and approval of articles.

Click here to download the training sheet.

Membership

Corporate Knowledge

By Kimberly Dimmick, Vice President of Membership

Primary contacts of corporate enterprise members will be asked about updating information for all wholly owned subsidiary locations and individuals that should be registered at each location.

Who are ARSA’s corporate enterprise members? A quick look at the member directory reveals these leading organizations:

Corporate Enterprise Membership

AAR Corp.

Boeing Company

Chromalloy

Delta TechOps Services Group

Gulfstream Aerospace Corporation

HAECO Americas

HEICO Aerospace Corporation

Honeywell International, Inc.

Lufthansa Technik AG

Moog, Inc.

MRO Holdings

NORDAM

Raytheon Technologies Corporation

ST Engineering North America, Inc

StandardAero Alliance, Inc.

STS Aviation Group

Triumph Airborne Structures, LLC

Members Getting Members in Action

ARSA wants to acknowledge, thank, and point out the following members utilizing the Members Getting Members (MGM) program.

| ARSA Referring Member | ARSA New Member | Credit |

| Fortner Engineering/HEICO | Elite Metal Finishing East, LLC | $180 |

| Fortner Engineering/HEICO | AMROC, INC. | $60 |

| SAI Flight Support Company | AIRTEC, Inc. | $120 |

We are looking forward to acknowledging the member that is credited with the total dues amount through this referral program.

Want to know more about the MGM program? Simply visit arsa.org/membership/members-getting-members/.

Welcome & Welcome Back – New & Renewing Members

ARSA’s members give the association life – its work on behalf of the maintenance community depends on the commitment of these organizations. Here’s to the companies that joined or renewed in May:

New Members

GAR-MRO Services, Inc, R02

NAS MRO Services , R03

Returning Members

Aero Accessories & Repair, Inc., R04, 2023

Aircraft & Component Technical Services, LLC, R02, 2009

ATP USA, Inc, R01, 2017

Aviation Avionics & Instruments, Inc., R03, 2012

Barfield Precision Electronics, LLC, R04, 1996

Central Cylinder Service, Inc., R01, 1985

Colorado Northwestern Community College, EDU, 2021

Consolidated Turbine Specialists, LLC, R03, 2018

Delta TechOps Services Group, Corp, 2002

First Class Air Repair, Inc., R02, 2016

Gables Engineering, Inc., Assoc, 1995

Genesis Aviation, Inc., R04, 1994

Helicopter Services, Inc., R01, 2019

Linear Motion LLC, R02, 2017

MTU Maintenance Dallas, Inc., R04, 2020

Sky Aircraft Maintenance, LLC, R01, 2021

Southwest Turbine, Inc., R02, 2018

ST Engineering Aerospace America, Inc., Corp, 2006

Tinker Airforce Base-Sustainment Center Flight Standards Management Office, Military, 2022

World Class Accessory, Inc., R01, 2007

A Member Asked…Forged Forms?

Q: Yesterday morning we got a call reporting a forged FAA Form 8130-3 that claims to have come from our repair station. The individual who called us did not receive the part, he was looking to buy it and just received a copy of the for up front.

I reported it to our PMI and he suggested I contact the SUP people, but we have not actually seen the part. Since we have no part, just a copy of a copy of a forged certificate, I’d like to contact the office before submitting a report on the program website. Do you know of a phone number or email where I could forward the information to the SUP division?

A: Thank you for your concern for aviation safety!

It’s too bad the civil aviation authorities don’t have much jurisdiction over fraud, particularly in an international environment.

What is useful to both the aviation safety agencies are the facts, and only the facts. So, in the present case, it seems that all you know is:

(1) A prospective part buyer received a copy of an FAA Form 8130-3 from a third party that looked suspicious. The buyer queried you after checking the paperwork and upon review it is obvious the documentation has been altered substantially from what your company released under the same Work Order number.

(2) You have a copy of your originally issued form as well as the form provided to you by the prospective part buyer. You also have background information on the customer associated with the work order number.

The facts that would be helpful to the authorities, but maybe not to the parties involved are:

- The potential purchaser’s information—the one that brought the potential fraud to your attention. Name, address, contact information, company name, and whether the individual or company has a certificate from a aviation safety agency.

- The same information for your customer since the “chain” from your FAA Form 8130-3 to the potential buyer starts with your customer.

- The same information for any exchange in the chain—including the company that presented the altered FAA Form 8130-3 to the potential purchaser that contacted you.

Each of those companies may become a “person of interest” in the suspected illegal activity.

If there is no certificate issued by the civil aviation authority that can attach the foreign companies, the issue would have to be investigated by another authority in each country. Although 14 CFR part 3 may be used to initiate an investigation of persons in the United States. (See also, the Legal Brief explaining when actions can result in criminal investigations.) From the few facts provided above the authorities are very unlikely to do much more investigating. The U.S. criminal authorities will investigate what is within their jurisdictions – starting no doubt with your customer. Once the article leaves the United States, the investigation may have to be turned over to the next nation that received the item.

That does not stop you from making an announcement, if you wish, on your website saying that it has come to your attention that your paperwork is being altered by persons unknown. Any questions regarding documentation received with an article should be directed to XXXX.

Finally, ARSA has been trying to discourage the easy exchange of FAA Form 8130-3s. Customers apparently request a copy of the form that will come with the part to determine if it is “acceptable” before making a purchase or exchange. While the practice may be okay with direct use known long standing customers, like airlines or owner/operators or other repair stations, it is not a good idea. Copies of forms are ripe for fraudulent applications and as with you, are used for nefarious purposes.

I don’t know if this helps, but there you go!

Have questions about aviation regulatory compliance, legislative policy, or ARSA resources? Ask ARSA first!

Advertising – Engaging Statistics

There are numbers that make you sit up and pay attention.

Tracking “engagements” (clicks) that result from an advertisement provides an immediate return on investment. For advertisers, the visits provide more information, access to quotes, show videos, or otherwise continue the dialogue with a potential customer or employee.

The statistics on clicks from ARSA periodicals and on ARSA.org, show 15,415 “engagements” since last July.

ARSA’s own publicity produced another 4,786 engagements, bringing the total clicks to 20,101 during that period.

Since February, advertisers have received 33 percent more of these visits with an average of almost 2,000 per month.

These numbers don’t lie; ARSA ads work. Get started at www.arsa.org/advertising to get those clicks going to you!

Resources

ARSA strives to provide resources to educate the general public about the work of the association’s member organizations; should you need to provide a quick reference or introductory overview to the global MRO industry, please utilize AVMRO.ARSA.org.

About ARSA PAC

ARSA’s Political Action Committee helps elect congressional candidates who share ARSA’s commitment to better regulation and a strong aviation maintenance sector. But ARSA is prohibited from sending PAC information to members who haven’t opted in to receive it.

Careers in Aviation Maintenance

How do you share the industry’s story with the people who could be its future? Teach them about the great work done every day to keep the world in flight. (Even if we can’t recruit somebody, we sure can make them thankful for our work.)

U.S./EU Maintenance Annex Guidance

See all of the association’s public updates since 2012 on the Maintenance Annex Guidance between the United States and European Union. The page focuses in particular on matters related to parts documentation issues arising since MAG Change 5 was issued in 2015.

Industry Calendar

| Event/Meeting | Dates | Location |

| 2024 FAA-EASA International Aviation Safety Conference | 6/11-13/2024 | Washington, DC |

| MRO BEER | 6/26-27/2024 | Vilnius, Lithuania |

| Farnborough Air Show | 7/22-26/2024 | Farnborough, United Kingdom |

| World Remanufacturing Conference | 9/10-12/2024 | Chicago, IL |

| 2024 NBAA Business Aviation Convention & Exhibition | 10/22-24/2024 | Las Vegas, Nevada |

| ARSA Annual Conference | 3/18-21/2025 | Arlington, Virginia |

the hotline is the monthly publication of the Aeronautical Repair Station Association (ARSA), the not-for-profit international trade association for certificated repair stations. It is for the exclusive use of ARSA members and federal employees on the ARSA mailing list. For a membership application, please call 703.739.9543 or visit arsa.org/membership/join. For information about previous editions, submit a request through arsa.org/contact. This material is provided for educational and informational purposes only. It does not constitute legal, consulting, tax or any other type of professional advice. Law, regulations, guidance and government policies change frequently. While ARSA updates this material, we do not guarantee its accuracy. In addition, the application of this material to a particular situation is always dependent on the facts and circumstances involved. The use of this material is therefore at your own risk. All content in the hotline, except where indicated otherwise, is the property of ARSA. This content may not be reproduced, distributed or displayed, nor may derivatives or presentations be created from it in whole or in part, in any manner without the prior written consent of ARSA. ARSA grants its members a non-exclusive license to reproduce the content of the hotline. Employees of member organizations are the only parties authorized to receive a duplicate of the hotline. ARSA reserves all remaining rights and will use any means necessary to protect its intellectual property.

© 2024 Aeronautical Repair Station Association