March 2014

Table of Contents

Latest News

ARSA President’s Message

ARSA on the Hill

Regulatory Outlook

Quality Time

Membership

Welcome New Members

Regulatory Compliance Training

AVMRO

International News

Upcoming Events

Latest News

ARSA Concludes Successful 2014 Annual Repair Symposium

From March 19-21, ARSA held its 2014 Annual Repair Symposium. The event highlighted the association’s legislative and regulatory successes this year and provided members with up-to-date information critical to navigating the current regulatory environment.

The Symposium began Wednesday with a successful Legislative Day on Capitol Hill. Members spoke with their lawmakers about the economic importance of the MRO industry, the need for robust technical workforce development programs, and how to mitigate congressional micromanagement by highlighting that “safety is good business.”

On Thursday, panelists provided association members with updates on the key government initiatives that will impact the aviation industry, developments regarding air certification and maintenance oversight programs, customer collaboration, and business opportunities related to cloud technology.

Members also heard from ARSA President Gary Jordan, who highlighted the association’s successes in key regulatory and legislative areas while looking forward to great work ahead. Jordan also highlighted ARSA 20/20, a strategic plan unveiled in October 2013 that provides a roadmap to help its members safely navigate the turbulent skies of the future. (For more, see ARSA President’s Message, below.)

To review or re-live the Symposiums events and content, please visit the 2014 materials page. If you were there, please take a moment to complete the feedback survey. Let us know what we did well, what we can do better, and what you’d like to see on next year’s agenda.

Mark your calendars for next year’s symposium, which will which will take place on March 18-20, 2015 at the Ritz-Carlton in Pentagon City. We hope to see you there, and that you’ll consider making your company an integral and visible part of the event by sponsoring the in 2015.

A light, steady rain could not dampen the enthusiasm of ARSA members in Washington on March 19. Legislative Day attendees crisscrossed Capitol Hill, piling into the elevators of the various House and Senate office buildings to directly engage staff and members of Congress on key issues for the aviation maintenance industry.

After a morning kick-off and panel discussion on industry legislative priorities, members conducted nearly 40 meetings with congressional leaders, including Senators Marco Rubio (R-Fla.), Patty Murray (D-Wash.) and Reps. Martha Roby (R-Ala.) and Adam Schiff (D-Calif.). ARSA members educated Congress on workforce development issues, the importance of effective government/industry relationships, and the economic impact of international MRO operations. (For more, see ARSA On the Hill, below.)

ARSA supports its members in all of their legislative advocacy by providing them with comprehensive priorities for each congressional session. We are standing by to help you connect with your lawmakers.

It Works: Symposium Engagement Creates FAA Action

By Crystal Maguire, Vice President of Operations

During the association’s 2014 Annual Repair Symposium “Opening Salvo” with the Federal Aviation Administration’s Aircraft Certification Office, an ARSA member informed the agency that some of its designees are still insisting on putting “Domestic Shipment Only” or “Not for Export” on FAA Form 8130-3s for new articles. The company was told that the practice was being taught to designees during FAA training even though it is no longer required by regulation or guidance material. The result is unnecessary delays and increased costs when foreign customers subsequently reject the parts.

The FAA representatives at the event agreed that the practice was not required and promised to look into the matter. Subsequently, the agency verified that the instructions were not being provided by its training and has agreed to issue an internal memorandum to ensure its personnel are not incorrectly advising industry that the verbiage is mandatory.

On Thursday, March 20th, ARSA Managing Director and General Council Marshall S. Filler presented the Leo Weston Award for Excellence in Government Service to Neil Eisner. The Weston Award, which was created in 2006, is given regularly by ARSA to individuals who have made a lasting impact on the practice of good government.

Mr. Eisner retired in 2013 as the Assistant General Counsel for Regulation and Enforcement at the U.S. Department of Transportation. He played a major role in the creation of the first-of-its-kind the internet-accessible public docket as well as an innovative, intranet-based rule-making management system. He is now an adjunct professor at American University’s Washington College of Law, and he has published multiple articles and presented numerous speeches in different forums on a variety of subjects.

Upon presenting the award to Mr. Eisner, Filler explained: “We present this award to Neil not [just] because he is a good friend, but because he is a staunch advocate of good government.”

Get the Recognition Your Company – and Industry – Deserve: Support ARSA’s Leading Edge Public Television Documentary Project.

By Brett Levanto, Operations Director

ARSA announces an exciting opportunity for members to help publicize the positive impact of our industry. The association has contracted with Leading Edge (http://www.leadingedgeseries.com/) to produce a series of videos about aviation maintenance.

Including a 6-minute documentary hosted by former Dallas Cowboys Head Coach and sports broadcaster Jimmy Johnson, the series will provide insight about the broad impact of MRO on the economies, industries, and peoples of the world. The series will reach an influential and well-informed audience through distribution to public television stations in all 50 states as well as in short ads on networks like MSNBC, CNN, and CNBC.

In addition to running on broadcast and cable television, the videos will be distributed online and made available for ARSA and member use. Altogether, these resources will become important tools to educate the media, lawmakers, voters, and current and prospective workers about the industry’s economic and safety contributions to world markets.

Play a Starring Role

You can join us in this effort by sponsoring the project. Not only will you be helping us to provide valuable knowledge to a broad constituency, you will be a part of the work. A $7,500 contribution will provide your company:

- Recognition as a supporter during the documentary and profile credits, and in ARSA project marketing materials;

- The opportunity to submit b-roll footage for possible inclusion; and

- A sneak peak at the videos for review and comment.

To become a sponsor, complete and submit this form. You will be invoiced for your contribution.

FAA to Consider Drug & Alcohol (D&A) Tests for Foreign Repair Stations

On March 13, the Federal Aviation Administration (FAA) announced it is seeking comments on an Advance Notice of Proposed Rulemaking (ANPRM) that would require drug and alcohol testing of maintenance personnel who work on aircraft operated by U.S. air carriers (part 121) in facilities outside the United States.

To comply with congressional mandate, the agency is considering developing a rule that would require employees of FAA-certificated foreign repair stations and other maintenance providers who perform safety-sensitive work on U.S. air carrier aircraft to be subject to a drug and alcohol testing program, which would have to meet FAA standards and be consistent with the applicable laws of the country where the repair station is located.

“ARSA looks forward to ensuring the congressionally mandated drug and alcohol testing requirements are implemented ‘consistent with the applicable laws of the country in which the repair station is located,’” said ARSA Executive Director Sarah MacLeod. “Final action cannot be allowed to jeopardize the delicate framework of international civil aviation agreements and national sovereignty. ARSA encourages the international aviation community to submit comments and urge their governments to do the same.”

Questions the FAA is seeking comments on include:

- Which drugs are most misused in a particular country? If testing programs exist, are they administered by a national regulatory authority? Are industry participants required to establish such programs under the country’s laws and regulations, or does industry do that voluntarily?

- Should the program require testing for the same drugs the FAA requires tests for in the United States? At what concentrations should alcohol and drug tests be considered “positive?”

- Does a particular country allow or require random drug and/or alcohol testing? If so, what is the process?

- If a country does not allow or require random drug and/or alcohol testing, are there laws that prohibit random testing? What other methods might successfully deter employees from misusing drugs or alcohol while performing safety-sensitive duties, or within a certain period of time before performing such duties? How would such misuse be detected?

- What are the standards that employees who have violated drug and alcohol regulations should meet before they are allowed to return to performing safety-sensitive maintenance work?

Comments are due Friday, May 16, 2014.

Stay tuned to ARSA for more on this developing story.

ARSA and TeamSAI Deliver Global MRO Economic Assessment

By ARSA Staff

On March 12, ARSA and TeamSAI Consulting (TeamSAI) released the 2014 Global MRO Market Economic Assessment. The study provides a 10-year forecast of the global air transport maintenance, repair, and overhaul (MRO) market and examines the aviation maintenance industry’s current economic and employment impact.

“The [economic] report is a valuable new tool,” stated ARSA Executive Vice President Christian Klein. “It will help our members plan for the future, help the public better understand how repair stations fit into the economy, and help policymakers understand the economic implications of laws and regulations that affect repair stations.”

The next day, ARSA used the report’s findings to illustrate for Congress the significant economic impact the industry has in communities across the country and urged lawmakers to keep the sector’s contributions and safety record in mind when considering legislative proposals. (For more, see ARSA on the Hill, below.)

“To ensure the U.S. aviation maintenance industry remains internationally relevant, repair stations must be able to compete globally. Congress and the administration should encourage the negotiation of more bilateral aviation safety agreements (BASAs), respect our current international aviation accords, and refrain from micromanaging the aviation maintenance sector through unnecessary mandates that offer no flight safety benefit,” said ARSA Vice President of Legislative Affairs Daniel B. Fisher.

To highlight the global importance of aviation maintenance, the report describes a vibrant $57.7 billion worldwide commercial MRO industry that is expected to grow to $86.8 billion in the next decade. TeamSAI also analyzed the flow of trade between various regions and market conditions in specific maintenance sub-sectors (airframe, engine, component and line maintenance).

“For over 14 years now, TeamSAI has been proud of its role to quantify and clarify for MRO industry leaders the various opportunities and risks facing their businesses. This year is no exception, with significant analysis of repatriation opportunities for many airframe MROs as well as an in-depth analysis of cross-border MRO import/export flows,” said David A. Marcontell, TeamSAI president and COO.

Obama Submits FY 2015 Budget Proposal

On March 4, President Obama submitted his fiscal year (FY) 2015 budget to Congress and the aviation industry was distinctly in his crosshairs.

The administration is once again proposing a new $100 per flight surcharge for the use of the air traffic control system, an idea overwhelmingly opposed by the aviation industry. Additionally, the budget recommends increasing passenger security fees (from $5.60 to $6.00) just three months after Congress enacted legislation to raise them. Beginning July 1 , passengers will pay $5.60 one-way, regardless of connections ($11.20 roundtrip); if the president has his way, the fee will be increased to $6.00 per one-way trip.

Meanwhile, the Obama budget calls for a 2.2 percent cut in the Federal Aviation Administration’s (FAA) gross total funding level in FY 2015 (details of funding levels for specific FAA operations programs were not released). The biggest cut would be in the Airport Improvement Program, a fund used for airport construction.

Overall, the administration proposes increased fees on the aviation community while doing nothing to address an FAA inspector shortage and delayed certifications. Fortunately, as in past years, very little of the president’s proposal will ever receive serious consideration.

ARSA President’s Message

By Gary Jordan, President of the Aeronautical Repair Station Association and President and CEO, Jordan Propeller Service

Editor’s Note: ARSA President Gary Jordan provided members with an overview of the association’s recent activities and goals in remarks delivered at the 2014 Annual Repair Symposium’s Membership Meeting and Breakfast. The following is the text of Mr. Jordan’s prepared remarks. It is provided in this edition of the hotline in place of Legal Briefs in order to provide members with a comprehensive year-in-review.

Good morning, I’m Gary Jordan, ARSA’s 2014 president and president of Jordan Propeller Service.

I would like to officially call the 2014 annual membership meeting to order and on behalf of the board of directors, welcome you to this year’s symposium.

I’d first like to introduce the board of directors if they’d please stand when I call their names.

Each segment of the industry is represented on ARSA’s Board. First, ARSA vice president and Sonico’s vice president of sales, Jim Perdue, along with Gary Fortner of Fortner Engineering, represent component maintenance, which makes up the vast majority of ARSA membership.

The association’s treasurer, Gary Hudnall, ensures general aviation interests are on the radar.

Ian Cheyne of BBA’s Dallas Airmotive represents engine maintenance providers.

Dave Latimer, from TIMCO, represents companies that work on large aircraft.

Chris Erickson from Erickson AirCrane represents the helicopter industry.

I’d like to welcome to the board our newest director: Warner Calvo, who represents the Association’s international members and is the Quality and Safety Director at Coopesa—a company with fifty years servicing customers from all latitudes in the Western Hemisphere.

And finally, Basil Barimo of the NORDAM Repair Group, who couldn’t be here this week, ensures various corporate, business, and airline maintenance issues are addressed.

The big news this past year: Nearly a decade after a congressional mandate banned FAA certification of new foreign repair stations, the TSA issued its repair station security rule in January.

Regulatory delay finally yielded to congressional pressure and the threat of legislative action. If not for the hard work of ARSA’s legislative team and active member companies highlighting TSA’s delay, we’d likely still be urging Congress to lift the ban.

The team is now working hard to help members comply with the new rule. In the last few months, the Association developed a security compliance checklist, held educational webinars, and communicated with TSA officials to ensure both government and industry understand the rule’s practical implications. There are still some wrinkles to iron out, but rest assured association staff will continue to push on TSA until security requirements are clearly understood by, and communicated to industry.

The next big thing on the association’s legislative agenda is FAA reauthorization; the current FAA funding bill expires in September 2015. In years past, the industry was forced to play defense as lawmakers, bombarded with false safety and economic information about contract maintenance, considered proposals detrimental to repair stations. This year, ARSA has positioned itself to proactively engage key aviation policymakers early in the process. With the help of active members, we look forward to helping to craft a bill that we can be proud of, not only for what we prevented from happening, but also for what affirmative action we took to ensure industry benefits for years to come.

Wednesday’s Legislative Day is a great example of how much ARSA’s legislative program has grown. For example, in 2003, 14 attendees participated in the annual fly-in and on Wednesday, more than 50 members attended nearly 40 meetings with their members of Congress. Through this kind of direct engagement and collective action, this association can ensure that our voices are heard and that our representatives and senators lead the way in advancing our cause.

ARSA’s political action committee also continues to grow. The PAC is the maintenance industry’s vehicle for supporting congressional candidates who are supportive of the association’s policy priorities. This past year the Part 145 Club grew to 21 members and over $7,000 in personal contributions. With pivotal midterm elections coming up, I hope the U.S. citizens in the room will join me and make a pledge to support ARSA PAC. I hope all of you will consider participating in ARSA’s political program and getting involved in the 2014 elections. Remember: the people elected this fall will be ones writing the next FAA bill. There’s no better time than before the election – when they need your vote – to start educating them about your company we get their vote when the bill comes to floor.

Whether it was through facility visits for lawmakers and staff, grassroots action, or attending political events, ARSA members have made great strides in the legislative arena. Nonetheless, threats and opportunities abound on Capitol Hill, and if we all choose to act when given the opportunity, ARSA’s legislative team will continue to make great strides on our behalf.

You’ve heard a lot about ARSA’s regulatory advocacy activities these past few days; however, one of the association’s biggest projects this year was laying the groundwork to improve consistency of regulatory interpretation.

In November of 2012, the Consistency in Regulatory Interpretation Aviation Rulemaking Committee (or as Sarah calls it, the “cry arc”) made various recommendations which included a methodology to ensure proper classification and resolution of inconsistent application of regulations.

In an apparent effort to implement the recommendation, in December the FAA issued a memorandum dictating the cancellation of all “unofficial” guidance materials. We can all imagine the extremely negative consequences this memo would have on current understandings with our local offices; thus, ARSA joined industry colleagues asking for the memo’s withdrawal or, at the very least, its delay, until a methodology for gathering, reviewing, and incorporating all guidance and policy information can be established and implemented.

To that end, ARSA is developing a database to gather and organize any and all agency-issued documentation that explain or interpret regulations. It all would be organized by the regulation it supports; aiding both industry and the agency in collection and consolidation efforts. The database would also provide a mechanism for addressing regulatory questions or disputes based on facts and the applicable regulations and guidance.

The system would be available to ARSA members and would further the association’s greatest member benefit: access to regulatory expertise. So stay tuned!

In other association news, in October ARSA unveiled its strategic plan, ARSA 20/20. The plan provides a roadmap to help its members safety navigate the turbulent skies of the future including elevating ARSA’s international presence and promoting uniform application of existing rules and regulations. The plan is available for review and comment on ARSA’s website; we hope you will take the time to provide feedback on this important document.

In furtherance of the strategic plan, the Board of Directors approved a bylaw amendment in October that restructured the member categories to better align with today’s industry segments. Among other things, the restructure created a membership category for students and learning institutions to further ARSA’s workforce development initiatives.

To that end, the Association also entered into a formal exchange relationship with our friends at the Aviation Technician Education Council. The association is supporting that organization’s efforts to update maintenance technician schools’ regulatory curriculum requirements and ensure incoming certificated mechanics are prepared to fill twenty-first century aviation maintenance jobs.

In addition to ATEC, this past year ARSA partnered with many other organizations to expand its member services, products, and influence. You’ve heard about the association’s partnership with Team SAI to provide economic industry data and develop other long-term projects on industry metrics. We are also very excited about our affiliation with NATA compliance services—with whom we will provide drug and alcohol management tools to the industry—as well as the production company Leading Edge.

As part our ongoing PR efforts on behalf of the industry, ARSA will work with Leading Edge this year to create a series of short videos to run on public television highlighting the aviation maintenance industry. You can be a part of this work. ARSA is now soliciting sponsorship for the project; interested companies will receive recognition in the documentary’s credits and marketing materials. If you’re interested, sponsor forms are available at the registration desk and on ARSA’s website.

The association also worked to expand and improve its online training program. The pre-recorded webinar library is available on ARSA’s website and includes twenty-five sessions on topics such as the use and availability of ICA, major minor repairs and alterations, enforcement processes, answering a letter of investigation, regulations impacting the sale and purchase of aircraft parts and much, much more. The pre-recorded webinar library will continue to expand as live sessions are held every month. I encourage all of you to take advantage of this fantastic member benefit if you haven’t already.

In conclusion, I’d like to take a moment to brag on the caliber of ARSA’s membership, illustrated by the number of respondents on this past week’s member survey. Twenty percent of members completed it online, which is an impressively high number in the world of surveys. It is a testament to the level of engagement ARSA enjoys from its membership and something we should all be very proud of.

We look forward to an equally engaged audience for this afternoon’s symposium feedback survey. Watch your email for a link to the survey as well as electronic conference materials. Your input is vital to ensuring that ARSA can serve you even better at next year’s symposium. Mark your calendars: it is scheduled for March 18-20, 2015 here at the Ritz Carlton. I look forward to seeing you there.

As ARSA’s President, I pledge to ensure the association continues to push the envelope. I thank the ARSA staff for their continued hard work on our behalf. It is truly a special organization, one dedicated to the progress of our industry, and I am proud to play such a key role.

ARSA on the Hill

In March, ARSA’s legislative team focused on coordinating the most successful Legislative Day in recent memory.

Program highlights included a panel discussion with senior aviation staffers, a policy briefing, and a political engagement tutorial. In total, participants attended nearly 40 meetings with congressional offices to educate lawmakers about the aviation maintenance industry, the need for a skilled technical workforce, the impact of regulations, and other issues important to repair stations.

On March 13, ARSA formally delivered its 2014 Global MRO Market Economic Assessment to congressional offices. In a letter accompanying the data, the association said, “The study makes clear that, although maintenance may be the least visible segment of the aviation industry, in addition to helping U.S. airlines become safer and more competitive, repair stations are significant economic contributors throughout the country.” Both the letter and state-by-state economic analysis were also made a part of the record for the Senate Aviation Operations, Safety & Security Subcommittee’s hearing titled, “The U.S. Aviation Industry and Jobs: Keeping American Manufacturing Competitive.”

With pivotal mid-term elections slated for November, ARSA has been actively engaging with congressional candidates during visits to Washington. We are also implementing a PAC strategy that focuses on supporting lawmakers and candidates who have demonstrated leadership on the industry’s top priorities and are poised to shape the next FAA reauthorization process. Is there a candidate we should be supporting? Let us know!

Ensuring our friends get through an increasingly difficult primary process is a crucial aspect of our plan. ARSA formally launched its 2014 PAC fundraising effort during Legislative Day. In order to learn more about ARSA PAC, please fill out solicitation consent today!

Regulatory Outlook

An Overview of the FAA – Tomorrow

By Larry Richards, Senior Manager, CAVOK, A division of Oliver Wyman, Inc., 720 Whitley Road, Keller, Texas 76248. © 2014 Larry Richards ALL RIGHTS RESERVED.

Expanding the Air Transportation Oversight System (ATOS)

In early 2001, the Federal Aviation Administration (FAA) Flight Standards Service (AFS) established a new program office called Systems Approach for Safety Oversight (SASO) and charged the office with expanding the Air Transportation Oversight System (ATOS). ATOS focuses on safety attributes – responsibility, authority, procedures, controls, process measurement, and interfaces – that link together and form the foundation of a robust system. AFS initially deployed ATOS at 10 of the nation’s largest passenger air carriers and the SASO office’s mandate was to increase the program to cover all certificate holders under the purview of AFS.

The SASO office began by gathering all available data on the pitfalls and lessons learned from previous oversight systems, Office of Inspector General (OIG) and National Transportation Safety Board (NTSB) reports, and a myriad other data. Additionally, the SASO office utilized industry contractors, AFS field inspectors, supervisors, and managers to develop strategies and objectives for the next evolution of the oversight system.

SMS in a Nutshell

At the same time, the concept of safety management systems (SMS) gained popularity in the aviation industry. An SMS consists of four pillars or components. They are:

- Safety policy – A certificate holder’s written and unwritten policies and procedures for conducting operations with a high degree of safety.

- Safety promotion – The methods and techniques a certificate holder uses to promote the safety policy.

- Safety risk management – A process to apply ongoing risk management to the safety policy.

- Safety assurance – Continual internal verification and validation of a certificate holder’s safety policy.

SMS is becoming standard throughout the aviation industry worldwide. Entities such as the Joint Planning and Development Office (JPDO), International Civil Aviation Organization (ICAO), and civil aviation authorities (CAA) and product/service providers recognize SMS as the next step in the evolution of safety in aviation. Similar systems exist in the management of other critical areas such as quality, occupational safety and health, security, environment, etc.

SMSs for product/service providers (certificate holders) and regulators integrate modern safety risk management and safety assurance concepts into repeatable, proactive systems. SMSs emphasize safety management as a fundamental business process to be treated as an other aspect of business management.

Developing the Safety Assurance System (SAS)

The SASO program office named the AFS next evolution oversight system after one of the four components, the Safety Assurance System (SAS). SAS is not a replacement of System Safety or ATOS, but rather a further refinement of their foundational philosophies.

SAS utilizes the concepts and philosophies of System Safety and SMS and will be deployed in two phases. The first phase will begin around May 2014 and will replace ATOS for all part 121 air carriers, and National Program Guidelines (NPG) for all part 135 air carriers and all Part 145 air agencies. Phase 1 deployment of SAS will reach every FAA field office in the world and will impact more than 7,200 certificate holders, approximately 85 part 121s, 2,400 part 135s and 4,800 part 145s, both inside and outside the US. Phase 2 will deploy around 2018 and will replace NPG for the remaining certificate holders. There are more than 13,000 air operator and air agency certificates overseen by the FAA. Upon completion of Phases 1 and 2 deployments, SAS will be the FAA’s single oversight system for all FAA certificate holders around the globe.

SAS has the potential to bring about far better utilization of AFS resources. Because the FAA is currently facing budget, staffing, and facility cuts, SAS will enable the FAA to focus its dwindling resources on risk. SAS allows for scalability of oversight based on size and scope of each certificate holder, as well as individual levels of risk.

The FAA will notify each certificate holder prior to the Certificate Holding District Offices transition to SAS. The administration anticipates that the impact on each certificate holder will be minimal. However, keep the following rule in mind: Your mileage may vary.

Final Documents/Your Two Cents

This list includes Federal Register publications, such as final rules, Advisory Circulars, and policy statements, as well as proposed rules and policies of interest to ARSA members. Read more at http://arsa.org/wp-content/uploads/2014/04/hlMar14-FDYTC-20140331.pdf.

Quality Time

Editor’s note: The views and opinions expressed by contributing authors do not necessarily state or reflect those of ARSA, and shall not be used for endorsement purposes.

Import Classification for Repair Stations

This is the second in a series of articles discussing import into the United States of aircraft parts. Last month we explained that classifications of goods is based upon the U.S. Harmonized Tariff Schedule. This month we will look more closely at the basic harmonized tariff codes applicable to aircraft parts.

U.S. import law applies to goods that enter the customs territory of the United States. Each such part must be classified correctly in order to assess the tariff status of the part. Most aircraft parts will fall within the scope of the Agreement on Trade in Civil Aircraft, which provides for the duty-free entry of civil aircraft and their parts into signatory nations (including the United States). But there are significant exceptions to this provision, and there is a significant minority of aircraft parts that will not be classified under the “aircraft parts” provisions of this Agreement [more on this next month!].

Most aircraft parts are categorized under Chapter 88 of the Harmonized Tariff Code, and the most commonly used code will begin with 8803 (which is for parts). The additional numbers after the initial “8803” help to specify exactly what sort of aircraft parts they are. Civil aircraft propeller parts are characterized as 8803.10.00.30. Civil aircraft undercarriage parts are 8803.20.00.30 if they are intended for aircraft used by anyone other than the Department of Defense or the Coast Guard (the numbers would change if you altered any of these particulars).

Seeing a pattern to these numbers? The first set of digits (8803) indicates that it is an aircraft part. If the second sequence is “10” then it is a rotor or propeller part. If it is “20” then it is an undercarriage part. If it is a “30” then it is an “other” part from an airplane or helicopter.

For these particular subheadings, the third sequence will always be “00” but in other headings and subheadings, you can have different third sequence numbers that help to further distinguish different goods. The fourth sequence helps to further distinguish the nature of the parts, so for example in these subheadings a fourth sequence of “15” usually means the part is for use in a civil aircraft but the aircraft is used by the Department of Defense or the United States Coast Guard. A fourth sequence of “30” usually means the part is for use in a civil aircraft that is NOT used by the Department of Defense or the United States Coast Guard

As you can see, most civil aircraft parts imported by U.S. repair stations will be described as by harmonized tariff code 8803.30.00.30. Civil aircraft parts classified as 8803.30.00.30 may usually be entered into the U.S. on a duty free basis.

But, unfortunately, import classification of aircraft parts is not always this simple. There are many aircraft parts that fit into listed exceptions, and these parts are characterized under different tariff codes. Some of these tariff codes require the payment of import duties (the parts are not treated as duty-free under the Agreement on Trade in Civil Aircraft).

Next month we examine the exceptions.

This series is meant to support the ARSA community, so if you have questions, please feel free to email them to us at Jason@washingtonaviation.com. We would love to have your questions help drive topics for future articles (please be sure to let us know whether you are suggesting topics for future articles or seeking legal advice so that we do not inadvertently treat your inquiry the wrong way!).

Seller beware – Measure Twice Cut Once

Are you thinking of selling your business? Has another company asked you if you want to sell? Before getting too deep in the sale process it is worth taking some time to plan ahead. Understanding the due diligence process is one key to a successful transaction.

The goal of the due diligence process is to provide the buyer with an opportunity to review necessary records to assess the accuracy of the seller’s representations. Negotiations are usually based on the seller’s representations of the facts, both verbally and in the written records of the business, as referenced in the sale agreement. The cost to a buyer of litigating to recover amounts owed pursuant to warranties or other contract adjustments for faulty or fraudulent representations could be significant. Even if monies are recovered that may not fully compensate a buyer for their lost time and business opportunity. Therefore, the buyer needs a method of checking the facts which form the basis for the transaction representations. That process is known as the buyer’s due diligence. This gives the buyer a chance to review the seller’s records and make a more informed assessment of the deal before closing. In the end it reduces the chance for disputes and helps the parties settle in on a mutually agreed price for the business.

Typically a buyer presents a list or outline of the types of information it will require in a “data room” as part of their due diligence review. It is important to keep in mind that these outlines are not set in stone. If gathering the materials for a particular item on the list is either too costly or time consuming it may be possible to modify the content in the data room in advance of disclosure to a buyer. A buyer may or may not come back and ask for more information than is made available in the data room.

In recent years it is more and more common for sellers to conduct their own due diligence in advance of preparing the formal buyer’s data room. This process is completed before the prospect of a possible sale is even announced to possible buyers. The advantages to this approach are:

- It typically costs less for a seller to fix a problem in advance than to allow a buyer to price the fix into the purchase price for resolution later;

- If the seller can’t fix the problem completely it may be able to mitigate the adverse impact of its presence on review by a buyer;

- Problems not detected before the buyer’s due diligence can turn into deal breakers if detected by the buyer as part of its own due diligence without seller’s specific disclosure; and

- Since the buyer will want to complete its own due diligence anyway why not pave the way for a smooth process by detecting items in advance that may be found later as part of the buyer’s review.

The extent of the seller’s due diligence does not generally have to be as extensive as the possible review by a buyer. Keep in mind no one should know the business better than the seller so the seller should be able to assess issues more efficiently than a buyer. The seller should be able to spot problems faster because it should know where to look to find them.

Steven counsels businesses operating in high-risk industries – including aviation – he provides templates, tools and training that will improve contracting efficiency, close deals faster and control costs.

Membership

Member Spotlight: TIMCO Aviation Services – Greensboro, NC

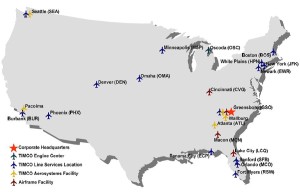

TIMCO Aviation Services was founded in 1990 with a core business of airframe base maintenance. It has since added a variety of shop and line-maintenance services and in February 2014 became a stand-alone subsidiary of HAECO—one of the largest providers of MRO services in the world. Headquartered in Greensboro, North Carolina, TIMCO businesses operate at locations throughout the United States.

TIMCO recently drew the attention of CNBC’s Where the Jobs Are series. With looming retirements and global air traffic forecast to grow by 5% a year until 2032, the company has been reaching out to schools and community groups to attract applicants and establish training programs for their needs. In a full day visit to their facility at Piedmont Triad International Airport, Business News Reporter Mary Thompson highlighted these efforts by TIMCO to build a sustainable talent pipeline right in their back yard.

TIMCO recently drew the attention of CNBC’s Where the Jobs Are series. With looming retirements and global air traffic forecast to grow by 5% a year until 2032, the company has been reaching out to schools and community groups to attract applicants and establish training programs for their needs. In a full day visit to their facility at Piedmont Triad International Airport, Business News Reporter Mary Thompson highlighted these efforts by TIMCO to build a sustainable talent pipeline right in their back yard.

The coverage was an opportunity for TIMCO both to educate the general public about the economic impact of the aviation maintenance market and also to show the members of their community how they can thrive together. It also gave Vice President of Industry & Government Relations Kip Blakely a chance to work with the media to highlight not just where the jobs are, but who TIMCO is as well.

“We were excited about the opportunity to participate in the Where the Jobs Are series, as it gave us a great opportunity to highlight the challenge our industry is facing with regard to skilled labor and to showcase some of the measures we are taking to try to help solve the problem in the communities where we operate.” He added, “Our work with our industry colleagues through ARSA has provided a strong basis to help us better understand the state of our industry, and has also encouraged us to find ways we can work together to bolster its strength and success in the future.”

Through ARSA, all members are able to share in the exposure generated by this kind of coverage. TIMCO has been an ARSA member since 2000.

For more information, visit http://www.timco.aero/.

Are you an ARSA member who would like to be in the “Member Spotlight?” If so, please contact Brett Levanto at brett.levanto@potomac-law.com.

Each month, the hotline spotlights key regulatory, legislative, and business leaders making important contributions to the aviation industry. This month we look at Jeh Johnson, the Secretary of Homeland Security.

Jeh Johnson, Secretary of Homeland Security

Jeh Charles Johnson was sworn in on December 23, 2013 as the fourth Secretary of Homeland Security. Prior to joining DHS, Secretary Johnson served as General Counsel for the Department of Defense, where he led the more than 10,000 military and civilian lawyers and oversaw the development of the legal aspects of many of our nation’s counterterrorism policies, spearheaded reforms to the military commissions system at Guantanamo Bay in 2009, and co-authored the 250-page report that paved the way for the repeal of “Don’t Ask, Don’t Tell” in 2010.

Jeh Charles Johnson was sworn in on December 23, 2013 as the fourth Secretary of Homeland Security. Prior to joining DHS, Secretary Johnson served as General Counsel for the Department of Defense, where he led the more than 10,000 military and civilian lawyers and oversaw the development of the legal aspects of many of our nation’s counterterrorism policies, spearheaded reforms to the military commissions system at Guantanamo Bay in 2009, and co-authored the 250-page report that paved the way for the repeal of “Don’t Ask, Don’t Tell” in 2010.

Secretary Johnson’s career has included extensive service in national security, law enforcement, and as an attorney in private corporate law practice. Secretary Johnson was General Counsel of the Department of the Air Force from 1998 to 2001, and he served as an Assistant U.S. Attorney for the Southern District of New York from 1989 to 1991.

In private law practice, Secretary Johnson was a partner with the New York City-based law firm of Paul, Weiss, Rifkind, Wharton & Garrison LLP. In 2004, Secretary Johnson was elected a Fellow in the prestigious American College of Trial Lawyers, and he is a member of the Council on Foreign Relations.

Secretary Johnson graduated from Morehouse College in 1979 and received his law degree from Columbia Law School in 1982.

Take Advantage of ARSA’s Members Getting Members Program, Get 10% Off on Membership Dues

The best form of advertising is word of mouth. Use the Members Getting Members Toolkit to recruit an ARSA member and your company will receive a discounted membership rate for your next membership term. Get more information at http://arsa.org/membership/members-getting-members/

Target Your Message: Advertise Today in ARSA’s Newsletters and Website!

Exhibit, Sponsor the 2015 Repair Symposium

As the maintenance industry’s top event devoted exclusively to regulatory compliance, the ARSA Symposium attracts a highly qualified professional audience. Use this opportunity to promote your company while showing support for ARSA. Get more information at http://arsa.org/news-media/events/arsa-symposium/arsa-annual-repair-symposium-sponsorship/

Q: My FAA-certificated part 145 repair station is located on or adjacent to an airport, but I haven’t been contacted by the Transportation Security Administration regarding compliance with the new security rule (49 CFR § 1554). What do I need to do?

According to the Transportation Security Administration (TSA), all repair stations required to implement the repair station security rule’s “Security Measures” have been contacted by letter from a local agency representative.

Remember, only FAA-certificated part 145 repair stations that are located on or adjacent to an airport covered by a security program under 49 CFR § 1542 must provide point of contact information to TSA and implement Security Measures to prevent the unauthorized operation of large, unattended aircraft capable of flight. If you’re unsure if the airport is covered by a 49 CFR § 1542 security program, contact the airport security coordinator.

For repair stations operating on or adjacent to 49 CFR §1542 airports that haven’t received initial communication from TSA, ARSA will facilitate contact with the agency on your behalf.

Check Out ARSA’s Library of Recorded Webinars and Online Training Classes

ARSA is pleased to announce that recorded online training classes and webinars are now available for member purchase. Check back often as courses will be continually added. Read more at http://arsa.org/training-2/online-training/.

Welcome New Members

- Alkan Air – Cairo, Egypt

- Av8 MRO, LLC – Houston, TX

- SEAL Aciation, LLC – Ft. Lauderdale, FL

- T&W Electric Service, Inc. – Lakeview, MI

Regulatory Compliance Training

Test your knowledge on § 145.109 ratings.

AVMRO

ARSA monitors media coverage on aviation maintenance to spread the word about the valuable role repair stations play in their communities by providing jobs and economic opportunities and in civic engagement. These are some of this month’s top stories highlighting the industry’s contributions.

International Jet Aviation’s Dream Chaser 4 Lifts Spirits of Make-A-Wish Kids (AIN Online)

Senior’s Profit Rises on Higher Demand for Aircraft Parts (Reuters)

United Airlines Opens New Widebody Hangar at Newark Liberty (Wall Street Journal)

New Businesses Set to Bring 150 Jobs to Santa Teresa (Fox14 – Texas)

Want a Job in a Fast Growing Industry? Look to the Skies (CNBC)

More Than 4,500 Attend Women In Aviation Conference (AIN Online)

AAR Hosts Career Day for Miami Central Students (AIN Online)

Free Online Course From ERAU (AV Web)

Jet Aviation St. Louis Wins Diamond Award for Excellence from the Federal Aviation Administration for Second Consecutive Year (Aviation Pros)

Good Deeds: ATS Donates 747 Aft Flap for EvCC (The Herald Business Journal)

Aircraft Mechanics Recruited in San Bernardino County Program (San Bernadino Sun)

Fla. group partners with JetBlue to expand aviation opportunities (NewsChief.com)

Tempus Jets Builds MRO Business in Maine (AIN Online)

AerSale Receives EASA Certification and New Mexico Sales Tax Exemption (Aviation Pros)

International News

Fleet-related dynamics in the Asia Pacific to influence the demand for qualified technical personnel

The last several years have been especially favourable for the aviation industry in the Asia-Pacific, especially so for the local low cost carriers. According to the latest estimates, at the moment there are 47 LCCs in the region, operating around 1,000 aircraft and accounting for about 20% of the region’s seat capacity. With the growing appetite of Asian travellers as concerns cheap air travel solutions, most of the major aircraft manufacturers have released a number of impressive forecasts with regard to aircraft demand in the Asia Pacific. However, as there are signs that the local fleets are actually outgrowing the existing demand, local carriers will probably be not the only ones to face certain challenges.

“As more and more carriers may choose to dispose of the older, less-fuel-efficient aircraft to keep up yields, the focus of the MRO providers will inevitably shift as well, since the market share of the new generation aircraft will naturally increase. However, the new technologies used in the new models require to apply new inspection and maintenance techniques, and imply the global deficiency of staff capable of performing such operations. Therefore, the region might face the growing demand for the requalification of the current generation of technicians. This, in turn, is likely to become a major challenge to the local training providers, since such processes are especially time-costly. Thus, even the most remote possibility of such changes in demand must be addressed by the relevant players with all the seriousness,” concludes Kestutis Volungevicius

To provide more international coverage, ARSA presents a monthly roundup of world events pertaining to the industry.

SIA Engineering Supports SilkAir (Air Transport World)

Fokker Performs Russian Modifications (Air Transport World)

Monarch Aircraft Engineering Academy Celebrates First 1,650 Engineers Trained (Aviation Pros)

Bombardier Inaugurates Regional Support Office in Toluca, Mexico (AVI Trader)

Tigerair Australia Expands Partnership with BAE Systems (AVI Trader)

Air Works India Wins Aircraft Maintenance Contract from Dana Executive Jets (Times of India)

GMF AeroAsia Reaches Agreement with Sriwijaya Air and Honeywell (AVI Trader)

Lufthansa Technik’s Good Result Creates Foundation for Investment (AVI Trader)

New Home for Lufthansa Technik’s Central Materials Technology (AVI Trader)

Tigerair Signs Deal for Long-Term Fleet Renewal and Expansion (Air Transport News)

Boeing, Iraqi Airways Partner with Non-Profit Organization to Bring Smiles to Children in Iraq (Air Transport News)

MTU Maintenance Signs Contract with Saudi Aramco for Maintenance of CF34-8E Engines (AVI Trader)

Aircraft MRO Centre Will Increase People’s Income (National News Agency of Malaysia)

Upcoming Events

Previous issues:

| 2014: | Jan | Feb | |||||

| 2013: | Jan | Feb | Mar | Apr | May | June | July |

| Aug | Sept | Oct. | Nov | Dec. | |||

| 2012: | Jun | Jul | Aug | Sep | Oct | Nov | Dec |

| SPONSORED CONTENT |

The FAA is very concerned about counterfeit aircraft parts. They call them Suspected Unapproved Parts (SUP). Having any in your inventory could be a legal disaster !!

The FAA is very concerned about counterfeit aircraft parts. They call them Suspected Unapproved Parts (SUP). Having any in your inventory could be a legal disaster !!

- There is only one centralized DataBase of Suspected Unapproved Parts – Over 60,000 of them. Find the ones on your shelves before the FAA Fines you.

- There is only one integrated PMA/AD System. Find ADs that apply to or reference any of almost 1,000,000 PMA parts. Do multi-level PMA research.

- Due Diligence is the key phrase and The Aviation DataBase® is the only source of an easy and inexpensive way to do it. Head off the legal problem before it occurs.

- There is a User friendly and searchable copy of the Flight Standards Information Management System (FAA Order 8900.1) in The Aviation DataBase®.

- Do you need an Aviation Regulatory Library: Over 18,000 ADs – Large & Small AC, Over 1,500 Type Certificate Data Sheets, Over 1,200 FAA Advisory Circulars.

- Call Aviation DataSource, Inc. (800) 952-8844.You can be using The Aviation DataBase® within minutes.

the hotline is the monthly publication of the Aeronautical Repair Station Association (ARSA), the not-for-profit international trade association for certificated repair stations. It is for the exclusive use of ARSA members and federal employees on the ARSA mailing list. For a membership application, please call 703.739.9543 or visit http://arsa.org/membership/join/.

This material is provided for educational and informational purposes only. It does not constitute legal, consulting, tax or any other type of professional advice.

Law, regulations, guidance and government policies change frequently. While ARSA updates this material, we do not guarantee its accuracy. In addition, the application of this material to a particular situation is always dependent on the facts and circumstances involved. The use of this material is therefore at your own risk.

All content in the hotline, except where indicated otherwise, is the property of ARSA. This content may not be reproduced, distributed or displayed, nor may derivatives or presentations be created from it in whole or in part, in any manner without the prior written consent of ARSA.

ARSA grants its members a non-exclusive license to reproduce the content of the hotline. Employees of member organizations are the only parties authorized to receive a duplicate of the hotline.

ARSA reserves all remaining rights and will use any means necessary to protect its intellectual property.

© 2014 Aeronautical Repair Station Association