2017 – Edition 7 – August 4, 2017

Table of Contents

Note: The order of material varies in hotline emails, but is always presented the same on this landing page. Readers scrolling through content on or printing this page will find it organized consistent with the table of contents.

Sarah Says

SLC 2017

ARSA Works

Legal Briefs

ARSA on the Hill

Quality Time

Training

Membership

Resources

Industry Calendar

Sarah Says

Courts or Congress – The Devil and the Deep Blue Sea

By Sarah MacLeod, Executive Director

The vagaries of the American democratic system become evident when citizens pursue justifiable but complex results.

Let’s take the association’s determination to return a repair station’s ability to unilaterally surrender its air agency certificate. Up until 2014, a repair station could voluntarily surrender its certificate without any required agency action or reaction. In its November 2014 updates to 14 CFR part 145, the FAA took the unprecedented step of subjecting surrendered repair station certificates to “acceptance for cancellation” (see, § 145.55).

ARSA led a regulatory effort calling for the removal of the requirement by petitioning for rulemaking with the aid of many industry allies. The petition – and the ongoing cause to reinstate the right to surrender a certificate – stand on solid justification: The requirement for the agency to take action when a repair station certificate is surrendered is unique in aviation. Forcing a surrendering repair station to await the pleasure of the agency runs counter to the interest of aviation safety; if the certificate holder is a threat, the surrender removes the safety risk. The requirement to obtain the agency’s “acceptance for cancellation” increases administrative burdens for both parties, particularly considering the agency has never explained how it will exercise its discretion for issuing such an acceptance. The January 2015 petition was denied by the FAA and a subsequent request for reconsideration remains unaddressed.

Being determined to ensure repair stations do not face the uncertainty of having to have a surrendered repair station certificate “accepted for cancellation,” ARSA has taken the unprecedented step of asking for legislation. ARSA’s legislative team worked tirelessly to get an amendment introduced to FAA reauthorization legislation that would return the repair station’s right to unilaterally and voluntarily surrender its certificate.

Convincing lawmakers that a safety agency is wrong is no small task – the FAA has “justified” its position by stating it is trying to keep “bad actors” out of the industry. In reality, the agency can take action against any “person” it believes violated a regulation, including individuals that have contributed to the revocation of a certificate. The surrender of a corporate entity’s certificate does not mean the agency cannot investigate and issue an order against an individual “bad actor.” To intimate differently is misleading and frankly unjustifiable.

Most repair stations surrendering certificates are doing so because they (1) sold the assets to someone else that did not want to amend the certificate, (2) have decided to go out of business or (3) have legitimate business reasons not to serve the aviation industry. To hold up a legitimate business decision without a direct and immediate aviation safety justification should not be acceptable to the agency, the industry or lawmakers. To treat one type of certificate holder different than another – for example, an air carrier can unilaterally decide to surrender its certificate – is also unacceptable.

To have to demand action from Congress to get an executive branch agency to see the light is certainly not the preferred way of getting policy work done, but it can be a necessary step. Our current effort is similar to the lawsuit the association filed against the FAA over drug and alcohol testing “at any tier in the maintenance contract.” ARSA attempted to explain to the FAA that its desire to test for drug and alcohol use beyond “aircraft maintenance” was arbitrary and would not result in any increase in safety. Indeed, it would be impossible to enforce. Making matters worse, inspectors enforced their own definitions of of what was covered by the term “aircraft maintenance.” ARSA’ predictions have generally come true, but the courts would not reverse the agency’s action. As a result, the industry faces continued uncertainty about what contractors, subcontractors, sub-subcontractors, sub-sub-subcontractors (you get the idea) need to be tested. Investigations and enforcement rarely seek beyond the contractor level but when they do, uneven and often unfair results become evident.

Unfortunately, there are few choices on how actions by an executive agency can be challenged: It is either in the courts or in Congress. ARSA does not like to turn to either of those bodies to solve an issue with the aviation safety agency. It would like to work with the FAA to solve or resolve issues based upon facts and data, not feelings and fears. However, when good efforts do not result in change, one has to decide between the devil and the deep blue sea.

SLC 2017

Analyze the Agenda

The 2017 Strategic Leadership Conference is the chance for maintenance community leaders to “engage for impact” at the highest levels of government. ARSA’s team is setting the stage for that work by (1) building a brief agenda of substantive content, high-level speakers and open discussion to prepare attendees to carry the industry’s message and (2) scheduling meetings for participants with executive branch leaders and policy makers as well as a few leaders in Congress.

To ensure you’re prepared – or to confirm you need to attend – review the agenda. See who will be joining us in Washington on October 18-19 and what they’ll be saying. It’ll be your turn, then, to add to the script:

2017 SLC Agenda (Click Here)

Wednesday, October 18, 20176:00 p.m. to 9:00 p.m. Reception with the Administrator |

|

| Join industry and aviation policy community leaders for an evening of conversation and networking. The FAA Administrator has been invited to share his agencies efforts to improve the quality of oversight and regulation.

The Honorable Michael Huerta, FAA Administrator* |

|

Thursday, October 19, 2017Washington Court Hotel |

|

| 8:00 a.m.–8:30 a.m. | Breakfast |

|

|

|

| 8:30 a.m.–9:15 a.m. | Welcome & Setting the Stage |

| Christian A. Klein, Executive Vice President, ARSA

|

|

| 9:15 a.m.–9:45 a.m. | Keynote Conversation |

| Our keynote speaker will share insights on Delta’s decision to start a repair station, the benefits and challenges of being a repair station associatied with an airline, risks and opportunities facing the global MRO sector, and how MRO companies can work together to ensure the industry’s growth and success.

Don Mitacek, Senior Vice President – Technical Operations, Delta TechOps* |

|

| 9:45 a.m.–10:45 a.m. | Advocating for You |

| Panelists will, discuss how and why leading maintenance companies are getting engaged in the policy process, both on Capitol Hill and “back home.”

David Storch, Chairman & CEO, AAR Corp. |

|

| 10:45 a.m.–11:15 a.m. | Networking Break |

|

|

|

| 11:15 a.m.–12:15 p.m. | International Opportunities |

| Panelists will focus on the importance of manufacturers and repair stations that are independent of type and production certificate holders. Discussion will revolve around supporting development of independent manufacturing and repair sources in the international regulatory arena and protecting intellectual property rights.

Al Givray, Partner, Davis Graham & Stubbs & General Counsel, The Nordam Group |

|

| 12:15 p.m.–1:30 p.m. | Lunch with Special Guest |

|

|

|

| 1:30 p.m.–5:00 p.m. | Industry Meetings with Policymakers |

| Delegations of SLC attendees will fan out across the nation’s capital to meet with senior executive and legislative branch officials to build the maintenance industry’s visibility, promote ARSA policy objectives and gather information about policymaker priorities.

|

|

| 6:00 p.m.–9:00 p.m. | Reception and Dinner |

| After a busy day, join senior industry colleagues for a relaxing evening of networking.

|

|

*Invited.

Event registration is extremely limited in order to maintain the high-level focus of the SLC. If you haven’t already, register today to ensure you have a place at the table:

Click here to visit the main event page (then bookmark it).

First round of sponsors to be unveiled soon, get your company on the list. Sponsorship opportunities available on the main event page; requests may be made via a registration form or by contact Brett Levanto at brett.levanto@arsa.org or 703.739.9543 Ext. 103.

Don't need more information? Register or sponsor right here...

2017 Registration & Sponsorship Form

2017 SLC Registration & Sponsorship Form

Oops! We could not locate your form.

ARSA Works

ARSA Files Brief in Accountable Manager Litigation

On July 17, ARSA filed an amicus brief urging the Ninth Circuit Court of Appeals to reconsider the relationship between the regulatory responsibility of an “accountable manager” and his or her potential criminal liability.

In U.S. v. Weygandt, a number of repair station employees pled guilty to various charges related to the issue of FAA Form 8130-3s incorrectly certifying completion of tests required by component maintenance manuals. Prosecutors also indicted and convicted the repair station’s accountable manager of conspiracy based on that individual’s general responsibility for work performed in the facility.

For deeper analysis of the issue and review of the points in the brief, check out this edition’s “Legal Brief.”

To read the complete brief, click here.

U.S. Signs Maintenance Agreement with Singapore

On July 12, the FAA signed and released the initial Maintenance Agreement Guidance (MAG) with the Civil Aviation Authority of Singapore (CAAS).

The MAG details the agencies’ responsibilities under the Maintenance Implementation Procedures (MIP) signed by the United States and Singapore in February 2016. It also describes the compliance requirements for approved maintenance organization certificates held by persons from and between each country.

The MAG is divided into four sections:

(1) Section A. Interaction between the FAA and CAAS that entails implantation procedures and compliance with the terms of the MIP.

(2) Section B. Requirements for SAR-145 AMOs located in the United States.

(3) Section C. Requirements for 14 CFR part 145 repair stations located in Singapore.

(4) Section D. Temporary revisions to the MAG pending the incorporation of a revision to the MAG.

The agreement is the most-recent execution of the 2004 U.S.-Singapore Bilateral Aviation Safety Agreement (BASA) and – like the MIP – is the first of its kind in Asia. There are almost 60 FAA-certificated repair stations in Singapore, an extremely large number given the country’s 300 square miles. Progress toward reciprocal acceptance in the world’s fastest-growing region for aviation business represents a significant international development.

To access the MAG, click here.

RCCB to Clarify Guidance on 100 Percent Replacement

On July 11, the FAA responded via email to ARSA’s June 29 request for clarity on the ability of repair stations to replace 100 percent of an article while performing maintenance. The agency’s Regulatory Consistency Communication Board (RCCB), to which the request was submitted, “has carefully evaluated [the] issue and determined it will be accepted by the RCCB for resolution.”

The agency will provide a status update within 45 days, so stay tuned for more information. To learn about the complete request, visit arsa.org/100-percent-replacement.

Final Documents/Your Two Cents

This list includes Federal Register publications, such as final rules, Advisory Circulars and policy statements, as well as proposed rules and policies of interest to ARSA members.

Legal Briefs

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

Being Held “Accountable”

In ARSA’s July 17 amicus brief (see piece in ARSA Works section of this edition), the Ninth Circuit Court of Appeals was urged to rehear a case involving an accountable manager’s regulatory obligations under 14 CFR.

In U.S. v. Weygandt, repair station employees fraudulently issued FAA Form 8130-3s certifying that component maintenance manuals were followed. When it was discovered that the tests outlined in those documents were not performed, repair station employees asserted that they did not have the necessary equipment. The individuals responsible for signing and issuing the Form 8130-3s pled guilty to various charges, and the accountable manager was indicted for conspiracy.

At trial, the prosecution consistently highlighted that the accountable manager was responsible for what takes place at the repair station. The misleading emphasis on that position’s responsibility, coupled with the testimony of another accountable manager that predicated his own guilt solely on the title, enabled regulatory responsibility to become tantamount to criminal culpability.

A panel of the Ninth Circuit upheld the conviction and the defendant petitioned for a rehearing before the entire Court of Appeals (called an en banc hearing). ARSA’s brief supports a rehearing because the regulatory context of the accountable manager’s responsibilities was absent at trial and in the panel’s disposition of the case.

The brief details the history and purpose of the accountable manager position within the international regulatory framework. In addition, ARSA explained that the FAA’s expressed intent not to impose personal liability on accountable managers for the certificate holder’s operations failed to be considered.

If the Panel’s decision stands, it sets a dangerous precedent that will support criminal acts of any repair station employee to be imputed to an accountable manager. That should make everyone with the title nervous.

ARSA on the Hill

FAA Bill in Holding Pattern

By Christian A. Klein, Executive Vice President

After a month of intense activity on the FAA reauthorization front in June, the process slowed in July under the press of other business in the lead up to the congressional August recess.

In June, both the House Transportation & Infrastructure and Senate Commerce, Science & Transportation Committee’s passed separate versions of legislation to reauthorize the FAA. Aside from providing a budget blue

print for the agency through 2021, the legislation contains a host of aviation policy provisions related to everything from certification reform to FAA workforce training.

For the first time in decades, the bills do not contain provisions targeting repair stations, which we ascribe in large part to the aggressive outreach by ARSA and its members in recent months to educate legislators about the economic impact and important aviation safety role repair stations play.

FAA Bill Maintenance Amendments Box Score

| ARSA Proposal | In House Bill | In Senate Bill |

| Adding “aviation maintenance” to stakeholders on new Certification & Oversight Advisory Committee | Yes – Amendment by Rep. Hank Johnson (D-Ga.) adopted in committee by voice vote | Yes – Amendment by Sen. Jim Inhofe (R-Okla.) adopted in committee by voice vote |

| Asking FAA to explore ways to enhance value of repairman certificates | No – Rep. Eddie Bernie Johnson (D-Texas) has filed amendment | Yes – Amendment by Sen. Jim Inhofe (R-Okla.) adopted in committee by voice vote |

| Directing FAA to undertake rulemaking to reinstate voluntary surrender of repair station certificates | No – Rep. Dan Webster (R-Fla.) has filed amendment | Yes – Amendment by Sen. Jim Inhofe (R-Okla.) adopted in committee by voice vote |

| Directing GAO to study causes, effects and solutions to aviation technician shortage | Yes – Amendment by Rep. Cheri Bustos (D-Ill.), Brenda Lawrence (D-Mich.) and Bruce Westerman (R-Ark.) adopted in committee by voice vote | No – ARSA is working to identify sponsor |

| Creating grant program to support aviation maintenance workforce development initiatives | No – ARSA is working to identify sponsor | No – Sen. Jim Inhofe (R-Okla.) may sponsor amendment on Senate floor |

FAA Bills Include Important ARSA-Proposed Amendments

This reauthorization cycle, ARSA has gone on the offensive and has been working with various members of Congress to add amendments to the FAA bill on regulatory and workforce issues important to aviation maintenance (see “Box Score”).

Specifically, amendments were adopted to the House and Senate bills during committee consideration adding aviation maintenance to the stakeholders on the FAA’s new Certification & Oversight Advisory Committee. During Senate committee markup, amendments offered by Sen. Jim Inhofe (R-Okla.) were also adopted to restore the right of repair stations to voluntarily surrender their certificates and to ask the FAA to explore ways to enhance the value of repairman certificates. Reps. Dan Webster (R-Fla.) and Eddie Bernice Johnson (D-Texas) have also filed amendments on those issues to the House bill, which will hopefully be added before it hits the House floor.

During House committee markup, lawmakers adopted an amendment by Reps. Cheri Bustos (D-Ill.), Brenda Lawrence (D-Mich.) and Bruce Westerman (R-Ark.) calling for the Government Accountability Office to investigate the aviation technician shortage. Sen. Inhofe has also expressed interest in offering an amendment to the Senate bill creating a new aviation maintenance workforce development grant program. ARSA is on the hunt for a House sponsor for a parallel amendment.

House Rules Committee Chairman Pete Sessions (R-Texas), whose district has a large concentration of repair stations, has also been an important ally as we pave the way for amendments to the House bill.

Say Thanks To Our Champions!ARSA is fortunate have several members of Congress are going to bat for repair stations and supporting maintenance-related FAA bill amendments If someone from your state is on the list below, please shoot a quick note of thanks. It doesn’t have to be anything fancy and could be as simple as: “Thank you for your leadership on aviation maintenance issues in the FAA bill. As a member of the YOURSTATE repair station industry, I sincerely appreciate your efforts on our behalf.” (Clicking on the names below will open up a blank email address to their aviation staffers.) |

Other Priorities, Controversial Provisions Delay FAA bill Action

Despite early optimism that the House and Senate might take up their FAA bills before the August recess, aviation policy is taking a backseat to other issues. The Senate is mired in a long-running debate about Obamacare; the House has been focusing a defense authorization bill and on passing appropriations bills to keep the government running past Sept. 30.

Separate issues have added complexity to the FAA bills in the House and Senate. The House legislation would private air traffic control (ATC) in the United States, taking that function away from the FAA. While that strategy is strongly supported by House T&I Chairman Bill Shuster (R-Penn.), President Donald Trump and the airlines, privatization is opposed by the general aviation community, most Democrats and some rural Republicans. This vocal opposition made it difficult for Shuster to round up the 218 votes he needs to pass the bill in the House.

The Senate bill, which doesn’t include ATC privatization, contains a separate controversial provision to provide more flexibility for pilot training. While regional airlines support the language, which is designed to help address the pilot shortage, it has drawn sharp criticism from Senate Minority Leader Chuck Schumer (D-N.Y.) and family members of victims of the 2009 Colgan Air crash in upstate New York. Schumer has threatened to block the bill if the pilot training provision is not modified before the legislation reaches the Senate floor.

More information about the House FAA bill is available at: transportation.house.gov/21st-century-airr-act.

More information about the Senate bill is available at: www.commerce.senate.gov/public/index.cfm/pressreleases?ID=8D616600-D134-4131-B7A7-CD1FC50ADA1C.

Jennifer Weinbrecht, vice president of compliance at Component Repair Technologies in Mentor, Ohio hosted Tim Ross, district director for Rep. Bob Gibbs (R-Ohio), a member of the House aviation subcommittee, during his recent visit to CRT.

What’s Next and What Can You Do?

The current short-term authorization for the FAA enacted last summer is set to expire on Sept. 30 (see the counter below). At this point, it’s a virtual certainty that Congress will have to enact another short-term extension to keep money for the FAA flowing past that date. The big question is how long the extension will be.

Given all the progress in recent months and similarities between the House and Senate bills, we’re still optimistic Congress can get FAA reauthorization done this year. Given the importance of restoring certainty to FAA funding and aviation policy, ARSA and its members can play an important role in keeping pressure on. With that in mind, here’s what you can do to help:

First, if you haven’t already (and thanks to the many ARSA members around the county who have!), please send a quick note to your congressional offices urging them to support the maintenance-related amendments to the House and Senate FAA bills. To do so:

(1) Identify your members of Congress here.

(2) Identify the aviation staffer in each office (list of House staffers is here; list of Senate staffers is here).

(3) Send them a note of support. Need a place to start? Here’s a template:

Subject: Support FAA bill aviation maintenance amendments

Dear Name:

I’m YOURTITLE at YOURCOMPANY, an FAA-certificated aviation maintenance company in YOURCITY.

I’m writing to urge you to support maintenance-related amendments to the FAA bill related to voluntary surrender of repair station certificates, repairman certification, creating a new grant program to support aviation technician training, and asking the Government Accountability Office to examine the technical worker shortage in our industry.

Together, these provisions would help reduce the regulatory burden on companies like mine and further efforts to recruit and train the next generation of aviation technicians in-demand, well-paying careers in our industry.

Thank you for your consideration.

When you send the note, CC me (christian.klein@arsa.org) so I can follow up and provide more information.

Second, consider hosting a member of Congress or congressional staffer at your facility. In recent weeks, congressional staffers have visited ARSA members Component Repair Technologies in Mentor, Ohio and MOOG Aircraft Group in Fargo, North Dakota. These visits are an excellent opportunity to educate policymakers about what your company does and how you’re tied into the local and global economy. Feedback from the Hill and our members about these visits is universally positive. ARSA is standing by to assist in planning a meeting at your facility, including outreach to congressional offices and providing talking points and briefing materials. Send me an email at christian.klein@arsa.org if you want more information.

Third, get on Twitter and follow me (@caaklein), ARSA Vice President of Communications Brett Levanto (@levantoair), and ARSA (@ARSAworks) to keep up to date on important developments and news related to the FAA reauthorization push.

Thanks for standing with ARSA as we continue to fight for your interests on Capitol Hill and get the FAA bill over the goal line!

Quality Time

Editor’s note: The views and opinions expressed by contributing authors do not necessarily state or reflect those of ARSA and shall not be used for endorsement purposes.

SAS: The FAA’s New Approach to Risk-Based Safety Oversight

By Carol Giles, President, The Giles Group

Part Two – How did we all get SAS?

The first part of this two-part series reviewed the history of the FAA’s oversight systems that ultimately led to the implementation of Safety Assurance System (SAS).

This part will look at how the FAA rolled out its system safety philosophy from the Air Transportation Oversight System (ATOS), to the Repair Station Assessment Tool (RSAT) and least but not last SAS.

After ValuJet in May 1996, an internal review team recommended the FAA design and implement the ATOS. The oversight system was to improve safety by examining trends and correcting problems before an accident occurred. This first step toward system-safety oversight originally targeted the top ten U.S. air carriers – later it included all of them.

The FAA’s system safety philosophy was broader than the ones based solely on regulatory compliance; ATOS included the allocation of resources based on risk. It also forced air carriers to implement internal systems to identify and mitigate hazards and risks. ATOS included data collection tools in the form of questions and checklists designed to systemically examine an air carrier’s organizational design, performance and resultant risk to aviation safety.

ATOS implementation came with major growing pains. Inspectors were not appropriately trained and thus were inadequately prepared to properly collect and evaluate information. The industry didn’t comprehend the system, the agency’s expectations or the effects of the new approach. The system safety philosophy went beyond simple compliance and data collection tools were not always based on the plain language of the regulations. Many questions came from internal guidance, advisory circulars and unwritten “best practices.” Safety inspectors were supposed to encourage or “sell” action on non-regulatory findings as an added safety benefit. The uncoordinated approach resulted in confusion and complaints. As the system matured, air carriers were able to perform internal evaluations using the ATOS tools although standard and stable usage of the system was still elusive.

External concerns over contracting maintenance added new demands to the system safety oversight model. To address the OIG and GAO audits regarding this topic, the FAA developed the RSAT in 2007. RSAT was intended to provide a comprehensive, standardized repair station oversight planning and evaluation assessment. It was designed to identify areas of concern or criticality about a specific repair station, and target FAA resources to the areas of highest risk.

The system’s 14 elements established a baseline oversight program. Through inspection-generated data, a specific baseline for each repair station was to be created. The FAA could then design and implement appropriate follow-on or recurring oversight activities. Unfortunately, similar to the roll out of ATOS, the FAA did not prepare its workforce or the industry to assimilate the new oversight system. The RSAT’s limitations also precluded inspectors from using it effectively or efficiently. Coupling the lack of training and standard data, led to the inability to prioritize oversight based on risks.

In 2009, the International Civil Aviation Organization (ICAO) revised several annexes to include implementation of safety management systems for aircraft operators, maintenance organizations, air navigation services providers and airport operators. In 2010, ICAO published Annex 19 dedicated to the civil aviation agency’s safety management system.

The FAA began developing its own SMS to comply with the new ICAO standards. For the commercial operator requirements in ICAO’s Annex 6, it was a natural leap to evolve ATOS toward a safety assurance oversight model. In early 2014, the FAA announced the rollout of SAS as the safety assurance pillar of SMS. It is a set of policies, procedures and checklists for safety inspectors to verify compliance with the regulations by validating a certificate holder’s programs and operation. The initial deployment was completed by the end of 2015, and pertained to air carriers and commercial operators. Today the FAA has expanded its implementation to include repair station and other certificate holders.

This change in oversight methodology impacts aviation companies as well as inspectors. SAS monitors and measures the performance of the certificate holder’s operation by using audit information, as well as data analysis of the investigations conducted by the FAA and the certificate holder. Inspectors, certificate holders and applicants can share SAS-related information through a secure web-based portal. The FAA encourages all certificate holders to use the portal, but it is only “mandatory” for new applicants.

The SAS oversight model has five modules:

(1) Configuration.

(2) Planning.

(3) Resource management.

(4) Data collection.

(5) Analysis assessment action.

Only two – the configuration module and the data collection module – directly involve and depend on industry involvement and support.

The configuration module refers to any requested change to a certificate, like adding an aircraft or rating. It allows the certificate holder to enter the change via the external portal. The difference between this ability and the “old fashion way” lies in the automation attached to the portal that allows Operations Specifications and other certificate information to be updated automatically. Otherwise, the inspector must enter the same information to support the request and the certificate holder must wait for the agency’s resources to allow a change to take place.

Data collection occurs during FAA visits. The inspector uses data-collection tools (DCTs), similar to a checklist, to ensure the certificate holder’s (or applicant’s) system complies with the intent of the regulations and safety standards. However, we are faced with questions in the DCTs that go beyond regulatory compliance and also rely on ACs and inspector guidance material. While there was a greater effort by the FAA to train the inspector work force, there is still the strong desire by inspectors to have certificate holders comply with the SAS DCTs, not the plain language of a regulation. Some inspectors have gone as far as saying that a certificate holder’s manuals need to be “SAS compliant”. The DCTs are oversight tools for the inspector and a tool for the industry to use if so inclined. It is not a requirement that industry fill out the DCTs for the FAA.

After the inspector concludes the audit, results are entered into a database that feeds SAS and aids inspectors in risk assessment and planning future oversight activities. This data can also help the certificate holder review its systems to ensure that it is compliant with the regulations and operating to the highest standards.

As a certificate holder, it would be wise to use this data as a part of internal audits. After all, it’s not a bad thing to see what the FAA sees. The process and information can help the certificate holder with its own safety assurance.

Throughout both of these articles, it is clear to see that a series of significant safety events and other external forces resulted in the FAA changing its way of conducting oversight. Each iteration, all based on system safety, had challenges with both training and consistent application by inspectors.

The industry will have to stay tuned to see how long SAS will stick around before it is reinvented into the “NextGen” oversight system where the audits are conducted by robots and the regulations are applied equally across the board.

Since founding The Giles Group in 2011, Carol Giles’s industry experience, regulatory knowledge and relationships across aviation have contributed to crucial compliance solutions and resolutions for major airlines and leading MRO providers, as well as successful renewal certifications for U.S. and international maintenance facilities.

Editor’s note: The views and opinions expressed by contributing authors do not necessarily state or reflect those of ARSA and shall not be used for endorsement purposes.

Running a Criminal Background Check

By Claudia Culmone, Communications Specialist, NATA Compliance Services

As part of the new-hire evaluation process, one of the options available to you is to run a criminal check on the person you are considering for employment. You may be wondering if such an action is actually necessary. Checking the criminal records of your employees may provide you with clues into an applicant’s future behavior and alert you of potential issues. Three types of online database criminal history records checks are available: the National Criminal Records Check, the State Criminal Records Check and the County Criminal Records Checks.

The National Criminal Check is a report that is compiled from several sources. These sources include records provided by states throughout the United States, the FBI Terrorist List, the Multi-State Sex Offender Database, and federal/state/local wanted fugitive lists. It is important to keep in mind that the contribution of states’ records is completely voluntary. Therefore, some states, such as Pennsylvania, do not submit information to the national database. Despite this, conducting a National Criminal Check is an effective way to determine if a deeper review of a person’s past should be initiated.

For states that do not contribute to the national database, or for a more localized search, the State Criminal Check is another option. Each state maintains its own database of criminal offenses and this report offers a general check to see if the employee may have a record. However, it is important to understand that there are some limitations. For example, just as states have the right to opt out of reporting to the national database, counties have the final decision in what they send to the state. Some counties may decide not to include certain misdemeanors such as traffic offenses or even driving while intoxicated. Additionally, only offenses listed in the state’s penal code will appear on the report and if the database is not updated on a regular basis, it may not show recent offenses.

The County Criminal Check is considered the most thorough overview of a person’s past interactions with the criminal justice system. This report is compiled from court records within that county and includes all local and state offenses committed within that county. Because this check is jurisdiction-related, it is a good idea when running one to include neighboring counties as well. The limitation to County Criminal Checks is that it queries only records in that specified county.

Finding a criminal past does not necessarily indicate that the person is not the right fit for your company, depending on policies and regulatory requirements. Good people sometimes make bad decisions. However, conducting a criminal background check can be a useful tool in narrowing down your choice of candidates.

For more information please visit: info.natacs.aero/background-checks.

In addition to expertise in background checks and other compliance issues, NATA Compliance Services (NATACS) is an ARSA-approved preferred provider of solutions for a safe and compliant drug-free workplace. NATACS is a “one stop” solution that provides policy templates, plan setup, regulatory assistance, and program administration. For more information, visit https://www.natacs.aero/ARSA or call 800.493.9707.

Editor’s note: The views and opinions expressed by contributing authors do not necessarily state or reflect those of ARSA and shall not be used for endorsement purposes.

When Growth Outpaces Capacity – 2017 MRO Survey by Oliver Wyman

By Brian Prentice, Derek Costanza and John Smiley, Oliver Wyman

Oliver Wyman’s 2017 MRO survey finds that executives from the maintenance, repair, and overhaul industry are worried about an anticipated shortfall in the number of adequately trained mechanics at a time when the global airline fleet is expanding and modernizing.

Over the next decade, the record number of maintenance technicians eligible to retire will outpace the total of new mechanics entering the market globally. For example, by 2027 demand in the United States for maintenance technicians is forecasted to outstrip supply by 9 percent.

Additionally, the shortfall is expected to create expertise gaps in critical areas as the industry finds itself having to service a fleet that by 2027 will be almost equally divided between older and newer-technology aircraft. Already, a majority of survey respondents (78 percent) report it is getting harder to hire mechanics and the tightening labor market is pushing them to rely on overtime and other stop-gap efforts to keep up with demand.

Meanwhile, the promise of advanced analytics and game-changing technologies remains elusive for many in the aftermarket, with only 20 percent of respondents currently seeing a material impact on business operations from these technologies. Participating executives describe their industry as constrained by old IT systems (62 percent) that lack functionality and flexibility and are too often not compliant with changing regulations.

Given the looming labor shortage and failure to upgrade technology, Oliver Wyman sees a prospect for rising maintenance costs and an increase in turnaround times for scheduled maintenance. In response, airlines are likely to retain more spare aircraft as a backup for potential servicing delays.

If you have any questions regarding these materials, contact the MRO research team.

Click here to access the full report.

Click here (or see below) to access a video presentation of the report’s results or here to go directly to the presentation slides.

Oliver Wyman is a global consultation and analysis firm, performing a wide range of services across 14 different industries. In partnership with ARSA, the firm’s aviation experts perform an annual analysis of the international market for civil aviation maintenance. To learn more, visit: www.oliverwyman.com or arsa.org/market-assessment.

Training

Building a Positive Government Relationship

This session provides a roadmap for building a positive relationship with civil aviation authorities. It begins by describing the rules that should always be considered when engaging with aviation safety regulators, then provides instruction on how to introduce your company and maintain consistent contact – not just when there’s a problem. It concludes by providing strategies for maintaining a professional relationship with regulators.

Instructor: Sarah MacLeod

Click here to register and get access for 90 days.

As a repair station, dealing with the government, particularly the Federal Aviation Administration (FAA) is inevitable. Building a good relationship with government officials in good times will help keep the bad times at bay. ARSA works to provide its members with the tools to make the most out of every interaction with a regulator.

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit PotomacLaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

In addition to this training session, members should review the resources available from the association:

Part 65 – Overview

This session overviews 14 CFR part 65, Certification: Airmen Other than Flight Crewmembers. It introduces the statutory authority through which the FAA administers certificates and outlines the rules for application, issuance, testing, disqualification and duration of agency-issued certificates. It then introduces the five different certifications issued under part 65 by reviewing the relevant eligibility requirements for each.

Click here to register and get access for 90 days.

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit PotomacLaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

From the FAA – Don’t Get Dirty

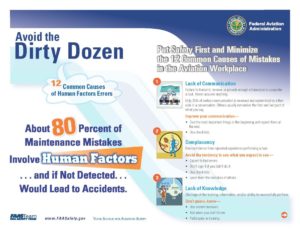

The FAA’s “Maintenance Hangar” on faasafety.gov contains information and resources the agency has produced or compiled to support safety in maintenance operations. The “toolbox” section includes alerts, guidance, tips, training information, posters and handout materials. Members of the maintenance community working on U.S.-registered aircraft should become familiar with these resources; at the very least they help highlight the areas considered most important by the agency.

To provide a taste of the content available in the “maintenance hangar,” this edition of the hotline is taking a look at the “dirty dozen” – the 12 common causes of mistakes in the aviation workplace. Check out the poster and make sure you’re working to control for the human factors in maintenance:

The “Maintenance Hanger” can be found at: www.faasafety.gov/content/TabLanding.aspx?tab=mechanics.

Regulatory Compliance Training

By ARSA Training and Regulatory Teams

Test your knowledge of 14 CFR §§ 65.1 – Applicability and 65.3 – Certification of foreign airman other than flight crewmembers.

Click here to download the training sheet.

Membership

Quick Question: Technician Workforce by Certification

Certification requirements are a key part of technical workforce development issues. As ARSA works to help close the skills gap and get aircraft technicians/mechanics/engineers to work, help the association capture data about the portion of repair station technicians holding certificates.

Please note that the survey appears on this page in an embedded window; you can scroll in the window to access the “Done” button and complete the questionnaire.

If you have questions or want to provide additional information, contact Brett Levanto (brett.levanto@arsa.org).

Click here to see what questions have been asked and answered…and keep a lookout for more.

2017 NextGen Awards – Celebrate Young Talent

ARSA’s commitment to building the aviation maintenance workforce of the future means celebrating the excellence of the men and women who already keep the world safely in flight. The association encourages its members to celebrate outstanding young personnel through Aircraft Maintenance Technology Magazine’s Next Gen Awards.

Criteria for selection include job commitment, industry involvement and contribution, professional achievement and innovation. Anyone working in any aviation maintenance field who will be 39 years old or younger on Nov. 1, 2017 is eligible for nomination. Winners will be featured in the magazine’s November/December issue and celebrated on AviationPros.com.

Click here to learn more and nominate someone today. The deadline for submissions is Sept. 8, 2017.

Anyone submitting a nomination is encouraged to contact ARSA’s Vice President of Communications Brett Levanto, so the association can join AMT Magazine in celebrating the best of this community’s young talent. Through its experience with the awards program in 2015, ARSA saw first-hand the vital importance of celebrating the maintenance industry’s most valuable resource: its people.

A Member Asked…

Q: Section 145.211(c)(iii) states that you must perform a hidden damage inspection on all articles that have been involved in an accident. In this instance, how is an accident defined? If an aircraft hits a tree while being transported on a trailer, is this an accident in the view of the regulations? My answer is no. An accident is only a flying or operational accident with an aircraft. If an aircraft is being transported before maintenance I do not view this as needing hidden damage, but I need ARSA’s assistance here.

A: There are two answers to your query: the regulatory one, where “accident” is defined by the NTSB (not the FAA) and the business one, which requires your work to result in a usable item. Therefore, the ARSA model repair station and quality manual defines “accident” thusly:

With respect to aircraft, the term is defined by the NTSB and means an occurrence associated with the operation of an aircraft which takes place between the time any person boards the aircraft with the intention of flight and all such persons have disembarked, and in which any person suffers death or serious injury, or in which the aircraft receives substantial damage. (See, 49 CFR § 830.2.)

With respect to other civil aviation articles, the term refers to the article being subjected to extreme conditions not covered by or anticipated to be corrected by maintenance data issued by the manufacturer. The repair station must have actual knowledge that the article was involved in such an occurrence.

When an article you received for maintenance has been subject to conditions that would render it “unairworthy” in some manner it would behoove the repair station to ensure that it was not releasing something that would fail. So, if the repair station has ACTUAL KNOWLEDGE of a condition that could not be discovered without a “hidden damage” inspection, it should be addressed.

For example, if you are told that something was dropped from a high platform to a concrete floor, you wouldn’t ignore the impact (no pun intended) that could have on the continued airworthiness of the article. Or if during the inspection process (or maintenance process) a condition was found that was obviously due to an extreme condition (overtemperature of an engine), it would be hard to ignore the finding. Indeed, if during the transport of the aircraft it was subjected to a condition that could render it unairworthy and that condition would be found or “cleared” by a “hidden damage” inspection, why wouldn’t the inspection be prudent?

Of course, the hidden damage inspection needs to be such that would find the unairworthy condition; a repair station may need help from a qualified engineer or the manufacturer, but it would be better than having the hidden damage render the article unairworthy, particularly when a repair station has ACTUAL KNOWLEDGE of the article’s “accident.”

Ironically, an aircraft can have an accident as that term is defined by the NTSB but it may have absolutely no impact on an installed article. Substantial damage to (or a fatality in) an aircraft does not automatically render every installed item on that aircraft “unairworthy.” Unfortunately, the regulations are not always logical. So, if an article is removed from an “accident aircraft,” a repair station must perform a “hidden damage” inspection. That inspection should include an explanation of the accident so that an appropriate parameter can be established for the article’s review. Some articles may only need to undergo a “normal” inspection found in the maintenance manual, while others may need a “special” inspection developed to find any “hidden damage.”

Have a question for ARSA? Click here to let us hear it.

Make ARSA’s Voice Your Own: Advertise

ARSA has a menu of advertising opportunities for arsa.org, the hotline and the ARSA Dispatch.

Take advantage of these great opportunities today to showcase your company, a new product or event. For more information go to arsa.org/advertise.

Stand Up for ARSA by Sponsoring in 2017

In order to provide world-class resources for its members, the association depends on the commitment of the aviation community. By sponsoring events and activities, supporters can help ARSA’s work on behalf of repair stations to endure.

Need a place to start? For information about opportunities, including sponsorship of the Strategic Leadership Conference in October (click here for info), contact Vice President of Communications Brett Levanto (brett.levanto@arsa.org).

Resources

ARSA strives to provide resources to educate the general public about the work of the association’s member organizations; should you need to provide a quick reference or introductory overview to the global MRO industry, please utilize AVMRO.ARSA.org.

AVMRO Industry Roundup

ARSA monitors media coverage on aviation maintenance to spread the word about the valuable role repair stations play globally by providing jobs and economic opportunities and in civic engagement. These are some of this month’s top stories highlighting the industry’s contributions.

You can explore these stories through ARSA’s Dispatch news portal.

Industry Calendar

ATEC Fly-In – Washington – Sep. 6-7

Aero-Engines Europe – Madrid – Sep. 13-14

MRO Europe – London – Oct. 3-5

Airline Engineering & Maintenance: North America – Miami – Oct. 18-19

AVMRO Strategic Leadership Conference – Washington – Oct. 18-19

MRO Asia-Pacific – Singapore – Oct.31-Nov. 2

Aerospace Manufacturing Asia-Pacific – Singapore – Nov. 1-2

Aero-Engines Asia-Pacific – Singapore – Nov. 1-2

Previous Editions

| 2017: | Jan | Feb | Mar | Apr | May | June | July | |||||

| 2016: | Jan | Feb | Mar | Apr | May | June | July | Aug | Sept | Oct | Nov | Dec |

| 2015: | Jan | Feb | Mar | Apr | May | June | July | Aug | Sept | Oct | Nov | Dec |

| 2014: | Jan | Feb | Mar | Apr | May | June | July | Aug | Sept | Oct | Nov | Dec |

| 2013: | Jan | Feb | Mar | Apr | May | June | July | Aug | Sept | Oct | Nov | Dec |

| 2012: | June | July | Aug | Sept | Oct | Nov | Dec |

the hotline is the monthly publication of the Aeronautical Repair Station Association (ARSA), the not-for-profit international trade association for certificated repair stations. It is for the exclusive use of ARSA members and federal employees on the ARSA mailing list. For a membership application, please call 703.739.9543 or visit http://arsa.org/membership/join/. This material is provided for educational and informational purposes only. It does not constitute legal, consulting, tax or any other type of professional advice. Law, regulations, guidance and government policies change frequently. While ARSA updates this material, we do not guarantee its accuracy. In addition, the application of this material to a particular situation is always dependent on the facts and circumstances involved. The use of this material is therefore at your own risk. All content in the hotline, except where indicated otherwise, is the property of ARSA. This content may not be reproduced, distributed or displayed, nor may derivatives or presentations be created from it in whole or in part, in any manner without the prior written consent of ARSA. ARSA grants its members a non-exclusive license to reproduce the content of the hotline. Employees of member organizations are the only parties authorized to receive a duplicate of the hotline. ARSA reserves all remaining rights and will use any means necessary to protect its intellectual property.

© 2017 Aeronautical Repair Station Association