2019 – Edition 10 – November 1

Table of Contents

Note: The order of material varies in hotline emails, but is always presented the same on this landing page. Readers scrolling through content on or printing this page will find it organized consistent with the table of contents.

The Lead

ARSA Works

Legal Brief

ARSA on the Hill

Regulatory Update

Training

Membership

Resources

Industry Calendar

The Lead

Don’t Let a Crisis Go to Waste … The Fight Isn’t Over

By Christian A. Klein, Executive Vice President

ARSA is pleased that Airbus has formally withdrawn its plan to charge repair stations a royalty for the use of the company’s maintenance data. The proposal was in clear violation of FAA rules and policy requiring design approval holders to make instructions for continued airworthiness (ICA) available to an airline’s chosen maintenance providers without restriction.

When unveiled this summer, the Airbus proposal sent shockwaves through the maintenance industry. But it also got the attention of airlines, who recognized the potential impact on both their costs and access to maintenance services.

While the decision to withdraw the royalty plan is an important development, the fight is far from over. Restrictive design approval holder (DAH) practices are nothing new for the industry or for ARSA. The association has been fighting for decades to get the FAA to enforce its maintenance data development and access rule. Unfortunately, that fight has largely been in the shadows and, with a few notable exceptions, airlines haven’t gotten involved.

By so brazenly seeking to turn maintenance data into a profit center, Airbus has elevated the visibility of the ICA issue among airlines. Airlines are critical to resolving maintenance data development and access issues once and for all.

By aggressively advocating for maintenance data development and access during the aircraft purchasing process, airlines could get contractual guarantees that ICA is made available as required by the regulations. That would give the airlines more flexibility in making maintenance contracting decisions, which will help reduce costs.

Airbus has unwittingly opened the door for conversations with owner/operator customers about data access issues. There’s never been a better time to educate them about the problems you have getting ICA and how it directly impacts the continued airworthiness of an aircraft or other product. Explain the rules and economics. Urge them to push back against restrictive practices that violate the regulations. And urge them to get their trade associations involved active in the fight.

ARSA Works

Act Now

Association members, allies and industry colleagues must support ARSA’s current initiatives to improve aviation policy. Here’s your to-do list for November 2019 (click each page link for more information and instructions):

Educate owner/operators about the challenges you face in getting ICA…

By aggressively advocating for maintenance data development and access during the aircraft purchasing process, airlines could get contractual guarantees that ICA is made available as required by the regulations. That would give the airlines more flexibility in making maintenance contracting decisions, which will help reduce costs. (See the lead piece and/or legal brief in this edition of the hotline for more information.)

Help an ARSA-led coalition get money from Congress for technician workforce grants…

Grant Funding in the Works, Needs Help

On Sept. 19, the Senate Appropriations Committee passed its version of the 2020 Transportation, Housing and Urban Development and Related Agencies (T-HUD) appropriations bill. It included a total of $5 million in funding for both the technician and related pilot education grant programs authorized in last year’s FAA law – half of the total authorized level. In June, the House version included full funding for both programs ($10 million total).

Use a good, but too-well hidden, example from the FAA as a model for engaging with local students…

Aviation STEM Events Can’t Be Hidden Gems

On Sept. 26, the FAA’s Aviation Safety Office (AVS) hosted its second STEM Careers Symposium at the agency’s headquarters in Washington, D.C. The event brought hundreds of local middle and high school students from the nation’s capital to 800 Independence Avenue for demonstrations, presentations and exhibits on aviation careers, skills and the government’s oversight of U.S. airspace.

What ARSA Has Done Lately – Third Quarter 2019

Each quarter the board of directors receives reports on the association’s activities. Step into a board member’s shoes by reviewing ARSA’s work on behalf of aviation safety between July and September 2019:

Regulatory Advocacy

- Secured appointment (SM) to congressionally mandated FAA Safety Oversight and Certification Advisory Board (SOCAC).

- Encouraged industry attendance at Small Business Administration regional regulatory roundtables as well as national regulatory fairness hearing.

- Encouraged industry participation in FAA Engine Safety Review by attending/supporting Oct. 24 Engine & Airframe Engine Integration Safety Summit.

- Organized industry participation in “Nixing the Fix: Workshop on Repair Restrictions,” hosted by the U.S. Federal Trade Commission on July 16 in Washington, D.C.

- Confirmed FAA removal from agency guidance of the non-regulatory requirement for repair station applicants to submit a “letter of compliance.”

- Received an “interim response” from the FAA’s Regulatory Consistency Communications Board (RCCB) regarding 2017 request for clarity regarding the right of repair stations to replace 100 percent of an article while performing maintenance.

- Congratulated incoming FAA Administrator Steve Dickson in letter outlining key industry priorities for the agency.

- Commented on EASA Notice of Proposed Amendment (NPA) 2019-05, “Embodiment of safety management system (SMS) requirements into Parts 145 and 21 of EASA’s rules.”

- Developed and circulated to allies for comment Sec. 625 workforce grant program notice for eventual submission to FAA.

- Continued support of the Aviation Rulemaking Advisory Committee’s (ARAC) Part 145 Working Group—developed template for acceptable methods of compliance, developed logistics, invitations, agenda, working documents and co-chaired in-person meeting.

Legislative and Lobbying

- Continued leading lobbying coalition to secure funding for new aviation maintenance workforce and pilot education grant programs created by Sec. 625 of last year’s FAA bill.

- House Transportation-House & Urban Development and Related Agencies (T-HUD) appropriations bill includes full funding ($10 million) for the programs.

- Senate T-HUD bill contains partial funding ($5 million for both).

- Coordinated and participated in multiple meetings with congressional staff and allied organization representatives to reinforce association priorities on contract maintenance, delegation and stakeholder engagement.

- Submitted comprehensive statement on ARSA workforce priorities in conjunction with Sept. 26 House aviation subcommittee hearing on FAA reauthorization implementation.

- Sent letter to leaders of the Senate Armed Services Committee in support of Sec. 803 of House-passed FY 2020 National Defense Authorization Act, which would require DoD to develop guidelines and resources related to the acquisition or licensing of intellectual property, including maintenance technical data.

- Contributed $500 from ARSA PAC to House Transportation & Infrastructure Committee Ranking Member Sam Graves (D-Mo.).

Communications and Surveys

ARSA in the News – Selected Industry Coverage

Big Data Thinkers Starting to Get More Realistic About Data Sharing

Sept. 19, 2019

Aviation Week/MRO Network

The recent FlightGlobal Aerospace Big Data Conference in Miami appeared to advance the discussion on more realistic grounds than had sometimes been common before, according to Brett Levanto, vice president of operations at the Aeronautical Repair Station Association.

DOT’s Cert Committee Encompasses Spectrum of Industry

August 28, 2019

AIN Online

The U.S. Department of Transportation has selected officials representing a large swath of the aviation industry to make up its newly formed Safety Oversight and Certification Advisory Committee (SOCAC).

Boeing and Airbus Under the Spotlight: Safety ‘Doesn’t Come First’ in the Cosy World of Aircraft Regulation

July 29, 2019

The Times [London]

In the ballroom of the Pullman Hotel in Cologne last month, top officials from the European and American aviation watchdogs rubbed shoulders with hundreds of executives from the world’s largest aircraft manufacturers at their annual safety conference.

Court Overturns NTSB Findings in Falsification Case

July 23, 2019

AIN Online

Finding the NTSB did not follow its own precedents, the U.S. Court of Appeals for the District of Columbia overturned a certificate revocation of the Kornitzky Group…While ruling favored the company, the Aeronautical Repair Station Association fears it might have been for the wrong reason.

ARSA-placed Industry Editorials

| AMT Magazine | The “Good Example” Movement August/September Edition | Brett Levanto |

| Aviation Week | Make Every Day an Air Show July Edition | Christian A. Klein |

| Dear Mr. Administrator August Edition | Brett Levanto |

|

| Bilateral or Bust? September Edition | Sarah MacLeod & Christian A. Klein |

|

| DOM Magazine

|

Except When it Does July Edition | Sarah MacLeod |

| Scraping Off the Rust August Edition | Brett Levanto |

Surveys

- Conducted “Quick Question” surveys:

- SMS adoption (September)

- This is Your Professional Life (July)

- Completed development of Aviation Career Path Survey targeted at students, teachers and guidance counselors; considering distribution strategies/timelines (stay tuned for distribution/implementation).

Events, Meetings and Training

Meetings

- July 1: Christian met with Rich Efford/Aerospace Industries Association (AIA) to discuss political threats to maintenance contracting.

- July 9: Christian coordinated a meeting and facility tour with Miami-area congressional district staff at HEICO.

- July 10: Christian spoke at the Greater Miami Aviation Association’s July meeting.

- July 11: Christian and Brett met with Steve Douglas and Anthony Dinota/Oliver Wyman to discuss collaborative efforts.

- July 16: Sarah met with Rick Domingo/FAA to discuss pending issues and priorities.

- July 16: Christian attended the Federal Trade Commission’s (FTC) Nixing the Fix workshop on restrictive OEM practices.

- July 17: Christian attended the House Transportation & Infrastructure Committee aviation subcommittee’s hearing on the “State of Aviation Safety”.

- July 17: Christian met with Scott Verstandig/Aircraft Owners and Pilots Association (AOPA) to discuss grant program lobbying efforts.

- July 20: The firm and ARSA hosted the annual City Boy Farm summer social event, which was attended by industry colleagues.

- July 22: Christian met with Natalie Hartman/Lufthansa to discuss collaborative opportunities and membership development.

- July 23: Christian and Brett participated in a conference call with Crystal Maguire/Aviation Technician Education Council (ATEC), Ryan Goertzen/AAR and James Brown/STEM Education Coalition to discuss collaborative opportunities on workforce issues.

- July 24: Christian coordinated and participated in 10 meetings with House aviation subcommittee staff and subcommittee member offices to discuss contact maintenance and workforce issues.

- July 24: Christian participated in a fundraiser for House Transportation & Infrastructure Committee Ranking Member Sam Graves (R-Mo.)

- July 25: Sarah, Christian and Brett participated in a conference call with Owen Bruce/FAA to discuss technology initiatives related to workforce development.

- July 30: Brett attended AeroClub of Washington luncheon with guest speaker Jerry Moran (R-Kansas).

- July 31: Sarah met with Ali Bahrami/FAA to discuss pending issues and priorities.

- July 31: Christian and Josh Krotec/First Aviation met with FTC staff to discuss restrictive OEM practices.

- July 31: Christian coordinated and participated in five congressional meetings with House aviation subcommittee member offices.

- 12: Christian attended the swearing-in ceremony at the U.S. Department of Transportation for new FAA Administrator Steve Dickson.

- 13: Christian and Brett met with staff from the Ritz Carlton Pentagon City to discuss upcoming ARSA events.

- 14: Christian and Brett had lunch with Cade Clark and John Shea/Helicopter Association International (HAI) to discuss shared legislative priorities.

- 14: Christian and Brett participated in a conference call meeting of the Choose Aerospace Steering Committee.

- 14: Christian coordinated the nominating committee call with Dave Latimer and Gary Fortner.

- Aug 14: Sarah and Brett participated in conference call with Government Accountability Office (GAO) staff on FAA Compliance Program review.

- 20: Brett participated in a conference call with Louis Soderlind/Swedish Trade Council to discuss international aviation workforce issues.

- 5: Christian hosted a membership onboarding call for ALA North America leadership.

- 9: Christian and Brett participated in a call with representatives from ATEC, AAR, the STEM Education Coalition and Sheree Utash from Wichita State University, a member of President Trump’s workforce development board, to discuss the Sec. 625 grant program and other workforce development initiatives.

- 10: Christian participated in the quarterly Transportation Security Administration Aviation Security Advisory Committee (ASAC) meeting.

- 11: Christian spoke at the ATEC Legislative Luncheon about ARSA’s workforce development initiatives and the Sec. 625 grant program.

- 11-12: Brett participated in the FlightGlobal Aerospace Big Data Americas conference in Miami.

- 11-13: Sarah co-chaired in-person ARAC Part 145 Working Group meeting in Lee Summit, Kansas.

- 12: Christian met with Jonathon Frye/National Air Transportation Association (NATA) to discuss joint legislative efforts.

- 17: Christian met with Paul Feldman/General Aviation Manufacturers Association (GAMA) to discuss joint legislative efforts.

- 17-18: Sarah participated in GA Engine Summit in Burlington, Massachusetts.

- 18: Brett met with Chris Sharp/FAA to discuss agency’s workforce development initiatives, committees and Aviation and Space Education Program resources.

- 19: Sarah participated in the FAA’s Aviation Rulemaking Advisory Committee meeting.

- 19: Sarah, Christian and Brett participated in a conference call with GAO staff on the transition to quieter aircraft.

- 19: Christian attended the fall meeting of the U.S. Chamber of Commerce’s Transportation Infrastructure and Logistics Committee.

- 25: Christian hosted a lunch at the Army and Navy Club for ARSA member Washington, D.C. representatives.

- 25: Christian participated in a conference call with Dan Spatz/Columbia Gorge Community College to discuss the Sec. 625 grant program and CGCC’s new A&P school.

- 26: Christian met with Rich Efford/AIA to discuss foreign repair station and certificate reform issues.

Training

- Presented six live human factors training sessions:

- Dirty Dozen: Complacency (Aug. 27)

- Dirty Dozen: Lack of Knowledge (Sept. 3)

- Dirty Dozen: Distraction (Sept. 5)

- Dirty Dozen: Lack of Teamwork (Sept. 17)

- Dirty Dozen: Fatigue (Sept. 24)

- Dirty Dozen: Lack of Resources (Sept. 26)

- Q4 live training sessions scheduled [and completed]:

- Dirty Dozen: Pressure (Oct. 1)

- Dirty Dozen: Lack of Assertiveness (Oct. 8)

- Dirty Dozen: Stress (Oct. 10)

- Dirty Dozen: Lack of Awareness (Oct. 22)

- Dirty Dozen: Norms (Oct. 29)

Collaboration via ARSA Board Roundtable with Industry, FAA

ARSA board members and association allies participate in an Oct. 17 roundtable at the headquarters of Airlines for America in Washington, D.C.

On Oct. 17 and 18, ARSA’s Board of Directors made its regular fall visit to the nation’s capital. For the second year, directors participated in an afternoon industry roundtable before returning to the Ritz-Carlton Pentagon City (site of ARSA’s Annual Conference each March; stay tuned for 2020 registration information) for the board’s annual meeting.

Following the model established in 2018, the Thursday roundtable session featured member engagement, discussions with allied associations and facetime with the FAA. After lunch at the Old Ebbitt Grill with D.C. representatives from ARSA member companies, the board headed down the street the Airlines for America’s headquarters for an afternoon of substantive discussion.

Reflecting ARSA’s years’ worth of coalition building efforts – particularly its ongoing campaign to establish and federally fund aviation workforce grant programs – the roundtable discussion brought strong participation from other industry trade associations. Each ally representative gave a short briefing on the most pressing issues facing the organization’s membership. These reports reflected the diversity of the industry’s interests and underscored the need for the aviation community to support one another, bolstering efforts across a wide range of topics.

A quick glance at the concerns of each organization in attendance:

Aircraft Electronics Association – Reconciling the plain language of 14 CFR part 145 with FAA guidance and enforcement of the repair station rule. (AEA Vice President of Government & Industry Affairs Ric Peri is co-chair with ARSA Executive Director Sarah MacLeod on the ARAC Part 145 Working Group.)

Aircraft Owners and Pilots Association – Supporting the national airspace and developing legislation to establish a center for aviation excellence to study and support industry needs.

Aviation Suppliers Association – Removing all regulatory and business impediments (and preventing new ones) to the safe handling and shipment of aircraft parts.

Aviation Technician Education Council – Overhauling and modernizing 14 CFR part 147, the rule governing aviation maintenance training schools.

Helicopter Association International – Educating policymakers about the harmful impacts of legislation aiming to limit the use of helicopter air tours or rotorcraft operations in specific geographic areas.

Modification and Replacement Parts Association – Ensuring that regulatory developments are safety focused while supporting necessary systems, procedures and resources to utilize PMA/DER repairs.

National Air Carrier Association – Helping make good use (and limit increases) of passenger facility charges and supporting reasonable, safety focused promulgation of rules related to aircraft seat pitch and evacuation.

National Air Transportation Association – Dealing with enforcement inconsistencies and setting standards for “through the fence” maintenance as well as educating industry regarding use of aircraft management companies.

Regional Airline Association – Managing requirements related to aircraft certification and management of resources required by the regulators for operation.

In addition to these specific interests, each presenter noted concern and focus on growing the aviation workforce of the future. This central theme, on which ARSA has focused for several years, has become a galvanizing force for the aerospace community, attracted the attention of lawmakers across the country and has become a primary interest of new FAA Administrator Steve Dickson.

The administrator’s workforce focus – which ARSA encouraged in its letter welcoming him to the agency – was relayed along with other points of interest when executives from the FAA’s Office of Aviation Safety (AVS) arrived for the second half of the afternoon. Associate Administrator for Aviation Safety Ali Bahrami, Flight Standards Executive Director Rick Domingo, Policy and Innovation Division Director Mike Romanowski and Certification Procedures Branch Manager Dan Elgas stayed beyond their allotted time to interact with the group. After fielding questions and covering points from the AVS Strategic Plan, the government officials encouraged industry to help address problems in oversight by sharing clear examples.

The value of the meeting’s collaboration was best described by Jim Coon, AOPA senior vice president of government affairs and advocacy. “[Each of us] may care about a lot of issues,” Coon said during his briefing, relaying a lesson learned from his experience in Washington, “but you can only work one issue at a time.”

Considering the diversity of needs on display during the roundtable and the deep impact of the few central problems facing the aviation community, the importance of collaboration is quite clear. Since its only possible to work one issue at a time, managing them – and going deep enough on the big ones – takes teamwork. ARSA, its team members and the volunteer leaders on its board demonstrated shared commitment to that cooperation throughout the event.

Legal Brief

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

Law and Regulations Rule – Not Manufacturers

By Joseph Corrao, Vice President of Regulatory Affairs and Sarah MacLeod, Executive Director

Recently, a manufacturer of aircraft frequently found in airline fleets proposed to apply a surcharge on gross amounts billed by repair stations to air carrier customers (see this month’s lead piece about not letting a crisis go to waste). The manufacturer said the surcharge was necessary to recoup the cost of permitting access to the manufacturer’s maintenance data supporting the work performed on its aircraft.

An outcry ensued as operators pointed out they had already paid for access to that data, that their chosen repair stations would naturally pass the surcharge on to their customers as an appropriate overhead item and thus the operators would end up paying for the data twice.

The manufacturer withdrew the proposal, but the incident raised a question: What are the regulatory limits of a manufacturer’s obligation to provide maintenance data?

In the FAA Modernization and Reform Act of 2012, P.L. 112-95 (Feb. 14, 2012), at section 319, Congress made clear – and instructed FAA to make clear – that:

- Essential maintenance that could result in a failure, malfunction or defect endangering the safe operation of an aircraft if not performed properly or if improper parts or materials are used;

- Regularly scheduled maintenance; and

- Required inspection items (as defined by the Administrator)…

Could be performed on aircraft operated under 14 CFR part 121 only by—

- A part 121 air carrier;

- A part 145 repair station or a person authorized under § 17; or

- A person that provides contract maintenance workers, services, or maintenance functions to a part 121 air carrier or part 145 repair station and meets the requirements of the part 121 air carrier or the part 145 repair station, as appropriate, as long as the applicable part 121 air carrier is directly in charge of the covered work being performed, the covered work is carried out in accordance with the part 121 air carrier’s maintenance manual, and the person carries out the covered work under the supervision and control of the part 121 air carrier.

Under the statute, repair stations are among a limited group of entities authorized by Congress to work on airline aircraft. As a result of the law, the FAA issued a regulation resulting in § 121.368 that provides—

(e) Each certificate holder who contracts for maintenance, preventive maintenance, or alterations must develop and implement policies, procedures, methods, and instructions for the accomplishment of all contracted maintenance, preventive maintenance, and alterations. These policies, procedures, methods, and instructions must provide for the maintenance, preventive maintenance, and alterations to be performed in accordance with the certificate holder’s maintenance program and maintenance manual. (Emphasis added.)

Further, § 145.205 requires the repair station to follow the air carrier’s maintenance program and manual.

The question then becomes: Can manufacturers limit access to maintenance data in a way that inhibits the ability of qualifying third parties to accomplish necessary work on air carrier aircraft?

Section 21.50(b), states, in part:

The holder of a design approval…must furnish at least one set of complete Instructions for Continued Airworthiness to the owner of each type aircraft, aircraft engine, or propeller upon its delivery… Thereafter, the holder of a design approval must make those instructions available to any other person required by this chapter to comply with any of the terms of those instructions. In addition, changes to the Instructions for Continued Airworthiness shall be made available to any person required by this chapter to comply with any of those instructions.

In interpreting § 21.50(b), the FAA explained in its Policy Statement PS-AIR-21.50-01: “Type Design Approval Holder Inappropriate Restrictions on the Use and Availability of Instructions for Continued Airworthiness” (March 23, 2012) that:

It is not appropriate for a [Design Approval Holder] to place limitations on the use of its ICA between the owner/operator and the maintenance provider, whether the maintenance provider is rated or not, to perform that maintenance. A maintenance provider that is not rated, or is seeking the appropriate FAA rating to perform maintenance on the owner/operator’s products, may obtain ICA from the owner/operator. For those maintenance providers that have the necessary FAA rating, FAA Order 8110.54A, chapter 6 paragraph 4.a, states that the DAH would be required to make the ICA and any subsequent revisions available directly to the maintenance provider upon its request.

The FAA’s policy goes further:

[A] DAH may not inhibit an owner/operator from distributing ICA to current or potential future maintenance providers. Therefore, it is not acceptable for a DAH to limit the distribution of ICA through restrictive access or use agreements, or by adding restrictive language that would control the use of ICA by an owner/operator with respect to the maintenance of its product.

The FAA provided a non-exhaustive list of DAH practices deemed unacceptable under 14 CFR § 21.50(b), including—

(1) Requiring the owner/operator to install only DAH-produced or authorized replacement parts, articles, appliances, or materials.

(2) Requiring that alterations or repairs must be provided or otherwise authorized by the DAH.

(3) Requiring the use of only maintenance providers or other persons authorized by the DAH to implement the ICA.

(4) Establishing, or attempting to establish, any restriction on the owner/operator to disclose or provide the ICA to persons authorized by the FAA to implement the ICA.

It appears clear that Congress and the FAA’s policy agree: DAHs are prohibited from denying or limiting access to ICA to an owner and/or operator or its chosen maintenance provider.

ARSA on the Hill

Repair Station Legislation Likely in Any House Aviation Reform

By Christian A. Klein, Executive Vice President

House Transportation & Infrastructure (T&I) Chairman Peter DeFazio (D-Ore.) has longstanding concerns about contract maintenance and foreign repair stations in particular, so it’s hard to imagine the maintenance industry won’t be caught up in his legislative efforts.

DeFazio has harped on the fact that the FAA hasn’t complete a congressionally-mandated rulemaking on foreign repair station drug and alcohol testing. When the Transportation Security Administration (TSA) missed a similar deadline for repair station security several years ago, Congress banned the certification of new foreign maintenance facilities. The ban lasted from 2008 until the rules were issued in 2014. It’s likely DeFazio will seek a similar ban or other incursion in repair station business until the D&A rules are finalized.

Unions representing airline mechanics have stepped up their media outreach and lobbying in recent months and faulted the executive branch for failing to increase scrutiny of foreign repair stations and and finish the D&A rulemaking. As previously reported in the hotline, Rep. John Garamendi (D-Calif.) recently introduced a union-backed bill to shame airlines that use contract maintenance (foreign and domestic).

The political environment is creating enormous risk for the maintenance industry. Unions and their allies on Capitol Hill ignore the industry’s outstanding safety record and deny the fact that certification standards are the same for U.S. and foreign repair stations. They claim that U.S. air carrier contracting policies have cost U.S. jobs, ignoring the fact that repair stations employ six times more technicians than airlines, the industry’s outstanding safety record and all the ways that our industry has made airlines more efficient.

ARSA is concerned that Congress will pursue new maintenance mandates and restrictions that will put repair station jobs at risk. Banning new foreign certificates and making it harder for U.S. air carriers to send maintenance overseas would almost certainly lead to retaliation against U.S. industry. More than a third of U.S. repair stations hold at least one foreign certificate. Those companies – and their employees – would suffer the consequences of a maintenance trade war.

ARSA is stepping up efforts to make sure lawmakers understand the economic implications of passing bad laws to fix a problem that doesn’t exist. But the association’s resources are extremely limited and its team can’t do it alone. It’s time for the whole industry to wake up and get engaged. Here are some things you can do to help:

- Learn more about how ARSA PAC supports our advocacy efforts on your behalf and give us permission to ask for your support.

- Contact your congressional representatives to introduce your company and let them know that there are repair stations in their state that will be impacted by their decisions. You can find out who your representatives are by going https://www.govtrack.us/congress/members and download a list of aviation staffers in each office here.

- Tell your colleagues at non-member companies to join ARSA. We are the voice for the industry. The more members we have, the more effective advocates we’ll be for you. Don’t be shy about sending us member recruitment suggestions.

- Mark your calendar to attend ARSA’s 2020 Legislative Day on March 11 and make your case to Congress directly.

- Host a member of Congress at your facility to SHOW them what your company and colleagues do.

ARSA is standing by to help you be an advocate for your interests. Contact me at christian.klein@arsa.org for assistance.

|

Tell Congress to Make Aviation Workforce a Priority ARSA’s signature legislative victory in 2018 was convincing Congress to create a new grant program help repair stations recruit and train aviation maintenance technicians. Our priority now is getting the program funded … and we need your help. ARSA has completely revamped our grant program action center to help you learn more about the issue and urge your members of Congress to appropriate the money we need. It’s quick and easy. Take a second now the tell your elected represents to make aviation workforce a priority! |

Senate Approves Technician Grant Program Money

The new aviation maintenance workforce grant program created by last year’s FAA bill is a step closer to being funded.

On Oct. 31, the U.S. Senate approved an appropriations package for FY 2020 that includes the annual Transportation, Housing and Urban Development and Related Agencies (T-HUD) appropriations bill. Earlier this year, the House passed its own version of the T-HUD bill, which included full funding for the technician program and similar one for pilot education ($5 million each). The Senate T-HUD bill includes partial funding ($5 million for both).

The fact that both the House and Senate bills fund the grants is an important victory and makes it much more likely that Congress will provide at least some money for FY 2020 to help address the technician shortage. In the days and weeks ahead, ARSA and the coalition it is leading will be lobbying to include full funding for both programs in the final bill. However, there’s still considerable uncertainty about when the conference committee – which will be tasked with resolving differences between the House and Senate versions – will be up and running.

The way forward for the appropriations process itself is unclear. FY 2020 began on Oct. 1 with no appropriations bills for the coming year having been enacted into law. The federal government is currently operating under a short-term continuing resolution that will run through late November. It’s inconceivable that Congress will pass final versions of all 13 appropriations bills by then, so another CR (through December or early 2020) is a virtual certainty. Because the CRs fund federal operations at last year’s levels and because no money was appropriated for the grant programs in FY 2019, there won’t be any money for them until the FY 2020 legislation is finalized. The FAA has also not yet made any public announcements about how and when it will start accepting grant requests.

The bottom line is that programs are still on track to be funded in FY 2020 but it’s far from a done deal. ARSA members concerned about the technician shortage should contact their representatives and senators to urge their support for our coalition efforts. Everything you need to communicate with the Hill can be found by visiting: arsa.org/legislative/grant-program-action-center.

|

Want to Learn More About ARSA PAC? ARSA’s Political Action Committee helps elect congressional candidates who share ARSA’s commitment to better regulation and a strong aviation maintenance sector. In this critical election year, ARSA PAC has never been more important. But ARSA is prohibited from sending PAC information to members who haven’t opted in to receive it. Please take a second to give us prior approval to talk to you about ARSA PAC. Doing so in no way obligates you to support PAC. It just opens the lines of communication. Click here to give ARSA your consent today. |

Hearings Put Certification Front and Center

At House and Senate hearings the week of Oct. 28, Boeing CEO Dennis Muilenburg described the steps the company has taken to address problems with the 737 MAX and internal program management. He said the company has established a Board of Directors safety committee and created an internal Product and Services Safety organization to review and elevate safety concerns. The company has also restructured to require all engineers to report up to Boeing’s chief engineer.

“We know we made mistakes and got some things wrong,” Muilenburg told lawmakers. “We own that, and we are fixing them. We have developed improvements to the 737 MAX to ensure that accidents like these never happen again.”

However, that’s not likely to satisfy members of Congress. House Transportation & Infrastructure (T&I) Chairman Peter DeFazio (D-Ore.) said during the Oct. 30 hearing that the “737 MAX accidents show that we need reforms in how commercial aircraft are certified and how manufacturers, like Boeing, are watched and overseen by the regulator.”

House Aviation Subcommittee Chairman Rick Larsen (D-Wash.) echoed those sentiments. “I see one undeniable conclusion: The process by which the [FAA] evaluates and certifies aircraft is itself in need of repair,” Larsen said.

T&I Ranking Member Sam Graves (R-Mo.) cautioned against rushing to judgment and said that all the factors involved in the 737 MAX accidents should be considered, including pilot actions, airline operations, maintenance, and training programs. “[A]ny issues should be addressed, but only after we have the benefit of various investigative work yet to be completed,” Graves said. “Jumping to conclusions before that work is complete risks doing more harm than good.”

The hearings have done little to allay lawmaker concerns about the certification process and it’s likely the House T&I Committee will soon unveil a reform bill, possibly before the end of the year.

Let Us Tell You About It – ARSA PAC

In Washington, if you’re not at the table then you’re on the menu. Elected officials constantly consider policies that will directly impact the maintenance industry’s business. Many of them do so while knowing very little about aviation and even less about repair stations.

How can maintenance providers change that? ARSA’s legislative program provides a variety of resources. By working with the association, member organizations can become the kind of active constituents that make a difference. While the business of governing is completely separate from the effort of campaigning for office, it’s important to participate in the never-ending process of selecting members of Congress.

ARSA’s Political Action Committee (ARSA PAC) is a tool through which individuals in the aviation industry can amplify their political impact. ARSA PAC is a special fund that allows financial contributions to U.S. House and Senate candidates who support the legislative goals of the industry.

Only executive, management and administrative employees of ARSA member companies who have given solicitation permission can contribute. These employees must be United States citizens or lawful permanent residents (e.g., “green card” holders). ARSA PAC can only accept personal (not corporate) contributions.

To get more information about ARSA PAC, complete the solicitation consent form below. Completing the form in no way obligates you to financially support the PAC, it simply allows the association to provide more information (including how to actually give money). Providing this consent is the first step to helping provide the resources necessary to have our collective voice heard in the legislative decision-making process.

If you have questions about ARSA PAC or the legislative program in general, contact Executive Vice President Christian A. Klein (christian.klein@arsa.org).

ARSA PAC Solicitation Consent Form

Regulatory Update

MMT Meeting – MAG Change 7 Signed, Mutual Recognition Progress Slowed

This year’s Maintenance Management Team (MMT), comprised of the civil aviation regulatory authorities of Brazil, Canada, the European Union and United States met in Cologne, Germany during the week of Oct. 21. The MMT and its sister quadrilateral group, the Certification Management Team (CMT) focus on issues of common interest to the four authorities while recognizing that any formal changes to existing aviation safety agreements occur bilaterally.

For that reason, the MMT authorities spent most of the week engaged in various bilateral maintenance discussions. This was followed by an industry-authorities preliminary meeting on Oct. 24 to review the agenda for “industry day” which occurred on Oct. 25.

Industry representatives and the authorities updated attendees on:

- MMT action items (from the meetings in Ottawa and Brasilia in 2017 and 2018).

- MMT governance and collaboration strategy.

- Status of the ICAO airworthiness panel’s efforts in support of mutual acceptance by authorities of various maintenance oversight activities.

- FAA regulatory situation relating to mutual recognition of approved maintenance organizations.

- Status of SMS programs (both mandatory and voluntary).

- Authority briefings on the status of its bilateral agreements with the other MMT regulators.

Mutual Recognition

Regarding mutual recognition of approved maintenance organizations (AMOs) among the MMT authorities, ARSA and its industry colleagues were disappointed to learn that the FAA has no immediate plans to amend its regulations to allow the agency to enter into U.S.-Canadian-style bilateral maintenance agreements with other authorities.

The agreement with Canada, authorized in 14 CFR §§ 43.3, 43.7 and 43.17 and the FAA-TCCA Maintenance Implementation Procedures (MIP), allows work to be performed by maintenance providers in both countries on articles subject to their respective jurisdictions without the need for a separate certificate. Therefore, no fees apply as they do between the United States and Europe. Under the FAA-TCCA agreement, AMOs and certificated individuals work under the regulations of their geographic authority and only a few special conditions apply to component maintenance providers. Industry strongly supports having a similar arrangement adopted by the FAA and EASA, but it cannot occur without a rule change to 14 CFR (see § 145.53(b)). This is not the case in the EU because a bilateral agreement takes precedence over EASA regulations.

MAG Change 7

Of particular note was the announcement by the FAA and EASA that change 7 to the Maintenance Annex Guidance (MAG) had finally been signed. Although not yet posted on the FAA’s web site (stay tuned to ARSA for posting and comparison to change 6), it affirmatively addresses several issues of importance to ARSA and its members including the recognition that maintenance performed on U.S.-registered aircraft at FAA-EASA approved repair stations in the European Union does not require Form 8130-3 to document new parts. Such maintenance is not subject to the MAG because only a single FAA release is issued; unfortunately, the new regime only applies to aircraft maintenance. This issue was originally brought to the authorities’ attention by Gulfstream and while there was broad consensus that the aircraft manufacturer was correct, resolution got hung up due to the administrative delays in signing change 7, many of which were due to the FAA’s reorganization of its Flight Standards Service.

Another important MAG change embodied in change 7 addresses the procedure for approving articles for return to service when the design has only been approved by a single authority. This issue arose several years ago in the context of the Sukhoi Superjet because it has not been type-certificated in the United States. American component manufacturers needed a way to document work on those components but could not issue a dual release under the MAG since the FAA had never issued a type certificate for the aircraft. A work-around was developed to address the issue which will now be institutionalized in MAG Change 7. It will allow the issuance of single releases as more fully described in that document.

Unfortunately, there was no movement on the issue of documenting new commercial and commercial off-the-shelf parts. It appears that no further action will occur among the MMT authorities until EASA completes its parts documentation rulemaking (RMT.0018).

To follow ARSA’s coverage of MAG-related matters, visit (and bookmark) arsa.org/mag.

The next MMT meeting will occur in the fall of 2020 in Washington, D.C. In the meantime, ARSA and its industry partners will continue working the issues of importance to the international maintenance industry.

Final Documents/Your Two Cents

This list includes Federal Register publications, such as final rules, Advisory Circulars and policy statements, as well as proposed rules and policies of interest to ARSA members.

Training

Complete Human Factors Training Series – The Dirty Dozen in Depth

ARSA’s growing library of human factors training has reached a milestone: completion of “the Dirty Dozen in Depth” series. The twelve sessions were presented by ARSA Executive Director Sarah MacLeod, Executive Vice President Christian A. Klein and Vice President of Operations Brett Levanto and joined two original association-presented classes reviewing general human factors concepts.

For each element of “the Dirty Dozen,” the series provides a 60-minute session providing:

(1) Basic definitions and context.

(2) Aviation safety regulatory references.

(3) Examples.

(4) Mitigations.

(5) Exercises.

All of ARSA’s human factors training sessions have been accepted by the FAA for Inspection Authorization renewal credit under § 65.93(a)(4). To purchase multiple sessions at a discounted price, click here to view options for purchasing via a “tiered bundle.”

If you have questions regarding this series or any of ARSA’s training resources, contact Brett Levanto. For more information about ARSA’s online training program, click here.

On Demand – Human Factors Training Series

Each on-demand session is available for immediate viewing; registration provides all session materials as well as access to the recording for 90 days.

Session Title |

Registration/Information |

|

| Human Factors in Context | Click here. | |

| The Dirty Dozen – Human Factors Overview | Click here. | |

| The Dirty Dozen in Depth – Communication | Click here. | |

| The Dirty Dozen in Depth – Complacency | Click here. | |

| The Dirty Dozen in Depth – Lack of Knowledge | Click here. | |

| The Dirty Dozen in Depth – Distraction | Click here. | |

| The Dirty Dozen in Depth – Lack of Teamwork | Click here. | |

| The Dirty Dozen in Depth – Fatigue | Click here. | |

| The Dirty Dozen in Depth – Lack of Resources | Click here. | |

| The Dirty Dozen in Depth – Pressure | Click here. | |

| The Dirty Dozen in Depth – Lack of Assertiveness | Click here. | |

| The Dirty Dozen in Depth – Stress | Click here. | |

| The Dirty Dozen in Depth – Lack of Awareness | Click here. | |

| The Dirty Dozen in Depth – Norms | Click here. |

Registration for an ARSA-provided training session includes:

- Unlimited access for 90 days to the recording made available after the live session is complete.

- A copy of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of the class, as well as any test material.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

From the Navy – HFACS

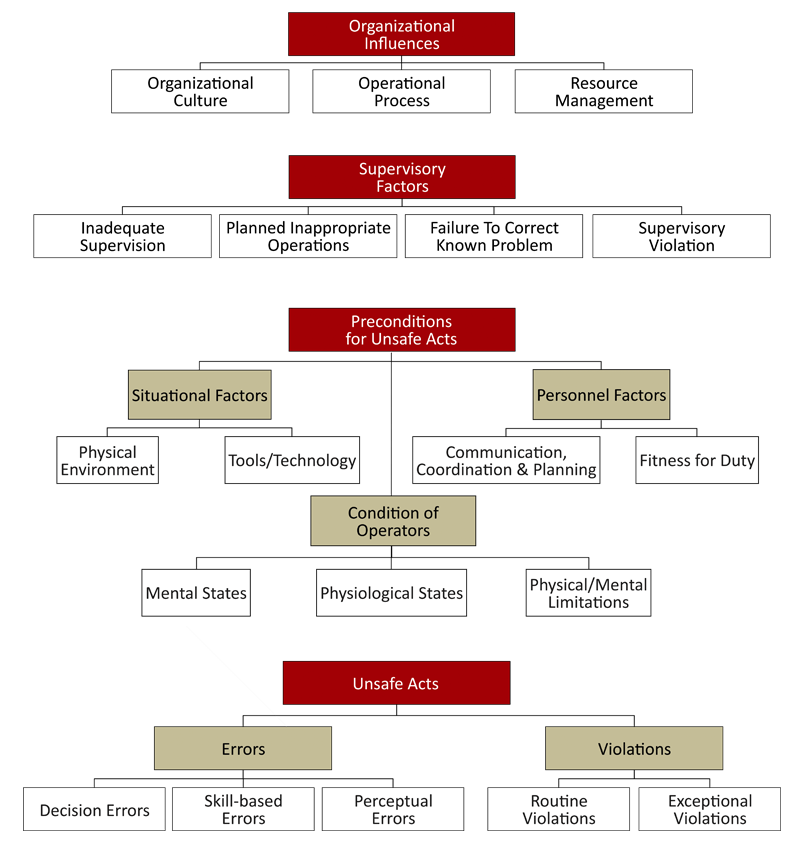

The Human Factors Analysis and Classification System (HFACS) was developed by a pair of Navy psychologists who’ve continued their research, assessment and consulting of human factors impact on systems in the private sector.

These tools provide a way to assess what happened after an “event.”

“Using the HFACS framework as a guide, accident investigators are able to systematically identify active and latent failures within an organization that culminated in an accident. The goal of HFACS is not to attribute blame, rather to understand the underlying causal factors that lead to an accident,” the scientists’ website explains.

You can learn about HFACS as well as other models that inform human factors-related assessment by taking the association’s Human Factors in Context training session (arsa.org/human-factors-training) or visiting hfacs.com/hfacs-framework.

Regulatory Compliance Training

Test your knowledge of 14 CFR §§ 65.73 & 65.89 – Mechanic ratings and certificate display.

Click here to download the training sheet.

Membership

Dallas Airmotive’s Cheyne Elected ARSA President

The ARSA board of directors has elected W. Ian Cheyne as ARSA’s new president, the association’s senior volunteer leadership position. Cheyne is chief technical & regulatory officer for Dallas Airmotive, Inc., a Texas aviation company providing maintenance, repair and overhaul services for small gas turbine and turbofan engines.

Cheyne was elected during the board’s annual meeting on Oct. 18 following a day of industry roundtables in Washington, D.C. through which board members collaborated with ARSA’s executive team, aviation allies and executives from the FAA’s Office of Aviation Safety.

ARSA’s board of directors represents a broad range of international maintenance interests. Board members direct the association’s work to best serve the aviation community. Having served as a director since 2002, Cheyne will bring to his second presidency long experience in support of both the association as well as other industry organizations. David Latimer, senior vice president of regulatory compliance for Greensboro, North Carolina-based HAECO Americas and the association’s immediate past president, will continue his own long service on the board of directors for the next year.

“This isn’t Ian’s first rodeo,” said ARSA Executive Director Sarah MacLeod, noting that Cheyne was one of the association’s longest-tenured board members. “He is active in ARSA’s leadership as well as with other associations, stakeholder bodies and interest groups. In a period where industry collaboration, clear messaging and concerted effort is paramount, the timing couldn’t be better for his return to the association’s presidency.”

Cheyne with Immediate Past President David Latimer of HAECO Americas, after completing the board’s annual meeting at the Ritz-Carlton Pentagon City in Arlington, Virginia.

During the meeting, Gary Fortner, vice president of engineering and quality control for Fortner Engineering, was elected vice president and Terrell Siegfried, assistant general counsel and corporate secretary for the NORDAM Group LLC became the association’s treasurer. Cheyne, Fortner and Siegfried will each serve one year terms.

“I participate in a lot of board meetings,” Cheyne said, reflecting on his experience supporting his corporate postion and industry groups. “I go to a lot of events. meet with a lot of teams and support multiple committees. I’ve seen first hand, for a long time, how vital it is for ARSA’s work to be reinforced across the aviation community. Our collective efforts are good for policy, good for safety and good for business.”

Some new faces will be supporting Cheyne and the ARSA team over the next year. Josh Krotec, senior vice president of First Aviation Services, Inc. and Scott Jacob, director of quality for Columbia Helicopters, began their inaugural board terms. Krotec and Jacob replaced Gary Jordan of Jordan Propeller Service and Chris Erickson of Erickson, Inc, who will remain active association members having each completed more than 15 years of service as directors and officiers.

ARSA’s Board of Directors pose with team members at the completion of the board’s annual meeting at the Ritz-Carlton Pentagon City in Arlington, Virginia.

Lufthansa Technik Puerto Rico Spotlights MRO Economic & Workforce Impact

Lufthansa Group Chairman & CEO Carsten Spohr (in engine, on left) hosted Puerto Rico Governor Wanda Vázquez Garced (center) and other government officials at LTPR’s facility in Aguadilla on Oct. 15.

On Oct. 15, Puerto Rico Governor Wanda Vázquez Garced and Manuel Laboy Rivera, the island’s secretary of economic development and commerce, visited Lufthansa Technik Puerto Rico’s (LTPR) facility in Aguadilla for a first-hand look at the company’s operations and training programs.

LTPR is fully owned by Lufthansa Technik AG specializing in the Airbus A320 family narrow body aircraft. Since opening in July 2015, LTPR has grown into a five-bay facility with a workforce of 400 employees.

The visit, which was hosted by Lufthansa Group Chairman & CEO Carsten Spohr, was also attended by U.S. Ambassador to Germany Richard Grenell and Andreas Siegel, Germany’s consul general in Miami. During the visit, Allegiant Airlines confirmed a five-year partnership agreement with LTPR for base maintenance of its A320 family aircraft.

Workforce development was a central theme at the event. As part of its long-term commitment to the island’s economy, LTPR joined with the Aeronautical & Aerospace Institute of Puerto Rico in 2017 to establish the first federally approved aviation maintenance apprenticeship program to train the next generation of mechanics.

“LTPR is a shining example of the partnership the Lufthansa Group has forged with the local community in Aguadilla and both the Commonwealth of Puerto Rico and federal government,” Spohr told the government officials and employees at the start of the event.

Secretary Rivera highlighted the impact of the aerospace sector, which employs approximately 5,000 Puerto Ricans. “We will continue to support this sector through multiple resources and initiatives … to make Puerto Rico one of the main places to offer services to the aerospace sector,” he said.

Gov. Vázquez Garced thanked Lufthansa for opening the facility and for its confidence in the Puerto Rican economy. “It is an important investment and contribution for our Island,” she said. “Thank you for the trust and commitment to our people.”

Earp Aviation Plays Perfect Host

On Oct. 8, Earp Aviation Repairs opened its doors for a carefully planned ribbon-cutting ceremony at its Chandler, Arizona facility.

On Oct. 8, Earp Aviation Repairs opened its doors for a carefully planned ribbon-cutting ceremony at its Chandler, Arizona facility.

Among the 100 or so participants in the event were Chandler Mayor Tom Haskins and U.S. Representative Greg Stanton as well as individuals from the U.S. Chamber and representing the offices of U.S. Senators Kyrsten Sinema and Martha McSally. Invitations, logistical details and organization for the event were carefully managed for months by long-time ARSA supporter Bob Arnett (see “Arnett Sets the Pace” in the August edition of the hotline to see how his efforts are exemplary for the entire maintenance community).

“The ribbon cutting was a big success,” Arnett said, reflecting on the opportunities for business development, community building and policy engagement available as a result of the ceremony. “Spent time alone speaking with Congressman Stanton about the industry and issues. Gave him a copy of the presentation to take with. He brought up the talk in Washington about the use of repair stations and especially foreign ones so I gave him straight scoop on that.”

Arnett also made connections regarding the association’s ongoing advocacy related to the Technician Workforce Grant Program authorized in last year’s FAA law. He noted the engagement of both state and national lawmakers on the topic and that the Arizona governor’s office has shown interest in technical skill development.

no images were found

Welcome & Welcome Back – New & Renewing Members

ARSA’s members give the association life – its work on behalf of the maintenance community depends on the commitment of these organizations. Here’s to the companies that joined or renewed in October:

New Members (Member Category)

ALA – Advanced Logistics For Aerospace, Inc. dba ALA North America, Assoc

T&C Aviation Enterprises, Inc., R01

The Zee Company Inc., R02

Renewing Members (Member Category, Member Since)

AE&C Services, LLC, R02, 2017

Aeronautical Technology, Inc. dba Precision Aero, R03, 1993

Aircraft Inspection Services, Inc., R01, 2013

Amway Aviation dba Alticor, Inc., R02, 2018

AOG Aircraft Service Inc., R01, 2018

Arkwin Industries, Inc., R03, 1994

Avocet Aviation Services, LLC, R03, 2014

CanRep Inc., R02, 2018

Commercial Jet, Inc., R04, 2010

Cross-Check Aviation, R03, 2003

Curtiss Wright Controls, Inc., R03, 2012

Dassault Falcon Jet do Brasil, R02, 2010

Dassault Falcon Jet-Wilmington Corp., R05, 2002

Eagle Creek Aviation Services, R04, 2016

Empire Airlines, Inc. d/b/a Empire Aerospace, R03, 2002

EuroTec Vertical Flight Solutions, LLC, R02, 2004

Federal Express Corporation, Assoc, 2000

Florida Jet Center, Inc., R02, 2013

Global Parts Aero Services, R01, 2012

Gulf Aerospace, Inc., R02, 2005

Helicopter Accessory Service East Inc., R01, 2018

Jordan Propeller Service, Inc., R02, 2002

KLM Royal Dutch Airlines-Engineering & Maintenance, Assoc, 2010

Mach II Maintenance, R04, 2018

Midway Aerospace, R02, 2004

Midwest Turbine Services, R01, 2015

Millennium International, R03, 2013

MTI Aviation, Inc., R01, 2011

PPG Industries Inc.-dba PPG Aerospace, R02, 2005

Schaeffler Aerospace USA Corporation, R02, 2012

Southern Air Repair Corp., R01, 2016

S Tec Corporation, R02, 2016

Soniq Aerospace, LP, R01, 2016

Southwind Aviation Supply, LLC, R01, 2008

Team Aerospace, Inc., R01, 2005

Tech-Aire Instruments, Inc., R01, 2012

Trace Aviation, R02, 2017

Unipak Aviation, LLC, R02, 2003

Quick Question – 2020 Annual Conference Planning

In Washington, D.C., planning for 2020 is typically focused on the next presidential and congressional elections. Though ARSA’s legislative team is busy actually getting things done on Capitol Hill before all thoughts turn completely to politics, the association is focused on preparing for the 2020 Annual Conference (mark your calendars for March 10-13).

Help with that planning – and make next year’s event as valuable as possible for all participants – by sharing your thoughts through this month’s “quick question.”

Note: The question is displayed in its own, embedded window. If the “Submit” button is not visible on the screen, you must scroll within the survey window in order to submit your response.

If the embedded survey does not appear/load, open the survey independently by visiting: www.surveymonkey.com/r/qq-conference.

Click here to see what questions have been asked and answered…and keep a lookout for more.

For more information about this or any other question, contact Brett Levanto (brett.levanto@arsa.org).

A Member Asked…

Q: Customers expect articles to be repaired to the latest component maintenance manual (CMM) to the extent that any component inducted on the day the CMM revision is release they expect the approval for return to service to reference the new revision. They do not consider any kind of processing time to update routers, work instructions, etc. everything should be as instant as the electronic release of the CMM.

As a solution, I’m considering adding a phrase in the repair station quality manual (RSQM) for CMM revisions, that gives us up to 30-days after release to work to the latest revision.

Has anyone else come to you with this? Thoughts?

A: Guidance on processing updates to technical data can be found in Order 8900.1, Volume 6, Chapter 14 – there are three scenarios:

(1) An update that does not change any technical requirements can be instituted immediately and the new revision number can be used even on WIP since the maintenance performed will meet both the old and new versions.

(2) An update that does change technical requirements that can be “immediately” instituted but will not be used on WIP because other documents must be changed or updated like travelers and routers; once those are changed, the “new” manual will be referenced.

(3) An update that requires new equipment or tooling that cannot be instituted until the new equipment or tooling is obtained and personnel are trained (which usually involved number (2) above plus training on the new equipment). That will be instituted no later than (pick the number of) days after the equipment has been received, properly placed and calibrated (if necessary), all documents have been amended and training is complete.

Member questions should be submitted through the inquiry system run through ARSA’s new online member portal. Members can use their portal access to submit inquiries by logging in through arsa.member365.com/sharingnetwork.

Make ARSA’s Voice Your Own: Advertise

ARSA has a menu of advertising opportunities for arsa.org, the hotline and the ARSA Dispatch. Take advantage of these great opportunities today to showcase your company, a new product or event. For more information go to arsa.org/advertise.

Stand Up for ARSA by Sponsoring

In order to provide world-class resources for its members, the association depends on the commitment of the aviation community. By sponsoring events and activities, supporters can help ARSA’s work on behalf of repair stations to endure.

Need a place to start? For information about opportunities, contact Vice President of Operations Brett Levanto (brett.levanto@arsa.org).

Resources

ARSA strives to provide resources to educate the general public about the work of the association’s member organizations; should you need to provide a quick reference or introductory overview to the global MRO industry, please utilize AVMRO.ARSA.org.

ICA Issue Page

Since its inception, ARSA has worked to ensure that basic safety information (i.e., Instructions for Continued Airworthiness [ICA], including component maintenance manuals [CMM]) is made available at a fair and reasonable price to operators, maintenance providers, and any other person required by 14 CFR to comply with those instructions. ICA Issue Page

Brexit Resource Page

On June 23, 2016, citizens of the United Kingdom voted to withdraw from the European Union in a national referendum. As the process of making that withdrawal happen drags on. This page is provided as a resource for the aviation maintenance community regarding the transition. Brexit Resource Page

Careers In Aviation Maintenance

Every year, more people are flying. The expansion of the global middle class and improvements in technology have opened aviation markets – for passengers and cargo – to a broader public than ever before. As the the flying public gets larger, more men and women are desperately needed to keep the world safely in flight.

Quick Question Portal

See what ARSA has asked and what’s been answered and participate in the conversation about what’s going on in the aviation maintenance world.

AVMRO Industry Roundup

ARSA monitors media coverage on aviation maintenance to spread the word about the valuable role repair stations play globally by providing jobs and economic opportunities and in civic engagement. These are some of this month’s top stories highlighting the industry’s contributions. You can explore these stories through ARSA’s Dispatch news portal.

Industry Calendar

| Conference | Dates | Location |

| MARPA Annual Conference | 11/5-6/2019 | Washington, DC |

| MRO Latin America | 1/22-23/2020 | Cartagena, Columbia |

| Heli-Expo | 1/27-30/2020 | Anaheim, CA |

| MRO Middle East Summit & Expo | 2/24-26/2020 | Dubai, UAE |

| ARSA Annual Conference | 3/10-13/2020 | Washington, DC |

| MRO Australasia | 3/10-12/2020 | Brisbane, Australia |

| AEA International Convention and Trade Show | 3/24-27/2020 | Nashville, TN |

| ATEC Annual Conference | 3/29-4/1/2020 | Fort Worth, TX |

| MRO Americas | 4/28-30/2020 | Dallas, TX |

| Farnborough Air Show | 7/20-24/2020 | Farnborough, UK |

| Business Aviation Convention & Exhibition (NBAA-BACE) | 10/6-8/2020 | Orlando, FL |

the hotline is the monthly publication of the Aeronautical Repair Station Association (ARSA), the not-for-profit international trade association for certificated repair stations. It is for the exclusive use of ARSA members and federal employees on the ARSA mailing list. For a membership application, please call 703.739.9543 or visit arsa.org/membership/join. For information about previous editions, submit a request through arsa.org/contact. This material is provided for educational and informational purposes only. It does not constitute legal, consulting, tax or any other type of professional advice. Law, regulations, guidance and government policies change frequently. While ARSA updates this material, we do not guarantee its accuracy. In addition, the application of this material to a particular situation is always dependent on the facts and circumstances involved. The use of this material is therefore at your own risk. All content in the hotline, except where indicated otherwise, is the property of ARSA. This content may not be reproduced, distributed or displayed, nor may derivatives or presentations be created from it in whole or in part, in any manner without the prior written consent of ARSA. ARSA grants its members a non-exclusive license to reproduce the content of the hotline. Employees of member organizations are the only parties authorized to receive a duplicate of the hotline. ARSA reserves all remaining rights and will use any means necessary to protect its intellectual property.

© 2019 Aeronautical Repair Station Association