2024 – Edition 7 – August 5

Table of Contents

Note: The order of material varies in hotline emails, but is always presented the same on this landing page. Readers scrolling through content on or printing this page will find it organized consistent with the table of contents.

President’s Desk

Conference Corner

Regulatory Updates

ARSA Works

Legal Briefs

ARSA on the Hill

Training

Membership

Resources

Industry Calendar

The President’s Desk

Priming the Punch Pump

My family’s company made a commitment to the ARSA team decades ago. My father was a founding member, and I haven’t missed an Annual Repair Symposium since 2001. Our quality department has saved countless dollars and hours by using the association’s model publications: the E100 method of documenting parts for maintenance under the U.S.-EU MAG was a powerful example. That free resource was available to us all because of every company that primed ARSA’s pump.

ARSA punches above its weight on a million-dollar budget, ARSA respects the value of every dollar invested by its members and provides powerful strike for the entire industry. This value has many monikers: an access to experts, an insurance policy, an investment in cost avoidance, a voice for good government, a down payment to defend against inspector preference. Whatever a company labels its support, those dollars have an immediate value.

During your business’ yearly budget cycle, prime the pump of good business by investing further in the association and your human resources:

(1) Members Getting Members – Pay your membership through recruitment: Every referring member receives a credit of 10 percent of the new member’s dues. It doesn’t take many referrals to enjoy a yearly “cost avoidance” strategy that tracks real dollars saved.

(2) Training – ARSA’s expanding training library is quickly approaching the 100-hour milestone for courses; registration includes copies of all materials and unlimited viewing for 90 days for every session. Let this program work for you in all ways—short term knowledge, long term advertising through sponsor sessions or series.

(3) Advertising & Sponsorship – Align your company with the association’s commitment to compliance and quality. Highlight your company before customers, policy makers, and executive branch management. ARSA’s in-house advertising program provides targeted exposure for immediate, medium, and future financial success of your company and the association.

(4) Events – The Annual Conference, with its Executive-to-Executive Briefings, Legislative Day, and Annual Repair Symposium, is the international civil aviation maintenance community’s premier event for regulatory compliance and networking. The registration cost has an immediate return on investment. Sponsoring the Conference establishes medium- and long-term benefits through company recognition and its commitment to regulatory compliance and aviation safety.

(5) Publications for compliance – While ARSA’s Model RSQM Compilation can ensure effective regulatory compliance for members and non-members alike, members are given access to valuable publications through the free tools at arsa.org/publications. These compliance documents can provide an immediate return from the dollars spent on membership fees.

Priming ARSA’s pump primes your own; the higher the investment, the more punch delivered.

|

Gary Fortner 2024 ARSA president | Fortner Engineering & Manufacturing, Inc. vice president of engineering |

Conference Corner

Sponsor Salute

Conference sponsors represent the best of ARSA’s membership. Here’s to all 22 organizations that committed to the maintenance community’s premier substantive event. See and celebrate those that made the commitment, then plan (and budget!) to join them in 2025.

Platinum

|

|

|

Gold

Silver

Contributors

|

Save the date to see your company celebrated next year:

March 18-21, 2025

Regulatory Updates

Time is Running Out

U.S. repair stations are running out of time to apply for a UK Civil Aviation Authority (CAA) repair station certificate.

On Dec. 31, 2024, the UK CAA will no longer recognize EASA certificates held by U.S. repair stations. After that date, repair stations working on products and articles under the UK CAA’s control must obtain a certificate through the U.S.-U.K. bilateral agreement, Maintenance Implementation Procedures, and Maintenance Agreement Guidance.

To date, the UK CAA has received approximately 300 applications from U.S. facilities, whereas there are over 900 certificates issued by EASA. If your repair station wishes to receive its UK certificate before the end of the year, it should enter the application process. It will take action by both the FAA and the UK-CAA to obtain the latter’s certificate; and there will no doubt be a backlog.

Both British and American regulators have contacted ARSA requesting assistance encouraging applications. The FAA plans to email InFO 22004 to every address associated with a repair station’s OpSpec A007 to stimulate attention.

ARSA members have access to the association’s cross reference matrices that demonstrate compliance with the special conditions. To request your updated copy of ARSA’s free “tools for members”, which is delivered as a .zip file, complete the order form at arsa.org/publications.

Poring Over MAG Change 9

In June, the FAA and EASA published change 9 to the Maintenance Annex Guidance issued under the bilateral agreement between the two civil aviation authorities. As described in the summary of changes provided by the agencies, MAG change 9 contained mostly administrative updates. The special conditions do not include a requirement for U.S. repair stations to implement safety management systems (SMS)…yet.

ARSA has prepared cross-reference matrices for compliance with the special conditions and assistance with the supplement guidance in MAG change 9. The matrices include “red-lined” versions showing edits between changes 8 and 9. The matrices are available as part of ARSA’s free “tools for members.” To request your updated copy, which is delivered as a .zip file containing the matrices for both EASA and UK CAA compliance, complete the order form at arsa.org/publications.

Since the change has been released, enterprising members have pored over the new language and among the key observations shared with the association that are not reflected in the record of revisions.

Member Report

The EASA Visit Report Form (SIS Form 8) was updated to include that a repair station must retain maintenance records for three years after the performance of work.

ARSA Response

14 CFR sec. 145.219(c) requires that a repair station retain records demonstrating compliance with part 43 for a least two years from the date the article was approved for return to service. EASA rules generally prescribe a 36 month record retention period (see, e.g., Part-M M.A.305 Aircraft continuing airworthiness record system).

Past MAGs have referenced a 3 year record retention period for EU AMOs (see U.S. EU MAG 8, Section C, Appendix 1 (“Guidance for the FAA Supplement”) at 9.4(i). Additionally, the compliance checklist for an EASA SIS visit to the Flight Standards Office in both MAGs 8 and 9 states, “Review FAA Office repair station files to verify … 2. Records are retained for a 3 year period.” (Emphasis added.) The special conditions applicable to U.S. repair stations in Annex 2 of the FAA-EASA bilateral say nothing about record retention periods.

In light of all the foregoing, the addition of the statement, “Does the repair station retain maintenance records for 3 years after the performance of work?” in MAG 9, Sec. A: Appendix 2 is either a mistake (i.e., it was intended to be included in the checklist for an audit of an EU repair station) or another example of the FAA acquiescing to EASA.

Member Report

Paragraph 10.11.1 was edited to note that an authorized release document issued by the PAH must accompany new components consumed in maintenance subject to the MAG.

ARSA Response

The “from the PAH” language is in the TIP, which EASA has relied on to require an EASA Form 1 or FAA Form 8130-3. This dependence is the very reason U.S. repair stations face a debacle related to parts documentation (see below). There are literally millions of parts that do not have a government form (EASA or FAA) attached by the “PAH.” ARSA’s contention is the whole thing is out of whack: The export is the maintenance action, not a new part transaction. Nevertheless, the unrecognized edit has been reported to EASA and the FAA to determine whether it was deliberate or a mistake.

The association encourages all its enterprising members to review change 9 against their current systems and make use of ARSA’s cross reference matrices (with red-lined changes) for EASA compliance.

Government Training Resource: Participating in Regulatory Review

The U.S. Office of Management and Budget provides training sessions covering “effective participation in Executive Order 12866 meetings with the Office of Information and Regulatory Affairs.” The association’s review of the training provides some insight on how to make the meetings worthwhile .

Executive Order 12866 governs the Office of Management and Budget’s (OMB) U.S. Office of Information and Regulatory Affairs’ (OIRA) process for reviewing significant regulatory actions. The executive order directs the government to make the regulatory review process more accessible, which OMB does by allowing any member of the public to request a meeting with OIRA about their views on pre-decisional rules.

The OMB’s “how to” guide on requesting EO 12866 meetings includes a short informational video and transcript, providing simplified context of the rulemaking process.

For significant rulemaking activities, OMB conducts EO 12866 meetings during both the proposed and final rule stages. During each 30 minute meeting, OIRA personnel will be a “listening ear” on the rulemaking’s potential impact on industry. ARSA’s team participated in a 2023 meeting with OIRA in the leadup to the FAA’s publication of its notice of proposed rulemaking extending repair station drug testing requirements. Any member of the public – including personnel from ARSA member organizations – may request a meeting via reginfo.gov.

There are three ways to find a regulatory action on the website:

(1) Navigate to the “Regulatory Review” menu and select “Regulatory Review Dashboard.”

The Dashboard includes a list of all regulatory actions currently under review and may be sorted by agency using the “View” drop down. To request a meeting related to any action, click the “Request EO Meeting” link to the right the list entry.

(2) Use the search function in the top right corner of the page – which opens an advanced search field – to find a regulatory action by keyword. Click the “Pending Review” link next to the correct action, then click “Request EO Meeting.”

(3) If you have the Regulation Identifier Number (RIN) from the rulemaking action, navigate to the “Regulatory Review” menu and select “E.O. 12866 Meetings,” then click the “Schedule” button. On the scheduling page, enter the RIN and click “ENTER.”

Follow the steps to verify an active email and submit the form after confirming the regulatory action is listed correctly at the top. Include additional meeting attendees and upload relevant documents for review by OIRA personnel. After verifying your email address, OIRA will contact you with a meeting date and time.

The OMB hosts periodic training sessions in which they will discuss “(1) what an E.O. 12866 meeting is; (2) how members of the public may request and schedule a meeting; (3) the format of E.O. 12866 meetings; (4) what type of information or input is most helpful to receive during an E.O. 12866 meeting; and (5) what makes for an effective presentation during an E.O. 12866 meeting” (Federal Register). Anyone interested in registering for these sessions can do so by emailing publicparticipation@omb.eop.gov.

ARSA member companies are key interested parties with the advanced aviation knowledge needed to influence pending regulations. OMB is directed to specifically request such expert input, so the association encourages member attention to meeting opportunities.

Member primary contacts receiving the Daily Intelligence newsletter from ARSA should keep a lookout for “OMB Dashboard Entries” as notice of opportunities to schedule meetings.

ARSA Works

What ARSA Has Done Lately – Second Quarter 2024

Each quarter the board of directors receives reports on the association’s activities and fiscal health. Step into a board member’s shoes with this overview of the financial, operations, legislative, and regulatory reports highlighting advocacy on behalf of aerospace safety for the second quarter of 2024.

Fiscal Health

Halfway through the year ARSA’s finances are on track or exceeding 50 percent of the budget. The management team is exploring new options to facilitate payment transactions, e.g., Zelle, for members and other users of association services.

Membership

Effective recovery of first quarter lapsed members surged the year-to-date renewal rate past 94 percent.

| Q2 Membership Renewal Rate | YTD Membership Renewal Rate | ||

| Total Renewed | 69 | Total Renewed | 142 |

| Total Recovered | 3 | Total Recovered | 10 |

| Total Paid Memberships | 72 | Total Paid Memberships | 152 |

| Total in Retention Process | 10 | Total in Retention Process | 10 |

| Total Memberships Invoiced | 82 | Total Memberships Invoiced | 162 |

| Renewal Rate | 87.8% | Renewal Rate | 93.8% |

Regulatory Advocacy

- Submitted joint comments with Aircraft Electronics Association on Modernization of Special Airworthiness Certification (MOSAIC) rulemaking.

- Continued leadership of U.S. Department of Transportation (US DOT) Aerospace Supply Chain Resiliency Task Force, with Sarah leading report development.

- Supported initiation of FAA Instructions for Continued Airworthiness Aviation Rulemaking Committee.

- Participated in 2024 FAA-EASA Aviation Safety Conference:

- Met with new EASA Executive Director Florian Guillermet and leadership team.

- Brett moderated panel discussion on emerging technologies in aviation maintenance.

- Initiated conversation with US DOT Inspector General to support implementation of FAA Reauthorization Act sec. 821 (“Consistency of Policy Application in Flight Standards and Aircraft Certification”).

- Obtained clarification that the FAA has no objection to use of EASA Form 1 for triple releases.

- Engaged with U.S. Department of State, U.S. DOT, and European members to register objections to proposed FAA foreign repair station drug and alcohol testing rule at annual S.-EU Air Transport Agreement Joint Committee Meeting.

Legislative and Lobbying

- Supported enactment of FAA Reauthorization Act of 2024, including ARSA priorities:

- Regulatory:

- Creation of ICA ARC (Sec. 349).

- US DOT audit of Flight Standards and Aircraft Certification Services on consistency of policy and regulatory interpretation and the application of policies, orders, and guidance related specifically to repair stations, supplemental type certificates, and technical standard orders (Sec. 821).

- Consistency in interpretation and application of policies, orders, and guidance (Sec. 822).

- Creating position of Assistant Administrator for Rulemaking and Regulatory Improvement; responsibilities include developing and managing FAA’s regulatory agenda, reviewing regulations on an ongoing basis to enhance safety and reduce burdens, and improving accountability in responding to petitions for rulemaking and exemptions (Sec. 202).

- Creating review team (including outside experts) to improve regulation and guidance development (Sec. 205).

- Requiring final determination on investigation to be made within two years of issuance of LOI (Sec. 805).

- Enhancing oversight of foreign repair stations (including surprise inspections, limitations on use of repair station stations in CAT II countries, and licensing requirements for supervisory personnel) (ARSA opposed but negotiated to limit impact) (Sec. 302).

- Workforce:

- Quadrupling funding for ARSA proposed Sec. 625 aviation workforce grant programs and creation of new program for manufacturing workforce (design and production approval holders) (Sec. 440)

- Rulemaking to facilitate military to civil technician career transition (Sec. 424).

- Improving FAA data about aviation workforce (Sec. 402).

- Making Women in Aviation Advisory Committee permanent (Sec. 403).

- Exploring early part 65 mechanic testing for high school students (Secs. 405 and 414).

- Urged inclusion of language in 2025 National Defense Authorization Act to encourage greater use of FAA approvals (PMA parts and DER repairs) by DOD and enhanced access to maintenance data on DOD contracts.

- House NDAA contains ARSA supported language directing U.S. Air Force and Navy to make greater use of commercial dual use parts (Sec. 171).

- Senate NDAA contains language (not aviation specific) requiring contractors to provide the DoD fair and reasonable access to all repair materials, including parts, tools, and information, used by the manufacturer or provider or their authorized partners to diagnose, maintain, or repair the good or service (Sec. 828).

- Regulatory:

- Participated in PAC event for House Transportation & Infrastructure Committee Chairman Sam Graves (R-Mo.) with House Speaker Mike Johnson (R-La.) ($1,000).

- Initiated members conversations re: PAC check delivery meetings in Florida, Oklahoma, and Kansas.

- Began identifying new congressional database service to support ARSA congressional advocacy.

ARSA in the News – Selected Industry Coverage

Maintenance staff shortage in U.S. could clip aviation industry’s wings

April 1, 2024 | The Japan Times

The United States is grappling with a shortage of maintenance workers in the aviation industry, with baby boomers retiring and others changing jobs during the pandemic.

Industry Honors Birth of Wright Mechanic Charles Taylor

May 24, 2024 | AINOnline

While the “holiday” perhaps doesn’t glean much attention among the general public, the Aeronautical Repair Station Association (ARSA) cites the importance of celebrating the commitment, integrity, and skill of every aircraft mechanic and those who honor and support them. “This is Taylor’s legacy and our shared responsibility,” said ARSA.

Maintenance Staff Shortage Could Clip Aviation Industry’s Wings

March 31, 2024 | Agence France-Press

In the United States, around 4,000 maintenance, repair and overhaul companies employ some 185,000 aviation maintenance technicians and engineers. This forms around 44 percent of the global total, according to the Aeronautical Repair Station Association.

ARSA-placed Industry Editorials and Content

| AMT Magazine | Know the Boundaries May/June 2024 | Brett Levanto |

| Aviation Week | Boeing Debacle Highlights Need for Fully Integrated SMS April 2024 | Sarah MacLeod |

| Aviation Cooperation Behind Taylor Swift’s Super Bowl Travel May 2024 | Christian Klein |

|

| Regulatory Rulemaking Requires Attention to Detail June 2024 | Brett Levanto |

|

| DOM Magazine | When the Government Defers to Itself April 2024 | Brett Levanto |

| A Good Test May 2024 | Brett Levanto |

|

| Remembering if it’s My Certificate or Yours June 2024 | Brett Levanto |

Bringing Advertising In-house

Year-to-date sales and renewal exceeded budget and far outpaced income from previous vendor. Team will use AVMRO.arsa.org as a recruitment tool.

Surveys

- Human Factors Findings for Training Development (Reply Now)

- “The Name Game” (Accelerate Aviation Foundation)

- Inventory Costs for EASA Compliance (Reply Now)

Training & Meetings

Training

- Early planning to provide “workshop” resources for government personnel.

- Improving automated training notification delivery.

- Renewed general training subscription for a corporate member.

- New part 21-focused training subscription for a non-member.

- New human-factors training subscription for a regular member.

External Meetings

- Sarah held recurring meetings regarding the Part 145 Working Group (and AMC development) and engagement with both FAA Flight Standards and Aircraft Certification Services.

- Sarah and Christian attended multiple meetings of the DOT Aerospace Supply Chain Resiliency Task Force and the Instructions for Continued Airworthiness Aviation Rulemaking Committee.

- Christian attended multiple TSA Aviation Security Advisory Committee and subcommittee meetings.

- Christian had multiple meetings with the NDAA Steering Committee.

- Christian had monthly meetings regarding Department of Labor resources for supporting the aviation workforce.

- Christian and Brett held monthly collaboration calls with Oliver Wyman.

- Christian attended multiple meetings of the ASAC Airport & Insider Threat Subcommittee.

- Brett and Sarah held multiple meetings with various members supporting RSQM Compilation customizations.

- Christian and Brett were interviewed by Aviation View Magazine for its Aviation and Maintenance Series (Apr 5).

- Christian had lunch with Sterling Wiggins of the U.S. Chamber of Commerce (Apr 11).

- Christian lunched with representatives from GAMA, AEA, and MARPA to discuss next steps for MMT study on digitalization (Apr 15).

- Sarah met with an industry consultant regarding DER appointments and selection (Apr 15).

- Brett met with Andrew Rachmell of Purdue University regarding the education alliance partnership (Apr 18).

- Sarah and Brett met to review questions asked during a Senate Commerce Committee hearing on Boeing oversight (Apr 26).

- Christian and Maike Denda met with contacts regarding the DOL apprenticeship opportunities (Apr 29).

- Christian attended the NATA Chairman’s Reception (May 15).

- Christian met with several members of the Remanufacturing Association Alliance (May 23).

- Brett participated in multiple prep sessions for the ARSA-moderated panel at the FAA-EASA International Safety Conference Panel (May 30, Jun 4).

- Christian attended the House T&I Committee Reception for FAA reauthorization (June 3).

- Christian attended an EASA meeting on MAG issues (Jun 6).

- Sarah, Marshall, Christian, and Brett attended the FAA-EASA International Safety Conference (Jun 11-13).

- Christian attended the reception for Rep. Sam Graves hosted by Speaker Johnson (Jun 13).

- Sarah, Christian and Brett viewed the Senate Homeland Security Committee hearing on Boeing’s Broken Safety Culture (Jun 18).

- Christian participated in an MMT Industry Prep session (Jun 20).

- Sarah, Christian, and Brett met with Bob Ireland and Justin Madden of Airlines for American to discuss the Supply Chain Task Force, ICA ARC, and association collaboration (Jun 24).

Expanding the FAA’s Acknowledgement of its Paperwork Burden

On July 29, ARSA commented on a Federal Register notice requesting comment regarding the paperwork burden associated with FAA requirements for repair station certificate applications. The association’s comments, based on the agency’s past justifications to the Office of Management and Budget regarding its collection of information under the Paperwork Reduction Act, explained the government is drastically underestimating the burden associated with an application made under § 145.51.

Under the PRA, executive branch agencies like the FAA must regularly request OMB review and approval for collection of information from the public. The notice begins the process for the ninth review of repair station application burden since the current part 145 was established in 2001. The FAA’s past supporting statements to OMB – there has not yet been a statement released for this year’s request – focused solely on the completion of the Form 8310-3. These assessments ignored the manuals and documents applicants must prepare to accompany the form and only estimated six to 19 hours of burden on repair station personnel, depending on the organization’s size.

ARSA’s comments reviewed the complete requirements of § 145.51(a). The paragraph states an application must include numerous documents including repair station, quality, and training program manuals, as well as an organizational chart, facility description, and other detailed lists. Based on the association’s experience assisting members implement its RSQM Compilation, the comments estimated the FAA has underestimated its paperwork burden by as much as 900 percent (based on a conservative estimate).

“As a result [of this underestimation], the agency has a well-noted backlog of persons seeking certification but awaiting review,” the comments said. “Before continuing this request to OMB, the FAA should audit its application requirements and procedures to assess the full burden associated with the rule and current agency practices.”

To read the complete comments, click here.

Repairman History Points ARAC to Certificate’s Future

On July 19, the FAA Aviation Rulemaking Advisory Committee (ARAC) delivered the final report of its Repairman Certificate Portability Working Group to FAA Rulemaking Executive Director Brandon Roberts after its unanimous acceptance. The report, which was presented to ARAC in June, includes thorough regulatory analysis in response to a March 2021 tasking to provide advice and recommendations on the most effective ways to allow a repairman certificate issued under part 65, subpart E to be transferrable from one employing certificate to another.

Since its first meeting in May 2022, the working group analyzed the history of part 65 and the FAA’s application of its rules. In the case of modern repairman, that history begins in 1945 with the creation of a “limited mechanic” certificate by the Civil Aeronautics Board. The new airmen, which were replaced by repairmen in 1952, allowed for the inspection and supervision of propeller and instrument maintenance – bridging the gap between the authority of air carrier/air agency certificates and individual mechanics.

“Title 14 CFR part 65 subpart E remains substantially unchanged since its publication 70 years ago as 14 CFR part 24, subpart B,” the report said. “However, the FAA has significantly altered the application for and issuance of the repairman certificates through various guidance changes that have inconsistently attempted to limit the privileges and opportunities of those certificates. Additionally, without knowledge of the regulatory history, the FAA workforce issues the certificate based on the misunderstanding that the repairman is a lesser certificate than a mechanic certificate. Rather, the repairman certificate is a limited mechanic certificate that needs to be held to the same technical standard as today’s mechanic’s certificate with respect to the task, function, or specialty performed.”

To increase the modern value of the repairman certificate by using its regulatory origin, the working group made four recommendations:

(1) Update FAA policy to establish updated procedures for agency review of repairman applicant qualifications, which remain valid unless the individual’s certificate is revoked or suspended.

(2) Align repairman ratings with those of the certificated organization employing them.

(3) Issue a new advisory circular referencing the Airman Certification Standards to ensure basic repairman requirements align with the “limited mechanic” of its origin.

(4) Revise part 65 to recognize repairman certificates as limited mechanic certificates that need not be surrendered between employers.

To review the report, which includes draft guidance in its appendices, click here.

Advertising Yourself

AVMRO.arsa.org provides a comprehensive introduction to the aviation maintenance industry. It’s a resource that shows, in quick snapshots, the vitality and value of the international aerospace maintenance community.

Maintenance organizations can use its content by—

(1) Finding a local school.

(2) Finding the principal and at least one guidance counselor.

(3) Sending them a link to AVMRO.arsa.org with an offer to share how your company’s work fits into the aerospace industry.

Final Documents/Your Two Cents

This list includes Federal Register publications, such as final rules, Advisory Circulars and policy statements, as well as proposed rules and policies of interest to ARSA members.

Legal Briefs

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

Protecting the Protected

By Sarah MacLeod, Executive Director

During my tenure on the Instructions for Continued Airworthiness (ICA) Aviation Rulemaking Committee (ARC), it has become abundantly clear to this participant the agency has lost its way. Among the tasks assigned is the request for industry to:

D. Propose how to protect intellectual property while achieving safety objectives: Identify what intellectual property factors exist that may affect the content of ICA and its availability to product owners and maintenance providers. Describe how these factors can be addressed while preserving the purpose of ICA. Consider whether requirements for ICA availability must be based on maintenance programs or specialized providers, which may lead a maintenance provider to need only a subset of ICA, rather than complete ICA, to perform required maintenance.

The first two sentences establish the task drafters’ misunderstanding regarding protection of private property rights by the government. First, it is the agency that sets the rules that control safety, not applicants or certificate holders. Intellectual property, when properly identified, must be kept confidential by all federal government entities (and thus employees). The Dynamic Regulatory System is replete with examples of how government employees are to protect intellectual property, even from Freedom of Information Act requests.

If information considered intellectual property is required to be made public to fulfill an aviation safety regulatory obligation, it is up to the industry to protect its rights in that property. The agency has little to do with ensuring a private citizen protects the intellectual property associated with the service bulletin required to correct an unsafe condition as mandated by an airworthiness directive.

The agency can only control aviation safety, it cannot dictate how the person responsible for providing the information must or can protect it. Appropriate warnings, labeling, and non-disclosure agreements have worked well. If those protections are not being enforced, it is not a safety problem, it is a commercial one. The government’s job is to define what is required to be provided in the interest of “continued airworthiness”. From there intellectual property ownership can be claimed and, if valid, enforced when the information is misused. In my experience, solid intellectual property right claims have halted alleged misuse and resulted in compensatory exchanges. In no event did the government help or hinder the process.

Even more disheartening evidence of mixing apples with oranges is that the last two sentences have nothing to do with the first two. Whatever recommendation the ARC has for addressing content and availability must also deal with the partial manual issue, but it has little to do with intellectual property.

The real fight among the members of the ICA-ARC is over content and availability. The expectations of the owners and maintenance providers for ICA and the reality of FAA ever enforcing the requirements for development and dissemination information “essential to continued airworthiness” is made clear by the wording of the tasks before the ARC.

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

Layman Lawyer – The P in Pear

By Brett Levanto, Vice President of Operations

The layman lawyer is continuing an exploration of Safety Management Systems as a human factors practice by diving into each element of the PEAR Model.

The primer in the June 2024 hotline introduced “people, environment, actions, and resources” as a safety assurance structure. Building off the explanation of that model in ARSA’s human factors training, the PEAR Model focuses the capabilities and limitations primarily affecting “human” performance. Some examples:

- Personal: Size, Age, Gender

- Physical: Strength, Sensory Function

- Physiological: Nutrition, Health, Lifestyle, Alertness

- Psychosocial: Interpersonal Conflicts, Personal Loss, Duty Fitness

- Psychological: Workload, Experience, Knowledge, Training, Attitude

Despite the once-common advice to “not bring your home life with you to work” and “leave your job at the office,” it’s impossible. Absent the fictional “severance” procedure, there is no point at which a human’s entire life experience and physical existence won’t impact performance. Having any chance at a “safety culture” demands attention:

- Align individual characteristics with tasks. Consider the need for rest breaks, interpersonal support, or whether some attributes align better or worse with certain tasks, e.g., having a larger technician trying to work in a confined space with little maneuvering room.

- Consider physical skill as a competency. A sharp pair of eyes can help move a visual inspection along quickly. Bolster overall performance by supporting technical knowledge and experience with physical advantage.

- Support the elements making people best prepared. Provide healthy food options in break rooms or offer considerations for health and wellness programs.

- Encourage (and teach) self-assessment to understand the impact of states of mind on work performance.

- Make workload and other personal management metrics part of oversight. The “dirty dozen” and accidents in aviation maintenance is littered with psychological factors.

| Who’s Driving? ARSA Executive Director Sarah MacLeod recently saw Pixar’s Inside Out, so the association’s team has been reflected on how its core emotions drive its actions. Share (anonymously) which of these five emotions drives you in this month’s people-focused quick question. |

ARSA’s overview training session references the Three Stooges performance as aviation professionals in “The Dizzy Pilots.” Larry, Curly, and Moe’s work is entertainingly inhibited by several personal factors. “Interpersonal conflict” was the Stooges’ entire reason for being: The trio spends far more time arguing with one another than focusing on any task. They obviously lack the necessary experience, knowledge, training, and attitude to perform serious work. These psychological attributes are further inhibited by their physical statures and the assumed impediments of larger lifestyle choices.

Regardless of how well real-world managers, supervisors, inspectors, technicians, clerks, HR specialists, or anyone else working in aviation compares to a vaudeville comedy act, tending to the capabilities and needs of the people is a key element of safety management.

ARSA on the Hill

The Dog Days

By Christian Klein, Executive Vice President

This month’s column could be titled, “ARSA off the Hill” as the association’s primary legislative objective – enactment of the new FAA reauthorization law – is done, making implementation of the new law the top priority.

For example, Sec. 821 of the bill directs the Department of Transportation Inspector General (DOT IG) to audit the FAA’s Flight Standards and Aircraft Certification Services regarding consistency in interpretation and application of policies, orders, guidance, and regulations. ARSA is meeting with the DOT IG in August to discuss the directive.

Congress is in recess through the end of August so members can campaign, but there is a need to keep an eye on the appropriations process, which provides funding for FAA operations, and the FY 2025 National Defense Authorization Act. The latter is where ARSA seeks to include language making it easier for repair stations to work for the Department of Defense.

The control of the legislative and executive branches of the U.S. government are both at stake in the 2024 elections. While Republicans control the House of Representatives with 220 seats to the Democrats 212 (there are currently three vacancies, two Democrat and one Republican). Democrats only need a net gain of four seats to take control of that Chamber. The situation is reversed in the Senate, where Democrats hold 51 seats (47 Democrats plus four independents) so the GOP needs two seats to gain control. With margins likely to be similarly narrow in 2025, the outcome of the presidential election could decide Senate control: if the parties are evenly split, the vice president casts the Senate’s tie-breaking vote.

ARSA encourages members to engage with candidates from both parties so no matter who comes out on top, aviation maintenance can continue to be influential. The simplest way is to host a facility visit to learn about your company, meet your workers, and see first-hand what aerospace maintenance contributes. ARSA will assist in making contact with congressional offices, an agenda for the visit, and briefing materials. Also, keep an eye out for opportunities to engage candidates at community events and fundraisers.

ARSA’s legislative success depends on member activism. Make this the year you get active (if you’re not already!)

|

Want to Learn More About ARSA PAC? ARSA’s Political Action Committee helps elect congressional candidates who share ARSA’s commitment to better regulation and a strong aviation maintenance sector. In this critical election year, ARSA PAC has never been more important. But ARSA is prohibited from sending PAC information to members who haven’t opted in to receive it. Please take a second to give us prior approval to talk to you about ARSA PAC. Doing so in no way obligates you to support PAC. It just opens the lines of communication. Click here to give ARSA your consent today. |

Finding Your Member of Congress

In the summer of an election year, senators and congressmen want to meet constituents. ARSA members should take advantage of this interest to schedule facility visits, town halls, meet and greets, or any other excuse to spend time with the person representing your business in Congress.

As ARSA Legislative Day participants hear every year, building an ongoing relationship with your elected officials is really a matter of simple effort. The most successful constituents are patient and persistent…and they know how to use a few simple tools for finding their members of Congress.

Who represents you?

Using ARSA’s Legislative Advocacy Tools – provided all year by Conference sponsor Aircraft Electric Motors – find your elected officials by entering your zip code in the “Election Center.” (Remember to enter your personal zip code and also the one for all facilities associated with your company; there may be multiple officials/offices with an interest in your needs.) Get started at arsa.org/congress.

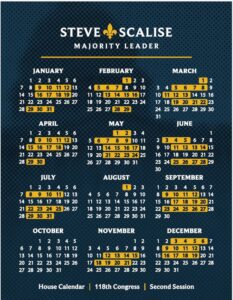

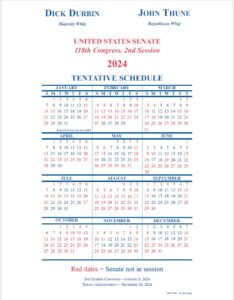

When will they be home?

Members of the U.S. Congress try to spend as much time in their states/districts as possible. Both the House and Senate leadership have published session calendars for 2024. By reviewing these calendars, you can determine when your senators and congressman are likely to be “back home” by looking for dates not in session. Review the schedule documents below and find updated information at www.congress.gov/calendars-and-schedules.

| House | Senate | |

|

|

What do you do now?

Contact use the contact resources available at arsa.org/congress to get in touch with the offices that represent you and invite them to visit your facility on one of the dates for “district work.” For talking points and other guidance, visit arsa.org/legislative or contact ARSA.

Aviation Life Calendar

August Through November

Something exciting happens every day in an aviation career.

If you want to keep aviation in the forefront of career choices, celebrate success every day with these resources. Every one provides a positive view of the industry’s ability to make the impossible an everyday event by individuals from every walk of life, socio-economic level, race, creed, color, religion, orientation, and physical capability.

Check back regularly for updates.

| Month | Day | Event or Celebration |

| All | All | This Day in Aviation |

| August | All | This Day in Aviation History – August |

| August | 16 | National Airborne Day |

| August | 19 | National Aviation Day |

| August | 19 | Orville Wright’s Birthday |

| August | 25 | Amelia Earhart Flies Coast to Coast – Nonstop |

| August | 30 | First African American in Space |

| September | All | This Day in Aviation History – September |

| September | 4 | Global Talent Acquisition Day |

| September | 15 | Hispanic Heritage Month |

| October | All | This Day in Aviation History – October |

| October | 4 | World Space Week |

| October | 20 | International Air Traffic Controller Day |

| November | All | This Day in Aviation History – November |

| November | All | National Aviation History Month |

| November | 8 | National STEM/STEAM Day |

Training & Career Development

Part 65 Repairman Certificates

This session reviews the requirements of 14 CFR part 65 subpart E, which concerns aviation repairmen. It presents the language of part 65 in the context of parts 121, 135 and 145 as well as agency guidance regarding the management of repairman applications. Throughout, the session connects and compares the repairman’s requirements to those of the mechanic’s certificate issued under part 65.

Instructors: Sarah MacLeod & Brett Levanto

Click here to register and get access for 90 days.

This is the third session on part 65 the association has made available (see the other two below). Want all three? Click here to purchase together and save.

Other Sessions on Part 65 (Click title to see more)...

Part 65 – Getting a Mechanic's Certificate

This session reviews the requirements of 14 CFR part 65 subpart D, which concerns aviation mechanics. It walks through the requirements for an individual to apply for a mechanic’s certificate, then defines the privileges and limitations bestowed on that individual by his or her certificate. Finally, it covers the enhancements to a mechanic’s privileges produced by obtaining Inspection Authorization.

Instructor: Sarah MacLeod

Part 65 – Overview

Part 65 – Overview

This session overviews 14 CFR part 65, Certification: Airmen Other than Flight Crewmembers. It introduces the statutory authority through which the FAA administers certificates and outlines the rules for application, issuance, testing, disqualification and duration of agency-issued certificates. It then introduces the five different certifications issued under part 65 by reviewing the relevant eligibility requirements for each.

Instructor: Sarah MacLeod

Registration for an ARSA-provided training session includes:

- Access to the on-demand, recorded version of the webinar to be made available after the live session is complete (or at time of purchase, for on-demand classes).

- A copy of the presentation and all reference material with links to relevant resources and citations.

- Upon completion of the class as well as any test material, a completion certificate.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit PotomacLaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Going Global Again

International markets mean expanded business opportunities that require an expansive regulatory understanding.

A Primer on International Regulatory Law

This session summarizes the framework for international safety regulation, introduces ICAO’s mechanisms for allocating regulatory responsibilities among member states and addresses the important role bilateral agreements play in enhancing efficiency and facilitating international commerce.

Click here to register and get access for 90 days.

International Obligations

This session provides history and context for international aviation safety regulations. It explains the background to the Chicago Convention, the establishment and authority of the International Civil Aviation Organization (ICAO) to set the standards and responsibilities of civil aviation authorities.

Click here to register and get access for 90 days.

Bilateral Agreements

This session focuses on the purpose and scope of bilateral agreements and describes how they are developed and structured. The presentation explains specific activities covered in a typical BASA including design approvals and post-design approvals, production and surveillance, export airworthiness approvals, technical assistance between authorities and special arrangements. It also covers bilateral maintenance agreements, their associated special conditions and the latest maintenance developments out of ICAO.

Click here to register and get access for 90 days.

European Enlightenment

This session provides the history behind the bilateral airworthiness agreements (BAA) and bilateral aviation safety agreements (BASAs) between the United States and European nations. Provides the background to the development of the European Union Aviation Safety Agency (EASA) through the Joint Aviation Authorities (JAA). It explains how implementation procedures for design and production are negotiated separately from implementation procedures for maintenance.

Click here to register and get access for 90 days.

Registration for an ARSA training session includes:

- Access to the on-demand recording of each session for 90 days.

- Digital copies of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of each class.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Instructions for Continued Airworthiness

View ARSA’s three-part series on instructions for continued airworthiness (ICA), led by Managing Director and General Counsel Marshall S. Filler. ICA has been a key focus of ARSA’s work on behalf of the maintenance community for decades and it continues to demand attention from aviation businesses worldwide. Turn the association’s experience into your benefit.

ICA – The Basics

This session overviews the regulatory basis for ICA, including what documents are considered ICA and the obligations of design approval holders to prepare, furnish and otherwise make them available under 14 CFR § 21.50(b). It also covers the related regulations that apply to operators and maintenance providers regarding the use and availability of ICA. Finally, it shows how the FAA has interpreted some of the more important ICA requirements in Order 8110.54.

Click here to register and get access for 90 days.

ICA – The Business Side

This session explains the importance of ICA and describes ARSA’s efforts to strike an appropriate balance between often-competing regulatory and business considerations. It also addresses various design approval holder (DAH) business practices that affect the availability and use of ICA and explains the FAA’s policy prohibiting DAHs from engaging in certain behaviors. It also explores various FAA ICA legal interpretations and some of the issues being examined in an ongoing anti-trust inquiry by the European Commission’s Competition Directorate.

Click here to register and get access for 90 days.

ICA – Case Study: Testing Your Knowledge

This session will test participants’ knowledge of ICA-related provisions in 14 CFR and FAA guidance by presenting several hypothetical case studies. Each one will focus on one or more of the significant ICA regulatory principles.

Click here to register and get access for 90 days.

Click here to purchase all three sessions together and receive a “bundle” discount.

Note: Sessions must be viewed in order. Completion of each pre-requisite – either via live session or on-demand recording – is required for access to subsequent classes.

Registration for an ARSA training session includes:

- Access to the on-demand recording of each session for 90 days.

- Digital copies of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of each class.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Regulatory Compliance Training

Test your knowledge of 14 CFR §§ 21.11, 21.13, and 21.15, applicability and application for type certificates.

Click here to download the training sheet.

Membership

ARSA Remembers – Ronald “RC” Craig Cannady (1936-2024)

Ronald Craig “RC” Cannady, past ARSA president and mentor to executive director Sarah MacLeod, died at his Georgia home on July 25. He was 88.

Born in Georgia, RC spent his early years in Jacksonville, Florida. After his own father’s death in 1947, RC spent summers working on a family farm in his birth state. A hardworking young man from a poor family, he cultivated a patch of vegetables to purchase necessities and occasional splurges on luxuries like a bathing suit for nearby Jay Bird Springs. These formative years made him tenacious and dedicated with a dream of one day being a prosperous landowner.

After high school, RC joined the Air Force. Having grown up watching aircraft operate out of Moody Field (later Moody Air Force Base) and remembering his father’s service in the Army Air Corps, Sargeant Cannady became a top electronics instructor at Kessler Air Force Base in Mississippi before moving to California after his honorable discharge.

RC met his wife, Evelyn, on the west coast before the pair began a globe-spanning life together. He worked for Chevron Oil and later served overseas for the U.S. Central Intelligence Agency, a government career that took him across Africa as chief communications officer for Pan African Airlines.

Returning from overseas, RC founded Aerotron Aircraft Radio in an attic in Long Beach, California. His business quickly grew internationally and became an active member of the maintenance community. RC served general aviation interests on ARSA’s board in the 1990’s and 2000’s, guiding the association’s transition to management under the law firm of Obadal, Filler, MacLeod, & Klein, P.L.C. As a director, he had particular interest in membership oversight and growth and was an early sponsor of the Annual Repair Symposium (still the central part of ARSA’s Annual Conference week). He retired from the board in 2005.

These many career highlights and successes were sidelights to an incredible personal life. In 1983, RC realized his full dream of land ownership by purchasing a 15,000-acre cattle ranch outside of Prescott, Arizona. On the ranch and around the world, he shared his life with his family and countless international stars and dignitaries like Rod Stewart, Dean Martin, Dick Clark, and world leaders including Queen Elizabeth II of England. Among many awards and honors was recognition from the president of Kuwait when Aerotron helped rebuild Kuwaiti Airlines after the first Gulf War.

RC’s generosity of spirit, hardnosed business sense, and commitment to others left a lasting impression on all who knew him. ARSA’s team shares its condolences with RC’s family and its gratitude for his service to the aviation industry and the inspiration of his life well lived.

To read the full obituary, click here.

In lieu of flowers, the family requested donations in honor of RC to Tunnels to Towers.

Those wishing to share a condolence or remembrance with the family may do so by visiting www.shlagrange.com.

Celebrating a Master – Anthony Imparato

The FAA recognized the chief operations officer of ARSA member Aero Instruments & Avionics, Inc. Anthony “Tony” Imparato with its Master Mechanic Award. The award recognizes the lifetime accomplishments of senior mechanics, honoring professionals with 50 years or more of civil and/or military maintenance experience.

ARSA member Aero Instruments & Avionics, Inc. is in his home state of New York. His career began as a line mechanic for Capital Airways at JFK International Airport after his 1974 graduation from Aviation High School in Queens.

He left the flight line to become a maintenance manager and technical instructor for Eastern Airlines. He continued his career with increasingly senior roles at Butler Aviation, AAR Aircraft Component Services, Kellstrom Industries, and Barfield, where he retired as accountable manager in 2021. His short retirement ended with his return to an advisory role with Aero Instruments and Avionics.

“When you first start out, you really don’t know much,” Imparato said after receiving his award. “You’ve got a certificate, but you really don’t know what airplanes are all about. I learned from the people that I worked with…and they took the time to…teach the younger people. That was a great thing for me.”

Imparato carried on the example of those veterans who helped him grow. He served on the board for George T. Baker Aviation College for Miami Dade and is a past chairman for the Beacon Council Aviation Committee for Miami Dade in addition to actively engaging with industry groups like ARSA. Across this service, he remembers fondly the challenge of training pilots and maintenance personnel.

ARSA’s team congratulates Tony and thanks him for his long service to the maintenance community, the aviation world, and the public it serves every day.

What accolades are your teammates celebrating? Share with ARSA so we can join the festivities.

Pay to Play

By Kimberly Dimmick, Vice President of Membership

Is there a cost to pay using a credit card to pay membership dues? Yes, and it is either born by the member or ARSA depending on the state laws.

An additional cost (in time and effort) is the new two-factor authentication process protecting both the association and the member from fraudulent activities. That means filling out a form with a reCAPTCHA box to provde you’re a human, which gives access to a payment portal requiring authentication from an email address or phone number.

To avoid charges and hassles pay “for free” by using ACH or sending a check.

Welcome & Welcome Back – New & Renewing Members

ARSA’s members give the association life – its work on behalf of the maintenance community depends on the commitment of these organizations. Here’s to the companies that joined or renewed in July:

New Members

AM Aviation Services LLC dba A&M Aviation LLC, R01

Gyros Unlimited dba North Bay Aviation, R03

Preflight Repair Services, Inc., R01

Pro Star Aviation LLC, R04

Sunvair, Inc, R04

Renewing Members

Aero Design Services, Inc., Affil, 2000

Aero-Mark MRO, LLC dba Fairhope Aerospace, R02, 2015

Aerospace Engineering Group, S.L., R03, 2014

Aircraft Ducting Repair, Inc., R03, 2002

Aircraft Specialties, Inc., R03, 2019

AMETEK Aircraft Parts & Accessories, Inc. , R03, 2023

Aviation Repair Resources, Inc. (ARR), R02, 2009

Aviation Repair Technical, Inc., R01, 2023

CorpAir Supply Company, Inc. dba AVMATS Component Support, R02, 2001

Cosgrove Aircraft Services, Inc., R01, 2021

Cross-Check Aviation, R02, 2003

Dan Brauhn-Indian Hills Community College, EDU, 2015

E.U.A. Air Support, Inc., R01, 2003

Florida Jet Center, Inc., R02, 2013

Ford Instruments & Accessories, LLC, R01, 2018

Gyro Specialist, Inc., R01, 2011

Jet Center MFR dba Southern Oregon Skyways, R03, 2006

Marana Aerospace Solutions, Inc. dba Ascent Aviation Services, R06, 2023

National Flight Services, Inc., R03, 1991

Pacific Aerospace, LLC, R01, 2005

PT. Wira Jasa Angkasa , R03, 2021

SAI Flight Support Company, R01, 2016

Signature Engines, Inc., R02, 2017

Southwest Airmotive Corp., R01, 2012

Rotorcraft Repair & Manufacturing, LLC, R01, 2019

TAE Aerospace, Inc., R01, 2019

Texas Air Services, Inc., R02, 2003

The Boeing Company, Corp, 1996

Unical 145, Inc., R04, 2012

Unicorp Systems, Inc., R03, 2003

A Member Asked…Anti-NDI norms?

Q: I would like to get your input on the “norm” among repair stations that when performing a “repair” of a component (vs. an “overhaul”) that the nondestructive testing of a piece part is NOT mandatory, even if the CMM requires it.

It seems that if the component was disassembled to the extent that one can hold the part in one’s hand, it must be NDT’d whether it’s a repair or an overhaul. The reasoning being, what justification does one have NOT to NDT it?

Is there a regulatory basis for not performing NDT of part just because the maintenance is a “repair”?

A: The technicians and others that have created or followed the “norm” need to read several regulations very carefully: Every person performing maintenance must do so in such a manner as to return the article (top assembly) to at least its original (or properly altered) condition, using as reference the manufacturer’s instructions and/or other acceptable methods, techniques, and practices as required by § 43.13.

Person means an individual, firm, partnership, corporation, company, association, joint-stock association, or governmental entity. It includes a trustee, receiver, assignee, or similar representative of any of them.

The regulations on doing work properly and in accordance with the appropriate methods, techniques, and practices apply to every individual performing maintenance, not just the repair station (that will approve the work for return to service) as is clear from the first three words of § 43.13: “Each person performing…”

Maintenance means inspection, overhaul, repair, preservation, and the replacement of parts, but excludes preventive maintenance.

When an article (top assembly) is disassembled, all exposed parts must be inspected to determine whether any need repair (if one is available) or must be replaced because it fails an inspection that determines if it can be reused. If it passes the inspection, it can be used as the replacement (reinstalled) when reassembly takes place. You do not know if you need a repair or replacement (all steps in a maintenance action) without an inspection (the most fundamental action associated with every maintenance job)!

Repair is an action taken on an internal piece part to restore its original or properly altered condition, e.g., welding, removing and replacing coatings, grinding, building up and grinding down, resize or reshaping. Yes, it can also be used to describe the “entire work scope” if less than an “overhaul,” but the individual steps must be taken and recorded in repair station records associated with the individual(s) performing the actions (see, § 43.9(a)(3)).

Overhaul is merely one form of maintenance, to use the word in the description of the work performed required by § 43.9(a)(1) every action required by the appropriate manufacturer’s manual or other approved procedure must be followed (see, § 43.2(a)). The use of the word has nothing to do with performing each step properly, which is everyone’s responsibility, it is merely one way to describe a maintenance action that was as complete as possible.

Finally, a warning about “norms.” If you don’t know the rules of aviation, don’t play the game, because lives depend upon every person following the rules. Making a maintenance record describing the work or referencing a manual is required by the federal government, as is following the recordkeeping system of a repair station employer. “Each person performing” any step or making any part of the maintenance record must understand and be responsible for following acceptable methods, techniques, and practices to meet the original (or properly altered) condition requirement. When a norm deviates from the required knowledge and regulations, it can result in charges of falsifying records that carry heavy penalties and can lead to criminal charges and other dire consequences.

Have questions about aviation regulatory compliance, legislative policy, or ARSA resources? Ask ARSA first!

Quick Question – Who’s Driving

ARSA Executive Director Sarah MacLeod recently saw Pixar’s Inside Out, so the association’s team has been reflecting on how its core emotions – Joy, Sadness, Anger, Disgust, and Fear – drive its actions.

From Psychology Today:

“What’s really powerful about this film is how accurate it is to cognitive, developmental, and clinical psychology. The 5 emotions used in this film are in fact 5 of the 6 scientifically validated universal emotions (the 6th one being surprise)…. What messages does this movie send to its viewers? Many, actually, but perhaps the most important one is this – our emotions are all important, every single one of them. They all serve an important function and we cannot selectively feel some but not others.”

Since personal reflection is a vital element of human factors and safety management, ARSA offers this month’s “quick question” as an opportunity for self-reflection. Which of the five emotions most often drives you?

Share (anonymously) in this month’s people-focused quick question.

Note: The question is displayed in its own, embedded window. If the “Submit” button is not visible on the screen, you must scroll within the survey window to submit your response.

If the embedded survey does not appear/load, open the survey independently by visiting: https://www.surveymonkey.com/r/arsaemotions.

Click here to see what questions have been asked and answered…and keep a lookout for more.

Resources

ARSA strives to provide resources to educate the general public about the work of the association’s member organizations; should you need to provide a quick reference or introductory overview to the global MRO industry, please utilize AVMRO.ARSA.org.

About ARSA PAC

ARSA’s Political Action Committee helps elect congressional candidates who share ARSA’s commitment to better regulation and a strong aviation maintenance sector. But ARSA is prohibited from sending PAC information to members who haven’t opted in to receive it.

Careers in Aviation Maintenance

How do you share the industry’s story with the people who could be its future? Teach them about the great work done every day to keep the world in flight. (Even if we can’t recruit somebody, we sure can make them thankful for our work.)

U.S./EU Maintenance Annex Guidance

See all of the association’s public updates since 2012 on the Maintenance Annex Guidance between the United States and European Union. The page focuses in particular on matters related to parts documentation issues arising since MAG Change 5 was issued in 2015.

Industry Calendar

| Conference | Dates | Location |

| Aero-Engines Europe | 9/10-11/2024 | Amsterdam |

| World Remanufacturing Conference | 9/10-12/2024 | Chicago, Illinois |

| World Sustainability Symposium | 9/24-25/2024 | Miami, Florida |

| MRO Asia-Pacific | 9/24-26/2024 | Singapore |

| IAQG Meeting Week & 56th General Assembly | 10/21-24/2024 | Tokyo |

| MRO Europe | 10/23-24/2024 | Barcelona |

| 2024 NBAA Business Aviation Convention & Exhibition | 10/22-24/2024 | Las Vegas, Nevada |

| MRO Australasia | 11/13-14/2024 | Brisbane, Australia |

| NATA Aviation Business Conference | 11/13/2024 | Nashville, Tennessee |

| AOPA High School Aviation Symposium | 11/17-19/2024 | Atlanta, Georgia |

| ARSA Annual Conference | 3/18-21/2025 | Arlington, Virginia |

| IAQG Meeting Week & 57th General Assembly | 4/7-10/2025 | Brussels |

the hotline is the monthly publication of the Aeronautical Repair Station Association (ARSA), the not-for-profit international trade association for certificated repair stations. It is for the exclusive use of ARSA members and federal employees on the ARSA mailing list. For a membership application, please call 703.739.9543 or visit arsa.org/membership/join. For information about previous editions, submit a request through arsa.org/contact. This material is provided for educational and informational purposes only. It does not constitute legal, consulting, tax or any other type of professional advice. Law, regulations, guidance and government policies change frequently. While ARSA updates this material, we do not guarantee its accuracy. In addition, the application of this material to a particular situation is always dependent on the facts and circumstances involved. The use of this material is therefore at your own risk. All content in the hotline, except where indicated otherwise, is the property of ARSA. This content may not be reproduced, distributed or displayed, nor may derivatives or presentations be created from it in whole or in part, in any manner without the prior written consent of ARSA. ARSA grants its members a non-exclusive license to reproduce the content of the hotline. Employees of member organizations are the only parties authorized to receive a duplicate of the hotline. ARSA reserves all remaining rights and will use any means necessary to protect its intellectual property.

© 2024 Aeronautical Repair Station Association