2015 – Edition 5 – June 5

Table of Contents

Sarah Says – Get Off the Fence

By Sarah MacLeod, Executive Director

There are three kinds of men. The ones that learn by reading. The few who learn by observation. The rest of them have to pee on the electric fence for themselves. -Will Rogers

Everything is a learning experience, no matter how smart you thought you were at the beginning. Successful people learn more from defeat than victory. Experience is a great teacher in professional growth and personal well-being. Sometimes learning is about electric fences.

In aviation, learning can come with a high price. Sometimes the cost is financial, with civil penalties, enforcement burdens and litigation expenses shocking a certificate holder into compliance. On the worst of occasions, we lose something more; careers and lives can be altered forever by one bad day in a hangar or a component shop.

As regulatory compliance experts, ARSA answers far too many calls after that bad day. An ARSA membership is an insurance against many problems. While legal and technical support is also available when your business is in distress, the association provides the tools to help you avoid trouble in the first place.

- Regulatory and legislative guidance. The association maintains a full tank of information about the rules, how to comply with them and strategies for dealing with enforcement agencies. Since bad rules often come from bad laws, ARSA’s legislative team is on the Hill every day preventing Congress from micromanaging the aviation maintenance industry and finding ways for you to get involved.

- Instruction and discussion. In addition to regulatory training, ARSA will host discussion-oriented sessions to explore key regulatory and business issues via our online webinar platform. The first of these – an overview of the new contract maintenance rule – was held on May 28. (If you missed it, you can purchase an on-demand recording of the session by clicking here.)

- A problem-solving network. ’ll find another example in this edition of the hotline). When you have a question, ARSA connects you to the answer.

My phone will still ring, I’m sure, but through ARSA it will be quieter. The association will show you the electric fences and help chart routes around them. We’ll be there for you if you really need to learn the hard way, but let us prevent you from getting zapped in the first place.

Hotline Features

ARSA Joins STEM Leadership Council

By Brett Levanto, Vice President of Communications

On May 14, the STEM Education Coalition welcomed ARSA as a new member of its Leadership Council. Alongside the Aviation Technician Education Council (ATEC), ARSA’s new position will give the aviation maintenance industry a voice in the science, technology, engineering and math universe.

Though many think of STEM in relation to advanced academic degrees, the majority of STEM-related work is performed by hands-on technicians and specialists. In 2013, the Brookings Institution determined that half of all American STEM jobs are available to workers without a four-year college degree. The STEM Education Coalition works aggressively to raise awareness about the importance of preparing students for this kind of highly-technical work.

STEM has long been associated with rocket scientists, the coalition’s Executive Director James Brown explained at ARSA’s 2015 Annual Repair Symposium, but the future of the technical workforce depends on the people who build and maintain the rockets.

Get Involved

In addition to the small Leadership Council, the STEM Coalition supports an expansive collection of affiliate members – over 600 organizations. By signing up you will connect your staff with key updates as well as the opportunity to add your voice to letters, petitions and initiatives on behalf of the technical workforce.

Click here to get started.

ARSA on the Road: Cleveland, Ohio

By ARSA Communications Staff

On May 13, ARSA’s Vice President of Communications Brett Levanto presented at the Regional Airline Association’s (RAA) 40th Annual Convention in Cleveland, Ohio. Levanto was joined by Amy Kienast, vice president of the Aviation Technician Education Council (ATEC) and career director at MIAT College of Technology, to discuss Policy Solutions for a Stronger Technical Workforce.

The panel discussion was developed based on the jointly-released study of the same name performed by researchers at the College of William and Mary. In addition to the analysis presented in the original report, Levanto and Kienast explored a series of initiatives intended to help grow the aviation workforce of the future. The pair not only described the work undertaking by ARSA and ATEC, they also outlined steps for industry members to strengthen their own talent pipelines.

To see the presentation, and learn what your business can do to shore up future talent, visit potomac-law.com/raa2015.

Levanto took advantage of his visit to the Buckeye State by touring Component Repair Technologies’ facility in Mentor, Ohio. At CRT, he was able to see first-hand the world-class aviation workforce discussed at the RAA convention. Through dedication to its people and commitment to excellence, CRT has forged a place as both a vital part of the global aviation community and a leading employer in its own community.

For CRT, empowering its people is a key facet of its dedication to customer service. A sign on the wall reminds each employee: “Our signatures are a reflection of our commitment to quality.”

This “on the road” experience is vital to connecting Washington policy with business reality. Contact us to learn how to bring the association to your facility and show off your commitment to the flying public.

Meet the Interns: Silvia E. Marroquin, Legal Intern

By Silvia E. Marroquin

I was born in Florida and moved to France at the age of nine, then to Spain six years later. I completed my undergraduate studies in Sciences Po Paris (France) where I majored in Political Science and Public Policy and specialized in Latin American studies. For my final year, I attended Kings College London where I majored in Law and War Studies.

My attraction to legal studies motivated me to enroll in Sciences Po Law School, where I was exposed to a unique practical and global vision of the law. This allowed me to tackle legal education and to embrace a multidimensional approach to the law. Most important, I completed my academic development through practical international experience and was challenged at the International LLM program at IE Law School in Madrid.

My oldest memories are playing with airplane toys and being fascinated by these flying creatures, unaware of the huge technical complexities and the diverse industry that kept them aloft. My personal exposure to this field, together with a strong interest for acquiring legal experience in the United States, have been a driving force for coming to ARSA.

During my last year in law school I majored in International Private and Public Law and International Arbitration. At ARSA, I am mostly interested in the comparative law aspects and future challenges of aviation regulatory frameworks.

As a recent graduate, I plan on enjoying this year to learn and gain experience while I apply to Master of Laws (LLM) programs for the fall of 2016, in order to practice law in both the United States and France.

I hope to gain a further understanding of the fascinatingly complex aviation regulatory framework. I am particularly enthusiastic about grasping the tensions between the technical realities of aviation and the governmental regimes sometimes disconnected from the industry’s needs: something that is not uncommon to other fields of the law!

I consider myself fortunate to be surrounded by a team of inspiring experts that unquestionably make this experience an enriching professional and personal step.

Meet the Interns: Danny Boatright, Legal Intern

By Danny Boatright

I was born in Southern California and joined the United States Marine Corps just months before my 18th birthday. The events on September 11th 2001 were so indelible in my formative years that I felt driven to service. Aviation had always been a part of my life, so when I joined the military I was originally contracted to work as a line mechanic on AH-1W Cobras and UH-1N Hueys. With my first squadron, HMLA-775, I served two tours in Al-Taqaddum, Iraq where I met my beautiful wife, Ileana.

After Iraq I was transferred to several different units including HMM-764 – a CH-46 (Phrog) squadron on Edwards Air Force Base – and then to the 3rd Civil Affairs Group on camp Pendleton, California. Since I was serving as a reservist, I was able to attend California Baptist University where I earned a dual major in Political Science and Philosophy.

Through my mechanic’s background I grew to appreciate the technical and human realities that affect performance. The collegiate experience gifted me with an additional perspective and mindset that I consider essential to understand the industry.

At the time, I was offered an opportunity to earn an aviation mechanic’s license with both Airframe and Powerplant endorsements based on my military occupational specialty. I decided to take this opportunity and soon was offered a job at Airborne Tactical Advantage Company (ATAC) out of Pt Mugu, California. At ATAC, I worked as a line mechanic on their MK-58 Hawker Hunters. Soon after, I was contacted by AAR Airlift who asked me to work as an in-flight mechanic on their Bell 214ST program in Shindand, Afghanistan.

I am now in the process of earning a Juris Doctorate with a certificate in Public Policy from Catholic University’s Columbus School of Law. In the pursuit of a well-rounded legal experience, I aspire to work for a short time as a clerk for a Federal Judge in a courtroom. After my legal education I hope to build a career in the aviation industry.

ARSA Works and So Can You – Association Internship Program

By ARSA Communications Staff

Want to follow in Danny and Silvia’s footsteps? Obadal, Filler, MacLeod and Klein, PLC, the firm that manages the Aeronautical Repair Station Association, continually accepts law and graduate student applications for its internship program.

Interns will gain firsthand knowledge of the legislative and regulatory process and get a behind-the-scenes look at public policy and the impact it has on critical sectors of the economy. Interns will monitor developments in the nation’s capital, draft content for various publications, conduct research on a variety of policy issues, attend industry and congressional events and play a hands-on role in support of the aviation maintenance industry.

Applicants must work well in a team setting and demonstrate independence and initiative in achieving specific tasks and overall objectives, in addition to possessing excellent written and verbal communication skills. Compensation and/or school credit is available, and hours are flexible to accommodate student schedules.

To submit an application, click here.

ARSA Works

To see all the ways that ARSA is working as the voice of the aviation maintenance industry, visit our ARSA Works page.

By ARSA Regulatory Staff

Conditions under which a repair station works away from its fixed location have changed dramatically over the years. At one time, the need to perform work under the auspices of a repair station certificate was limited to a permanent location, or in the event of a special circumstance, such as an aircraft on the ground, away from that fixed location.

Today, work is performed at various locations away from the fixed location, some are familiar sites or facilities known to the repair station and used sporadically to meet customer demands and business needs. Other locations may be ad hoc, where work is done at a customer’s behest for varying periods of time. Some repair stations utilize mobile repair units that may travel across state lines or even internationally to address commercial obligations and provide customer maintenance services.

In response to numerous member inquiries regarding 14 CFR § 145.203, working away from the fixed location, ARSA developed an advisory that would provide 14 CFR part 145 repair stations a “compliance road map.”

The purpose of the advisory is to outline the ability and conditions for repair stations to work away from their fixed locations, and methodologies for controlling such work under its quality system, taking into account the current business environment.

The association requests industry review and comment on the draft advisory. Once observations are disbursed, the association will work with the agency to ensure the guidance is acceptable for compliance with working away regulatory requirements, including utilization of mobile units.

Submit your comments to arsa@arsa.org either by tracking changes in the Microsoft Word document (download below) or submitting stand-alone written remarks.

Reducing Audits – Symposium Success & Industry Survey

By ARSA Regulatory Staff

Connections made at the association’s premier event can have immediate business impact: A member attending this year’s Annual Repair Symposium successfully eliminated an unnecessary review of its foreign repair station.

After taking note of the FAA’s declared effort to reduce redundant audits, the member queried the agency about an upcoming audit of a facility located in Europe that performs maintenance for an U.S. air carrier. The FAA responded to the query within a matter of days, confirming that the audit was both directly contrary to the United States/European Bilateral Aviation Safety Agreement (BASA) Maintenance Implementation Procedures (MIP) and to agency efforts to reduce redundant audits.

The Annual Repair Symposium offers one venue for members to learn and interact with regulators and colleagues, but ARSA keeps its ear on the ground to stay apprised of these types of issues affecting its members year-round. Currently, ARSA is collecting responses to a survey to determine the audit burden placed on the contract maintenance industry. The results will quantify issues of common concern regarding the untenable reality of non-stop, overlapping, and duplicative audits.

Please take the time to provide your company’s at https://www.surveymonkey.com/r/2015AuditsSurvey.

Member participation is critical to ARSA’s success, and – as highlighted by one member’s elimination of a duplicative audit based upon information received at the 2015 Annual Repair Symposium – it is critical to member companies’ success too.

Questionnaire: Improving Airworthiness Directives

By ARSA Regulatory Staff

Remember the grounding of aircraft in 2008 over allegations of non-compliance with airworthiness directives? Well, because of the widespread disruptions the FAA chartered the Airworthiness Directive Implementation Aviation Rulemaking Committee (AD ARC). That committee worked long and hard to develop policies, procedures and “best practices” that would improve the development, implementation, oversight and enforcement of these important safety rules.

While the final report outlining deliverables and implementing actions is focused on air carriers, the issues are not unique to the airline community. It seems everyone can agree that a successful AD will provide for:

- Clear requirements

- Consistent interpretation

- Compliant incorporation

- Effective oversight

It also cannot be disputed that improvements to the process should result in a reduction of:

- Ambiguous, overlapping, extraneous or erroneous AD requirements

- AD corrections/supersedures/revisions to address ambiguities, errors and oversights

- AMOCs to address AD/SB ambiguities, errors, corrections and oversights

- FAA enforcement actions

- Operator compliance clarification requests

- AEG support needed to respond to operator compliance questions from Aviation Safety Inspectors

- Fleet groundings due to non-compliance findings

To that end, industry participants developed a questionnaire to gather information on specific ADs. The data will support a determination as to whether the AD ARC deliverables and implementing actions have been effective or need more work. The submitted information will not be used to address the specific instances reported; rather, the data will be used to support AD process improvement recommendations.

While the questionnaire may appear to be aimed at the “bad” ADs, it also can and should be used to provide examples of clear, concise and easily understood directives. One questionnaire must be completed for each AD on which you would like to provide feedback; the process shouldn’t take more than 10 minutes.

To begin the questionnaire, please visit: http://www.surveygizmo.com/s3/1902342/AD-Questionnaire.

Contract Maintenance Mandates Document Released

By ARSA Regulatory Staff

On June 2, ARSA released a document detailing the mandates and restrictions imposed by the new air carrier contract maintenance rule, which takes effect on March 4, 2016.

ARSA worked diligently, both on the regulatory and the legislative fronts, to ensure the relationship between repair stations and air carriers would remain unchanged by the new rule. Consequently, most of the new mandates already exist and the impact on the aviation maintenance community should be minimal.

On May 28, ARSA hosted a webinar to overview the implications of the new rule and discuss compliance issues. An on-demand recording of that webinar is available for purchase. To access the recording, click here.

Legal Briefs

Counting on the Aviation Maintenance Workforce

By Laura Vlieg, Regulatory Affairs Manager

There is plenty of anecdotal information on a skilled labor shortage in the aviation maintenance industry. Without objective government-recognized numbers, it is very difficult to understand the magnitude, or pinpoint solutions. Yet no one is counting. Until the government knows how many individuals hold either a mechanic or repairman certificate, the workforce picture will be neither clear nor useful.

The government has been collecting occupational data since 1850 (first in the Census of Population). Unfortunately, information was not organized or uniform. The Standard Occupational Classification (SOC) system was created to provide a common framework for occupational cataloguing. Federal agencies are required to use the SOC system to collect, analyze, and disseminate occupational data. That information is then used by other federal agencies, Congress, international bodies, students, educators and employers.

The SOC system provides a hierarchical structure for categorizing occupations; when that structure fails to accurately reflect an industry’s occupations, a statistical void occurs. The aviation maintenance industry is presently in that void. The SOC system has been revised only a handful of times, but is currently undergoing revision. The Aeronautical Repair Station Association (ARSA) and the Aviation Technician Education Council (ATEC) believe it is essential that the aviation maintenance workforce framework be updated.

Under the current SOC framework, nearly all aviation maintenance professionals are classified as “aircraft mechanics and service technicians” without regard to certification or specialization (with the sole exception of avionics technicians). It is becoming increasingly evident that one category and one subunit for all aviation maintenance workers are insufficient.

A 2014 Report by the U.S. Government Accountability Office (GAO-14-237) highlighted the inadequacies. It points out that while “many employers may require employees to hold an A&P certificate,” the SOC system does not distinguish between certificated and non-certificated mechanics and “[a]s a result, labor market data may overestimate the number of available mechanics.” Without a better framework, there is no way to “examine whether starting earnings have increased,” for instance, in order to analyze trends in attracting entry-level workers.

While the FAA tracks mechanic and repairman certificates, the figures are not indicative of employment or career choices. As of December 31, 2014 the FAA had 341,409 mechanic and 39,566 repairmen certificates registered. However, it is difficult to track how or if the mechanic certificates are being used in aviation. According to the 2014 study that ARSA and ATEC published, “students are completing the aviation maintenance programs but electing to take jobs in other industries where wage or opportunity is greater.” That truth is reflected in other government numbers: individuals working in the aviation maintenance industry are far fewer than the registered certificates. According to the most recent Current Population Survey (CPS) there are 127,000 aircraft mechanics and service technicians. However, under the SOC classification, that number includes non-certificated individuals, and industry is left guessing about the breakdown.

Thus, ATEC, with the support of ARSA and other industry allies, is asking the SOC policy committee to create and accurately reflect the aviation maintenance workforce by tracking certificated mechanics, certificated repairmen, and non-certificated maintenance technicians separately.

To review the association’s submission, please contact Laura Vlieg at laura.vlieg@arsa.org.

ARSA on the Hill

It’s Time For A Smaller, More Accountable Government

By Rep. Bradley Byrne, R-Ala.

When I took over as chancellor of Alabama’s two year college system in 2007, I set out to fundamentally change the way our community college system operated. It didn’t take long before I started running into resistance. Time and time again, I heard the phrase “well that’s just the way it has always been done.”

To me, that is not an acceptable answer. As people, and as a government, we should always be looking for ways to improve and become more efficient. The same rule should apply to the federal government.

President Ronald Reagan once said that “no government ever voluntarily reduces itself in size. So government’s programs, once launched, never disappear. Actually, a government bureau is the nearest thing to eternal life we’ll ever see on this earth.”

President Reagan hit the nail on the head. I’ve only been in Washington for one year and six months, but it is clear that the federal government is too big. Since our nation was founded, the size of government has continually increased. In fact, I believe our Founding Fathers would be appalled to see the endless maze of agencies that the federal government has become.

It seems that while the Washington bureaucracy gets bigger, the main street economy just gets smaller. For every federal agency created, that is just one more department issuing regulations and mandates that often times restrict small businesses. It also seems like as the federal government gets larger, our personal freedoms get smaller and smaller.

Have you ever heard of the White House Commission on Presidential Scholars or the National Contact Center? What about the Citizens’ Stamp Advisory Committee? The merits of those organizations aside, I hope you get my point. The federal government is too big, and it is time we act to rein it in.

That’s why I introduced the Sunset Inefficient and Unaccountable Government Act, known as the Sunset Act. My bill would require Congress to review and renew the over 275 government departments, agencies and boards on a staggered basis every ten years. Agencies and departments directly related to national security would be exempt from abolishment.

My bill would put the burden on federal agencies and departments to justify their existence and explain to the Congress why they deserve to continue. Without Congressional renewal, the agencies will cease to exist. Congress will be forced to study and review the bloated federal government, and federal agencies will have to prove their worth and tighten their belts in order to remain in existence.

This isn’t a foreign idea. In fact, Alabama already has a Sunset Committee at the state level. When I was in the Alabama State Senate, we had to renew state agencies on a rotating basis, and it was an effective way to hold agencies accountable and ensure they remain responsive to the people. Washington could benefit from some of that Alabama commonsense.

I think two likely outcomes would come from my Sunset Act. First, I think some unnecessary agencies will cease to exist, and duplicative agencies will be combined. Secondly, I think the agencies that we do decide to keep will become more efficient and accountable, likely reducing the size and scope of what they do. In both cases, the American people would benefit.

Let’s stop accepting “that’s just the way it has always been done” as a credible reason for doing things. Let’s shake up the way Washington is run. Let’s remember that government is supposed to work for the people, not the other way around.

It is time we bring some accountability to the federal government. My Sunset Act would do just that, and I look forward to building support for this commonsense approach in Congress and working with ARSA members around the country to reform the way government does business.

Editor’s Note: From time to time, ARSA invites policy makers and congressional leaders to share their thoughts on the issues facing the country. Views expressed are those of the author and inclusion of content does not constitute an endorsement of any individual elected official or candidate.

Regulatory Outlook

ARSA Joins Effort to Fix Aviation Workforce Data

By Laura Vlieg, Regulatory Affairs Manager

On June 4, ARSA and a coalition of industry groups spearheaded by the Aviation Technician Education Council (ATEC), submitted comments to the current revision process of the Standard Occupational Classification (SOC) system asking the SOC Policy Committee to revise the system to more accurately reflect the occupations available in the aviation maintenance community.

The SOC system provides the framework for all occupational statistics collected and disseminated by federal agencies. For federal statistical purposes, it determines precisely which occupations exist and has a significant impact on the legislators, educators, employers and job seekers who utilize that data.

The coalition is comprised of groups vested in the health of the aviation maintenance industry that want a clearer picture of workforce needs. Signatories on the comments included ARSA, ATEC, Airlines for America, the General Aviation Manufacturers Association, the National Air Carrier Association, the Aerospace Maintenance Council, the Regional Airline Association, the Cargo Airline Association and a former member of the National Transportation Safety Board.

To learn more about the SOC system, check out this month’s Legal Brief.

FAA Finally Clarifies Designee Privilege

By ARSA Regulatory Staff

On May 13, the FAA clarified a repair specification designated engineering representative’s (RS-DER) ability to rescind an approval of engineering information. The issue arose when a member received a letter for its RS-DER “withdrawing” the approval of data being used to support a major repair. ARSA originally challenged this result in a Dec. 6, 2012 letter to the FAA and the agency responded to the original request on April 11, 2013. However, the response did not address the impact of such an action or how it may be challenged, so the association requested further clarification on June 5, 2013.

The agency agreed the regulation empowering DERs only grants the privilege of approving information; it does not give designees authority to make “unsafe condition” determinations. Therefore, the notification from the DER is merely that — a notification that the designee believes the substantiating data may not show compliance with applicable regulations. It puts the user on notice that additional data or a second opinion should be sought but does not “revoke” the approval and it does not mean that previous use of the data has created an unsafe (or even non-compliant) condition in articles that were processed under the approval.

Unless and until the FAA determines an airworthiness directive is required (because the use of the data created an unsafe condition), the articles or products worked on before the notification remain unaffected.

This list includes Federal Register publications, such as final rules, Advisory Circulars and policy statements, as well as proposed rules and policies of interest to ARSA members. To view the list, click here.

Quality Time

“Recreational or Medical” Marijuana vs FAA/DOT Drug Testing

By Shirley Negri, NATA Compliance Services © 2015 Shirley Negri ALL RIGHTS RESERVED

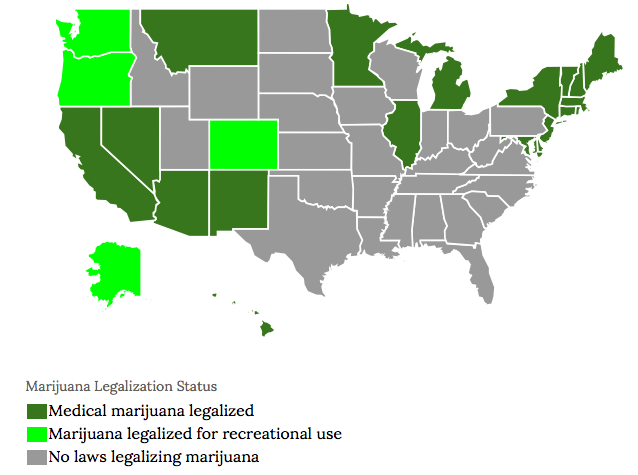

Nearly 50 percent of the United States currently has laws legalizing marijuana in some form. (See Map.)

How does this impact your repair station? Technically it doesn’t, if your operation performs maintenance on commercial aircraft operations including air tour for hire.

The Department of Transportation and the FAA maintain requirements that all “safety-sensitive or covered” employees (e.g., A&P Technicians, Sheet Metal Mechanics, Avionics Technicians) be subject to drug and alcohol testing. Further, regardless if marijuana was used for recreational or medicinal purposes in a state that has “legalized” the activity, detection of use will result in a positive drug test.

NATA Compliance Services (NATACS) is the aviation industry’s only full-service employee background investigation and HR-compliance company and an ARSA preferred provider. To learn more, visit http://info.natacs.aero.

Training

Personal Development – Unsweet Dreams

By ARSA Communications Staff

All of us want to invent that game-changing product, launch that successful company, write that best-selling book. And yet so few of us actually do it. TED Fellow and Brazilian entrepreneur Bel Pesce breaks down five easy-to-believe myths that ensure your dream projects will never come to fruition.

Click here to live your dreams (or at least learn a bit about them).

Policy Solutions for a Stronger Technical Workforce

By ARSA Communications Staff

In the face of expanding global markets and increased demand for a highly skilled, government-certificated labor force, business must overcome the looming retirements of more experienced employees, skill gaps, regulatory limitations on training programs and, most importantly, data sources that are inadequately designed for defining the problem.

At the Regional Airline Association’s annual convention in Clevelnd, Ohio, representatives from ARSA and the Aviation Technical Education Council (ATEC) provided a briefing on the jointly-released report “Policy Solutions for a Stronger Technical Workforce” and described a variety of initiatives through which industry members can help proactively build the aviation workforce of the future.

To download the presentation, please visit http://potomac-law.com/RAA2015.

On Demand: Keeping Your Covered Work

By ARSA Communications Staff

On March 4, 2015, the FAA unveiled a congressionally-mandated rule on air carrier contract maintenance requirements. On May 28, ARSA hosted a webinar discussion to overview the decades-long fight to minimize the rule’s impact on the aviation industry and cover the basic details of compliance.

An on-demand recording of the webinar is available for purchase. Click here to download now.

Membership

Member Spotlight – Columbia Helicopters

By ARSA Communications Staff

Based in Portland, Oregon, Columbia Helicopters is a global provider of helicopter services in support of aerial firefighting and natural resource extraction, as well as the operator of a well-known repair station focusing on heavy helicopter airframes and engines. Columbia has grown from a single-helicopter, family operation in 1957 into a world leader in commercial heavy-lift operations and helicopter maintenance.

To support its growing fleet of aircraft in the 1970’s Columbia began developing and expanding its internal maintenance support capabilities. Internal back shops were developed and eventually made the company virtually independent of OEM support. Today these shops include complete overhaul capability for engines, engine accessories, transmissions, avionics, rotor heads, electrical systems, hydraulic components and systems and virtually all 107 and 234 aircraft systems.

Using this internal maintenance capability to provide maintenance services to other companies or countries that operate large helicopters is a very significant and rapidly growing contributor to Columbia’s success as a world-class MRO. Columbia operates in 16 countries and its foreign customers include the Australian, Thai, Greek and Spanish Armies as well as the Singapore and Moroccan Air Forces. The overall growth of outside maintenance is a strategic initiative for the company and the rapid expansion of this business experienced in the last few years is expected to increase and continue on a sustained basis.

Columbia has shown a long-standing commitment to the training and development of its workforce – a ten-time winner of the William “Bill” O’Brien Aviation Maintenance Technician Employer Diamond Award of Excellence.

The Employer Diamond Award of Excellence, established in 1992, is given annually by the FAA in recognition of excellence in training to companies engaged full-time in repairing aircraft or component parts. Company eligibility for the Diamond Award also requires that 100 percent of the organization’s eligible employees were awarded an individual William (Bill) O’Brien AMT Award for the previous calendar year. The individual awards are Bronze, Silver, and Gold, each with its own requirements for training hours, and course work.

Columbia conducts employee training at its Portland facility, as well as via its internal website for its technicians working away from the home base. It also supplies courseware on DVDs to its mechanics working in remote areas where Internet access is either spotty or non-existent.

By providing a broad array of training options for its technical staff, Columbia Helicopters embodies the industry’s commitment to quality people with the right skills. Through dedication to its workers, the company is building the world-class workforce of the future.

To learn more, visit http://www.colheli.com/.

Have You Seen this Person?

Each month, the hotline spotlights key regulatory, legislative, and business leaders making important contributions to the aviation industry.

By ARSA Communications Staff

Congressman John Kline was born in Allentown, Pennsylvania and now represents Minnesota’s 2nd District in the U.S. House of Representatives. Kline was first elected to Congress in 2002.He earned a B.A. in biology at Rice University (1969), and a Master of Public Administration from Shippensburg University of Pennsylvania (1988).

Prior to arriving on Capitol Hill, Kline was a U.S. Marine Corps helicopter pilot. He served in Vietnam, commanded all Marine aviation forces in Operation Restore Hope in Somalia, flew the Presidential helicopter and served as Program Development Officer at Headquarters Marine Corps.

In 2010, John Kline was chosen by his peers to serve as the Chairman of the Education and the Workforce Committee – the first member of Congress from Minnesota selected for this position. A 25-year veteran of the Marine Corps, he also serves on the House Armed Services Committee.

As technical workforce development issues become more pressing in Washington and across the nation, Kline will become an ever more important player in the future of American businesses. From his position atop the House’s Education and Workforce Committee, Kline’s leadership will play an integral role in shepherding legislation that could bolster American technical skills and rejuvenate the future aviation maintenance workforce.

To learn more about Rep. Kline, visit: https://kline.house.gov/.

Take Advantage of ARSA’s Members Getting Members Program, Get 10% Off on Membership Dues

The best form of advertising is word of mouth. Use the Members Getting Members Toolkit to recruit an ARSA member and your company will receive a discounted membership rate for your next membership term.

Get more information at http://arsa.org/membership/members-getting-members/.

Target Your Message: Advertise Today in ARSA’s Newsletters and Website!

ARSA has a menu of advertising opportunities for arsa.org, the hotline and the ARSA Dispatch.

Take advantage of these great opportunities today to showcase your company, a new product or event. For more information go to http://arsa.org/advertise/

Exhibit, Sponsor the 2016 Repair Symposium

As the maintenance industry’s top event devoted exclusively to regulatory compliance, the ARSA Symposium attracts a highly qualified professional audience.

Use this opportunity to promote your company while showing support for ARSA. Get more information at http://arsa.org/news-media/events/arsa-symposium/arsa-annual-repair-symposium-sponsorship/

A Member Asked – Safety Sensitivity of Parts Handling

Q: Is the receipt and handling of parts or materials that will go into inventory for use in maintenance activities a safety-sensitive function that is covered by anti-drug and alcohol testing requirements?

A: No. There is a distinction between evaluating incoming parts and materials to ensure acceptable quality and performing a preliminary inspection of articles that will be maintained under the repair station certificate; only employees performing the latter function is required to be covered by an anti-drug and alcohol program. (14 CFR §§ 145.211(c)(1)(i), 145.211(c)(1)(ii) (requiring the RSQM to include separate procedures for (i) evaluating the quality of incoming materials and (ii) inspecting articles that will be maintained).

Drug and alcohol testing is required for employees performing safety-sensitive functions. Those functions include “aircraft maintenance and preventative maintenance duties.” (14 CFR §§ 120.7(p), 120.105(e), 120.215(a)(5)). Maintenance is defined as the “inspection, overhaul, repair, preservation, and replacement of parts.” Preventative maintenance includes “simple or minor preservation operations and the replacement of small standard parts not involving complex assembly operations.” (14 CFR § 1.1). The receipt and handling of parts and materials for inventory does not fall within either definition.

The receipt and subsequent handling of parts or materials (that will be used in future maintenance activities) is not, in and of itself, maintenance. Persons performing those activities would not be covered by the anti-drug and alcohol testing requirements. However, the person performing preliminary (or any other inspection) on articles being maintained under the repair station certificate will need to be in a DOT anti-drug and alcohol program.

Additionally, it is important that the description of employees’ duties, responsibilities, and authority in the repair station manual does not contain any contrary information. (14 CFR § 145.209(a)(3)).

AVMRO News Portal

ARSA strives to provide resources to educate the general public about the work of the association’s member organizations; should you need to provide a quick reference or introductory overview to the global MRO industry, please utilize AVMRO.ARSA.org.

AVMRO Industry Roundup ARSA monitors media coverage on aviation maintenance to spread the word about the valuable role repair stations play globally by providing jobs and economic opportunities and in civic engagement. These are some of this month’s top stories highlighting the industry’s contributions.

You can explore these stories through ARSA’s Dispatch news portal.

Upcoming Events

Paris Air Show – Le Bourget, Fance – June 15-21

AviationWeek: Commercial Aerospace Manufacturing Briefing – Le Bourget, France – June 17

Previous editions:

| 2015: | Jan | Feb | Mar | Apr | |||

| 2014: | Jan | Feb | Mar | Apr | May | June | July |

| Aug | Sept | Oct | Nov | Dec | |||

| 2013: | Jan | Feb | Mar | Apr | May | June | July |

| Aug | Sept | Oct | Nov | Dec | |||

| 2012: | Jun | Jul | Aug | Sep | Oct | Nov | Dec |

| SPONSORED CONTENT |

The FAA is very concerned about counterfeit aircraft parts. They call them Suspected Unapproved Parts (SUP). Having any in your inventory could be a legal disaster!!

The FAA is very concerned about counterfeit aircraft parts. They call them Suspected Unapproved Parts (SUP). Having any in your inventory could be a legal disaster!!

- There is onlyone centralized DataBase of Suspected Unapproved Parts – Over 60,000 of them. Find the ones on your shelves before the FAA fines you.

- There is onlyone integrated PMA/AD System. Find ADs that apply to or reference any of almost 1,000,000 PMA parts. Do multi-level PMA research.

- Due Diligence is the key phrase and The Aviation DataBase® is the only source for an easy and inexpensive way to do it. Head off the legal problem before it occurs.

- There is a User friendly and searchable copy of the Flight Standards Information Management System (FAA Order 8900.1) in The Aviation DataBase®.

- Do you need an Aviation Regulatory Library?: Over 18,000 ADs – Large & Small AC, Over 1,500 Type Certificate Data Sheets, Over 1,200 FAA Advisory Circulars.

- Call Aviation DataSource, Inc. (800) 952-8844.You can be using The Aviation DataBase® within minutes.

the hotline is the monthly publication of the Aeronautical Repair Station Association (ARSA), the not-for-profit international trade association for certificated repair stations. It is for the exclusive use of ARSA members and federal employees on the ARSA mailing list. For a membership application, please call 703.739.9543 or visit http://arsa.org/membership/join/. This material is provided for educational and informational purposes only. It does not constitute legal, consulting, tax or any other type of professional advice. Law, regulations, guidance and government policies change frequently. While ARSA updates this material, we do not guarantee its accuracy. In addition, the application of this material to a particular situation is always dependent on the facts and circumstances involved. The use of this material is therefore at your own risk. All content in the hotline, except where indicated otherwise, is the property of ARSA. This content may not be reproduced, distributed or displayed, nor may derivatives or presentations be created from it in whole or in part, in any manner without the prior written consent of ARSA. ARSA grants its members a non-exclusive license to reproduce the content of the hotline. Employees of member organizations are the only parties authorized to receive a duplicate of the hotline. ARSA reserves all remaining rights and will use any means necessary to protect its intellectual property.

© 2015 Aeronautical Repair Station Association