2024 – Edition 6 – July 2

Table of Contents

Note: The order of material varies in hotline emails, but is always presented the same on this landing page. Readers scrolling through content on or printing this page will find it organized consistent with the table of contents.

President’s Desk

Conference Corner

Regulatory Updates

ARSA Works

Legal Briefs

ARSA on the Hill

Training

Membership

Resources

Industry Calendar

The President’s Desk

Better Them Than Me

ARSA’s executive leadership spent three days in June at the FAA-EASA International Safety Conference Washington, D.C. along with several hundred industry colleagues as well as representatives from numerous civil aviation authorities.

ARSA members have been represented at this annual event for years, even before EASA existed. Usually on stage, as it was this year, and always in the face-to-face engagement allowed during sessions and breaks, ARSA exerts its impact on key officials. The team meets formally with European and American officials going all the way to the top – getting its introduction to new EASA Executive Director Florian Guillermet this year – and gladly rubs elbows with the handful of members making appearances.

This representation is vital and it’s well-performed by our association. I rely on the team to represent our interests as opposed to taking my own time to attend. ARSA’s team knows how to put a practical spin on the high-level topics that most presenters merely dance around. Attendance is vital for regulators: It offers exposure to the real-world experiences of industry, rather than remaining entrenched in the theories espoused internally.

For you (and for me, let’s be honest) the time is best spent in our own offices or on the facility floor getting work done. Events need to directly impact business or provide specific, practical engagement with government representatives. There are plenty of big expositions for your consideration on the business development front.

For practical engagement on substantive regulatory matters, the choices are more limited. From the desk of ARSA’s president, the obvious choice is the Annual Repair Symposium, held on the Thursday of the association’s Annual Conference Week each year. The Symposium is the original component and centerpiece of the Conference: A full day of substantive panel discussions with representatives from the FAA, EASA, the U.K. CAA, ANAC Brazil, and Transport Canada.

ARSA’s yearly panels provide legitimate opportunity for engagement. At the FAA-EASA Conference, you’ll find that each engagement allots minimal time for questions and ultimately fielded no legitimate answers or action. The Symposium is structured around taking discussion from the floor and stimulating legitimate direct engagement on issues that are impacting the work of repair stations around the world. (See an example in this month’s “Conference Corner.”)

That’s where I’m sure to spend my time: ARSA’s Annual Repair Symposium remains the unmissable travel block each spring; I’ve been every year since 2001. Be sure to plan your own trip to the U.S. capital city from March 18-21 of next year. You can make your own decisions about what other events deserve your time and attention, but when it comes to meetings like the FAA-EASA Conference better ARSA’s team than me.

|

Gary Fortner 2024 ARSA president | Fortner Engineering & Manufacturing, Inc. vice president of engineering |

Conference Corner

Five CAAs & SMS

Each March, ARSA’s Annual Repair Symposium – held on the Thursday of Conference Week – provides the maintenance community with an open forum to address regulators from the FAA, EASA, the UK CAA, ANAC Brazil, and Transport Canada.

Thursday, March 11 | 9:15 a.m. | Opening Salvo – Conversations with the Regulators ![]()

International agencies will provide updates on the regulations, policies and procedures governing the maintenance industry.

Neil Williams, Head of Airworthiness, Policy & Rulemaking, United Kingdom Civil Aviation Authority

Lawrence Josuá Fernandes Costa, Continuing Airworthiness Certification Manager, Department of Flight Standards, ANAC Brazil [Online]

Jeffrey Phipps (PDF Bio), Chief, Operational Airworthiness (AARTN), Transport Canada Civil Aviation

Ludovic Aron, Washington Representative, EASA

Karl Specht, Principal Coordinator Organisation Approvals, EASA [Online]

Dan Elgas, Acting Deputy Director, Policy and Innovation Division, Aircraft Certification Service, FAA

Tim Adams, Acting Deputy Director, Office of Safety Standards, Flight Standards Service, FAA [in person]

Clip: Q&A discussion on SMS implementation.

Save the date to take part next year:

March 18-21, 2025

Regulatory Updates

SMS is Coming…So They Say

On June 11, the FAA issued an Information for Operators (InFO) regarding Safety Management Systems requirements for U.S. repair stations holding EASA approval.

The InFO describes the FAA’s recent amendment to 14 CFR part 5 as introducing a “significant difference” between the American and European aviation safety regulatory systems. To address the difference, the FAA and EASA have established a new special condition under their bilateral agreement:

“This special condition requires FAA certificated repair stations located in the U.S. seeking initial approval or renewal of EASA Part-145 certification to establish, implement, and maintain an SMS,” the InFO said. “Participation with the FAA Voluntary SMS Program is deemed acceptable as a means to comply with the new requirement. The deadline for implementation of this requirement is December 31, 2025.”

Despite the InFO’s declaration, the June 20 release of change 9 to the FAA-EASA Maintenance Annex Guidance does not include a new special condition regarding SMS. There is no regulatory requirement for U.S. repair stations to have an SMS until that special condition is released, which may occur in MAG Change 10 – ARSA has heard chatter it is not far behind. None-the-less, with 18 months until the end of 2025, the association encourages members with EASA approvals to prepare for SMS implementation. As with other announcements of European arrivals (remembering Paul Revere’s April 1775 ride), hearing “the SMS is coming!” should not surprise the industry.

ARSA will support impacted repair stations during this transition period by:

(1) Working with regulators to push for smooth installation of SMS requirements into current quality systems.

(2) Continuing the member benefit facilitating access to SMS tools managed by the Aircraft Electronics Association.

(3) Updating the association’s Model RSQM Compilation to include SMS requirements.

(4) Handling confusion and communicating to provide clear information regarding compliance requirements and implementation dates.

FAA and EASA Publish MAG Change 9

On June 20, the FAA and EASA released change 9 to the Maintenance Annex Guidance associated with the bilateral agreement between the two civil aviation authorities. The compliance date for the new MAG is Oct. 8, 2024; this change does not amend the special conditions.

The record of revisions for change 9 included the following overview:

Section A – Authority Interaction:

-

- Form 8: restructuring of paragraphs to reflect EASA example supplement

Section B – Certification for U.S.-Based Repair Stations:

-

- Form 9: additional reference to OpSpec A101

- Appendix 1, Paragraph 1: added document management software

- Paragraph 10.12, 10.13: corrected EU Member States

- Paragraph 12.4: clarifies EASA member states

Section C – Certification Process for EU-based Approved Maintenance Organizations, Appendix 1:

-

- Paragraph 1: added document management software

- Paragraph 1.5: clarification on dangerous goods training added

- Paragraph 4: accountable manger statement amended

- Paragraph 7.1: release statement added

- Paragraph 7.4, 7.5: corrected EU Member States

The ARSA team is reviewing the new MAG and coordinating with regulators from both agencies. Stay tuned for updates, including edits to the association’s RSQM Compilation. To review developments in the bilateral relationship between the United States and European Union, visit arsa.org/mag.

To review change 9, click here.

ARSA Works

ARSA Leads “Can do” Panel, EASA Shares SMS Compliance Date

From June 11-13, ARSA’s leadership team participated in the 2024 FAA-EASA International Aviation Safety Conference in Washington, DC. The annual event alternates between Cologne and the American capital city as a venue for international regulators to interface directly with industry representatives.

The 2024 event’s theme “Preparing for the Decade Ahead” produced three days heavy with “new” challenges and opportunities but allowing time for current concerns. The final agenda included regulatory changes, standards development, and technological implementation but was bookended by the AOG Technics parts documentation scandal and new requirements for Safety Management Systems (SMS) implementation.

Though the FAA excluded repair stations from its expansion of SMS requirements in part 5, EASA has been clear a mandate for U.S. part 145 air agencies holding European approval under the bilateral agreement will be added to the two jurisdictions’ Maintenance Annex Guidance. Those awaiting the official change to the MAG (not made in change 9, see “NOTE” below) can pencil in an expected SMS compliance deadline of December 31, 2025: By that date all affected repair stations must have verified their compliance with the FAA’s voluntary program to continue their European approval.

NOTE: On June 20, 2024, the FAA published an InFO advising certificate holders of the Dec. 31, 2025 deadline. However, the June 20 release of MAG Change 9 did not include a new special condition regarding SMS.

ARSA’s Levanto (Left) stands with “Can Do” panelists (from right), Martin Ricklin, Lufthansa Group; Chris Parfitt, FAA; John Mathis, Delta Air Lines, and Eugenia Diaz Alcazar, EASA.

ARSA Vice President of Operations Brett Levanto moderated a June 12 panel on “Evolving Technologies for Maintenance and Inspection Functions,” including representatives from both regulators as well as Lufthansa and Delta Air Lines (both of which are connected to Corporate Enterprise Memberships through their maintenance organizations). On this “can-do panel,” Levanto highlighted the flexibility available to certificate holders under performance-based regulations. Acting FAA Aircraft Maintenance Division Manager Chris Parfitt punctuated the key point by sharing ARSA’s oft-repeated guidance that “if it’s not prohibited, it’s allowed.”

ARSA’s team also used the gathering for a meeting with new EASA Executive Director Florian Guillermet and his flight standards and certification team. The association regularly connects with regulators at all levels, getting to work with technical managers while maintaining relationships with top executives.

The event page, managed by the Aerospace Industries Association, still includes details for those curious about format and structure. To read the joint cooperation “pledge” made by the FAA and EASA at the close of the Conference, click here.

The 2025 event will return to Cologne from June 10-12.

To see coverage a previous International Aviation Safety Conferences, visit arsa.org/faa-easa-conference.

Repairman History Points ARAC to Certificate’s Future

On June 13, the FAA Aviation Rulemaking Advisory Committee (ARAC) received the final report of its Repairman Certificate Portability Working Group. The report includes thorough regulatory analysis in response to a March 2021 tasking to provide advice and recommendations on the most effective ways to allow a repairman certificate issued under part 65, subpart E to be transferrable from one employing certificate to another.

Since its first meeting in May 2022, the working group analyzed the history of part 65 and the FAA’s application of its rules. In the case of modern repairman, that history begins in 1945 with the creation of a “limited mechanic” certificate by the Civil Aeronautics Board. The new airmen, which were replaced by repairmen in 1952, allowed for the inspection and supervision of propeller and instrument maintenance – bridging the gap between the authority of air carrier/air agency certificates and individual mechanics.

“Title 14 CFR part 65 subpart E remains substantially unchanged since its publication 70 years ago as 14 CFR part 24, subpart B,” the report said. “However, the FAA has significantly altered the application for and issuance of the repairman certificates through various guidance changes that have inconsistently attempted to limit the privileges and opportunities of those certificates. Additionally, without knowledge of the regulatory history, the FAA workforce issues the certificate based on the misunderstanding that the repairman is a lesser certificate than a mechanic certificate. Rather, the repairman certificate is a limited mechanic certificate that needs to be held to the same technical standard as today’s mechanic’s certificate with respect to the task, function, or specialty performed.”

To increase the modern value of the repairman certificate by using its regulatory origin, the working group made four recommendations:

(1) Update FAA policy to establish updated procedures for agency review of repairman applicant qualifications, which remain valid unless the individual’s certificate is revoked or suspended.

(2) Align repairman ratings with those of the certificated organization employing them.

(3) Issue a new advisory circular referencing the Airman Certification Standards to ensure basic repairman requirements align with the “limited mechanic” of its origin.

(4) Revise part 65 to recognize repairman certificates as limited mechanic certificates that need not be surrendered between employers.

To review the report, which includes draft guidance in its appendices, click here.

ARAC members agreed to vote on accepting the working group’s recommendations; their responses are due July 8.

EASA Surveys Industry on Parts Documentation Proposal

In June, European regulators surveyed U.S. repair stations with EASA approval regarding a proposal addressing problematic parts documentation requirements.

According to EASA–

The proposal would be to establish exceptions to this (i.e. FAA Form 8130-3 not required) for new sub-assembly parts to be installed by US repair stations with an EASA approval on higher-assembly parts subject to repairs and subsequently exported to the EU.

“Parts without EASA Form 1” would also be included in these exceptions, and this would facilitate the export to the U.S. of “Parts without EASA Form 1” produced by EU industry.

For any question or inquiry regarding the survey, please contact EASA using the following email address: Maint_AB@easa.europa.eu. For details regarding ARSA’s efforts to help the agencies correct misunderstanding over parts documentation, visit arsa.org/mag.

Final Documents/Your Two Cents

This list includes Federal Register publications, such as final rules, Advisory Circulars and policy statements, as well as proposed rules and policies of interest to ARSA members.

Legal Briefs

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

Fighting Regulatory Fires

By Christian Klein, Executive Vice President

FAA regulations are the focus of ARSA’s advocacy and compliance assistance, but repair stations are impacted by federal and state regulatory schemes in numerous other areas. In recent weeks, ARSA has learned of a hazardous materials transportation issue potentially impacting repair stations who ship portable fire extinguishers and operators who utilize them on their aircraft.

Hazardous material transportation is regulated by the U.S. Department of Transportation’s Pipeline and Hazardous Materials Safety Administration (PHMSA). Relevant regulations are contained in Title 49, Subtitle B, Chapter I, Subchapter C of the Code of Federal Regulations (49 CFR parts 171 to 180). General requirements for shipping and packaging applicable to shippers by air, highway, rail, or water, or any combination thereof, are in part 173. Section 173.309 applies to the shipping of fire extinguishers, including, “fire extinguishers for installation in aircraft.”

Section 173.309(c)(2) states:

The internal volume of each cylinder may not exceed 18 L (1,100 cubic inches). For fire extinguishers not exceeding 900 mL (55 cubic inches) capacity, the liquid portion of the gas plus any additional liquid or solid must not completely fill the container at 55 °C (130 °F). Fire extinguishers exceeding 900 mL (55 cubic inches) capacity may not contain any liquefied compressed gas … (Emphasis added.)

The problem is that portable fire extinguishers in the cabin and cockpit of most commercial and general aviation aircraft utilize Halon 1211 (Bromochlorodifluoromethane), Halocarbon (e.g. Halotron), or blends of similar “liquified compressed gas” as extinguishing agents. In many or most cases, these extinguishers contain quantities of the extinguishing agent that, in conflict with § 173.309(c)(2), require a cylinder larger than 900mL internal volume.

Because § 173.1(b) states that, “A shipment of hazardous materials that is not prepared in accordance with this subchapter may not be offered for transportation by air, highway, rail, or water,” noncompliant fire extinguishers may not be shipped or carried on aircraft. ARSA is not aware of any exception.

The issue was identified by ARSA member Brian Tyminski of Tyms, LLC when PHMSA issued a special permit to an Alabama company to transport “non-specification cylinders exceeding 900 mL in capacity and containing a liquified gas as a fire extinguisher.” Because the permit specifically states that, “No party status will be granted …” no other company can make use of the permit.

Tyminski is concerned about exposure for the aviation industry given the wide range of manufacturers, sizes, models, and installations of fire extinguishers used for decades. Carriage of hand fire extinguishers is required by numerous FAA regulations (see, e.g., 14 CFR § 91.513(c)). FAA Advisory Circular 20-42D, which describes acceptable means of compliance for fire extinguishers kept on board aircraft, provides no option for less than 2.5 lbs. of extinguishing agent and thus practically requires a cylinder of at least 900 mL.

Tyminski’s company has applied to PHMSA for a special permit applicable to all liquified compressed gas cylinders over 900 mL. He points out that the average shipper, end user, or owner will not be able to ascertain the cylinder size if they do not have access to the instructions for continued airworthiness. The permit application therefore applies to a broad category of fire extinguishers rather than specific part or model numbers. If the permit Tyminski has requested is granted, other companies will be able to apply to PHMSA to become parties to it pursuant to § 107.107.

More information about the issue and permit application is available on the Tyms, LLC website. As ARSA continues to explore this issue, we welcome input from other members about how they have interpreted and addressed these PHMSA requirements.

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

Layman Lawyer – PEARing it Down

By Brett Levanto, Vice President of Operations

SMS has the aviation world’s attention as the go-to fix for production issues and operator management. While repair stations working solely under the FAA’s jurisdiction have so far been spared direct applicability under part 5, many outside the United States face existing CAA mandates and American facilities with EASA approval must be compliant by December 2025.

Under the U.S. rules, a “Safety Management System means a formal, top-down, organization-wide approach to managing safety risk and assuring the effectiveness of safety risk controls. It includes systematic procedures, practices, and policies for the management of safety risk.” The FAA’s explanatory webpage breaks SMS down – in a bulleted list including a typo – as a method of decision-making that supports a “sound safety culture.”

As a management discipline, SMS is a human factors practice. The introductory training required for anyone utilizing the tools available to ARSA members through the association’s partner Aircraft Electronics Association denotes significant time to human factors instruction before considering the mechanics of the program itself.

As explained in ARSA’s own human factors training, the subject is understood through a series of models: Schemes for applying broad elements to the specific needs of individuals and organizations. After the FAA-EASA Conference in June, which featured considerable discussion and one big SMS announcement (see “December 2025” above), AEA Vice President of Government & Regulatory Affairs Ric Peri suggested that an entire safety assurance process can be built around the “PEAR” human factors model:

- People

- Environment in which people work.

- Actions people take.

- Resources people need.

The PEAR model approaches/evaluates elements associated with human factors through its four areas, beginning with the “human beings” (people) that are undertaking the action, placing them into an environment, describing what they must do, and the resources needed to accomplish the task correctly. The elements and characteristics of each part of the model interrelate (what would you add to these?):

- People

- Personal: Size, Age, Gender.

- Physical: Strength, Sensory Limitations (Capabilities).

- Physiological: Nutrition, Health, Lifestyle, Alertness.

- Psychosocial: Interpersonal Conflicts, Personal Loss, Duty Fitness.

- Psychological: Workload, Experience, Knowledge, Training, Attitude.

- Environment in which people work.

- Physical: Location, Workspace, Lighting, Noise, Shift, Safety.

- Organizational:

- Direct: Supervision, Personnel, Employee-Management Relations, Pressures.

- Indirect: Crew Structure, Company Size, Profitability, Morale, Culture.

- Actions people take.

- Task Completion Steps.

- Task Sequencing.

- Performance Standards.

- Number of People Involved.

- Communication: Oral, Visual, Written.

- Information Control Requirements.

- Resources people need.

- Technical Publications/Regulations.

- Procedures/Work Cards.

- Paperwork/Signoffs.

- Computers/Software.

- Test Equipment.

- Hand/Power Tools.

- Heavy Equipment.

- Ladders/Platforms.

In a maintenance facility, each element in this model helps focus the organization on airworthiness. Tending to these characteristics ultimate provides for the company to “do…work in such a manner and use materials of such a quality, that the condition of the aircraft, airframe, aircraft engine, propeller, or appliance worked on will be at least equal to its original or properly altered condition.” The performance standard of § 43.13(b) is attained through human factors as a foundation of Safety Management Systems.

It seems like a lot to undertake, but the ultimate result is clarity and simplicity. And as French philosopher and mathematician Blaise Pascal wrote (which may be apropos to this article also), “If I had more time, I would have written a shorter letter.”

ARSA on the Hill

Foreign Repair Stations: In Crosshairs, But Dodging a Bullet

By Christian Klein, Executive Vice President

Sec. 302 of the recently enacted FAA reauthorization law imposes more unnecessary requirements on foreign part 145 repair stations and part 121 air carriers that use them for heavy maintenance. Thanks to advocacy by ARSA and allies, the disruption should be minimal.

The requirements are another result of lobbying by airline mechanic unions using false safety arguments about repair stations. The decades long demands urging congressional mandates to drive up costs of doing business continues the “death by a thousand cuts” strategy. The unions argue contract maintenance, particularly when performed outside the United States, isn’t as safe as work performed by airline mechanics. On the contrary, the airline safety record has improved dramatically as the use of repair stations – foreign and domestic – has become a business reality.

ARSA’s work to educate lawmakers about the safety record and the fact that all repair stations – no matter where located – work to the same standards continues to salve the harm of each cut. Legislators are made aware that FAA-certificated foreign repair stations are essential to the international operations of U.S. air carriers and in addition to the FAA, airlines, other regulators, and third-party auditing organizations closely scrutinize foreign repair stations. The union position (which is supported by vocal “consumer advocate” Ralph Nader, among others) continues to be pacified. Even though in the lead up to the recent FAA reauthorization it became clear that the bill would contain anti-foreign repair station language, ARSA was able to limit its negative impact.

The good news is that Sec. 302 (“Global Aircraft Maintenance Safety Improvements”) is a far cry from the potentially disastrous Safe Aircraft Maintenance Standards Act (SAMSA) introduced in 2019. While Sec. 302 will cause some heartburn, its impact is largely limited to foreign repair stations performing heavy maintenance and the U.S. air carriers that use them. Canadian approved maintenance organizations (AMO) serving U.S. part 121 carriers are unaffected because those facilities do not hold part 145 certificates under the U.S.-Canada bilateral. How the FAA will apply the law to other bilateral partners remains to be seen.

The new law requires:

Surprise Annual Inspections. The FAA must carry out “surprise” (i.e., without prior notice to the facility) annual inspections of all part 145 repair stations located outside the United States. Unlike SAMSA, Sec. 302 does not prohibit notification of the government of the country in which the repair station is located and must be consistent with U.S. obligations under international agreements and the applicable laws of the country where the repair station is located. (The new requirements have already been incorporated into the U.S. Code. See 49 U.S.C. sec. 44733(e).)

While the agency may not announce an inspection to the foreign repair station, it must announce it to the country and the civil aviation authority. The mandate will, no doubt, create unintentional consequences; hampering audits when essential repair station personnel are unavailable is only one.

Data Analysis (49 U.S.C. 44733(g)). A part 121 air carrier that “has had heavy maintenance work performed on an aircraft owned or operated by such carrier” must file an annual report with the FAA that includes:

- The location where any heavy maintenance work on aircraft was performed outside the United States; information already provided under section 121.368(h).

- A description of the work performed at each such location; also information already provided under section 121.368(h).

- The date of completion of the work performed at each such location; information that will be recorded against each aircraft in the carrier’s system under section 121.369(c).

- A list of all failures, malfunctions, or defects affecting the safe operation of such aircraft identified by the air carrier not later than 30 days after the date on which an aircraft is returned to service, organized by reference to aircraft registration number, that requires corrective action after the aircraft is approved for return to service; and results from such work performed on such aircraft. The air carriers obtain and retain this information under sections 121.701 and 121.703.

- The certificate number of the person approving such aircraft or on-wing aircraft engine for return to service following completion of the work performed at each such location; information associated with the records required by section 121.368(h).

The FAA must analyze the data and require “appropriate actions” by air carriers and repair stations based on any identified safety issue. However, the data air carriers submit is confidential to the same extent as voluntarily safety or security information.

Finally, given that this part of Sec. 302 references “work performed outside the United States” and not foreign part 145 certificate holders, it may be read to include work performed by Canadian AMOs.

Restrictions on CAT 2 Countries (49 USC sec. 44733(h)). The new law impacts countries that do not meet International Civil Aviation Organization (ICAO) standards and are therefore classified as Category 2 (CAT 2) by FAA’s International Aviation Safety Assessment Program. As of March 15, 2024, CAT 2 countries are Bangladesh, Russia, Thailand, Venezuela, and Eastern Caribbean Civil Aviation Authority members (Antigua & Barbuda, Dominica, Grenada, St. Lucia, St. Vincent and The Grenadines, St. Kitts, and Nevis). Click here for the most current IASA classification list.

The FAA is prohibited from accepting new repair station applications (renewals are unaffected) from a person located or headquartered in a CAT 2 country, nor may the FAA and a CAT 2 authority enter into a bilateral agreement with maintenance implementation procedures. And part 121 air carriers are prohibited from entering into new contracts for heavy maintenance work with a facility located or headquartered in a CAT 2 country. Given that CAT 2 countries are not maintenance hotbeds, we see limited impact.

Personnel Licensing (49 U.S.C. sec.44733(i)). The FAA must certificate supervisors and personnel authorized to approve for return to service at certain foreign repair stations as mechanics or repairman pursuant to 14 CFR part 65. Additionally, individuals who are responsible for approving an article for return to service or directly in charge of heavy maintenance work performed on part 121 air carrier aircraft must be available for consultation while work is performed.

Importantly, the new personnel licensing requirements are limited to heavy maintenance on an aircraft operated by a part 121 carrier. Heavy maintenance is defined at 49 U.S.C. sec. 44733(j)(2) as “a C-check, D-check or equivalent maintenance operation with respect to the airframe of a transport-category aircraft (including on-wing aircraft engines).”

A foreign repair station with personnel licensing requirements found equivalent by the FAA are automatically acceptable and section 145.157 already requires supervisors to be available for consultation and most personnel authorized to return work to service are equally qualified by foreign repair stations.

To minimize burdens and uncertainty, the FAA can quickly recognize equivalent foreign certification regimes or those that comply with ICAO’s aircraft maintenance license requirements in Annex 1, Chapter 4, paragraph 4.2 of the Chicago Convention.

Drug and Alcohol (D&A) Testing and Background Checks (49 U.S.C. 44733 note). Congress previously directed the FAA to craft a rule subjecting safety sensitive workers at foreign repair stations to drug and alcohol testing. The agency released its proposed rule earlier this year. The new law requires the D&A rule to be finalized within 18 months of the new law’s enactment (i.e., by mid-November 2025). Unlike past anti-repair station legislation, it does not impose any sanction on industry or the FAA if the rulemaking is not completed.

Additionally, the law directs the FAA (or another agency requested by the FAA) to require 49 CFR part 1540 subpart C employee security threat assessments at covered repair stations. A requirement that seems to cover repair stations located on or near airports that already subject employees to background checks.

Sec. 302 is an unfortunate blemish on an otherwise excellent FAA reauthorization law that included many ARSA proposals addressing inconsistent oversight, access to maintenance manuals, and the technician shortage. We appreciate Congress and our union colleagues willingness to negotiate Sec. 302 in good faith. While ARSA still sees the anti-foreign repair station provisions as “solutions in search of safety problems,” we will work with the FAA to implement the law’s requirements with the least disruption to either the agency or the industry.

|

Want to Learn More About ARSA PAC? ARSA’s Political Action Committee helps elect congressional candidates who share ARSA’s commitment to better regulation and a strong aviation maintenance sector. In this critical election year, ARSA PAC has never been more important. But ARSA is prohibited from sending PAC information to members who haven’t opted in to receive it. Please take a second to give us prior approval to talk to you about ARSA PAC. Doing so in no way obligates you to support PAC. It just opens the lines of communication. Click here to give ARSA your consent today. |

Finding Your Member of Congress

In the summer of an election year, senators and congressmen want to meet constituents. ARSA members should take advantage of this interest to schedule facility visits, town halls, meet and greets, or any other excuse to spend time with the person representing your business in Congress.

As ARSA Legislative Day participants hear every year, building an ongoing relationship with your elected officials is really a matter of simple effort. The most successful constituents are patient and persistent…and they know how to use a few simple tools for finding their members of Congress.

Who represents you?

Using ARSA’s Legislative Advocacy Tools – provided all year by Conference sponsor Aircraft Electric Motors – find your elected officials by entering your zip code in the “Election Center.” (Remember to enter your personal zip code and also the one for all facilities associated with your company; there may be multiple officials/offices with an interest in your needs.) Get started at arsa.org/congress.

When will they be home?

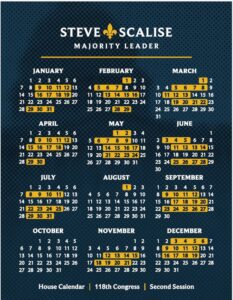

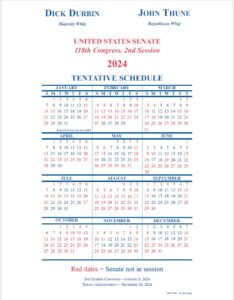

Members of the U.S. Congress try to spend as much time in their states/districts as possible. Both the House and Senate leadership have published session calendars for 2024. By reviewing these calendars, you can determine when your senators and congressman are likely to be “back home” by looking for dates not in session. Review the schedule documents below and find updated information at www.congress.gov/calendars-and-schedules.

| House | Senate | |

|

|

What do you do now?

Contact use the contact resources available at arsa.org/congress to get in touch with the offices that represent you and invite them to visit your facility on one of the dates for “district work.” For talking points and other guidance, visit arsa.org/legislative or contact ARSA.

Aviation Life Calendar

July Through October

Something exciting happens every day in an aviation career.

If you want to keep aviation in the forefront of career choices, celebrate success every day with these resources. Every one provides a positive view of the industry’s ability to make the impossible an everyday event by individuals from every walk of life, socio-economic level, race, creed, color, religion, orientation, and physical capability.

Check back regularly for updates.

| Month | Day | Event or Celebration |

| All | All | This Day in Aviation |

| July | All | This Day in Aviation History – July |

| July | 20 | Neil Armstrong’s First Moon Walk |

| July | 24 | National Amelia Earhart Day |

| July | 25 | National Hire a Veteran Day |

| August | All | This Day in Aviation History – August |

| August | 16 | National Airborne Day |

| August | 19 | National Aviation Day |

| August | 19 | Orville Wright’s Birthday |

| August | 25 | Amelia Earhart Flies Coast to Coast – Nonstop |

| August | 30 | First African American in Space |

| September | All | This Day in Aviation History – September |

| September | 4 | Global Talent Acquisition Day |

| September | 15 | Hispanic Heritage Month |

| October | All | This Day in Aviation History – October |

| October | 4 | World Space Week |

| October | 20 | International Air Traffic Controller Day |

Training & Career Development

The “Magic Form” – The 8130-3

Both of ARSA’s sessions explaining the policy issues and practical use of the FAA Form 8130-3 are available on-demand for immediate viewing and unlimited access for 90 days.

Click here to purchase both sessions together at a bundled discount.

FAA Form 8130-3 – Overview & History

This session reviews the history of the FAA Form 8130-3, Authorized Release Certificate, from its beginning as an export airworthiness approval, putting into context its evolution from an export document to its current usage.

Click here for more information and to register for this session.

FAA Form 8130-3 – Completion Instructions & Multiple Releases

This session walks through the steps for completing the FAA Form 8130-3, Authorized Release Certificate, Airworthiness Approval Tag. The training uses instructions developed as part of ARSA’s RSQM Compilation and focuses on language used for work to be issued a release under the regulations of multiple civil aviation authorities including a “dual release” under the U.S./EU bilateral agreement.

Click here for more information and to register for this session.

Registration for an ARSA-provided training session includes:

- Access to the on-demand, recorded version of the webinar to be made available after the live session is complete (or at time of purchase, for on-demand classes).

- A copy of the presentation and all reference material with links to relevant resources and citations.

- Upon completion of the class as well as any test material, a completion certificate.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit PotomacLaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Part 21 in Three Parts

In November 2016, Marshall S. Filler wrapped up a three-part series on 14 CFR part 21, “Certification Procedures for Products and Articles.” The entire series is available for unlimited on-demand viewing.

Want all three sessions? Click here to purchase them together and save.

Part 21 – Overview

This session provides an overview of the aviation safety regulations governing design and production of civil aviation products and articles as well as airworthiness certification of civil aircraft.

Click here to register and get access for 90 days.

Part 21 – Design Approvals & Design Changes

This session reviews the elements necessary to obtain design approvals for civil aviation products, including type certificates, amended type certificates and supplemental type certificates. It will explain the requirements for obtaining approval of design changes to those certificates including the changed product rule. Finally, it will describe the design requirements for obtaining a parts manufacturer approval and technical standard order authorization, and for obtaining approval of design changes to those articles.

Click here to register and get access for 90 days.

Part 21 – Production Approvals

This session explains the requirements for obtaining a production approval for civil aviation products and articles as well as the elements of an FAA-approved quality system and the method for making revisions to that system. It also addresses the privileges and responsibilities of production approval holders including the issuance of airworthiness approvals and authorized release documents for aircraft engines, propellers and articles.

Click here to register and get access for 90 days.

Registration for an ARSA training session includes:

- Access to the on-demand recording of each session for 90 days.

- Digital copies of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of each class.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Human Factors – Context & the Dirty Dozen

ARSA’s 14 hours of human factors training includes two overview sessions and a walk through of each element of “the dirty dozen.” For each element of “the Dirty Dozen,” the series provides a 60-minute session providing:

(1) Basic definitions and context.

(2) Aviation safety regulatory references.

(3) Examples.

(4) Mitigations.

(5) Exercises.

All of ARSA’s human factors training sessions have been accepted by the FAA for Inspection Authorization renewal credit under § 65.93(a)(4). To purchase multiple sessions at a discounted price, click here to view options for purchasing via a “tiered bundle.”

Session Title |

Registration/Information |

|

| Human Factors in Context | Click here. | |

| The Dirty Dozen – Human Factors Overview | Click here. | |

| The Dirty Dozen in Depth – Communication | Click here. | |

| The Dirty Dozen in Depth – Complacency | Click here. | |

| The Dirty Dozen in Depth – Lack of Knowledge | Click here. | |

| The Dirty Dozen in Depth – Distraction | Click here. | |

| The Dirty Dozen in Depth – Lack of Teamwork | Click here. | |

| The Dirty Dozen in Depth – Fatigue | Click here. | |

| The Dirty Dozen in Depth – Lack of Resources | Click here. | |

| The Dirty Dozen in Depth – Pressure | Click here. | |

| The Dirty Dozen in Depth – Lack of Assertiveness | Click here. | |

| The Dirty Dozen in Depth – Stress | Click here. | |

| The Dirty Dozen in Depth – Lack of Awareness | Click here. | |

| The Dirty Dozen in Depth – Norms | Click here. |

Registration for an ARSA training session includes:

- Access to the on-demand recording of each session for 90 days.

- Digital copies of the presentation and all reference material with links to relevant resources and citations.

- A certificate upon completion of each class.

The association’s training program is provided through Obadal, Filler, MacLeod & Klein, P.L.C., the firm that manages ARSA. To go directly to OFM&K’s online training portal, visit potomaclaw.inreachce.com. To learn more about the association’s training program and see course availability, visit arsa.org/training.

Regulatory Compliance Training

Test your knowledge of 14 CFR § 21.9, replacement and modification articles.

Click here to download the training sheet.

Membership

Payment Made Easy and Free

By Kimberly Dimmick, Vice President of Membership

In addition to being able to reduce or eliminate dues through ARSA’s Member Getting Members (MGM) program, paying membership dues can be free by using an old-fashion check or ACH as directed at the bottom of every invoice.

ARSA would like to accept other methods of cost-free payments through applications such as Zelle for your recurring membership dues. Stay tuned for a Quick Question on the methods you use to render payment on recurring accounts payable.

Advertising – Press(ing) Releases

ARSA broadly monitors aviation news. In addition to informing the team, press releases, editorials, trade press updates, and general media reports form the core of the association’s periodicals. Recognizing the broad range of its communications, many companies submit their media content for consideration in the Daily Intelligence and weekly Dispatch.

Allowing for the reach of these newsletters and the value of advertising placements ARSA will always consider the newsworthiness of a press release from non-member organizations. ARSA does not publish releases merely announcing commercial availability of products or services; companies wishing to get those messages out can expect to hear from us regarding advertising.

Member company news, such as expansions, promotions, acquisitions, and similar newsworthy announcements are almost always used when timely; but even so, blatantly commercial submissions will not be published.

What do you think? ARSA welcomes member input about its communication and advertising practices. The association’s goal is to share information and resources of value to the aviation maintenance community, while not allowing advertising opportunities to slip by. Contact us with thoughts.

Welcome & Welcome Back – New & Renewing Members

ARSA’s members give the association life – its work on behalf of the maintenance community depends on the commitment of these organizations. Here’s to the companies that joined or renewed in June:

New Members

Helicopter Express, LLC, Assoc

Structural Evaluation Technologies Inc. dba SETAERO , R04

Renewing Members

AAR Corp., Corp, 1985

Ametek Ameron, LLC dba Ameron Global Product Support, R01, 1989

Aeroworx, Inc, R02, 2010

Airborne Aviation Hawaii, R01, 2023

Bemidji Aviation Services, Inc., R03, 2017

General MRO Aerospace, Inc., R03, 2015

F&E Aircraft Maintenance (Miami) L.L.C , R06, 2012

Lynden Air Cargo, LLC, Assoc, 2000

MT Texas, LLC, R03, 1990

Marvel-Schebler Aircraft Carburetors, LLC, R02, 2011

Performance Repair Group, LLC, R02, 2013

PropWorks Propeller Systems, R02, 2021

R.W. Raddatz, Inc., R02, 2004

S & T Aircraft Accessories, Inc., R02, 2003

Summit Aerospace, Inc., R05, 2003

Turbine Weld Industries, LLC, R03, 2020

Vibrant Corporation, R02, 2021

Warner Propeller and Governor Co., LLC, R02, 2010

A Member Asked…The right rating?

Q: I am getting conflicting information as to what rating allows for the repair and overhaul of landing gear components.

I know there is a limited rating for landing gear components, but I have also read that depending on your “PMI’s interpretation” it could fall under an accessory limited or airframe limited rating.

Our managerial repair station currently holds a limited accessories and limited airframe rating. We overhaul main and nose landing gear assemblies as well as their components. The satellite repair station holds a limited accessories rating, our goal is for the satellite repair station to start overhauling landing gear components.

Any clarification would be greatly appreciated.

A: Setting aside the satellite situation for the moment, the rumor is true that working on landing gear components can be accomplished under several different ratings.

Let’s start with the definition of the term “airframe“, which under § 1.1 “means the fuselage, booms, nacelles, cowlings, fairings, airfoil surfaces (including rotors but excluding propellers and rotating airfoils of engines), and landing gear of an aircraft and their accessories and controls.”

So, “the landing gear…and [its] accessories and controls” fall under that definition.

Unfortunately, under § 145.61(b)(7), the FAA can also issue a limited rating for “[l]anding gear components. Add to that, a limited rating for landing gear components can also be issued under either § 145.61(a) for accessories (mechanical) or under “constituent part, or to any number of parts made by a particular manufacturer.”

What I would strongly recommend is to complete a self-evaluation under the limited accessory rating held today by the satellite and add the part numbers under the possibility offered by § 145.61(a) under “constituent part” language. If the agency denies the addition, hopefully, it will cite a regulation and provide you with its preferred rating in writing so an application for the “correct” rating can be made. The most important element is to get the agency’s decision in writing to address the next “PMI’s interpretation.”

Have questions about aviation regulatory compliance, legislative policy, or ARSA resources? Ask ARSA first!

Wait & See – The Name Game

Thank you to those who helped with the most pressing element of ARSA’s establishing a complementary 501(c)(3) charitable organization to support aerospace maintenance career development. The new organization will provide a means for the association’s team to broadly support the maintenance community’s personnel management needs and will work in concert with a number of partners supporting existing trade association allies.

While ARSA builds the substantive details, the respondents to the “quick question” soliciting ideas for its name – along with everyone else – can wait and see what came out on top. In the meantime, stay tuned for updates on all of the association’s workforce development efforts.

Click here to see what questions have been asked and answered…and keep a lookout for more.

Resources

ARSA strives to provide resources to educate the general public about the work of the association’s member organizations; should you need to provide a quick reference or introductory overview to the global MRO industry, please utilize AVMRO.ARSA.org.

About ARSA PAC

ARSA’s Political Action Committee helps elect congressional candidates who share ARSA’s commitment to better regulation and a strong aviation maintenance sector. But ARSA is prohibited from sending PAC information to members who haven’t opted in to receive it.

Careers in Aviation Maintenance

How do you share the industry’s story with the people who could be its future? Teach them about the great work done every day to keep the world in flight. (Even if we can’t recruit somebody, we sure can make them thankful for our work.)

U.S./EU Maintenance Annex Guidance

See all of the association’s public updates since 2012 on the Maintenance Annex Guidance between the United States and European Union. The page focuses in particular on matters related to parts documentation issues arising since MAG Change 5 was issued in 2015.

Industry Calendar

| Event/Meeting | Dates | Location |

| Farnborough Air Show | 7/22-26/2024 | Farnborough, United Kingdom |

| World Remanufacturing Conference | 9/10-12/2024 | Chicago, IL |

| 2024 NBAA Business Aviation Convention & Exhibition | 10/22-24/2024 | Las Vegas, Nevada |

| ARSA Annual Conference | 3/18-21/2025 | Arlington, Virginia |

the hotline is the monthly publication of the Aeronautical Repair Station Association (ARSA), the not-for-profit international trade association for certificated repair stations. It is for the exclusive use of ARSA members and federal employees on the ARSA mailing list. For a membership application, please call 703.739.9543 or visit arsa.org/membership/join. For information about previous editions, submit a request through arsa.org/contact. This material is provided for educational and informational purposes only. It does not constitute legal, consulting, tax or any other type of professional advice. Law, regulations, guidance and government policies change frequently. While ARSA updates this material, we do not guarantee its accuracy. In addition, the application of this material to a particular situation is always dependent on the facts and circumstances involved. The use of this material is therefore at your own risk. All content in the hotline, except where indicated otherwise, is the property of ARSA. This content may not be reproduced, distributed or displayed, nor may derivatives or presentations be created from it in whole or in part, in any manner without the prior written consent of ARSA. ARSA grants its members a non-exclusive license to reproduce the content of the hotline. Employees of member organizations are the only parties authorized to receive a duplicate of the hotline. ARSA reserves all remaining rights and will use any means necessary to protect its intellectual property.

© 2024 Aeronautical Repair Station Association