2015 – Edition 7 – August 7

Table of Contents

Overhauling Overhaul – A Self-Paced Training Session

Overhauling Overhaul

A Self-Paced Training Session

The FAA has issued another legal interpretation on the term “overhaul” – stimulating a flurry of member questions about the term’s applicability to the everyday work of maintenance providers. In this edition of the hotline, ARSA offers a complete education on the matter using the association’s three levels of training. Class is in session.

Required Reading: [Hotline Feature] Overhaul Reviewed Yet Again

Get background on the issue from ARSA’s initial post on the newest interpretation, including the association’s previous engagement with the agency on the topic.

Level 1: [Legal Brief] “Overhaul” – The Price of a Word

Learn the details and follow the word’s journey through decades of interpretation and debate.

Level 2: [A Member Asked] Inspected, Repaired or Overhauled?

Put the issue in context by considering it through the questions of fellow ARSA members.

Level 3: [Sarah Says] ARSA Insurance: Your Policy Against Bad Policy

Apply the lesson to your operations in the regulatory world. More importantly, apply ARSA’s work to your success in that world.

Sarah Says

ARSA Insurance: Your Policy Against Bad Policy

By Sarah MacLeod, Executive Director

ARSA membership is the most valuable and least expensive insurance policy your company owns: It is written against bad policy.

You may not want to admit it, but you have a pre-existing condition called “the government”; it is chock full of frustrating laws and bad rules that threaten the health of your business. How does the association write policy? It makes sure the government gets words right. A single word or phrase in a regulation or an offending sentence on Capitol Hill can mean disaster to an aviation business, ARSA policy fights for the right language so you don’t end up with a letter of investigation over sloppy phraseology.

ARSA insurance has paid and continues to pay large benefits; let’s look at a few examples of how carefully the association protects an industry against future heartache.

Overhauling Overhaul

The word carries considerable weight in the commercial world of civil aviation, but has limited regulatory value. It is the anchor of the often-used improper vernacular “MRO,” (a moniker that never appears in the CFR, is redundant, inaccurate and misconstrued, but I digress). Nonetheless, the agency has had to expend considerable effort on defining “overhaul” and the association has played its part.

The bottom line to a business is what you can charge for a work scope; when “overhaul” is used in a maintenance entry, it means more dollars. See how the association has influenced the FAA’s policy in this month’s Legal Brief.

Seriously

Last year, a single word was omitted from the newly-released repair station rule that would have upended the entire industry: Seven absent letters from § 145.221 made for a “serious” problem. In response, ARSA marshaled the aviation community to action and corrected the error before the rule even became effective.

Don’t believe us? What would it have cost your business to submit service difficulty reports for ALL failures, malfunctions and defects—in EVERY component, subcomponent and piece part? Yes, that is what the rule would have required. Don’t think the FAA would have enforced it? ARSA insurance only works for those who wish to comply with regulations; not for business-suicide strategists.

Acceptance for Cancellation

In January, a coalition of aviation groups led by ARSA objected to the requirement in § 145.55 that the agency must “accept” a surrendered certificate for cancelation. On July 13, the agency denied the petition to reinstate a repair station’s right to voluntary surrender.

Apparently, the FAA is so fanatical about its pursuit of “bad actors” that it is willing to use bad rules to do so. The wrong words are building blocks to bad rules. The association policy is to continue fighting for a right every other certificate holder enjoys—the ability to voluntarily surrender its certificate without further (or any) agency action.

When members run into trouble surrendering a certificate in future delicate business negotiations, ARSA will be ready to assist. It will also continue (and ramp up legislative) efforts to reinstate the right for a repair station to voluntarily surrender a certificate without unnecessary agency action.

Or New

In January, the association requested clarity regarding when the new owner of a repair station must apply for an amended or a new certificate. Considering the difference in application burdens between these two options, the subtle (no notice provided) inclusion of “or new” in § 145.51 without explanation is problematic. On July 20, the agency provided a clouded response and ARSA has asked again for clarification.

Insurance For the Compliance-minded

Certificated entities function efficiently and effectively only by reading and enacting the regulations and being compliant. Towards this end, the aviation community navigates by the language of the rules, but is often forced to do so through the whims of local inspector preferences (what I call “LIP”).

In Order 8000.373, the agency establishes a “compliance philosophy” that sets a preference for correction over enforcement when “deviations from regulatory standards, as defined in the aviation safety oversight guidance” (emphasis added) are found. In lock-step, at Osh Kosh, the new and not-to-be-long-standing FAA Chief Counsel announced the reorganization of the agency’s legal office to focus energy on “felonies” rather than “misdemeanors” ostensibly leaving “enforcement” of lesser offenses to LIP.

A laudable goal that can only be achieved by refining rules and refocusing stakeholders on their plain language, not on poorly-written, often conflicting or contradictory verbiage in “aviation safety oversight guidance” that creates and contributes to LIP. Before any consideration can be given to deviations, the standards must be clear to the industry and the agency’s workforce.

ARSA works long and hard and does ensure the regulations on which the system depends are clearly delineated and that “safety oversight guidance” mirrors, but does not deviate from the plain language of the rules. By doing so, it writes an insurance policy upon which the aviation industry can and does depend.

ARSA’s Self-Paced Training on the term “Overhaul”

You just read Level 3: [Sarah Says] ARSA Insurance: Your Policy Against Bad Policy

Other material:

Required Reading: [Hotline Feature] Overhaul Reviewed Yet Again

Level 1: [Legal Brief] “Overhaul” – The Price of a Word

Level 2: [A Member Asked] Inspected, Repaired or Overhauled?

Hotline Features

Compliance: The FAA’s Philosophy is ARSA’s Business

By ARSA Communications Staff

On June 26, Order 8000.373 became effective. The order, “Federal Aviation Administration Compliance Philosophy,” outlined the agency’s commitment to joint pursuit of a laudable goal.

Rather than resorting immediately to enforcement, the order outlines the FAA’s preference for corrective action when a certificated entity deviates from standards “as defined in the Agency’s aviation safety oversight guidance.” Should an entity fail to adopt improvements, or when it intentionally or recklessly violates a rule or present unacceptable risk to safety, enforcement action will be taken.

“The FAA establishes regulatory standards to ensure safe operations in the National Airspace System,” the order said. “The FAA’s safety system is largely based on, and dependent upon, voluntary compliance with these regulatory standards.”

“Voluntary compliance,” the agency states, is the linchpin of the entire regulatory structure. Through its resources for dealing with the government, the association provides tools and techniques for managing the human element of regulation. The agency’s announced philosophy is still dependent upon local inspectors being able to read and understand the pertinent regulations rather than establishing independent standards.

Every day, the association works to help its members clearly define, establish and pursue compliance. For individuals and businesses, it can go even further: Through an ARSA membership, repair stations can access the resources of Obadal, Filler, MacLeod and Klein, PLC. The association’s management firm has decades of experience in both compliance and enforcement issues – regardless of the agency’s philosophy, OFMK will help.

FAA Extension Inevitable as Deadline Looms

By ARSA Legislative Staff

Despite industry’s urging and congressional promises, the FAA’s current authorization (the FAA Modernization & Reform Act) is likely to receive an extension to give lawmakers more time to complete a new law as expiration looms on Oct. 1.

As it does with most larger federal agencies, every few years Congress must “reauthorize” the FAA. Reauthorization grants the agency the legal authority to operate and the process also gives lawmakers the opportunity to set policy priorities and target funding levels (actual spending is determined in appropriations bills).

While these should be routine and completed on time, recent history demonstrates it is difficult for Congress to reach consensus on aviation policy issues, resulting in delays and sometimes even agency shutdowns. In fact, the FAA Modernization & Reform Act was signed into law five years after its predecessor (VISION-100) expired, one lapse in spending authority and partial furlough of agency employees and 23 short-term extensions.

While the House Transportation & Infrastructure (T&I) Committee and the Senate Commerce, Science & Transportation Committee (the congressional panels with jurisdiction over the FAA) conducted hearings, met with stakeholders and promised a timely process, reauthorization legislation has yet to be introduced with less than two months before expiration. Once revealed, smooth sailing isn’t guaranteed. House T&I Committee Chairman Bill Shuster (R-Pa.) has promised a “transformational” bill, including major changes to air traffic control, which likely won’t make it an easy process.

All indications are the House will unveil its legislation in early September, but the Senate is operating on a much slower timetable, making an extension inevitable. The question is not whether a continuation will be needed, but how long it will last. Commerce, Science & Transportation Chairman John Thune (R-S.D.) indicated an extension well into next year is likely to give congressional leaders the time to plan floor consideration.

While preferred over shutdowns, ARSA believes short-term extensions are inexcusable. Congress had ample time to introduce, consider and enact a new reauthorization bill. It created the FAA and it needs to provide the agency the certainty and resources to do its congressionally-mandated job. Additionally, when lawmakers delay, industry is penalized. Aviation maintenance companies rely on the agency for certifications and inspections. Failing to provide the agency sufficient resources and timely authorizations results in administrative delays, undermining the industry’s competitiveness.

Be sure to keep your eye on the clock as we inch closer to the FAA Modernization & Reform Act’s expiration.

More of the Same: Government Report Criticizes Foreign Oversight

By ARSA Regulatory Staff

On July 16, the Department of Transportation’s Office of Inspector General (DOT-IG) issued a report criticizing FAA oversight of foreign repair stations in the European Union (E.U.).

The investigation was requested by Reps. Peter DeFazio (D-Ore.) and John Garamendi (D-Calif.). It focused on the effectiveness of the FAA’s process to transfer oversight to national aviation authorities (NAA) following the E.U.-U.S. bilateral aviation safety agreement (BASA). The DOT-IG also looked at the agency’s process for monitoring FAA-certificated repair stations operating under the BASA.

The reasoning presented in the report has become old and familiar. Previous analysis from both DOT-IG and the Government Accountability Office (GAO) noted issues with inspector training – a fact recognized by the industry-formed consistency of regulatory interpretation aviation rulemaking committee (CRI ARC). In reality, to note such shortcomings is incomplete and misleading.

The purpose of BASA is to enhance cross-border regulatory efficiency and help moderate costs for international aviation businesses. They allow countries to accept each other’s oversight, thereby focusing attention on the points where regulatory requirements differ. The value of these agreements has been well documented, but their success depends on commitment by each government to the cooperative tenants of the arrangement. By harping on the FAA’s inability to train and monitor its own as well as foreign inspectors, the report obscures the value of international collaboration and the true effectiveness of the oversight transfer.

The Obama administration’s duplicity cannot go unnoticed as it continues to criticize foreign repair stations even as the president and his congressional allies tout their pro-free trade record. Unfortunately, the report’s insistence that the FAA isn’t adequately overseeing FAA-certificated repair stations only adds “fuel to the fire” on Capitol Hill as Congress ramps up debate on FAA reauthorization. Consequently, ARSA and the broader industry must remain vigilant against threats to international agreements and the global aviation community.

Draft SUP Program Order Released

By ARSA Regulatory Staff

On July 15, the FAA released draft Order 8120.16A entitled “Suspected Unapproved Parts (SUP) Program,” which would cancel current Order 8120.16, “Processing Reports of Suspected Unapproved Parts.” The draft Order would shift program responsibility from Flight Standards Service Aircraft Maintenance Division (AFS-300) to the Aircraft Certification Service Design, Manufacturing, and Airworthiness Division (AIR-100) and clarify implementation responsibilities.

Comments to the new draft order are due Aug. 17. To download the draft order, and for more information on comment submission, visit the FAA’s Aircraft Certification Service (AIR) draft orders page.

Boeing Report Foresees Unprecedented Demand for New Technicians

By ARSA Communications Staff

On July 20, Boeing released its 2015 Pilot and Technician Outlook. The report forecasts the global commercial aviation industry will need more than one million new workers – 558,000 pilots and 609,000 maintenance technicians – to meet unprecedented demand between now and 2034.

“As global economies expand and airlines take delivery of tens of thousands of new commercial jetliners over the next 20 years,” Boeing’s report said, “there will be unprecedented demand for people to pilot and maintain these airplanes.”

The long-term demand for maintenance skills equates to roughly 30,000 new technicians per year, with need in every corner of the world. As already seen in ARSA’s 2015 Global Fleet and MRO Market Assessment, strong growth in Asia will lead global demand for the foreseeable future; more than one-third of all new technicians over the next two decades will fill positions in the region.

In North America, more than 100,000 new maintainers will be needed over the forecast period – 5,500 new positions each year and 19 percent of total growth. This addition to the existing workforce does not capture recruitment necessary to replace aging workers, whose retirements have been long-expected to deplete the industry’s existing personnel base.

The overall lesson is clear and has now become oft-repeated: As the global civil aviation market continues to grow, keeping the flying public safely aloft will require the dedicated effort of well-trained men and women supported by a healthy and cooperative international industry.

Get Involved

In the United States – visit ARSAaction.org and tell American lawmakers to support training programs and regulatory structures that foster technical skills.

Around the world – learn about ICAO’s Next Generation of Aviation Professionals Task Force (ARSA is a member) and the resource it provides the global industry.

By ARSA Regulatory Staff

On June 30, the agency issued another legal interpretation on the term “overhaul”—adding to the long list of explanations on the proper use of the term. Again the FAA summarizes the fact that the word can be used in a maintenance record to describe the highest level of work on an article. In other words, there are times that an article need only be cleaned and inspected to be described in a maintenance record as “overhauled.”

ARSA previously addressed the varying uses of the term in the context of component maintenance manuals (CMM), arguing that the regulations—not a manufacturer’s use of the term in its manual or instructions—dictate when an article is “overhauled.” With this new legal interpretation ARSA has done considerable research into the origins and use of the term (see more by following this month’s “Overhauling Overhaul” self-paced training material).

ARSA’s correspondence with the FAA regarding the use of this term can be found:

ARSA’s Self-Paced Training on the term “Overhaul”

You just read Required Reading: [Hotline Feature] Overhaul Reviewed Yet Again

Other material:

Level 1: [Legal Brief] “Overhaul” – The Price of a Word

Level 2: [A Member Asked] Inspected, Repaired or Overhauled?

Level 3: [Sarah Says] ARSA Insurance: Your Policy Against Bad Policy

ARSA Works

To see all the ways ARSA works as the voice of the aviation maintenance industry, visit our ARSA Works page.

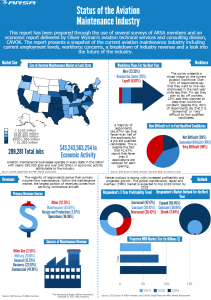

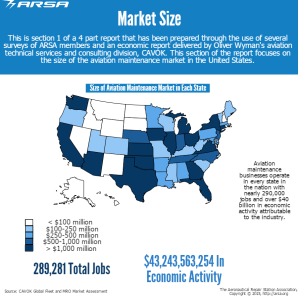

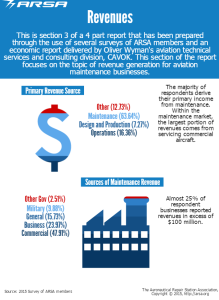

ARSA Illustrates Aviation Maintenance

By Brett Levanto, Vice President of Communications

In early 2015, ARSA ran multiple member surveys to collect industry data. The surveys, which include a workforce development questionnaire and the most-recent edition of the association’s annual member survey, captured insights about the opportunities and challenges facing aviation maintenance providers.

By merging this anonymous response data with the 2015 Global Fleet and MRO Market Assessment published by CAVOK, ARSA created a series of infographics that present a snapshot of the aviation maintenance industry. The graphics express insight on the current market, workforce concerns and industry revenues while also peering into the future.

As presented in the images – four capturing individual topic areas and one presenting all data together – this information is a valuable resource for repair stations and other aviation businesses. Association members and allies should use them to recruit potential employees, advocate with lawmakers and display the industry’s impact to the public at large.

Get Started

- Choose a graphic. If one of the issue areas is particularly important for you, focus on it. Want to go broad? Use the image with all of the data on it.

- In the United States? Use ARSA’s state-by-state economic data to put your own contributions in context. Are you part of a thriving statewide market or one of the precious few employers in this vital industry? Either way, you matter.

- Get the word out. Use social media, email colleagues, send copies to congressional offices, post to your website or click print and tack the graphics to the wall. Here’s your subject line: “Picture the importance of aviation maintenance…”

Infographics

Click the images below to view and download. When the full image appears right-click and select “save image as” to create a copy. You may also click here to download all graphics in a compressed folder.

| Full Graphic | |

|

|

| U.S. Market | Workforce |

|

|

| Revenues | Outlook |

|

|

Amend or New: Vagueness Persists

By ARSA Regulatory Staff

The FAA’s July 20 response to ARSA’s request for clarity regarding a new owner’s requirement to apply for an amended or new certificate when it obtains a repair station’s assets was less than lucid.

The association is attempting to obtain clear guidance on when the new owner of a repair station’s assets needs to apply for an amended or new certificate if it wishes to continue as a repair station. ARSA believes a bright line exists: When the new owner wishes to obtain a different certificate number, a new application must be filed.

If, on the other hand, the new owner wishes to keep the same certificate and merely amend the ownership and name, an application for an amended certificate would be submitted. In either event, if the housing, facilities, equipment, materials and key personnel do not change, processing the application should be swift.

Stay tuned as the association continues to seek clarity on this issue.

FAA on Voluntary Surrender: A Bad Rule to Pursue Bad Actors

By ARSA Regulatory Staff

On July 13, the FAA denied the industry’s rulemaking petition to reinstate a repair station’s right to voluntarily surrender its certificate.

In its new repair station rule, which became effective in November 2014, the FAA took the unprecedented step of subjecting surrendered certificates to “acceptance for cancellation” (see, § 145.55). A coalition of ten aviation industry members, led by ARSA, called for the removal of the requirement, since it is unique among aviation certificates, runs counter to the interest of aviation safety and increases regulatory administrative burden without any agency explanation as to how its discretion will be utilized.

In the petition, the industry noted the FAA’s ability to investigate individuals is unaffected by the surrender of the entity’s certificate. Therefore, denying a repair station’s right to voluntarily surrender its certificate bears no rational connection to the aim of ensuring safety through the investigation and banishment of “bad actors.”

The agency’s response ignored facts and simply re-stated the new rule’s preamble: investigators must prevent the surrender of a certificate so that enforcement action can possibly be taken. The FAA rejected the logic that its updates to § 145.51 allow the agency to refuse new applications if individuals involved materially contributed to circumstances where a repair station certificate was “revoked, or [was] in the process of bring revoked.”

Though § 145.51 empowers the FAA to protect aviation safety by denying the issuance of new certificates to “bad actors,” the agency continues to insist on its ability to deny the right of surrender to existing repair stations.

Additionally, the response completely ignored the coalition’s concern that disparate treatment – denying rights to repair station certificate holders but granting them to the rest of the aviation community – creates uncertainty for the entire industry.

On behalf of its members and the larger aviation world, ARSA cannot accept an incomplete and uncooperative response in this matter. Stay tuned as the association continues to pursue guaranteed rights for all certificate holders.

ARSA Works: Continue in Service

By ARSA Regulatory Staff

On July 9, ARSA delivered a letter to the FAA aircraft maintenance division regarding the removal and reinstallation of components – a practice affectionately referred to as “salvaged part,” “cannibalized part,” “part recovery” or “continue-in-service” processes.

ARSA asserted that a repair station’s rating allows it to make continue in service determinations on internal or attached articles. These determinations are accomplished by reviews, visual inspections, checks or tests of sub-articles to determine if they are “serviceable as removed.” If no further maintenance actions or steps are required, the part can be used in the assembly under maintenance, another assembly or be placed into stock for future use.

The letter was initiated after an ARSA member received a letter of investigation questioning the repair station’s utilization of a recovered parts procedure. Contrary to the local office’s position, a rating for each type of article being reviewed, inspected or tested is unnecessary.

When a continue in service review performed during incoming inspection or during the course of maintenance on the “rated” article reveals that repairs or alterations must be performed, then the repair station must have the proper rating to perform the necessary work on the sub-article.

To see all the ways ARSA is working as the voice of the aviation maintenance industry, visit the ARSA Works page.

Aviation Coalition Does Its Part for Alternative Parts

By ARSA Legislative Staff

On July 7, ARSA joined six other aviation trade associations in urging Congress to refrain from mandating a duplicative and unnecessary FAA regulation.

Specifically, the coalition is concerned with efforts on Capitol Hill requiring the FAA to initiate a rulemaking pertaining to the identification and marking of “influencing parts.” Joining ARSA on the letter are Airlines for America (A4A), the National Air Transportation Association, the Cargo Airline Association (CAA), the Regional Airline Association (RAA), the National Air Carrier Association (NACA) and the Modification and Replacement Parts Association.

The current regulatory framework, which includes rules and related guidance dealing with all aircraft parts – particularly “life-limited” and so-called “influencing parts” – has a proven safety record. Nonetheless, lawmakers are considering requiring the FAA to expend its limited resources conducting a redundant rulemaking with no benefit to flight safety.

“The FAA has limited resources and many congressional mandates,” the group’s letter said. “Forcing the agency to initiate an unnecessary rulemaking in an area it has already issued regulations and guidance is a misallocation of scarce resources and creates inefficiencies.”

The associations also warned lawmakers that many aviation companies, including small businesses, would ultimately bear the economic burden. “While larger companies can better absorb the rulemaking process’ costs and even unnecessary regulation, those measures have a disproportionate impact on small entities. The bottom line is that no business can afford the time and few have the inclination to respond to and implement redundant rulemaking activities.”

Daniel B. Fisher, ARSA’s Vice President of Legislative Affairs added: “The FAA doesn’t have the resources to pursue duplicative rulemakings, particularly when there is no benefit to flight safety. Congressional leaders have prioritized an FAA reauthorization framework that will streamline regulatory processes and provide for greater collaboration with industry. Unnecessary rulemakings misdirect limited FAA resources from key safety initiatives and ultimately increase costs for aviation companies and customers.”

ARSA on the Road: Klein in the Golden State

By ARSA Communications Staff

From July 20-24, ARSA Executive Vice President Christian A. Klein carried the association’s flag to Southern California. During his four days on the west coast, Klein met with current and potential members during anoutreach event in Los Angeles co-sponsored by PPG Aerospace and Fortner Engineering and then was the keynote speaker at the kickoff the 10th annual Quantum User Exchange Group (QUE Group) conference in San Diego.

Klein gave Los Angeles outreach event attendees – which included congressional staff from the office of Rep. Tony Cardenas (D-Calif.) – an overview of ARSA activities and member benefits. The concerns expressed by attendees about the skilled technical worker shortage in particular underscored the importance of the association’s focus on the next generation of aviation professionals.

Klein told attendees at the QUE Group conference that the state of the aviation maintenance industry is strong but that there are clear risks on the horizon. He noted in particular the skilled technical workforce shortage, unnecessary and overlapping regulatory burdens from civil aviation authorities, micromanagement by Congress in the context of FAA reauthorization and political hostility to free trade.

However, Klein said, all these risks could be mitigated and managed by effective engagement by industry leaders. Klein then described the best ways to engage with key audiences, including lawmakers, regulators, workers and local government and school officials. He also discussed the many tools that ARSA provides to support engagement, including avmro.arsa.org, the association’s go-to site about the industry for journalists, policymakers and the general public, and arsaaction.org, the association’s grassroots action site.

Klein also played the association’s new documentary about the aviation maintenance, “You Can’t Fly Without Us,” which is playing on PBS stations around the country. He encouraged the audience to use the video as part of outreach efforts.

ARSA was grateful for the opportunity to participate in the QUE Group conference. To learn more about Component Control and ARSA’s other preferred providers, click here.

The QUE Group promotes Quantum Control software, one of the core products produced by ARSA preferred provider Component Control, and hosts annual conferences focused on the daily operation of aviation businesses. Quantum Control is a fully integrated business software solution developed for MRO and aviation logistics organizations. Aviation industry experts, Quantum Control users and Component Control staff participated in conference presentations, round-table discussion and software demonstrations.

Legal Briefs

This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential

“Overhaul”—The Price of a Word

By Ryan Poteet, Regulatory Affairs Manager

Since the introduction of another legal interpretation of the word overhaul, the association has been queried about exactly what it takes to describe work performed on an article with that term. The agency and the association have expended a lot of energy on the word.

There is a legal interpretation from 1991 making clear articles that cannot be disassembled may be deemed overhauled. Then there are letters among and between the association, certificate holders and the FAA that further diminish the regulatory meaning of the word. Now we are left with only one clear fact—if you perform the greatest extent of work possible on an item using manufacturer’s manuals or other methods, techniques and practices, the term can be used in the article’s maintenance record. How did we get to such crossroads?

The proper use of the term “overhaul” has been obfuscated by a basic misunderstanding of the word’s purpose, what’s actually required by the regulations and a commercial incentive to call every maintenance action an overhaul.

The original purpose of the term is directly related to an air carrier deeming line replaceable units (completed assemblies) “hard time” items that require overhaul at mandated periods under a continuous airworthiness maintenance program (CAMP). Therefore, under the regulations, the term applies to top assemblies, things that can be (as the regulation requires) disassembled,[1] cleaned, inspected, repaired as necessary, reassembled and tested in accordance with the procedures developed by the manufacturer (or other methods, techniques and practices). (See 14 CFR § 43.2(a) and 43.13.)

At some point industry and the agency mixed-up the requirements of § 43.2(a) with commercial expectations. The misconception persists that, in order for a “hard time” item to be deemed overhauled, all internal articles have to be overhauled (instead being repaired as necessary as mandated by § 43.2(a)).

Say an airline’s CAMP requires a hydraulic unit (a hard time item) be overhauled at particular intervals, without further instruction. For the top assembly to be “overhauled”, the unit must be disassembled, the internal parts are cleaned, inspected, repaired as necessary, and the top assembly tested in accordance with approved procedures. [2] Nothing in § 43.2(a) requires the internal components (e.g., a pump) of the hard-timed unit i.e., the hydraulic unit to be overhauled in order for the top assembly (the actual hard-timed article) to be deemed “overhauled.” (Now if a CAMP defines an overhaul to mean that every internal component must have the greatest work scope accomplished (i.e., each component must be overhauled), then the maintenance provider must follow those instructions under § 145.205. However, that is rarely the case.)

Because the term “overhaul” generates more revenue, there is an incentive to call every maintenance function by that term, even when that service is the same as an “inspection,” “test” or “repair.” There are certainly instances where there is no difference between and among any of those terms under today’s rendition of the term overhaul.

Whether an internal component that is inspected or repaired may rightfully be designated as overhauled will depend upon the extent of work available under the manufacturer’s instructions (e.g., Component Maintenance Manual, Aircraft Maintenance Manual) or other methods, techniques and practices acceptable to the FAA, such as a repair specification (which must, remember, include approved test procedures).

Take the hydraulic unit with a pump; for some pumps – like self-contained sealed units – an overhaul designation is appropriate for inspections and/or tests when the pump cannot be disassembled.

However, other pumps will have instructions for disassembly, replacement of parts, repairs, reassembly, and testing. A mere inspection and test would be insufficient work to warrant an overhaul designation because all of the available maintenance functions were not accomplished. An overhaul designation is also inappropriate where more than one repair is available and needed, but only one is accomplished. In this scenario the work described in the maintenance record must be “repair,” not “overhaul,” because the greatest extent of the work was not performed.

The regulations make clear that the internal components of a top assembly do not need to be overhauled in order for the top assembly to be deemed overhauled. That has not stopped the industry and agency from diminishing the intent and meaning of the word.

[1] The FAA has noted that disassembly need not be to the point where the article (or any of its component parts) is destroyed. Legal Interpretation to J.E. Murdock III, 1991 WL 11663129 (Nov. 26, 1991).

ARSA’s Self-Paced Training on the term “Overhaul”

You just read Level 1: [Legal Brief] “Overhaul” – The Price of a Word

Other material:

Required Reading: [Hotline Feature] Overhaul Reviewed Yet Again

Level 2: [A Member Asked] Inspected, Repaired or Overhauled?

Level 3: [Sarah Says] ARSA Insurance: Your Policy Against Bad Policy

ARSA on the Hill

Turn Up the Heat

By ARSA Legislative Staff

As Congress begins its August recess, give lawmakers and legislative staff an opportunity to see first-hand what your company does and how it fits into the aviation industry.

With the FAA reauthorization pending, threats and opportunities abound for your company and the broader industry. Lawmakers must understand the aviation maintenance industry’s economic impact, its safety record and the impact unnecessary congressional mandates have on your operational freedom, efficiency and ability to grow. The time is now to host a facility visit. And it’s never been easier!

ARSA’s legislative team is standing by to identify appropriate lawmakers, facilitate the visit and provide materials and resources to ensure the tour is a success.

You don’t need to be an aviation policy expert or even current on congressional news and happenings. Just be yourself! Don’t shun this valuable opportunity. All parties benefit: Members of Congress meet your employees and show their commitment to the local business community while witnessing your company’s contribution to the economy and flight safety.

Contact Daniel today.

Already have a facility visit scheduled? Let us know. We can update you on the industry’s policy priorities and publicize the visit afterwards giving your company valuable visibility among the broader industry.

Hosting a facility visit is an easy and fun way to raise the profile of your company and your industry. It’s also a great way to build relationships with the legislators who will serve your interests down the road. Get the process started today!

Regulatory Outlook

By Crystal Maguire, Vice President of Operations

A revised version of the association’s draft Working Away Advisory is available for industry comment; contributors are asked to submit feedback by Sept. 15.

In response to numerous member inquiries regarding 14 CFR § 145.203, working away from the fixed location, ARSA developed an advisory that would provide 14 CFR part 145 repair stations a “compliance road map.” The initial draft document was released in June (see previous story for more information about the advisory and its purpose). Feedback was received and incorporated. Thank you to those who participated.

Submit your comments to arsa@arsa.org either by tracking changes in the Microsoft Word document (download below) or submitting stand-alone written remarks.

Final document for member review: http://arsa.org/wp-content/uploads/2015/08/ARSA-WorkAwayAdvisory-20150806.docx.

International Cooperation — Bilateral Development

By Silvia Marroquin, Legal Intern

Manufacturers, operators and maintenance providers must navigate an industry that cannot be contained by political borders. National aviation and diplomatic authorities must engage to ensure civil aviation-related businesses can operate internationally.

Efficient and economic use of government resources is enshrined in the spirit of the Chicago Convention of 1944, as overseen by the International Civil Aviation Organization (ICAO). The Chicago Convention, along with ICAO’s complementary policy, auditing and capacity-building efforts, is the framework for commercial air transport maintenance and alteration activities being performed on foreign soil.

However, in the absence of a single world-wide regulatory regime, national aviation authorities (NAA) must create laws for their own country and negotiate bilateral agreements with others to properly utilize resources enabling businesses to more easily perform work on an international scale. These government-to-government arrangements manage aviation safety regulatory interfaces through mutual recognition.

The Bilateral Aviation Safety Agreement (BASA)

In the U.S., a BASA is defined in Advisory Circular 21-23B as “a government-to-government agreement…to facilitate the recognition of procedures for the reciprocal acceptance of various approvals”.

A BASA also sets the terms by which NAAs cooperate and assist one another in resolving safety issues in design, production, flight operations, environment certification and maintenance.

Each NAA still holds responsibility for making “findings” of compliance; however the information and data can be with full recognition of the other signatory country’s system.

Implementation Procedures

Understanding all of the components of BASAs, including implementation procedures (where they exist), is vital for aviation entities.

Implementation procedures outline the standards, rules, practices, and systems the nations will use for mutual acceptance. They address aircraft certification (implementation procedures for airworthiness), maintenance (maintenance implementation procedures, which includes repair station surveillance), environmental testing and approval, and technical cooperation in general.

Without implementation procedures, a BASA is just an opportunity for world aviation leaders to take handshake photos with reduced positive impact for the maintenance community. For instance, the United States has entered into dozens of cooperative contracts, however only a few of them contain implementation procedures and even fewer have specific instruction for maintenance operations. In fact, the bilateral with Canada is the only one that is truly reciprocal; Canada does not require the issuance of an additional certificate, saving the costs associated with its application and maintenance.

Economic Impact

As ARSA documented in 2011, repair stations pay several times more to obtain or renew certificates from foreign civil aviation authorities without a BASA. Clearly, there is a strong incentive to negotiate cross-border aviation agreements.

It is equally important for businesses to understand regulatory responsibilities when performing work overseas in all countries with or without bilateral agreements and implementation procedures.

Current Bilaterals

To operate internationally, industry must understand the complex agreements in place. To assist, ARSA produced a BASA compilation chart, showing executive agreements and implementation procedure(s) by country.

To download the chart, click here.

This list includes Federal Register publications, such as final rules, Advisory Circulars and policy statements, as well as proposed rules and policies of interest to ARSA members. To view the list, click here.

Quality Time

Oliver Wyman’s 2015 MRO Survey – Domo Arigato, Mr. Roboto

By Brett Levanto, Vice President of Communications

The results of Oliver Wyman’s 2015 MRO Survey were released during Aviation Week’s MRO Americas Conference in April. This installment of the annual report presented the views of more than 100 senior aviation executives about future innovation and technology development.

In general, respondents foresee that rapidly-improving technologies will drive business outcomes and demand action by repair stations to keep up with the times. Whether it’s through the use of data to predict maintenance needs, wearable technology that will change how maintainers interact with aircraft and components or the use of additive manufacturing (3D printing) to fabricate parts, repair stations will need to invest in new capabilities.

As western airlines drive to replace aging fleet members – as predicted by ARSA’s 2015 Global Feet and MRO Market Assessment – next generation fixed-wing and rotorcraft will demand advanced maintenance capabilities. All in, what the report calls “disruptive change” from innovation will challenge leaders will need “clarity, purposeful analysis and opportunity selection to capitalize on innovation.”

It may not yet be time to report to a robotic supervisor and deal with artificially intelligent FSDOs, but the future of MRO will be defined by the management of advancing technology.

For more information on the survey, click here.

For more-expansive data and reporting on aviation maintenance – including ARSA’s 2015 Global Fleet and MRO Market Assessment performed by CAVOK, a division of Oliver Wyman – visit the association’s data and advocacy center.

Training

Personal Development — Human Factors: CRM

By ARSA Communications Staff

According to ICAO, “human factors” are about people — about people in their working and living environment, about their relationships with equipment, procedures and the environment and (just as importantly) about their relationships with other people. Its two objectives can be seen as safety and efficiency. Take half an hour to learn from the FAA about the history of crew resource management (CRM) by learning from incidents when human factors became aviation failures. Click here to get started.

FAA Resources: Attend the Academy

By ARSA Communications Staff

ARSA staff members search for resources, guides and tools that might be useful for our members as they work to ensure global aviation safety. This installment comes from the FAA Academy; its doors are open.

The academy provides technical and managerial training and development for the government’s workforce as well as the aviation community on topics including regulatory standards, safety training and technical operations. Attendance at an academy course is an opportunity for maintenance providers to engage directly with the agency and learn about its position on key issues.

Finding a Class

- Access the academy’s online course catalog at https://www.academy.jccbi.gov/catalog.

- Browse scheduled classes through each category presented on the catalog’s main page by clicking on the linked category name of interest.

- Click on “Search Training Items” to search all potential classes (regardless of schedule) by number or keyword.

- Click on “Search Schedule Offerings” to search scheduled classes by number.

- On any results screen, click the linked “Item No.” to see course details, including description and upcoming schedule.

Determining Cost

- For any class offering, determine the tuition using the FAA Academy Reimbursable Course Price Listing. The document provides tuition information for scheduled classes as well as information on field-delivered courses.

Request Training

- Provide contact information and details about requested course or courses through the academy’s training request portal.

- For questions or other issues, click here to access AMA-200’s contact information.

Regulatory Compliance Training

Membership

Member Spotlight – R.W. Radditz

By Sarah Hartley, Communications Intern

Founded by R.W. Raddatz in 1987, RWR, Inc. is an FAA and EASA compliant repair station based in Deerfield Beach, Florida. With expertise in the aviation and aerospace fields, RWR manufactures aircraft parts and tools and specializes in standard and DER repairs.

Founded by R.W. Raddatz in 1987, RWR, Inc. is an FAA and EASA compliant repair station based in Deerfield Beach, Florida. With expertise in the aviation and aerospace fields, RWR manufactures aircraft parts and tools and specializes in standard and DER repairs.

The company is known for superior quality and service. In addition to serving noteworthy MROs, airlines and OEMs, RWR was certified by Boeing to manufacture piece parts for the International Space Station. They meet customer needs with their wide range of knowledge, experience and technical understanding of manufacturing and repair processes.

While R.W. Raddatz works hard to ensure aviation safety, ARSA gives members like RWR a voice in Washington. It’s of critical importance for repair stations to remain compliant so they can continue to serve the aviation industry – ARSA helps make that possible.

To learn more about R.W. Raddatz, visit: http://www.rwraddatz.com/.

Have You Seen this Person? Peter Neffenger

By Sarah Hartley, Communications Intern

Peter Neffenger, Administrator, Transportation Security Administration

After reports of fake weapons making their way past TSA in tests at busy U.S. airports, the new Transportation Security Administration chief Peter Neffenger was sworn in on Monday, July 6.

He now oversees security operations related to U.S. air travel and transportation systems and leads 60,000 employees at 450 airports across the country. TSA is a risk-based counterterrorism agency and Neffenger plans to make it stronger by tightening airport security. ARSA’s own Daniel Fisher congratulated Neffenger on his appointment and reinforced the importance of good repair station security.

Neffenger supports TSA’s risk-based security system, PreCheck, and plans to make it stronger. He also vowed to keep lawmakers up to date on his progress as he understands the importance of TSA’s mission to the security of this nation.

Before his TSA appointment, he was the 29th vice commandant of the Coast Guard, deputy national incident commander for the 2010 BP-Horizon oil spill and held numerous officer positions in the Coast Guard.

In 1982 he was commissioned through the Coast Guard Officer Candidate School after earning his bachelor’s degree from Baldwin Wallace University. During his active duty career he earned master’s degrees from Harvard University, Central Michigan University and the U.S. Naval War College. Neffenger is a member of the Pacific Council on International Policy and a former U.S. Senate Appropriations Committee fellow.

To learn more about the new TSA administrator, please visit www.tsa.gov.

Take Advantage of ARSA’s Members Getting Members Program, Get 10% Off on Membership Dues

The best form of advertising is word of mouth. Use the Members Getting Members Toolkit to recruit an ARSA member and your company will receive a discounted membership rate for your next membership term.

Get more information at http://arsa.org/membership/members-getting-members/.

Target Your Message: Advertise Today in ARSA’s Newsletters and Website!

ARSA has a menu of advertising opportunities for arsa.org, the hotline and the ARSA Dispatch.

Take advantage of these great opportunities today to showcase your company, a new product or event. For more information go to http://arsa.org/advertise/

Exhibit, Sponsor the 2016 Repair Symposium

As the maintenance industry’s top event devoted exclusively to regulatory compliance, the ARSA Symposium attracts a highly qualified professional audience.

Use this opportunity to promote your company while showing support for ARSA. Get more information at http://arsa.org/news-media/events/arsa-symposium/arsa-annual-repair-symposium-sponsorship/

A Member Asked – Inspected, Repaired or Overhauled?

Another legal interpretation of the word overhaul brought a series of member questions that help to put the issue in context.

Q: Can you please clarify when to use inspected, repaired or overhauled on maintenance records?

A: The answer is: it depends. Mainly it depends upon the available maintenance data – are there instructions from the manufacturer of the article? If so, what work scope is contemplated for the specific article being maintained? An inspection? A test? Complete information on disassembly, cleaning, inspecting, repairing, replacing parts, reassembling and testing?

If there is maintenance data from the manufacturer available or the maintenance provider or airline has provided instructions, such as a repair specification with approved testing procedures. The bottom line is that to place “overhaul” on a maintenance record greatest possible work scope needed must have been accomplished in accordance with the available maintenance data.

Q: As long as required maintenance is performed (and assuming no more information is available) then may inspected, repaired or overhauled be used interchangeably?

A: Under the regulations, legal interpretations and aviation safety inspector guidance, the answer is yes provided the greatest extent of work has been accomplished on the article.

Under commercial terms, maybe—since overhaul has a different connotation under a contract, it may elicit more requirements and/or income.

Q: Let me turn to the available maintenance data; for some components there is Aircraft Maintenance Manual (AMM), Structural Repair Manual (SRM) and Component Maintenance Manual (CMM). The AMM or SRM may be published by the aircraft manufacturer and the CMM by the article manufacturer or by the aircraft manufacturer. Some components don’t have a CMM. The only maintenance data may be an SRM section or there is no SRM section and the Chapter 51 general section is all that is available. For an overhaul, I assume the “greatest work possible” would be found in the CMM – if one exists?

A: Good assumption. It also doesn’t matter whether the data is in the form of an aircraft maintenance or structural repair manual, maintenance manual, component overhaul manual or other accepted and/or approved maintenance information (see FAA’s letter to ARSA on this very subject). Also note that in the Giles letter, the “test” may need to be done on the aircraft (helicopter transmissions for example) and the maintenance record has to indicate the test is missing.

Q: And if no CMM exists, the SRM maintenance would be “greatest work possible?”

A: Again, a good assumption, but I wouldn’t make the leap without being positive and I would make certain the maintenance record reflected the work scope and the maintenance data used to accomplish that work just in case questions are asked later.

Q: Or could an overhaul be performed per an SRM even if a CMM exists?

A: Again, I wouldn’t make that leap without looking, but the best practice is for the maintenance record to reflect both the work performed and the specific data used—so if there is a greater work scope under another manual, at least the proper reference would be available in case of threatened enforcement action.

Q: For a repair, I assume CMM or SRM maintenance criteria could be used even if they both exist since a repair is not accomplishing the “greatest work possible?”

A: Another good assumption, the reference to the maintenance data used in the record or work order would pinpoint the extent of work performed, which is what the maintenance provider is approving for return to service.

ARSA’s Self-Paced Training on the term “Overhaul”

You just read Level 2: [A Member Asked] Inspected, Repaired or Overhauled?

Other material:

Required Reading: [Hotline Feature] Overhaul Reviewed Yet Again

Level 1: [Legal Brief] “Overhaul” – The Price of a Word

Level 3: [Sarah Says] ARSA Insurance: Your Policy Against Bad Policy

AVMRO News Portal

ARSA strives to provide resources to educate the general public about the work of the association’s member organizations; should you need to provide a quick reference or introductory overview to the global MRO industry, please utilize AVMRO.ARSA.org.

AVMRO Industry Roundup

ARSA monitors media coverage on aviation maintenance to spread the word about the valuable role repair stations play globally by providing jobs and economic opportunities and in civic engagement. These are some of this month’s top stories highlighting the industry’s contributions.

You can explore these stories through ARSA’s Dispatch news portal.

Upcoming Events

Industry Calendar

South Carolina Aerospace Industry Conference & Expo – Columbia, South Carolina – August 26-27

Air Capital Aviation Expo – Wichita, Kansas – August 27

AIMA Africa – Addis Ababa, Ethiopia – September 22-24

ACI-NA 2015 Annual Conference & Exhibition – Long Beach, California – October 4-7

ARSA Strategic Leadership Conference – Washington, D.C. – October 8

MRO Europe – London, England – October 13-15

EASA Annual Safety Conference 2015 – Luxembourg – October 14-15

Previous editions:

| 2015: | Jan | Feb | Mar | Apr | May | June | |

| 2014: | Jan | Feb | Mar | Apr | May | June | July |

| Aug | Sept | Oct | Nov | Dec | |||

| 2013: | Jan | Feb | Mar | Apr | May | June | July |

| Aug | Sept | Oct | Nov | Dec | |||

| 2012: | Jun | Jul | Aug | Sep | Oct | Nov | Dec |

| SPONSORED CONTENT |

The FAA is very concerned about counterfeit aircraft parts. They call them Suspected Unapproved Parts (SUP). Having any in your inventory could be a legal disaster!!

The FAA is very concerned about counterfeit aircraft parts. They call them Suspected Unapproved Parts (SUP). Having any in your inventory could be a legal disaster!!

- There is onlyone centralized DataBase of Suspected Unapproved Parts – Over 60,000 of them. Find the ones on your shelves before the FAA fines you.

- There is onlyone integrated PMA/AD System. Find ADs that apply to or reference any of almost 1,000,000 PMA parts. Do multi-level PMA research.

- Due Diligence is the key phrase and The Aviation DataBase® is the only source for an easy and inexpensive way to do it. Head off the legal problem before it occurs.

- There is a User friendly and searchable copy of the Flight Standards Information Management System (FAA Order 8900.1) in The Aviation DataBase®.

- Do you need an Aviation Regulatory Library?: Over 18,000 ADs – Large & Small AC, Over 1,500 Type Certificate Data Sheets, Over 1,200 FAA Advisory Circulars.

- Call Aviation DataSource, Inc. (800) 952-8844.You can be using The Aviation DataBase® within minutes.

the hotline is the monthly publication of the Aeronautical Repair Station Association (ARSA), the not-for-profit international trade association for certificated repair stations. It is for the exclusive use of ARSA members and federal employees on the ARSA mailing list. For a membership application, please call 703.739.9543 or visit http://arsa.org/membership/join/. This material is provided for educational and informational purposes only. It does not constitute legal, consulting, tax or any other type of professional advice. Law, regulations, guidance and government policies change frequently. While ARSA updates this material, we do not guarantee its accuracy. In addition, the application of this material to a particular situation is always dependent on the facts and circumstances involved. The use of this material is therefore at your own risk. All content in the hotline, except where indicated otherwise, is the property of ARSA. This content may not be reproduced, distributed or displayed, nor may derivatives or presentations be created from it in whole or in part, in any manner without the prior written consent of ARSA. ARSA grants its members a non-exclusive license to reproduce the content of the hotline. Employees of member organizations are the only parties authorized to receive a duplicate of the hotline. ARSA reserves all remaining rights and will use any means necessary to protect its intellectual property.

© 2015 Aeronautical Repair Station Association