Hotline Highlight – Nothing New

The hotline – ARSA’s premier member newsletter – contains news, editorial content, analysis and resources for the aviation maintenance community. All members should ensure they receive their edition the first week of each month. Not getting yours? Click here for direct access. For more information about the association’s periodicals, click here.

From the “President’s Desk”…

Nothing New

While the U.S. House of Representatives’ bill to reauthorize the FAA is a major step towards advancing policy fostered by ARSA, there’s a long way to go until the “Securing Growth and Robust Leadership in American Aviation Act” becomes law. The Senate is yet to act on its version, and there are considerable differences between the policymaking perspectives of the two chambers. The law eventually signed by the president will likely have a new tongue twisting name.

None of this is new. Big authorization laws require a lot of haggling between the chambers before they are ready for enactment.

What is also old news is ARSA’s outsized impact on the process. As reported by Executive Vice President Christian Klein, the House Bill directs the FAA to improve consistency in regulatory application, handle petitions with more transparency, establish time limits for investigations, and increase funding for marquee workforce grant programs, among the many things ARSA’s work provides its membership.

One of the provisions in the House bill has been a central focus of ARSA’s advocacy for decades: a directive to the FAA to task the Aviation Rulemaking Advisory Committee with identifying ways to improve access to instructions for continued airworthiness (ICA). It’s imperative to find practical ways of ensuring the best maintenance information is available when needed by those given the responsibly for continued airworthiness.

What Congress is asking the FAA to do is also nothing new. It is the same reason ARAC is investigating the value of repairman certificates. The body is a venue for all stakeholders to investigate and recommend regulatory actions that have a minimum impact on commercial issues, like the protection of intellectual property.

The inclusion of these priorities is a direct result of the years ARSA’s team and engaged members spent educating elected officials. By participating in Legislative Day, responding to calls to action, hosting facility visits, and being proactive local constituents, ARSA has given the international maintenance industry a real voice in American lawmaking.

While nothing may be new, the players are, so there is work to be done. Whether Congress completes its work before the Sept. 30 expiration of the FAA law or needs short term extensions, ARSA will bird-dog the process to the end (and beyond).

Become part of the work through arsa.org/legislative.

|

Josh Krotec 2023 ARSA president | First Aviation Services, Inc. senior vice president |

Previous Hotline Highlights

5/9/23 - Senators Introduce Foreign Repair Station Bill

May 9, 2023

From the “ARSA on the Hill” section…

Senators Introduce Foreign Repair Station Bill

Senators Shelley Moore Capito (R-W.Va.) and Tammy Baldwin (D-Wis.) introduced legislation that would impose new rules on foreign repair stations performing heavy maintenance on U.S. air carrier aircraft.

The Global Aircraft Maintenance Safety Improvement Act (S. 1256) is a slightly modified version of anti-foreign repair station legislation that passed the House in 2022. While the legislation was significantly improved (and renamed from “the Safe Aircraft Maintenance Standards Act”) during House T&I Committee negotiations last spring, it would still impose new and unnecessary burdens on U.S. air carriers, foreign repair stations, and their employees, and potentially expose U.S. facilities to foreign retaliation.

The legislation requires:

- Inspections of foreign repair stations without notice to the facility.

- Annual reporting by airlines to the FAA about where heavy maintenance is performed outside the United States and any defects discovered within 30 days of an aircraft’s return to service.

- Direct certification by the FAA of supervisory personnel and those authorized to approve an article for return to service at foreign repair stations performing heavy maintenance unless the FAA determines that those individuals are already certificated under an equivalent regime.

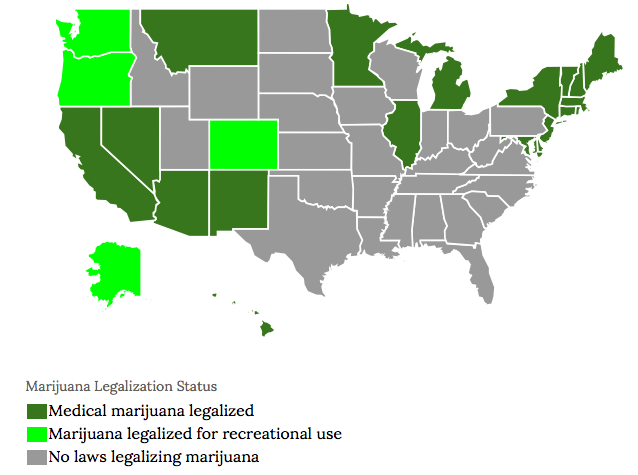

- FAA publication of a final drug and alcohol testing rule within two years of the bill’s enactment. If the agency fails to finish the assignment on time, the FAA administrator would be required to personally approve all international travel by FAA employees.

- Security threat assessments for foreign repair station employees.

Parallel legislation (H.R. 1716) was introduced in the House by Rep. Marcus Molinaro (R-N.Y.) on March 22. It includes additional restrictions, such as a prohibition on U.S. air carriers contracting for maintenance or the FAA issuing new certificates in countries that have Category 2 status based on the FAA’s International Aviation Safety Assessment. H.R. 1716 has 33 cosponsors.

ARSA opposes the legislation for several reasons, including the absence of any safety issue, a lack of FAA resources to accomplish all the bill requires, additional costs and burdens for foreign repair stations and their airline customers, and the risk of tit-for-tat retaliation against U.S. facilities by foreign authorities. While unions representing airline mechanics have promoted anti-contract maintenance language for decades, this is the first time a Senate bill has been introduced, let alone one with Republican support.

U.S. ARSA members are encouraged to contact their members of Congress to express opposition to the bill; foreign members should contact their embassies in Washington, D.C. or their home authorities to express concerns.

3/30/23 -What ARSA Has Done Lately

From the “ARSA Works” section…

Symposium Briefing – What Has ARSA Done Lately

Executive Director Sarah MacLeod and Executive Vice President Christian Klein opened the Symposium portion of the Annual Conference on March 16 with their annual “What We Have Done Lately” presentation. The brief session includes updates about key work performed by the association in the last year as well as instruction for maximizing membership value while helping move the enterprise forward. The briefing is provided in its entirety for the benefit of members.

Executive Director Sarah MacLeod and Executive Vice President Christian Klein opened the Symposium portion of the Annual Conference on March 16 with their annual “What We Have Done Lately” presentation. The brief session includes updates about key work performed by the association in the last year as well as instruction for maximizing membership value while helping move the enterprise forward. The briefing is provided in its entirety for the benefit of members.

Welcome & Introductory Remarks ![]()

Find out how the association is advocating for your interests with legislators, regulators, and the media. Information on how you can help advance the industry’s collective interests.

Sarah MacLeod, Executive Director, ARSA

Christian Klein, Executive Vice President, ARSA

2/6/23 - A Moving Experience?

February 6, 2023

From the “Membership” section…

A Member Asked…A Moving Experience?

Q: We will be moving to a new facility at the end of Q2 2023. Is there a checklist for regulatory items that need to be accomplished. I am new to this position and have never had to make changes to a repair station certificate. Let me know if you can help point me in the right direction.

A: Let’s start with the regulations that apply to a change in location, so you can understand what the agency should be requesting.

Section 145.105(a) states that “[a] certificated repair station may not change the location of its housing without written approval from the FAA.”

The request for written approval starts with submitting an application (FAA Form 8310-3); follow the instructions and in block 2 “reasons for submission” mark “Change in location or housing and facilities.” Enter the new address in “other” under block 2 along with a “see attached letter.”

The “attached letter” should explain how work will be accomplished before, during, and after the move. While the agency may attempt to stop work during the move, it should not do so since the purpose of giving approval is to allow work to continue. ARSA has a template letter that attempts to outline the information the company should provide about the move to ensure the agency the work will be accomplished in accordance with part 43 and the repair station manual and quality system.

Obviously, one of the things that will need to be done is updating the manuals to reflect the new location’s layout, etc. If you plan on using old paperwork until it is exhausted, explain how the paperwork will be made to reflect the new location after the move, e.g., a sticker will cover up the old location.

ARSA’s template letter is available as a free tool for members. You can get yours by requesting the entire .zip folder of forms, letters, and other documents included in the “tools.” Go to arsa.org/publications, scroll to the Order Form at the bottom of the page, select “Tool(s) for ARSA Members (Any),” and complete the form.

12/6/22 - Scaffolding for Career Building

December 6, 2022

From the “Creating Careers” section…

Scaffolding for Career Building

By Brett Levanto, Vice President of Operations

The association often reports on its efforts to bolster aviation careers rather than the workforce. It’s intentional.

Of course, the “w word” does appear – purely for the sake of good diction some variety is needed – but the team focuses on what employment means for the people working in aerospace. Working in our industry is not a job, it’s a career. When both employers and individuals think in those terms, we are better positioned to understand how professionals enter the industry and evolve. Not only can a first job in aerospace take you anywhere, but the candidates for those positions can and should be found all over. In ARSA’s push to foster aviation careers, the association has been clear and consistent in two key messages to its members:

(1) Aviation employers must think expansively about the broader ecosystem of technical talent. From old-school repair shops to advanced manufacturing facilities, the demand for what we used to call “blue collar” technical employees is broader and more colorful than ever before. Aviation doesn’t pretend to be special; it is. That knowledge must be used to embrace the industry’s place in the larger world.

(2) Maintenance providers must be ready to learn from good examples across all these industries. Like the automotive training program showcased at the 2022 Annual Conference, there is something instructive in every attempt at building skills.

ARSA’s colleagues at the Aircraft Electronics Association provide such an example. The AEA Apprenticeship Program, launched in 2019, is a U.S. Department of Labor approved Competency-Based Occupational Framework (CBOF) for Registered Apprenticeship programs. The AEA website explains: “CBOFs are designed by industry subject matter experts and define the purpose of an occupation, the job functions that are carried out to fulfill that purpose, the competencies that enable the apprentice to execute those job functions well, and the performance criteria that define the specific knowledge, skills, and personal attributes associated with high performance in the workplace.”

AEA President Mike Adamson, who helped lead the program’s development, explained it was produced based on the standards in part 145 after reviewing guidance in ACs 145-9 and 145-10. The technical aspects of the program were designed with input from maintenance providers and manufacturers and are meant to offer a shell for each company to build out with specific procedures. When tailored to the procedures of a facility, it provides foundational knowledge and specific competencies for technicians and is a pathway to individual certification. (The FAA acknowledged that completion of the entire program would satisfy the “formal training” requirement for repairman eligibility in

§ 65.101(a)(5)(ii).)

“[The framework] could be many things,” Adamson said. “A small shop picks it up and picks things out of it to build qualifications for their employees. A larger shop could pick it up soup to nuts and install the whole program. It’s got … a lot of potential for different things depending on how you want to use it.”

That potential is ARSA’s point of focus for its members, both for organization-wide development and individual aspiration. For the business, the 13 job functions identified by AEA create a “scaffolding” on which a tailored personnel development program can be built, defining required knowledge and experience (§ 145.151), outlining training to ensure capability to perform tasks (§ 145.163), and organizing qualifications on employment summaries (§ 145.161(a)(4)). For individual technicians, frameworks like AEA’s can be roadmaps for personal growth and development; after meeting “level 1” qualifications, ambitious professionals can progress to more-advanced study.

With these kinds of structures – and the thinking that goes behind them – we build careers.

ARSA encourages its members to review programs like AEA’s, which can be found at aea.net/apprentice, and to share other examples of apprenticeship, career development, and personnel advancement programs with the association via arsa.org/contact.

11/4/22 - Taking Charge Not Taking Over

November 4, 2022

Turning New Leaves

The changing seasons — the northern hemisphere heading towards winter — are a good reminder that ARSA is always growing. This edition of the hotline shows how it is undergoing alteration right now.

From the “President’s Desk”…

Taking Charge, Not Taking Over

In the run-up to October’s annual meeting of ARSA’s Board of Directors, I met with then-President Terrell Siegfried and the association’s executive team. Under the board’s electoral process, as the sitting vice president I was the presumptive candidate to succeed Terrell in the top volunteer position. The purpose of our meeting was to “wrap up” his year-long term and look ahead to mine.

The groundwork Terrell laid by focusing on membership development will endure – ARSA’s members are the weight behind its punch, as he is fond of noting – and I plan to help expand that focus to include all the ways ARSA empowers industry to take action for the collective good.

In all of my dealings with ARSA – beginning with my time as ad hoc government affairs chairman – I’ve quickly learned how to balance my business’ policy interests with the broader needs of everyone performing work under the aviation safety rules (whether in the United States or anywhere in the world). The association’s magic is in turning a chorus into a singular voice, one that calls out for improvements benefitting all maintenance providers.

As members, we best support this group engagement when we take charge of our own issues. “Taking charge” in this sense doesn’t mean dominating others but amplifying the concerns and needs of all. To ensure we all make the most of this opportunity, I intend to spend my term as president focusing on how ARSA’s growing membership can more effectively engage with regulators and legislators.

In that spirit, I’ll start my year with you by encouraging good use of the resources and tools that ARSA has already developed for us:

(1) Take an ARSA training class, then work with the team to incorporate these online sessions into your company’s training program (including developing new ones).

(2) Broaden ARSA’s reach by getting all contacts in your company registered in the member database. Make reviewing your organizational profile (which Kimberly Dimmick will send every renewal cycle) as important to that process as sending payment.

(3) Use ARSA publications. Both the free “tools for members” and the RSQM Compilation provide concrete benefit from the association’s years of experience; they will help you improve your own procedures and engage on issues that matter to us all.

(4) Show your face at the Annual Conference. Registration will open in December for the 2023 event, which will run from March 14 through 17.

There are a lot of ways to make the most of your ARSA membership. Following through is something you do not only for yourself and your business, but for all.

|

Josh Krotec 2023 ARSA president | First Aviation Services, Inc. senior vice president |

9/6/22 - Share Your News!

September 6, 2022

In this edition…

Connections

Whether its personal interaction at an event or fitting together the many details of an aviation business, this edition of the hotline gives members plenty to prepare.

From the “Membership” section…

Share Your News!

In addition to informing members of its work on the aviation maintenance industry’s behalf, ARSA uses its communications to celebrate the great work by repair stations, operators, manufacturers, service providers and everyone else with an interest in aviation safety. The association’s team fills its weekly Dispatch with news and updates from all over the world.

Ensure that your message gets out so your colleagues can celebrate with you by sending news items, press releases, and other updates to arsa@arsa.org. The team reviews all incoming content for potential inclusion in ARSA newsletters. Get the association on your distribution list today.

Note: The Dispatch is a news roundup that always links to primary sources. For best chance at inclusion, provide a link to your content. Acceptable sources include industry news or general media sites as well as your own hosted webpages/blog posts.

ARSA Newsletters and Outreach

Member contacts should regularly receive the following general communications from the association:

Weekly: Every Wednesday the Dispatch is distributed.

Monthly: The hotline is distributed the first week of each month (members only).

Various: Member alerts regarding specific events, activities or updates demanding specific attention are distributed as needed.

Membership Term Dependent: Renewal reminders begin flowing out 90 days before the expiration of membership term.

In addition to these large-scale distributions, ARSA team members will use their @arsa.org email addresses to coordinate directly with member contacts related to association business and industry matters.

Special Advertiser Distributions

From time to time, ARSA provides a mechanism for sponsors of its Dispatch and hotline periodicals to reach readers directly through “blast” emails. This advertising option gives companies a chance to show support of the association and to provide useful information and resources to readers. While receiving this message, ARSA subscribers and members should be assured that:

- The frequency of special “blast” messages is kept to a minimum. This maintains the special focus provided to advertisers sending the messages and prevents “overload” in readers’ inboxes.

- Advertisers are not provided direct access to newsletter subscription lists.

- ARSA team members review and approve all messages prior to distribution.

For questions about ways to stand up for the association through ARSA’s advertising options, contact Brett Levanto.

Advertising Solicitations

The association has recently decided to return advertising sales in house. Beginning Nov. 3 – active advertisers will hear from the team prior to that – only personnel with @arsa.org email addresses will solicit advertising sales. Interested in supporting ARSA and sharing your good work? Contact ARSA.

Spam Filters and Firewalls

It can sometimes be difficult for organizations like ARSA to get messages into your inbox. To ensure you have access to every periodical, alert, and update, place the following domains are on your “safe list”:

@arsa.org

@potomac-law.com

To learn more about ARSA’s communications efforts – including how to advertise – visit arsa.org/news-media. For assistance with technical issues, consult your organization’s IT department/assistant as necessary.

8/8/22 - Being Entitled

August 8, 2022

In this edition…

Knowing

From basic compliance to dealing with the government to relying on your own business network, this edition of the hotline re-enforces the value of knowledge.

From the “Legal Briefs”…

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

Layman Lawyer – Being Entitled

By Brett Levanto, Vice President of Operations

I’ll admit that “entitlement” can be a tricky word. In Washington, D.C. politics, it describes often-contentious government spending programs like Social Security and Medicare. In general culture and especially on some annoying corners of social media, the word describes the attitude and behaviors of people seeking special treatment or attention.

In aviation safety, there’s a very important and positive use of the term. In fact, this layman lawyer encourages his counterparts in the industry to remember just how “entitled” they are.

In January and again last month, this space provided a “layman lawyer” overview of the FAA’s Compliance Program. So far, this series has covered agency guidance to illustrate how inspectors and other officials are supposed to understand their responsibility to use critical thinking in assessing deviations for corrective action under that program. It’s useful to know how the agency instructs its people, but certificate holders must focus on the plain language of 14 CFR.

When working with companies seeking repair station certificates – particularly users of ARSA’s RSQM Compilation – ARSA Executive Director Sarah MacLeod often reminds them of an important statement in § 145.53(a), which says that with few exceptions “a person who meets the requirements of [part 145] is entitled to a repair station certificate with appropriate ratings prescribing such operations specifications and limitations as are necessary in the interest of safety.” (Emphasis added.)

The word “entitled” is not defined in 14 CFR. The common definition in the Merriam-Webster Dictionary is “having a right to certain benefits or privileges.” While an aviation safety inspector’s attitude may make it seem that certification is a blessing bestowed by the government, it is a right earned by persons demonstrating compliance with the plain language of the applicable rules. It is based on this simple principle that the association stands up to the government in showing compliance.

The submitter of this month’s “A Member Asked” showed the basics of this understanding. An inspector challenged the repair station’s manual revision process, citing a paragraph in Order 8900.1. “This is his guidance material, but to us it is not regulatory,” the member said.

Starting and ending with that awareness is essential to getting and maintaining a certificate and dealing with the government along the way. A certificate holder’s compliance responsibility is the minimum standards of the rules. When the FAA challenges you, show how your systems and procedures meet those standards and not the guidance provided to the aviation safety inspector.

By meeting the requirements of the rule, you are entitled to have and hold a certificate and its associated privileges. You earn this entitlement.

Help continue this discussion. Submit your “layman lawyer” experiences or questions via arsa.org/contact.

7/5/22 - Georgia on My Career-development Mind

In this edition…

Poetry in Motion

From musicals to Shakespeare to jazz standards, this edition of the hotline only hints at the full beauty of the association’s constant work to improve the aviation maintenance world.

From the “Quality Time” section…

Editor’s note: The views and opinions expressed by contributing authors do not state or reflect those of ARSA and shall not be used for endorsement purposes.

Georgia on My Career-development Mind

By Vance Zeumer, Manager – PMA Engineering, Chromalloy

Chromalloy – ARSA Corporate Enterprise Member – is an active participant in the Georgia Rural Collaborative Coalition. Meetings include representatives from a wide cross section of education professionals, state and county government, outside consultants, education auditing boards as well as the Air Force, Army, and Civil Air Patrol.

The coalition’s focus is on select rural counties in Georgia, but its principles can be applied to any county or school system and offer guidance for the broader technical skills development community. Mentors and industry partners are being cultivated near target counties, but participation in the coalition comes from across the entire state. Progress reports from action committees focus on military and aviation industry mentorship. The committees are building programs targeting students with relevant interests in aviation, including piloting, maintenance, engineering, manufacturing, computer science, and advancing technologies for electric aviation and advanced air mobility. Students can be connected to opportunities in a Georgia Charter and Career Academy (CCA) or an industry partner.

The initial goal is to help high school students pursue CCA training opportunities. Ideally, training would lead to an industry recognized certificate. Chromalloy has recognized that active participation in the Georgia effort (or seeking similar state-wide opportunities elsewhere) places maintenance providers at the forefront of hiring these students.

To encourage other ARSA members participation in this and other coalitions, I am pleased to provide an opportunity for input to Georgia’s CCA curriculum so proper skills are developed for the maintenance community in this state, which can lead to mentorship and guidance to candidate students by employers in other states.

The August meeting is scheduled for Aug. 31 in Eatonton, Georgia on Aug. 31; it is open to any Georgia employer. Even if you are not from Georgia, though, the efforts being made, and the resources being created can be helpful to any employer in the aviation industry.

Please contact me at vzeumer@chromalloy.com for ways to get involved.

McKinsey & Company articles

- Defining the skills citizens will need in the future world of work

- The future of work in America: People and places, today and tomorrow

- Thomas L. Friedman and James Manyika: The world’s gone from flat, to fast, to deep

Southern Regional Education Board (SREB)

6/7/22 - Campaign Contributions

June 7, 2022

In this edition…

Hitting the Trail

The U.S. midterm elections are rapidly approaching. This edition of the hotline covers political engagement in a way that’s less about campaigning for office and more about advocating for your industry.

From the “Legal Brief”…

Editor’s note: This material is provided as a service to association members for educational and informational purposes only. It does not constitute legal or professional advice and is not privileged or confidential.

Giving Campaign Contributions

By Christian A. Klein, Executive Vice President

There’s a lot at stake in this year’s mid-term congressional elections. Republicans smell blood in the water and are bullish about their chances of retaking both the House and Senate. Democrats aren’t going to give up control of Congress without a fight and the leaked Supreme Court decision has activated the party’s liberal base.

The outcome is uncertain, but this year’s elections will certainly be among the most expensive. At some point in the next few months, it’s likely you’ll be asked by a congressional candidate or a political action committee (PAC) for a campaign contribution. Making campaign contributions is a way to make your voice heard in the process. Talking to candidates when they’re “dialing for dollars,” attending fundraisers, or meeting to deliver a check is an excellent way to build visibility and an opportunity to discuss important issues.

A candidate won’t do what you ask just because you give them a check (that’s called bribery and is a crime); but it’ll put you, your company, your industry, and your issues on their radar screen. Because ARSA wants its members to be politically active and exercise their rights, this month’s “Legal Brief” provides some basic guidelines for providing campaign-related financial support.

The Federal Election Campaign Act (FECA), which is administered by the Federal Election Commission (FEC), establishes limits and prohibitions on who can get involved in campaigns. Corporations (including nonprofits), banks, and labor unions are prohibited from using general treasury money to make direct contributions to candidates (independent expenditures by these entities – advertising in support or opposition to a candidate – are beyond the scope of this article). Partnerships and limited liability companies (LLC) can make contributions if it is attributed as income for tax purposes to one or more of the partners or owners.

The primary sources of congressional campaign funds are individuals and PACs. A PAC is a separate segregated fund set up by a corporation, bank, or union to receive contributions from individuals. The PAC can then use those resources to make bigger contributions to candidates. (By law, trade association PACs can’t ask you for a contribution unless you’ve consented to be contacted, so be sure to provide ARSA PAC with prior approval.)

Even though all contributions (directly to candidates or indirectly via PACs) must come from individuals, not all individuals are eligible to contribute. By law, foreign nationals are not allowed to make contributions in conjunction with U.S. elections; the contributor must be a U.S. citizen or permanent resident (green card holder). Federal contractors are also prohibited from making contributions; however, the ban applies to “persons” who have entered or who are bidding on a federal contract. In most cases, the contractor is likely to be a corporation (which is already prohibited from contributing); however, contributions from partnerships and limited liability companies with federal contracts are also banned, as are contributions from individuals under contract to the federal government and sole proprietors of businesses with federal contracts.

In addition to sources of campaign funds, the FECA also puts limits on how much individuals and PACs can contribute to candidates for each election. Keep in mind that in a normal cycle, a congressional candidate will have two elections: the primary (where the party chooses its candidates) and the general (which happens in November). However, the contribution limits also apply separately to runoffs and special elections.

In the 2021-2022 election cycle, an individual may contribute:

- $2,900 per candidate per election.

- $5,000 to a PAC.

- $10,000 to a state, district or local party committee.

- $36,5000 to a national party committee.

In 2014, the Supreme Court struck down limits on the total or aggregate than an individual can contribute, so you can give maximum contributions to as many candidates as you want. Also, an individual cannot make cash contributions that exceed $100 (because cash is harder to track) and anonymous contributions are limited to $50.

For FEC purposes, the term “contribution” means more than just money; the term is defined broadly as anything of value give, loaned or advanced to influence a federal election. In-kind contributions are goods or services offered for free or less than the usual charge; paying for something on a candidate’s behalf is also considered an in-kind contribution. Campaigns must report in-kind contributions and they count against contribution limits.

As part of our 2022 campaign strategy, ARSA strongly encourages its members to host candidates at company facilities. The meetings are an excellent opportunity for a candidate to gain knowledge about your business and industry and meet employees (i.e., voters). Hosting a standard facility visit (meeting with company execs/owners and a tour) shouldn’t raise campaign issues. However, if you want to host an event at your facility (i.e., a rally or fundraiser for a candidate), but sure to familiarize yourself with the applicable rules.

Supporting candidates and industry PACs is just one way to impact America’s political process. ARSA is standing by to support your engagement.

5/10/22 - Collaboration Brings Results

May 10, 2022

In this edition…

Connections

From honoring absent friends to collaborating with allies to welcoming new leaders to engaging the government, this edition of the hotline shows just some of the ways ARSA builds connections for the good of its industry.

From “The President’s Desk”…

Collaboration Brings Results Across the Globe

According to Oxford Languages, collaboration is “the action of working with someone to produce or create something.” In the international business of aviation, collaboration with many diverse people and organizations produces useful results.

From its inception, ARSA understood the international nature of aviation and the need for mutual interests to be identified and to prevail. To that end, collaboration is key. That’s why NORDAM was a founding member of ARSA and why we continue our allegiance to the association today. This representational powerhouse facilitates collaboration among individuals, companies, unions, trade associations, appointed and elected government officials, local organizations, and foreign aviation authorities.

The association operates with limited resources, using its expertise to identify issues that must be addressed and support those matters that are being addressed. Whenever ARSA learns of a current or future need, it begins the process of collaboration. It seeks allies from across a wide ranging spectrum of parties to develop mutual positions. Even if a given concern doesn’t directly affect association members but instead their customers and business partners, we still support any resulting initiative with informational resources for the broadest perspective for decision-making.

Another level of collaboration that strengthens us as an organization? Collaboration among members. As president of ARSA, I want all members to understand the depth and breadth of its collaborative – and independent – process. To spread the word to reach every maintenance organization, and inspire them to join.

Why should every MRO be part of ARSA? The first reason is to receive the most current information on almost any regulatory compliance topic confronting an international aviation maintenance business. Incidentally, this is why it’s critical for you to respond to ARSA surveys – so we can keep our finger on the pulse of this community. Did you know an ARSA representative responds to written member queries within two business days and often sooner with practical and understandable answers? Even if we don’t know the answer immediately, because of our collaboration efforts, ARSA readily finds another dependable source to inform our response.

The next reason is the power of ARSA’s representation on the most important issues to aviation maintenance organizations. Our collaboration with allies during the worst of the COVID pandemic resulted in direct monies for aviation maintenance organizations. And ARSA leadership on the workforce development front resulted in a multi-year grant program supporting education of aviation maintenance technicians.

If those two reasons somehow are not convincing enough, I can tell you from personal experience ARSA’s publication of model documents to establish compliance with 14 CFR part 145 was invaluable to NORDAM. These documents empower any user to move from quality control to quality assurance to establish safety systems. Likewise, ARSA’s global footprint and its powerful collaborative capabilities helped our company establish a thriving certificated repair station in Taiwan. That’s across the globe from our headquarters in Tulsa, Oklahoma. And we achieved it in the midst of an unprecedented global pandemic.

If you have any questions the association team can’t answer about the importance of collaboration among all certificated maintenance organizations through ARSA membership: Please send me a message. I will explain in more detail why, as a leading innovator in composite repair for aerospace, NORDAM is convinced of it.

|

Terrell Siegfried 2022 ARSA president | NORDAM assistant general counsel and corporate secretary |

2/4/22 - Kissing Your SISter

February 4, 2022

In this edition…

Process Improvement

ARSA works key issues for years, revisiting and upgrading past efforts (with the help and feedback of members) regularly. This edition of the hotline delivers both new and familiar tools for use in pursuit of long-known goals.

From the “Regulatory Update” section…

Kissing Your SISter

The European Union Aviation Safety Agency (EASA) recently conducted Sampling Inspection System (SIS) visits in the United States. SIS visits are part of the U.S.-EU Maintenance Annex Guidance (MAG), and are a method by which the bilateral partners verify oversight of each other to the requirements of the MAG.

Reports that the SIS visits are resulting in findings directly against U.S. repair stations are troubling. In recent SIS visits, accusations that the MAG does not allow U.S. repair stations to use ARSA’s E-100 form to document a 14 CFR part 43 inspection of new parts that are not accompanied by Form 8130-3 issued by the production approval holder (or an FAA-designee) were brought to ARSA’s attention.

In 2016, the FAA provided ARSA a letter stating that the proper use of ARSA’s E-100 form, in combination with an 8130-3 (with a maintenance approval for return to service) complies with FAA regulations and the MAG. While the E-100 issue is being discussed yet again by the two authorities, we wanted to provide an understanding of how the SIS visits are supposed to work (see a complete review of the form’s functions in this edition of the hotline).

Bilateral relationships between civil aviation authorities (CAAs) are based on the notion of “trust but verify.” Before signing a bilateral agreement, and technical implementation procedures or maintenance implementation procedures or maintenance annex guidance, authorities audit each other’s legal system, regulations, and surveillance program to ensure the two systems of governance result in equivalent safety outcomes. Significant regulatory differences are addressed through the issuance of Special Conditions. Once the agreements are in effect, the authorities monitor each other’s oversight of the Special Conditions to maintain confidence in the equivalent level of safety and control.

In addition to the SIS visits (which are authorized by section 2.2. of the U.S./EU MAG), the signatories notify one another of regulatory changes, provide training to inspectors overseeing facilities operating under the MAG, and follow specific procedures to resolve differences in interpretation.

SIS visits are audits of the CAA’s oversight, not of the repair station or approved maintenance provider. Under the FAA/EASA MAG, only in the case of a Level 1 finding that lowers the safety standard and seriously impacts flight safety is the visiting CAA (in this case EASA) authorized to act directly. In the case of visits from EASA to monitor the FAA’s oversight, the MAG’s sec. 2.2.7.3 clearly states that, “For all other findings raised in the [CAA] visit report, [Approved Maintenance Organization] follow-up of the findings shall be accomplished by the [Flight Standards Office] and reported to EASA for closure with a copy sent to AFS-300.” In other words, corrective action on the part of the U.S. repair station after an EASA visit and finding is in the hands of the FAA, which must advise EASA when appropriate actions to resolve an issue have been completed.

On the other hand, if the SIS visit results in an issue of interpretation, the MAG sets out a process by which the matter can be elevated through the chain of command, meaning informal resolution by the respective Directors of Flight Standards or their designees, elevation to the Joint Maintenance Coordination Board (JMCB) and, if necessary, to the Bilateral Oversight Board (BOB).

In the absence of a level 1 finding, U.S. repair stations should understand the SIS visits do not impose any immediate obligation to change their practices unless the two authorities agree on the appropriate resolution in accordance with the MAG’s Special Conditions. And even when that is the case, the process by which corrective action and follow up is achieved resides with the host country’s CAA, in this case the FAA.

In cases where there is a disagreement between the agencies on how the Special Conditions should be interpreted, the MAG spells out a clear process whereby the issue can be resolved in an orderly, rather than precipitous, manner. The resolution is not to create a finding against the repair station or approved maintenance organization.

If you have faced issues related to a SIS visit, contact ARSA. To see all of ARSA’s coverage of the U.S./EU MAG, visit arsa.org/mag.

1/7/22 - Direct Access

In this edition…

Worth Doing Again

By building on success and learning from shortcomings, we get better every time around.

Year in review…

Direct Access

Delivering newsletter emails is a constant challenge. Figuring out how to play nice with firewalls, spam blockers and subscription issues is a constant struggle.

ARSA now provides an avenue for members to access the hotline’s landing page directly. To jump right into the “2021 Year in Review” edition, complete the form below, verifying your member information. (The form will remain on ARSA’s newsletter webpage; it will continue to direct to the current edition.)

12/3/21 - FAA Training on FFP

December 3, 2021

In this edition…

Life of the Party

This edition of the hotline looks expectantly towards the 2022 Annual Conference, with some key updates about the association’s ongoing advocacy. Reader challenge: Count the number of times the phrase “maintenance community’s premier substantive event” appears.

From the “Training” section…

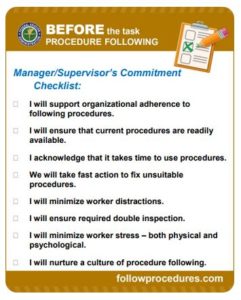

From the FAA – Failure to Follow Procedures

ARSA invites members to take advantage of the FAA’s training session “FFP: The Buck Stops with Me.” Here’s the session description from the agency:

While aviation maintenance personnel are fully aware of the consequences of failing to follow procedures (FFP) – and have likely received training on this issue – FFP continues to be one of the leading safety issues in aviation maintenance.

The purpose of the “FFP: The Buck Stops with Me” course is to help aviation maintenance personnel better understand and appreciate how an organization’s culture affects safety with respect to FFP. Once learners have completed the course, they will be equipped with the tools to champion a commitment to reduce FFP events in their working environments.

For session information and to register, click here.

11/5/21 - From ARSA's President

November 5, 2021

In this edition…

Who We Are

As ARSA turns towards a new program year, its team and board continue to focus on its core mission for the maintenance community. This edition of the hotline highlights ongoing work with a little reflection about shared commitment to the association.

From ARSA President Terrell Siegfried

Throwing Our Weight Around

Fellow ARSA member,

While I am relatively new to the board, I’m proud to represent a company that was a founding member of the Aeronautical Repair Station Association. That company, NORDAM, was itself founded on family values more than 50 years ago in Tulsa, Oklahoma by my father, Ray Siegfried. He foresaw a need to represent the shared interests of the global civil-aviation maintenance industry, providing seed money for the association in 1984.

Both organizations have grown through the decades by turning challenges into opportunities. Today, both are internationally known hard-hitters in the industry they serve.

In addition to aviation and many other interests, my dad loved boxing. So, while working with the ARSA team on a news release announcing my election as 2022 president, a familiar phrase kept coming to mind: “ARSA punches way above its weight class.” This consortium of a few dedicated, extremely knowledgeable people – fueled by a lean operating budget – has left a mark much greater than the sum of its parts on the global aviation marketplace.

Here’s their secret: While ARSA’s team provides the punch, its members provide the weight. Through investment, time and expertise, every company and contact in our member directory allows the association to be seen, heard and remembered while demanding consideration from international regulators and legislatures.

As your president, I am adding my personal weight to the association’s punch by asking you to practice your footwork, starting with these simple steps (click the links to learn more):

(1) Keep your membership in good standing. If your membership has lapsed, take the time to renew it; you won’t regret it. ARSA membership is insurance against future industry issues.

(2) Get everyone in your company signed up to receive ARSA communications to stay up to date on the latest industry news.

(3) Sponsor, register for and attend our Annual Conference to visit with congressmen, meet industry counterparts, show your face to international regulatory leaders and bring home lessons on how government action impacts your business’ future.

(4) Respond to the annual member survey, as well as the “quick questions” we ask every month. Your feedback shows what is important to you and prepares ARSA to fight for it.

(5) Recruit new members! Each one earns you a discount on your dues. In fact, scout enough rookies and your membership is free.

(6) Actually use your member benefits – These include access to model publications, discounts on training, and the right to Ask ARSA First! By taking full advantage of your member benefits, you’ll score a return on investment every year.

Like any boxer worth his salt, everyone who benefits from ARSA’s good work must pay their dues. This year let’s put in the effort to keep our stance strong as we generate the power and defensive skills to continue our mutual winning streak.

Sincerely,

Terrell Siegfried

2022 ARSA president | NORDAM assistant general counsel and corporate secretary

10/4/21 - Much to Report

October 4, 2021

In this edition…

Here We Go

The arrival of fall brings seasonally flavored coffee drinks, harvest-focused family activities and the ramp up of global aviation policy activity. This edition of the hotline won’t provide ARSA’s position on pumpkin-spiced lattes, but it will review a busy September of engagement on behalf of the maintenance community.

Since there was so much to report about September’s work, this “hotline highlight” directs readers to their own editions to check out four different updates (though you should read it all!):

From the “On the Move” section…

A Talent Showcase

The 2022 Aerospace Maintenance Competition will be held in conjunction with MRO Americas from April 25-28 in Dallas, Texas. The AMC provides an opportunity for current and future maintenance professionals to showcase their abilities and offers industry employers a chance to support and benefit from the skill and competitive spirit of these professionals.

From the “Training” section…

Thinking Simpler on IA Renewal

For several years, ARSA has been encouraging the FAA to streamline its procedures related to Inspection Authorization renewal course acceptability. In September, the agency began accepting comments on a draft Advisory Circular — a chance for public engagement in pursuit of sensible acceptance.

From the “ARSA Works” section…

CMT Expands ARSA’s Global Reach

One of the ways the association engages with industry and regulators to iron out problems in bilateral relationships is by participating in regular meetings of the Certification Management Team.

9/7/21 - 'Like Google for Regulations'

September 7, 2021

In this edition…

The Right Tools

From helping the FAA build a research database to making smart personnel decisions to navigating new international regulatory structures, this edition of the hotline shows how ARSA makes good on your investment.

From “Quality Time”…

Editor’s note: The views and opinions expressed by contributing authors do not necessarily state or reflect those of ARSA and shall not be used for endorsement purposes.

“Like Google for Regulations”

By The FAA DRS Development Team

What do the letters DRS mean to you? The FAA hopes they will come to mean quite a lot (and asks for your help in the process).

The Dynamic Regulatory System is going to turn some heads. DRS is a comprehensive knowledge center that combines an ever-expanding number of document types from more than a dozen repositories into a single searchable application. It will keep growing.

Bottom line: When you’re researching the aviation safety rules, DRS will isolate what you need in moments, not hours.

“This is a win across the board: for AVS, FAA, and for all of aviation,” said Ali Bahrami, Associate Administrator for Aviation Safety at the time of the system’s release. “Building DRS has been a huge undertaking. We reached beyond AVS to our global aviation partners. There’s a vast diversity of the kinds of jobs we do—and the kinds of information each of us looks for. DRS is a tailor-made solution for individuals as they do their own regulatory research. It’s like Google for aviation safety.”

DRS is a treasure trove. It centralizes aviation safety rules and related guidance. It includes all information found in the Flight Standards Information Management System, the agency’s Regulatory Guidance Library and more than a dozen other information sources. Information is updated every 24 hours.

Search results include links among and between CFR sections and related guidance or supporting documents – more than two million are available for search via a complex search engine. Users can make basic searches or construct advanced queries, applying a variety of filters to browse pending, current and historical versions of all documents.

In a word, DRS never gets old.

“The system represents a giant step forward in providing consistency and standardization of regulatory interpretation,” said DRS Program Manager Pete Devaris. “Research projects that used to take days of effort now can be done with a few clicks and in a matter of minutes.”

Making good on that giant step demands taking further steps. The system’s initial operating capabilities far exceed the requirements set by congressional mandates for DRS development, but there is much to be done. The FAA needs ARSA members’ help – along with the support of the entire aviation community – to improve the resource. As the agency adds features and functionality, it needs feedback right now:

(1) Make sure drs.faa.gov is bookmarked on every computer in your facility and a regular stop for regulatory compliance questions. (EDITOR’S NOTE: The authors encourage you to make the DRS your first stop for questions, but graciously accepted the association’s reminder that members should “Ask ARSA First.”)

(2) Carefully review instructions available at drs.faa.gov/help.

(3) Every time you use the system, consider the experience. How could it be better? Submit thoughts by clicking on “DRS Feedback” on the top banner of the site and submitting the form.

The Dynamic Regulatory System is a comprehensive knowledge center of regulatory compliance material from the FAA Office of Aviation Safety. Get started with the DRS by visiting drs.faa.gov.

7/2/21 - A Member Asked...A Blind Umpire?

July 2, 2021

In this edition…

Connecting

ARSA’s work is about making connections, not just between regulatory requirements and business needs but between people. From changes within its own team to distributing government resources to reporting back on event presentations, this edition of the hotline demonstrates how those relationships are made and maintained.

From the “Membership” section…

A Member Asked…A Blind Umpire?

Q: Are you aware of a vision test, (e.g., Jaeger #2) requirement for maintenance personnel other than those performing NDI/NDT or Welding tasks?

I can find requirements for flight personnel (part of medical certificates), industry standards for welding inspections and have located AC 65-31 for NDI persons, but I am unable to find a regulatory requirement for persons performing visual inspection during maintenance.

We have local policies that require inspectors to have vision tests, but I trying to run down any regulatory requirements.

A: There are no direct requirements—the regulatory hooks that ultimately require maintenance personnel to have good eyesight are:

Section 145.155 that requires inspectors to be:

(1) Thoroughly familiar with the applicable regulations in this chapter and with the inspection methods, techniques, practices, aids, equipment, and tools used to determine the airworthiness of the article on which maintenance, preventive maintenance, or alterations are being performed; and

(2) Proficient in using the various types of inspection equipment and visual inspection aids appropriate for the article being inspected.

It is hard to be proficient in using the equipment and “visual” inspection aids without having good eyesight!

Another regulation (that applies to all maintenance personnel) is § 145.163 that requires the training program to ensure persons are capable of performing assigned tasks. While physical capabilities (eyesight) are not “training,” it is hard to argue that a person with bad eyesight is capable performing maintenance tasks, let alone be an inspector…although umpires may be blind (HA).

With respect to “normal” MRO personnel; the general requirement for all repair station personnel is found in section 145.151(b), which states that a repair station must “provide qualified personnel to plan, supervise, perform, and approve for return to service the maintenance, preventive maintenance, or alterations performed under the repair station certificate and operations specifications…” (Emphasis added.)

I don’t know how one would provide “qualified” personnel if they did not have necessary physical attributes – lifting 50 pounds, being flexible enough to maneuver appropriately for the work required, etc. Again, while this may not be a direct requirement for adequate eyesight, it certainly falls within ensuring proper qualifications are set forth by the certificate holder.

On the pragmatic side, it seems checking a person’s driver’s license, could be used to verify that the person can perform general maintenance tasks and verify that task was performed properly, provided s/he uses any “corrective lenses” noted on the license.

6/8/21 - New Bill Would Create U.S. Aviation Advancement Center

June 8, 2021

In this edition…

Turning Back Time

As parts of the world (hopefully) emerge from the pandemic, certain storylines have begun to reappear. From celebrating history to workforce challenges to restarting personal engagement with Congress, this edition of the hotline shows how ARSA makes progress in familiar ways.

From the “ARSA on the Hill” section…

Workforce Is Priority for Proposed Aviation Advancement Center

Senators Jim Inhofe (R-Okla.) and Tammy Duckworth (D-Ill.), longtime champions for U.S. aerospace jobs, are leading a new effort to strengthen America’s 21st century aviation workforce.

On May 21, the senators introduced a bill to create a National Center for the Advancement of Aviation (NCAA), which would “serve as a national, independent forum to facilitate collaboration and cooperation between all sectors of aviation and aerospace stakeholders and related partners, with a particular focus on aviation and aerospace workforce development.”

The legislation (S. 1752) directs the NCAA to:

- Promote development of a well-qualified, well-trained civil and military aviation and aerospace workforce.

- Research and develop new aviation and aerospace training materials and products.

- Coordinate the dissemination of grants for the development of aviation and aerospace oriented high school STEM education curriculum.

- Facilitate collaboration between institutions of higher education or other research institutions engaged in aviation, aerospace or related research or technical development.

Senators Cindy Hyde-Smith (R-Miss.), Marco Rubio (R-Fl.) and Ron Wyden (D-Ore.) joined Inhofe and Duckworth on the bill as original cosponsors. Rep. Andre Carson (D-Ind.) introduced parallel House legislation (H.R. 3482) on May 26 with nine cosponsors, including House Aviation Subcommittee Chairman Rick Larsen (D-Wash.).

The legislation has been endorsed by ARSA, as well as member companies AAR, HAECO Americas, StandardAero, ST Engineering North America, STS Aviation Group, Triumph Airborne Structures and the Wencor Group, among others.

The strong industry and bipartisan support bode well for the legislation, which may be included in larger infrastructure package later this year. In the meantime, please use ARSA’s grassroots action site – presented by Aircraft Electric Motors – to send pre-prepared message to your elected representatives urging them to support the bill. It’s quick and easy. Just go to arsa.org/congress.

5/11/2021 - Manual Transmission Comes Standard

May 11, 2021

In this edition…

Modeling Success

This edition of the hotline serves as the official release of ARSA’s Model Repair Station & Quality Manual Compilation. Learn what that means and how the compilation – and its authors – can serve your business.

From the Lead…

Manual Transmission Comes Standard

By Brett Levanto, Vice President of Operations

An email subject line from ARSA Executive Director Sarah MacLeod inspired this article announcing the association’s comprehensive repair station documentation system.

MacLeod’s message delivered a complete documented compliance system to a client of ARSA’s management firm for submission to the FAA in support of a repair station certificate. The subject line “Manual Transmission” described the email’s purpose and read like a reference to a car’s stick shift.

Driving a manual transmission demands attention, knowledge and understanding of the car’s machinery. While “sticks” no longer come standard on new cars and aren’t even available on many common models, they provide an apt metaphor for the development of a company’s repair station, quality, forms and training manuals as well as supporting documentation and resources: Your hands, energy, and awareness must be directly and constantly involved to make it work.

After more than a year of intense scrutiny, ARSA has finished its overhaul of the documents available for purchase by repair station applicants and certificate holders. The association’s original Model Domestic Repair Station and Quality Manual, along with its various supplements and supporting tools, had helped countless applicants and certificate holders since its initial release in 2003. With changes in the FAA’s oversight system and years of helping members (and clients) customize the available documents, the time was right for a complete redevelopment.

The resulting compilation is a system for not only showing compliance but enabling applicants and certificate holders to continually improve efficiency and manage economic realities. In the true spirit of “manual transmission,” purchase of the comprehensive compliance system includes consultation with ARSA’s experts to help customize the documents. However, at either the “basic support” or “full customization” level, the purchaser must be hands-on and drive the process: At least 60 hours of hard work by the applicant or certificate holder is needed to fully realize the benefits. For the documents to “work” (i.e., to comply with the rules, meet business needs, and actually be followed by employees) direct involvement by the company is required.

The results of the effort can be reviewed, and members can still receive the revamped Forms Manual and forms as a free benefit by visiting arsa.org/publications.

Regardless of the options you select when purchasing an ARSA model manual, a hands-on manual transmission always comes standard.

4/6/21 - Cautious Optimism

April 6, 2021

In this edition…

Living On

While the recordings made during the 2021 Annual Conference will carry on the voices of participants, their work will live on – like the memory of old friends and mentors – because of the long-term determination of ARSA and its team. This edition of the hotline chronicles the event and presses on towards the next one.

From “2021 Economic Outlook”…

Cautious Optimism for 2021 and Beyond

For more information about the Annual Conference, including access to recordings and other resources produced during the event, visit arsa.org/conference.

The annual rollout of the Oliver Wyman/ARSA MRO market forecast in conjunction with the ARSA Conference is a must-attend event for industry leaders, reporters and policymakers interested in the aviation maintenance economic outlook. However, the release of this year’s report took on new importance as repair stations to recover from the most challenging business conditions in the industry’s history.

The annual rollout of the Oliver Wyman/ARSA MRO market forecast in conjunction with the ARSA Conference is a must-attend event for industry leaders, reporters and policymakers interested in the aviation maintenance economic outlook. However, the release of this year’s report took on new importance as repair stations to recover from the most challenging business conditions in the industry’s history.

Oliver Wyman Vice President Tom Cooper presented the report during 2021 ARSA Conference’s Legislative Day on March 10. His general assessment was that, while it will take some time to recover to pre-pandemic business activity levels, 2021 will be a much better year for the maintenance industry than 2020.

It could hardly be worse.

According to Oliver Wyman, global demand for maintenance services fell from $82.9 billion in 2019 to an estimated $50.3 billion in 2020, a 40 percent drop. Cooper said that at the height of the disruptions in the spring of 2020, global air travel demand and aircraft utilization were off by 80 percent and 75 percent respectively from prior years. 2020 was also the first time in modern commercial aviation history that the industry experienced a year-over-year decline in the active global commercial fleet size with 57 percent fewer new aircraft deliveries and twice as many aircraft retirements than in recent years.

According to Cooper, the worst is behind us and, if current positive trends continue, global demand for the active aircraft fleet is expected to fully recover by the first half of 2022 and maintenance demand will reach pre-COVID levels by second half of 2022.

However, there is still considerable uncertainty in the forecast, particularly when it comes to air carrier maintenance activity. Cooper discussed the four factors that will drive airline recovery: epidemiological timeline(whether and how the pandemic is constrained), traveler sentiment (whether people feel safe getting on aircraft), government restrictions (whether visitors will be freely welcomed from other countries) and macroeconomic conditions (whether the direction of the global economy will support a rebound in leisure and business travel).

Under Oliver Wyman’s most optimistic scenario, the global maintenance industry could grow to $117.6 billion per year by 2031. That assumes continued progress with vaccine distribution and a return to pre-COVID passenger demand levels by the end of 2022. If there are problems with vaccine distribution and/or efficacy or if the global economy fails to rebound, demand for maintenance services could be $15 billion lower than anticipated by the end of the decade.

The economic downturn took a significant toll on the industry’s workforce. An ARSA report released in mid-2020 determined repair stations had lost of quarter of their workforce to layoffs and furloughs in the first half of last year. However, with recovery taking hold, the industry workforce has rebounded slightly and is still an important driver of the U.S. economy. Oliver Wyman estimates that there are 273,000 Americans currently working in the maintenance sector (down from 296,000 pre-pandemic). Of those, two-thirds work at repair stations, 22 percent work for aircraft parts manufacturers and distributors and 11 percent are employed as airline mechanics.

“After an incredibly difficult year, ARSA members we’ve spoken to are generally optimistic about the future,” ARSA Executive Vice President Christian A. Klein said. “But as demand for maintenance services picks up, repair stations are once again facing a technical talent shortage, which we expect to be even more acute than it was pre-pandemic. After a year of just trying to survive, companies are having to pivot quickly back to recruitment and workforce development. It’s definitely causing some whiplash.”

The 2021 report’s executive summary and Oliver Wyman’s Interactive Forecast Dashboard are accessible at arsa.org/news-media/economic-data. The full report is available exclusively to ARSA members free on request. A recording of Cooper’s presentation is available to conference registrants via the event’s Online Meeting Organizer.

2021 Global Fleet & MRO Market Assessment

prepared by Oliver Wyman

Executive Summary: 2021 Global Fleet & MRO Market Forecast

Oliver Wyman Interactive Forecast Dashboard

11/6/20 - ...Except When They Don't

November 6, 2020

In this edition…

“Brave New World”

As Americans acted out their “voting plans” in the U.S. presidential election, ARSA’s work on behalf of the global aviation industry continued apace. Regardless of the political winds, the association’s work in October demonstrated that it stays on course.

From the “Legal Brief”…

Lawyers Ruin Everything…Except When They Don’t

By Christian A. Klein, Executive Vice President

Last month’s hotline described ARSA’s efforts (via the pro-bono services of Obadal, Filler, MacLeod & Klein (OFM&K)) to intervene in two National Transportation Safety Board (NTSB) cases involving FAA’s incorrect application of repairman certification rules (see “FAA Running Scared from Repairman Case Intervention”, “Legal Brief: Lawyers Ruin Everything” from last month and get an update with “NTSB Denial is Beside the Point” in this edition).

ARSA and the law firm could have added valuable insights to the proceedings, particularly about the plain language of the regulations and contradictory guidance material. However, despite the cases’ broad impact on ARSA members and their employees, the administrative law judge declined to let the association become a party because the FAA’s lawyers objected. Rather than trying to get to the right answer, the focus was on procedural issues, a classic case of process overwhelming justice.

Sarah referenced the influence of the fictional character Perry Mason on her decision to pursue a legal career. My early inspiration was the movie “Twelve Angry Men”, which underscores the point that everyone involved in the legal system is a human being that can make mistakes resulting in dreadful miscarriages of justice. The best way to avoid miscarriages of justice is to avoid legal proceedings; that is why “prophylactic lawyering” is needed.

“Prophylactic lawyering” means understanding your legal and regulatory obligations so little problems do not metastasize into big ones and, even worse, enforcement or criminal cases. More importantly when you do get caught up in legal proceedings, those early protective measures result in better outcomes.

With that in mind, here are some things to keep in mind when working with members of the Bar to ensure prophylactic measures achieve the desired result…

Members can read Christian’s guidance in this edition of the hotline.

10/2/20 - Lawyers Ruin Everything

October 2, 2020

In this edition…

“How To”

On all fronts of ARSA’s work, September provided ample evidence of how the association does what it does. For the discerning reader, there’s even exploration of why it does it all in the first place.

From the “Legal Brief”…

Lawyers Ruin Everything

By Sarah MacLeod, Executive Director

My first hero was Perry Mason; not only was the character a strong advocate, but he ensured justice always prevailed. Even the prosecutors supported the defense’s requests to bring the guilty party forward. The belief that the legal system brought justice drove me to volunteer at a public defender’s office. There I learned very valuable lessons about lawyers and the “practice” of law.

First, not all clients are innocent. There are some really bad folks out there and a defense attorney must put aside any thoughts of justice – the legal system is about the law and the accused party has a right to be represented no matter how reprehensible.

Second, everyone involved in the legal system are human beings that will make horrible mistakes, will stand by those errors and will not serve justice when silence is available. The saga of Richard Jewel illustrates that point.

Those lessons drove me to law school, where I learned even more about my chosen profession.

Members can read about what Sarah learned and how those lessons drive ARSA’s work in this edition of the hotline.

9/4/20 - Am I Reading This Right?

September 4, 2020

In this edition…

The Repairman Issue

In late August, ARSA took new action to pursue a decade-old goal: Reasonable enforcement of the repairman certificate requirements of 14 CFR part 65, subpart E. This edition of the hotline covers the issue from every angle while providing other key updates from the last month.

From the “Membership” section…

A Member Asked…

Q: My question is in regards to 14 CFR part 65, specifically § 65.101(a)(5) that indicates that the individual applying for a repairman certificate must have at least 18 months of practical experience in the procedures, practices, inspection methods, materials, tools, machine tools, and equipment generally used in the maintenance duties of the specific job for which the person is to be employed and certificated.

Let’s say I would like to be an inspector. Is it safe to say that I must have 18 months of practical experience in the procedures, practices, inspection methods, materials, tools, machine tools, and equipment generally used by inspectors? Or am I interpreting the eligibility requirements incorrectly?

A: Let’s get you on the right slalom course, then we can get you through the correct gates in the right order:

You do not need a repairman certificate to do inspections under the repair station certificate, the individual assigned those duties, responsibilities and authorities by the repair station needs to be qualified under section 145.155, which includes being:

- Thoroughly familiar with the applicable regulations in this chapter and with the inspection methods, techniques, practices, aids, equipment, and tools used to determine the airworthiness of the article on which maintenance, preventive maintenance, or alterations are being performed.

- Proficient in using the various types of inspection equipment and visual inspection aids appropriate for the article being inspected.

- Able to understand, read, and write English.

If the job position the repair station assigned includes the duties, responsibilities and authority to either supervise (§ 145.157) or approve work for return to service (§ 145.153), one of the qualifications for persons required to direct maintenance and/or to oversee persons unfamiliar with their tasks and/or to approve work for return to service for the repair station is to hold an appropriate part 65 certificate, that is either a repairman or mechanic certificate.

When a repair station recommends an individual for a repairman certificate, the air agency certificate holder must ensure the person is qualified under § 65.101. That section, as you note, requires the employer to ascertain (usually through the assessment made under the Training Program Manual and reference to the duties, responsibilities and authorities set forth in the RSQM for the position) whether the individual is:

- Specially qualified to perform maintenance on aircraft or components thereof, appropriate to the job for which he is employed.

- Employed for a specific job requiring those special qualifications.

After which the employer completes the Employment Summary (since inspectors, supervisors and persons authorized to approve work for return to must be on the Repair Station Roster). Based upon that information, the employer recommends the employee for certification.

The evaluation by the employer should determine that the person has at least 18 months of practical experience in the procedures, practices, inspection methods, materials, tools, machine tools, and equipment generally used in the maintenance duties of the specific job. If the person does not, the employer would ensure the individual completed training through the FAA-approved Training Program Manual procedures since that should certainly qualify as formal training that is acceptable to the Administrator.

Member questions should be submitted directly to the association’s team via arsa.org/contact.

8/7/2020 - House T&I Committee Reports Anti-Repair Station Bill

August 7, 2020

In this edition…

Knowledge is Power

July continued the pandemic-infused onslaught of tough-to-cope-with information. “Grim” survey response data. The re-emergence of threatening legislation from the U.S. Congress. More challenges in managing regulatory impact. ARSA’s work is focusing its knowledge into effort.

From “ARSA on the Hill”…

House T&I Committee Reports Anti-Repair Station Bill

On July 29, the House Transportation & Infrastructure Committee reported the Safe Aircraft Maintenance Standards Act (H.R. 5119). Dubbed “the anti-repair station bill,” the legislation would cause significant disruptions for the global aviation maintenance industry, U.S. air carriers, passengers and cargo shippers, general aviation operators and aerospace manufacturers. ARSA is leading a coalition of 10 organizations to defeat the legislation.

Given that H.R. 5119 was approved by the House T&I Committee last November, it’s unclear why the House T&I Committee leaders have chosen this moment to report it to the full House. The bill has been added to the Union Calendar, which means it is ripe for consideration on the House floor. Adding fuel to the fire, detrimental repair station language was included in the second major coronavirus relief passed by the House earlier this summer, so its clear that anti-repair station lawmakers and their union allies are determined to impose new restrictions on contract maintenance. ARSA opposes using regulatory policy and false safety arguments to achieve labor’s economic objectives. H.R. 5119 would make it even harder to recover the present economic crisis.

What you can do to help prevent H.R. 5119 from becoming law? Visit arsa.org/legislative/hr5119-actioncenter.

http://arsa.org/legislative/hr5119-actioncenter/

7/2/20 - ARSA Publications Overhaul

July 2, 2020

In this edition…

Learning Mode

Hotline readers should be quite familiar with ARSA’s commitment to learning and growth. In addition to the association’s commitment to training resources, its team constantly utilizes feedback and insight from its members. This month’s edition shares ongoing lessons of pandemic response, seeks input regarding event planning (Get the 2021 Conference on your calendar!) and teases some new projects

From the “Membership” section…

Under Construction – ARSA Publications Overhaul

One of the key benefits for the ARSA team and its members is development and access to model manuals, programs and supplements designed to assist companies with regulatory compliance. Anyone who visited the publications webpage in June noticed that ARSA’s most important models are not available for purchase or download.

Don’t panic: This is good news.

The ARSA team is currently overhauling its model repair station, quality, training program and forms manuals and related documents. When this update is complete, new versions will be available from the association.

During the overhaul of the part 145 documents, the other tools available only to ARSA members, e.g., the Working Away Advisory, Repair Station Security Resources, remain accessible. Each model or template is maintained and improved by the association based on industry experience, agency guidance and plain-language interpretation of regulatory requirements.

If you need assistance development or correcting repair station documentation, contact ARSA for more information and possible assistance by its management firm, Obadal, Filler, MacLeod & Klein, P.L.C.

6/5/20 - Asking Again

June 5, 2020

In this edition…

Consistent Focus

This edition of the hotline demonstrates how the attention of ARSA’s work remains focused on continual stakeholder engagement and commonsense tools for managing business and government.

From the “Membership” section…

Asking Again – A New Survey for 2020